Anchor device of first sliding and then fixing type combined steel anchor boxes of cable stayed bridge and construction method thereof

An anchoring device, cable-stayed bridge technology, applied in bridges, bridge parts, bridge construction and other directions, can solve the problems of unfavorable resistance, cutting vertical and horizontal steel bars, and the number of bundles, etc., and achieve the effect of good stress effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

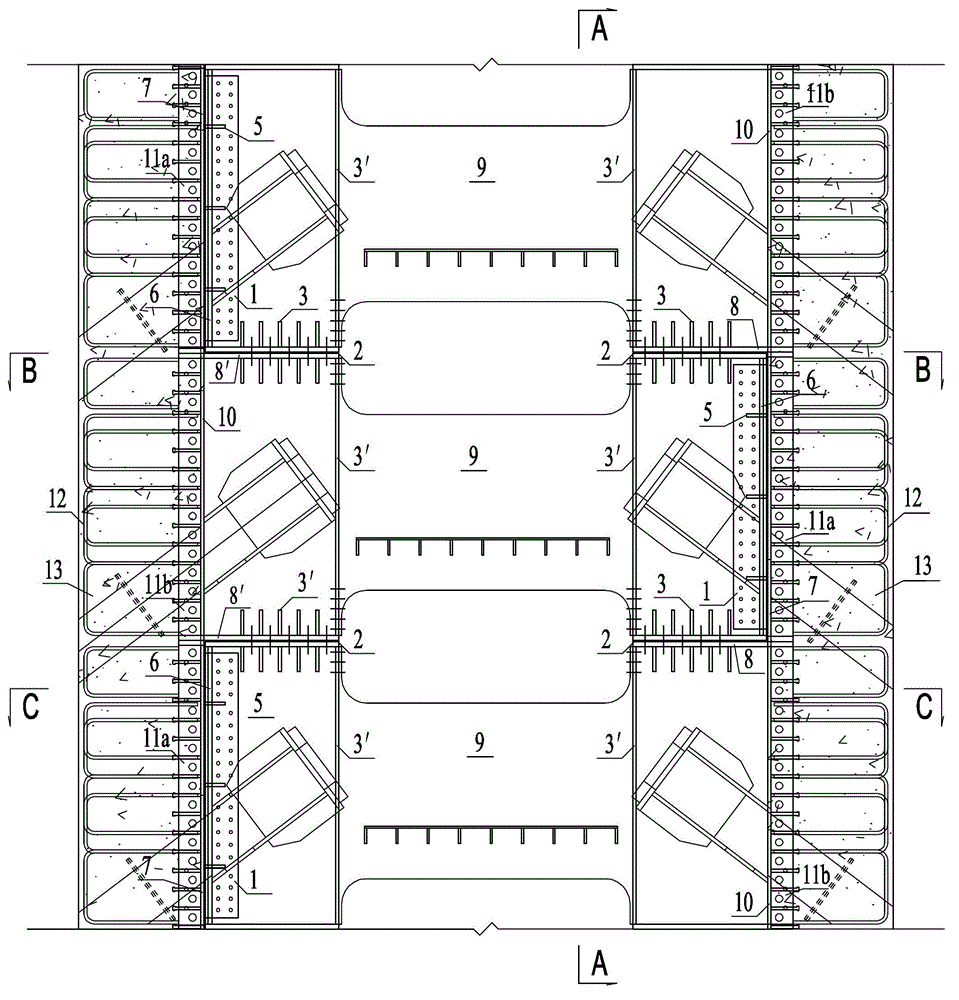

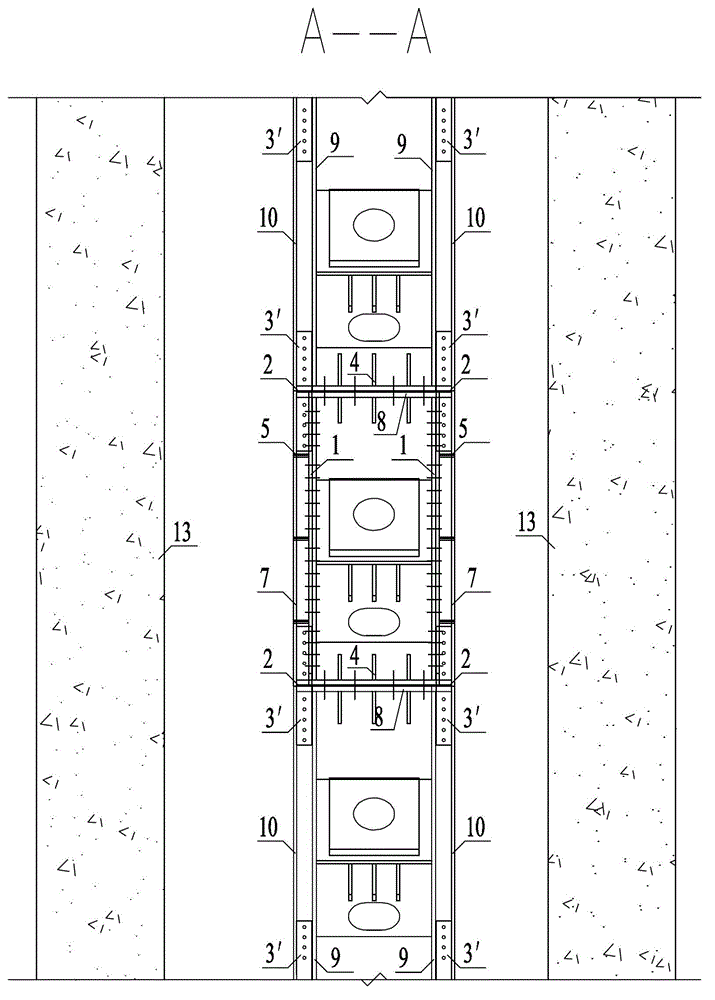

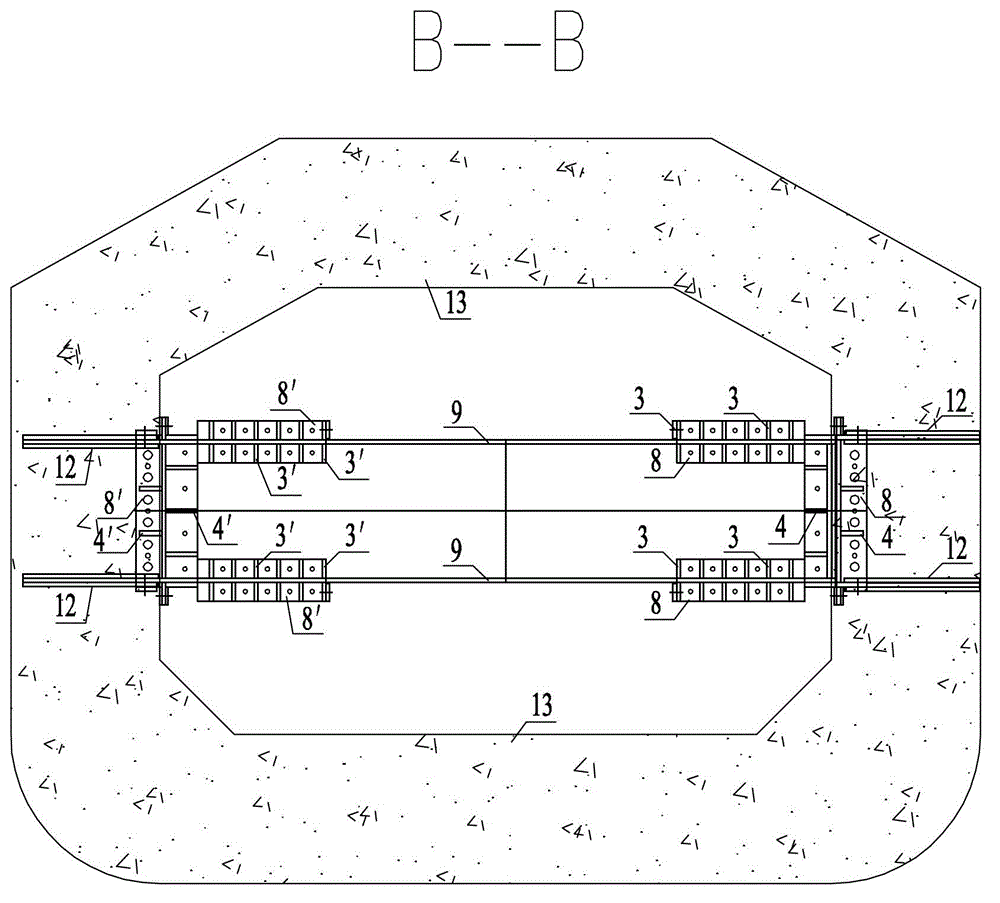

[0032] Such as Figure 1 to Figure 4 A kind of cable-stayed bridge slides first and then solidifies the combined steel anchor box anchoring device shown, this device comprises the multi-section anchor box section that is arranged continuously up and down, and each section anchor box section all has anchor box side pull plate 9, bolt connection end and fixed end, wherein, the anchor box side tie plate 9 is an H-shaped plate, the anchor box side tie plate 9 is located in the middle, the bolted end and the fixed end are respectively arranged at the left and right ends of the anchor box side tie plate 9, and The left and right ends of the anchor box side pull plate 9 are connected, the bolted ends and fixed ends in the upper and lower adjacent anchor box segments are arranged in a staggered shape, and the bolted ends in the upper and lower adjacent anchor box segments There is a sliding pair between the anchor box segment and the fixed end, and both the bolted end and the fixed en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com