Patents

Literature

58results about How to "Reduced bending resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

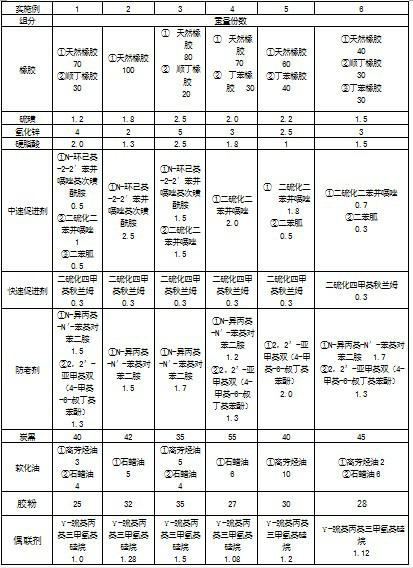

Sizing material for rubber shoe sole and preparation method thereof

The invention discloses a sizing material for a rubber shoe sole and a preparation method thereof. The sizing material comprises the following raw materials for preparing active ingredients in parts by weight: 100 parts of rubber, 1.2-2.5 parts of sulfur, 2-5 parts of zinc oxide, 1-2.5 parts of stearic acid, 1-3 parts of a medium-speed accelerant, 0.3 part of a high-speed accelerant, 1.5-3 parts of an anti-ageing agent, 35-55 parts of carbon black, 5-10 parts of softening oil, 25-35 parts of rubber powder and 1-1.5 parts of coupling agent. The preparation method comprises the following steps of: pretreating the rubber powder; plastifying rubber; compounding; milling, and the like. The rubber shoe sole produced by using a rubber powder formula and the preparation method thereof has the advantages of reduction in the tensile strength change rate by 3-5 percent, reduction in the tensile yield change rate by 5-8 percent, the same wear resistance and bending resistance as those of a rubber shoe sole produced without using rubber powder in the same type of products, smooth appearance handfeel, soft brightness and increase in grade. The sizing material is suitable for preparing rubber shoe soles of dress shoes and outdoor shoes.

Owner:JIHUA 3514 LEATHER & FOOTWARE

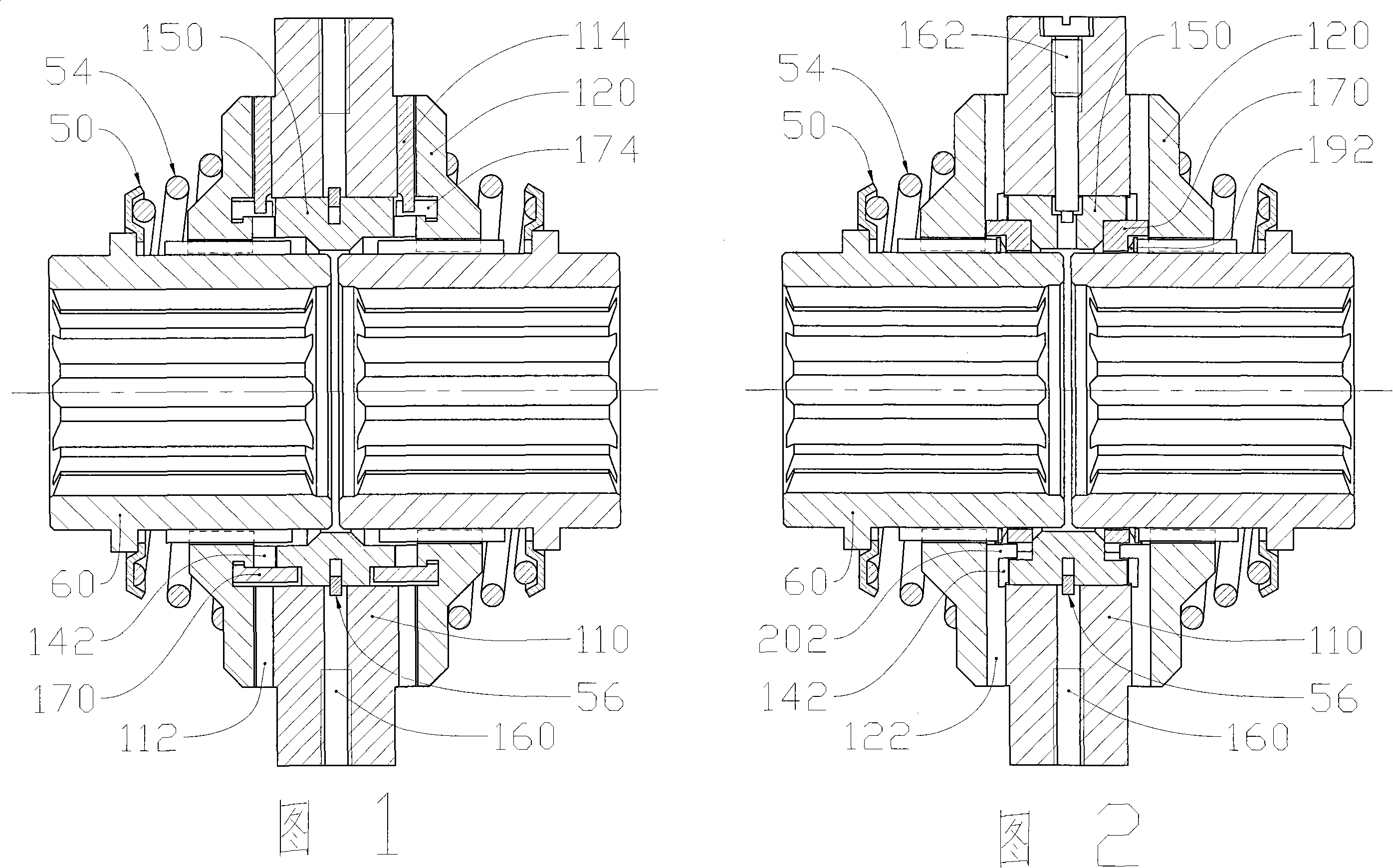

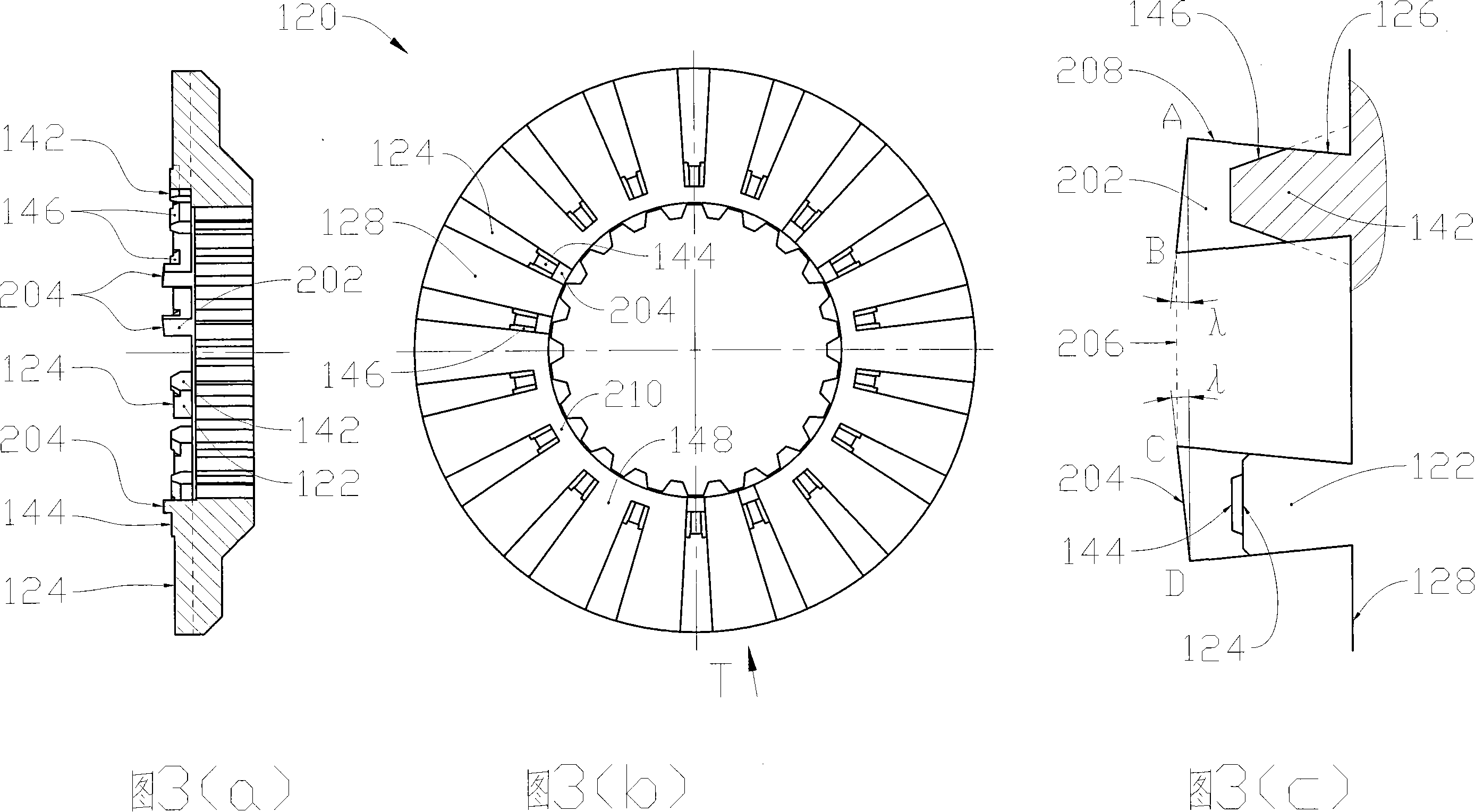

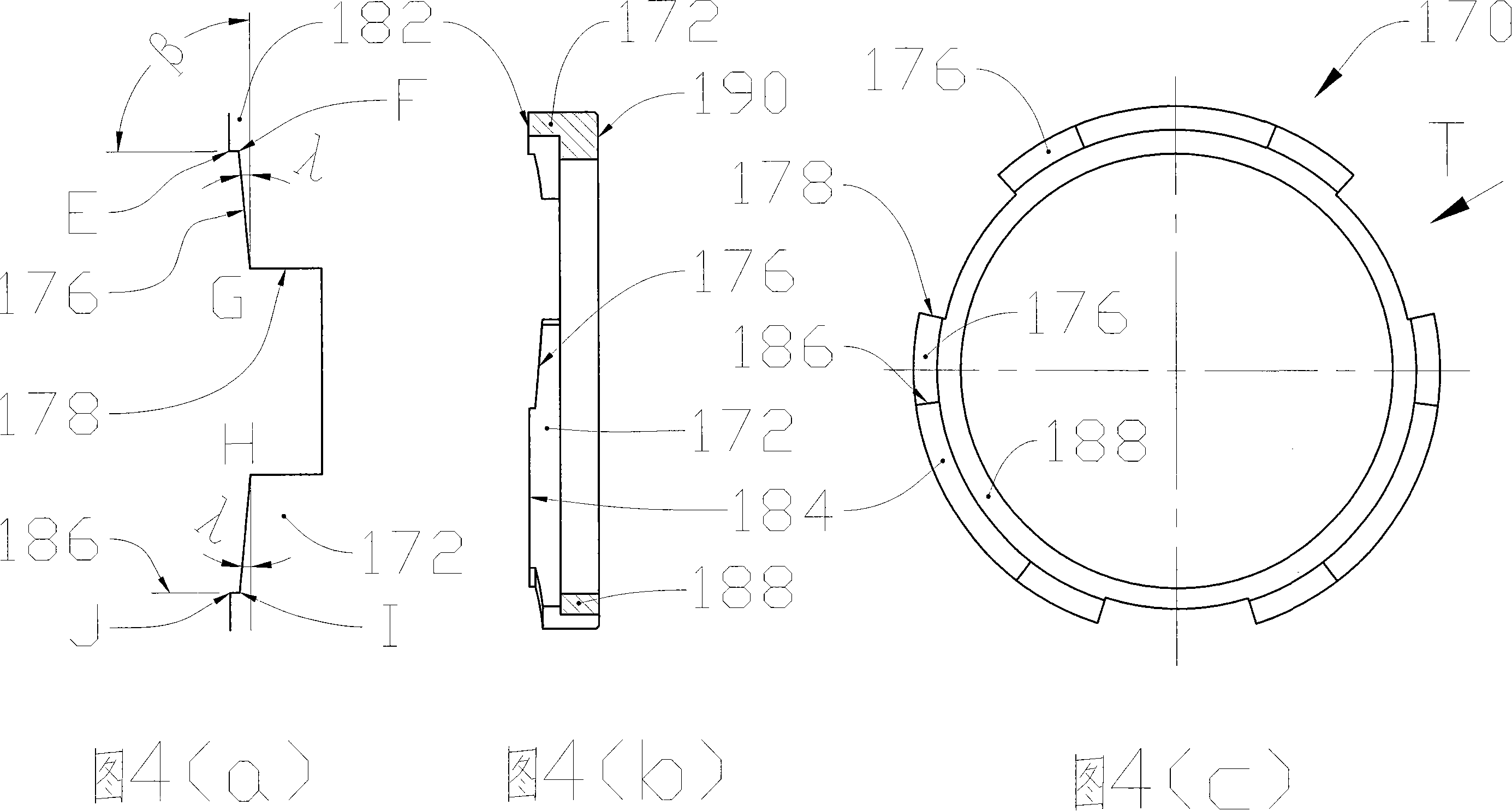

Basic mode jaw self locking speed differential gear

InactiveCN101118005ACircumferential degrees of freedom constantEliminate impact wearDifferential gearingsControl devicesSelf limitingSelf locking

The present invention relates to a basic jaw type self-locking differential, which has the characteristics of no collision, high reliability, and long service life. The present invention is characterized in that a force transmission tooth and separating teeth and an accessory blocking tooth which are positioned on driven rings are connected as a whole; a self-limiting type blocking embedding mechanism is embedded by two embedding mechanisms of a force transmission embedding mechanism and a separation embedding mechanism under the differential condition, and axially positioned in the two mechanisms and radially positioned in the two mechanisms, between the two mechanisms or outside the two mechanisms, a lift angle of both sides blocking the working surface is formed to enough ensure the friction self-locking collided on the both sides and the stability of the blocking operating condition, in order that the lift angle has the capabilities that the adaptive axle base changes and the abrasion is automatically compensated, and the slipping mode of no collision is unvaryingly maintained between the separating teeth in the operating condition, two processes of the self-separating block process and the embedding return process are absolutely reliable, and has no relation to the stability of the spring parameter compacted by the driven rings, hence the problem that the driven rings on the both sides are synchronously separated is not a problem any longer. The processing of the differential is obviously improved, the difficulty of the assembly is largely reduced, and the performance, the service life, and the interchangeability, etc. are remarkably improved.

Owner:洪涛

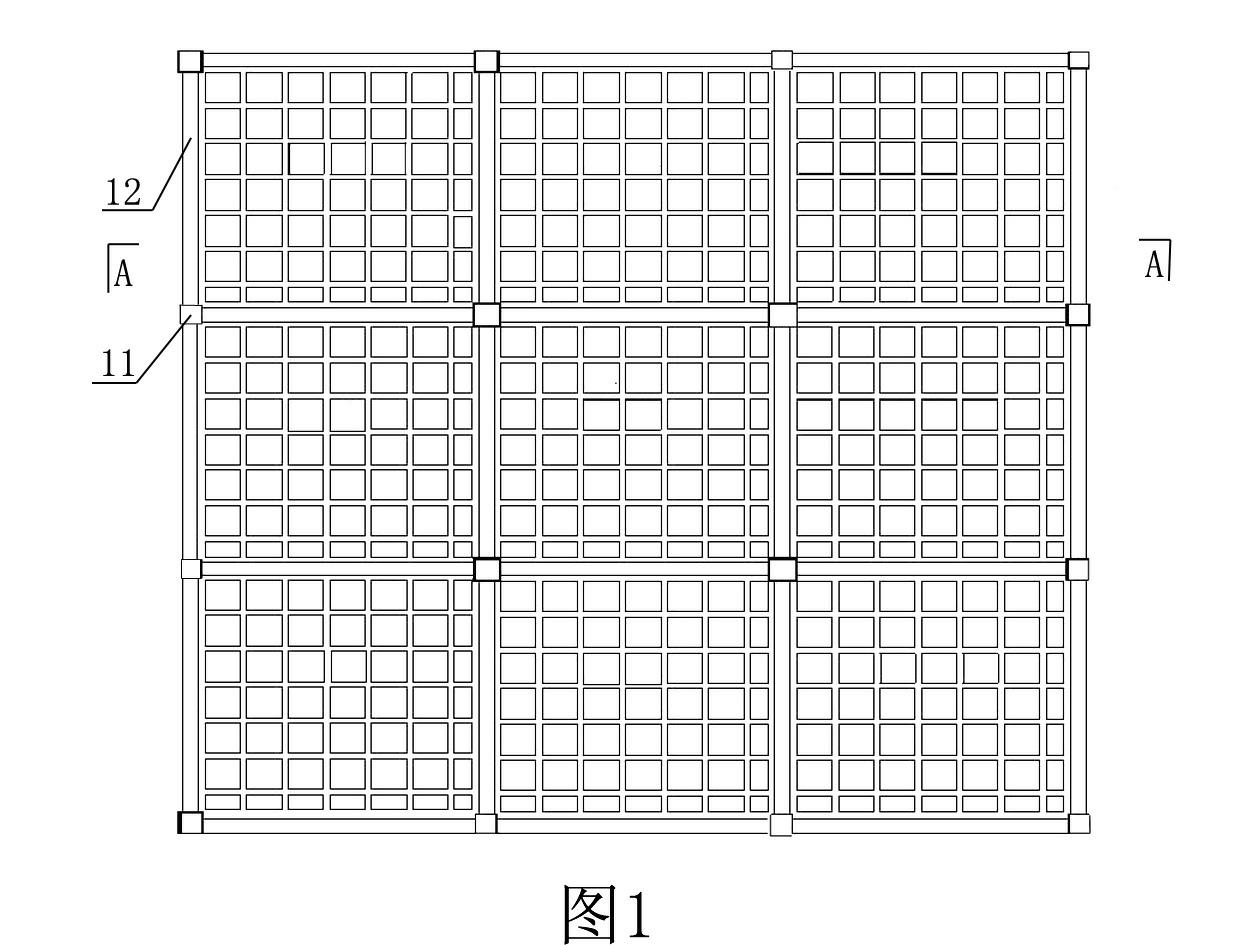

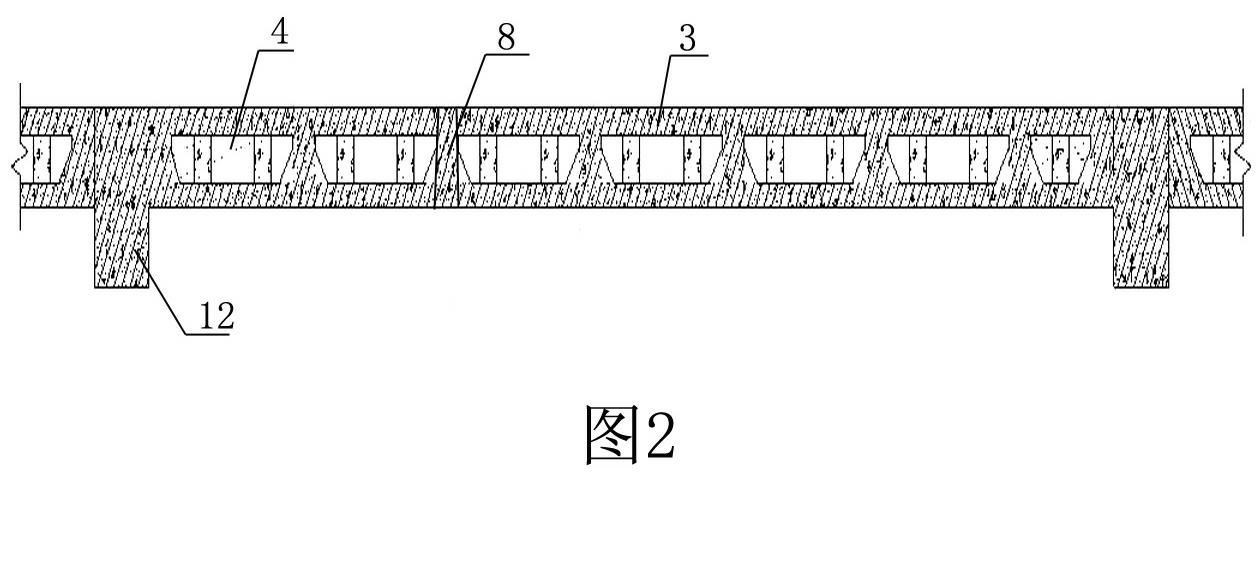

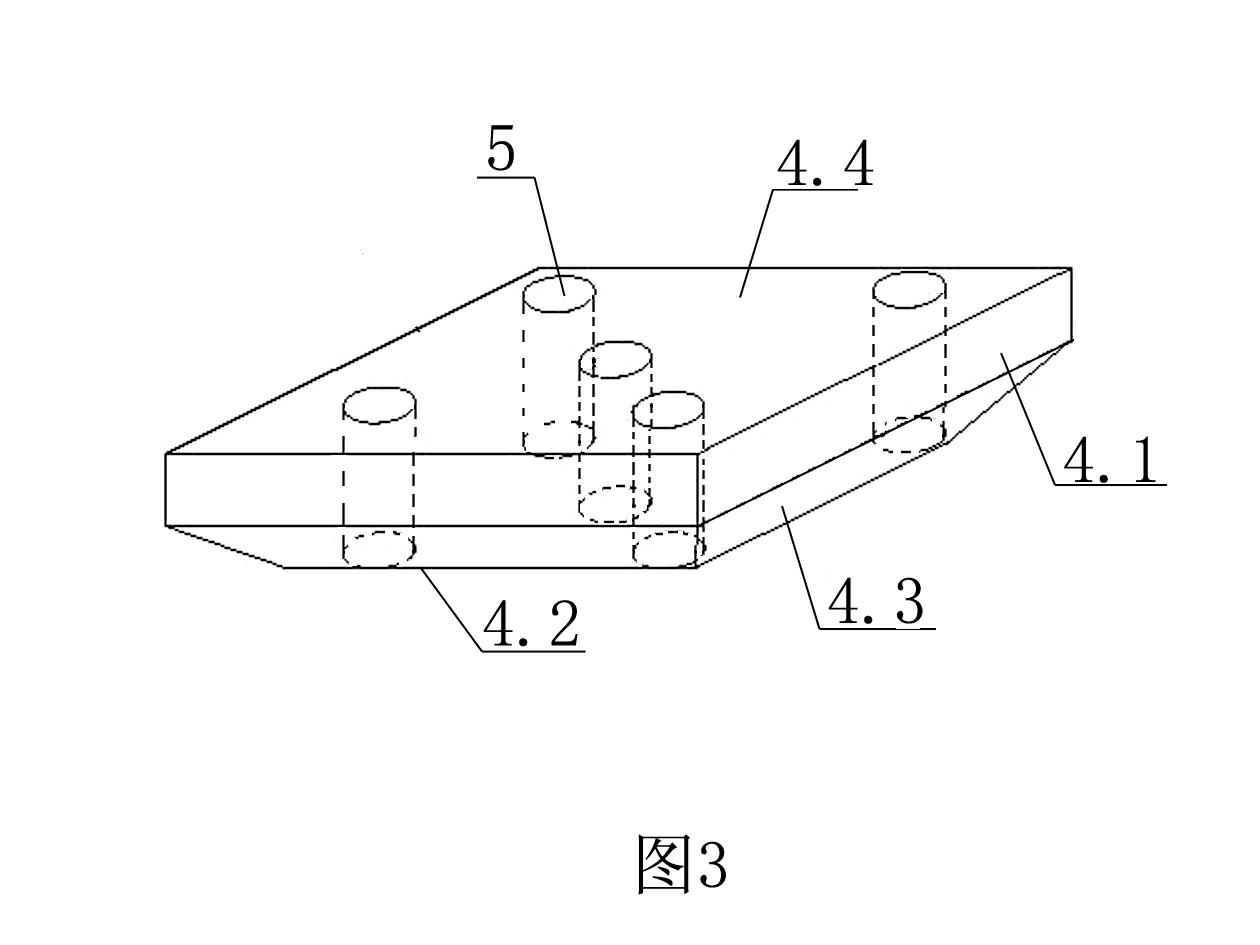

Phase change material (PCM) cast-in-place reinforced concrete large-size sandwiched floor and construction method thereof

InactiveCN102409788AGuarantee the pouring qualitySpeed up the flowFloorsBuilding material handlingReinforced concreteKeel

The invention relates to a phase change material (PCM) cast-in-place reinforced concrete large-size sandwiched floor and a construction method thereof. Concealed beams are arranged in the sandwiched floor at intervals; the sandwiched floor consists of a core die, upper steel bars, lower steel bars and outer-packed concrete; and the core die is a solid polystyrene block, the upper steel bars are bound on the top of the core die, the lower steel bars are bound on the bottom surface of the die core, and the steel bars and the core die are wrapped into a whole through the outer-packed concrete. An inner die floats upwards in the pouring process, and the lower steel bars and the upper steel bars are bound with the keel of a bottom template through anti-floating steel wires. The sandwiched floor has the advantages of light dead weight, good anti-seismic and sound insulation effects, no limit on embedded pipelines in the construction process and the like. The sandwiched floor can be widely applied to multi-layer and high-layer buildings with larger spans and loads and thicker floors.

Owner:北京建工博海建设有限公司 +1

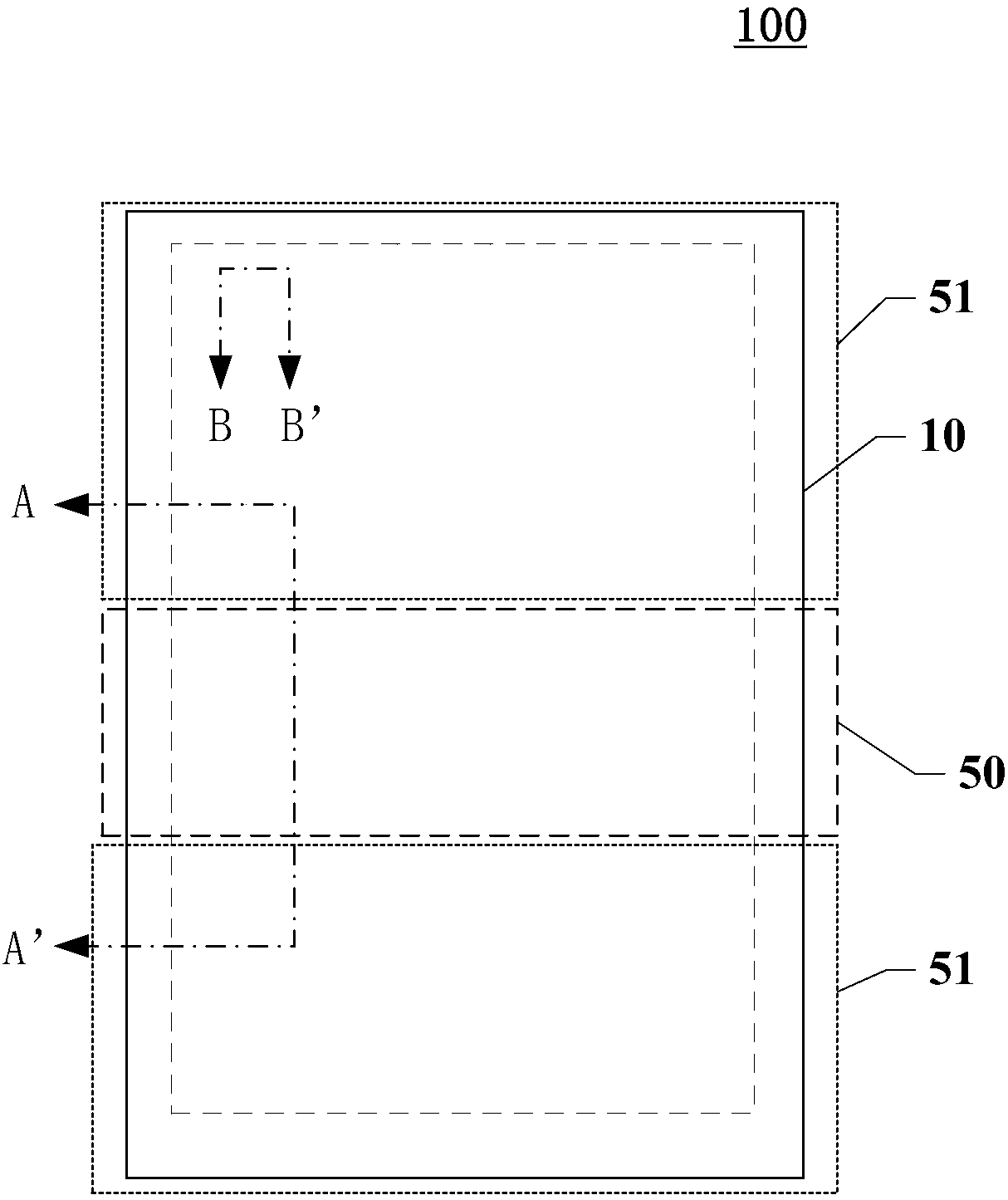

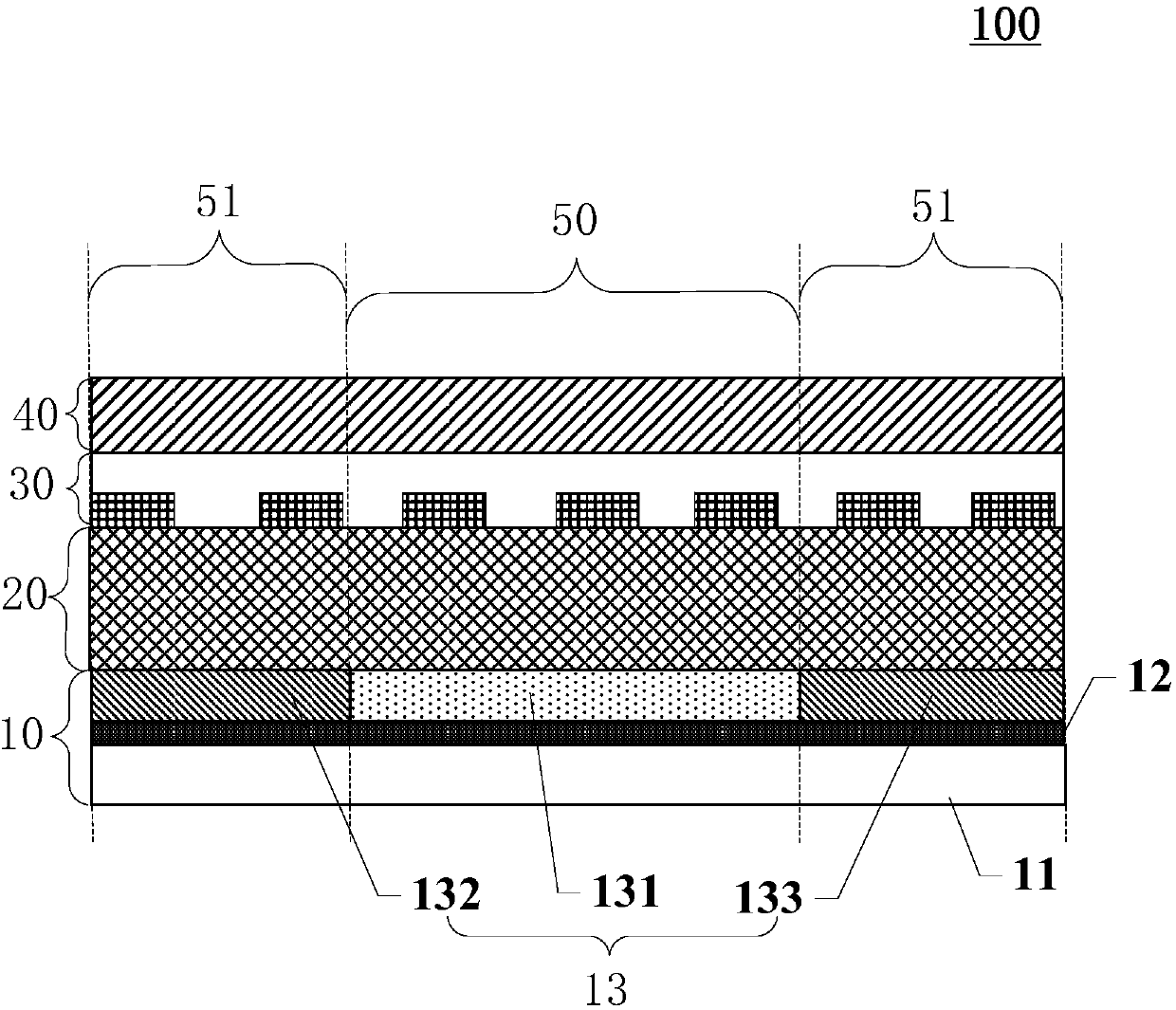

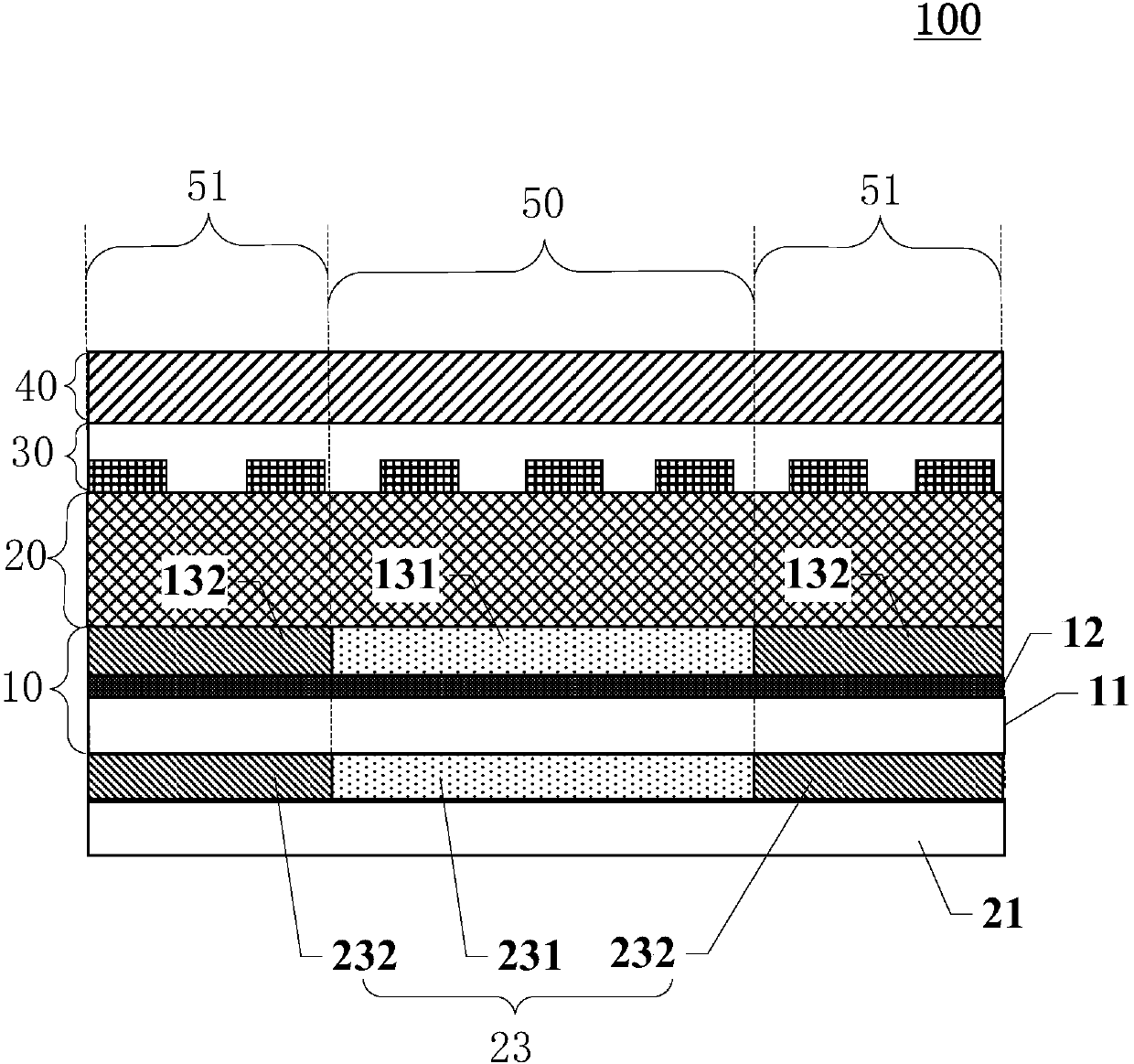

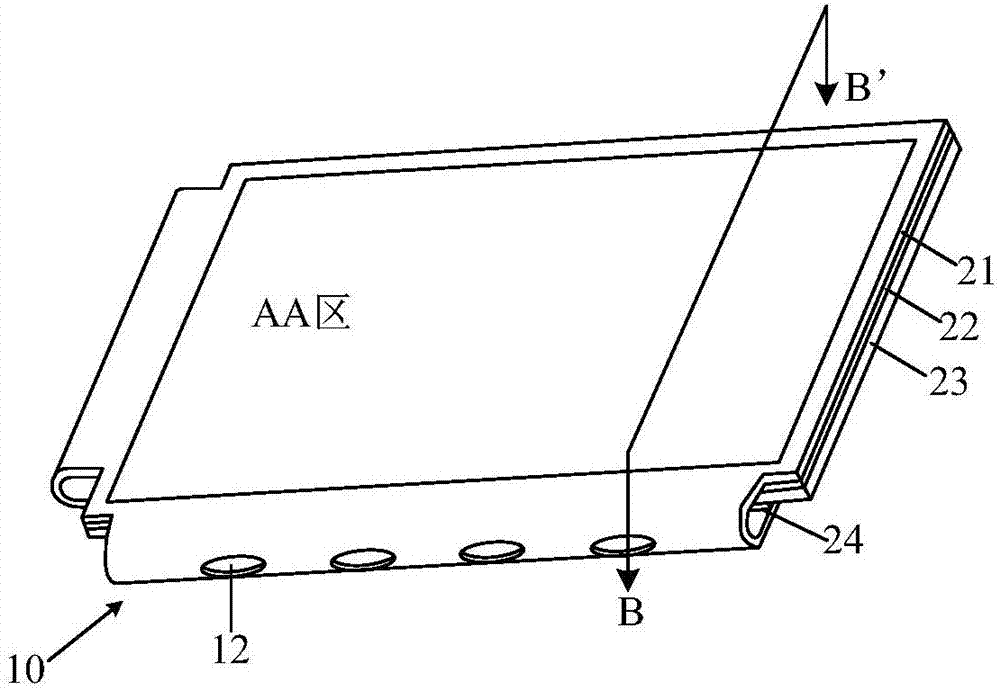

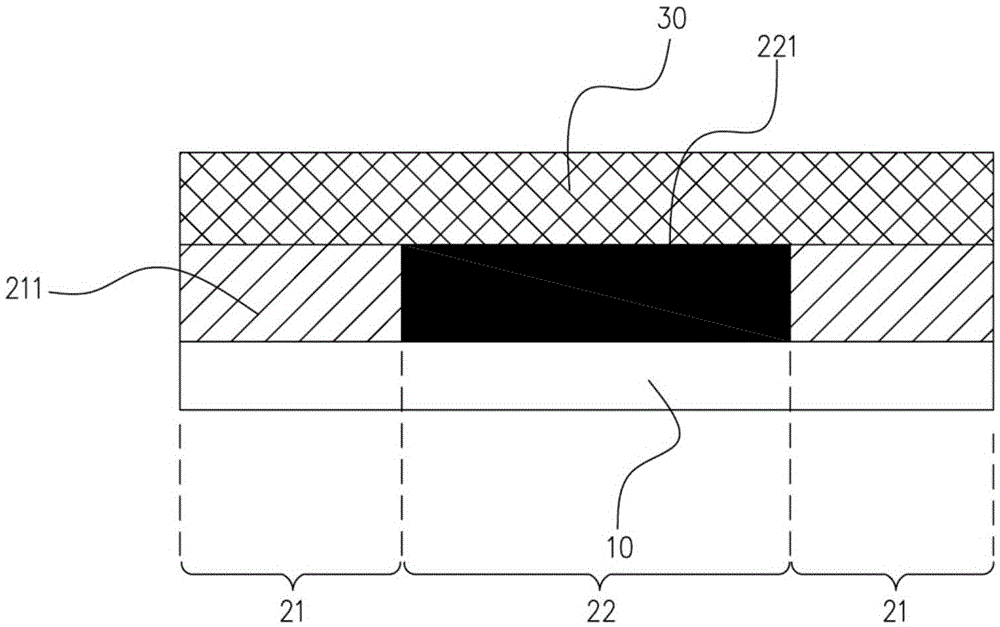

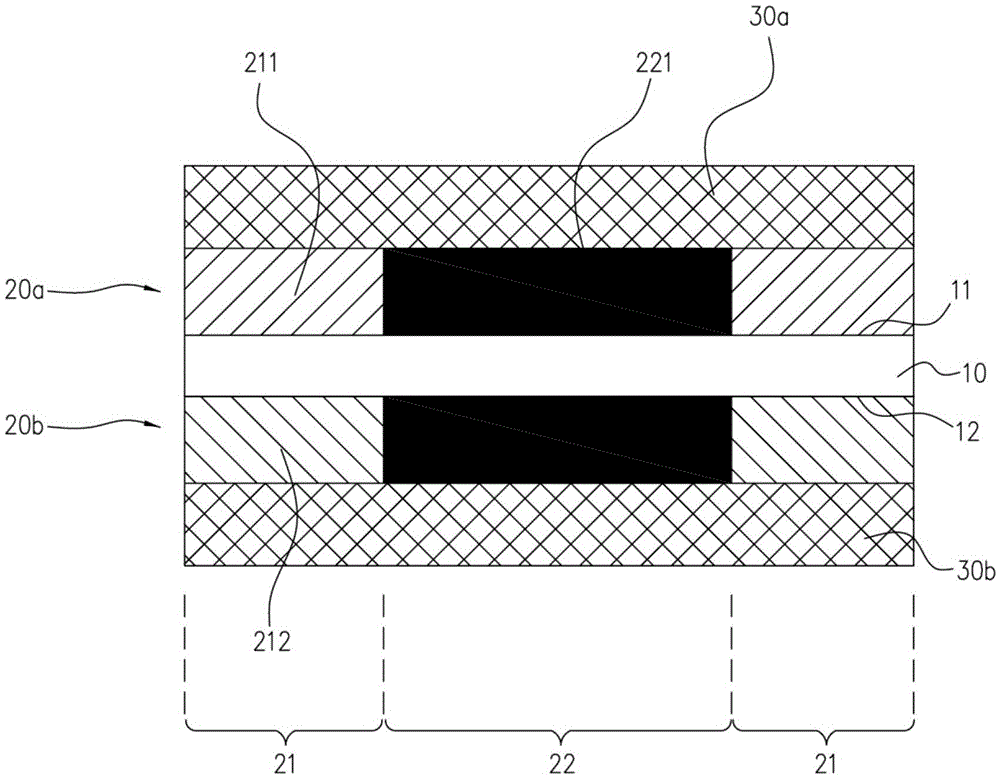

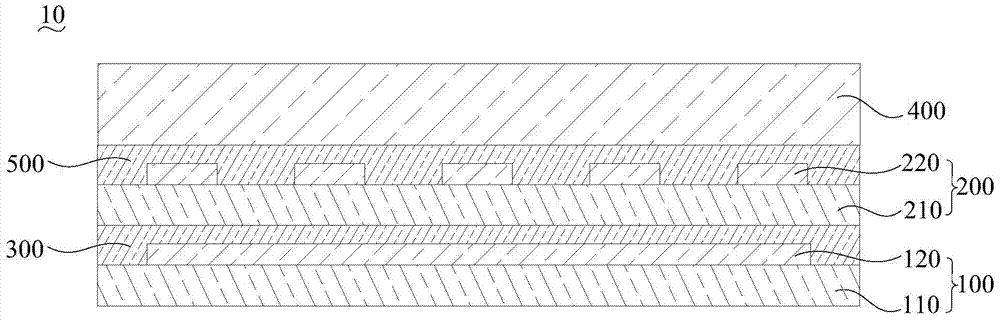

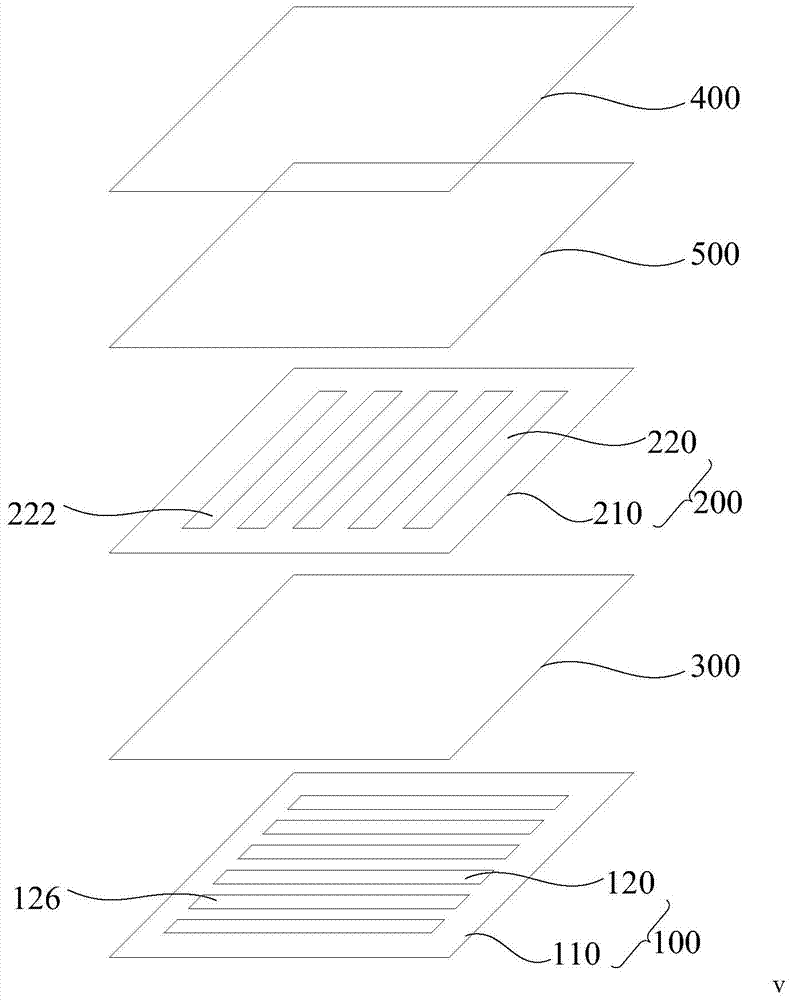

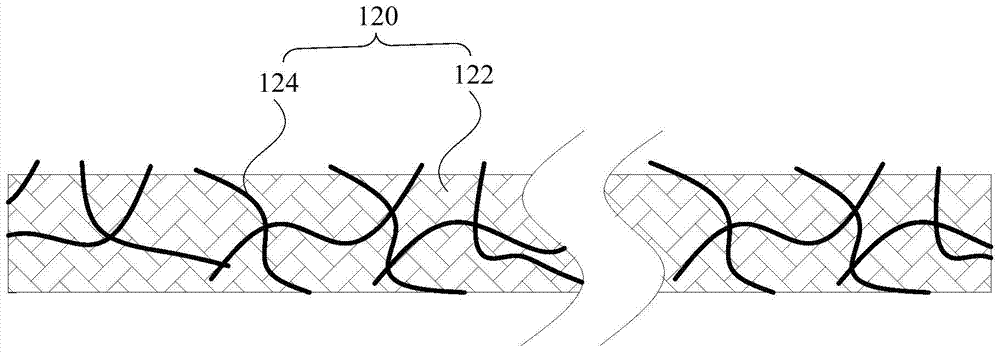

Display panel and preparation method thereof, and display device

ActiveCN108598138AIntegrity guaranteedAvoid crackingSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceComputer science

The application discloses a display panel and a preparation method thereof, and a display device, and relates to the technical field of the display. A bending area and a non-bending area a provided, the display panel comprises at least one substrate, and a driving function layer, a light-emitting function layer and a package layer which are orderly arranged on the substrate along a direction far away from the substrate; the substrate comprises a first flexible base plate, and a first nano-film and a buffer layer orderly arranged on the first flexible base plate along a direction vertically faraway from the first flexible base plate, wherein the buffer layer is located at one side, close to the driving function layer, of the first nano-film, and comprises a first buffer layer located at the bending area and a second buffer layer located at the non-bending area, the first buffer layer and the second buffer layer are arranged at the same layer and have the same thickness, and the first buffer layer comprises organic materials. Therefore, the completeness of the first flexible base plate can be guaranteed, and the bending resistance of the display panel can be improved.

Owner:WUHAN TIANMA MICRO ELECTRONICS CO LTD

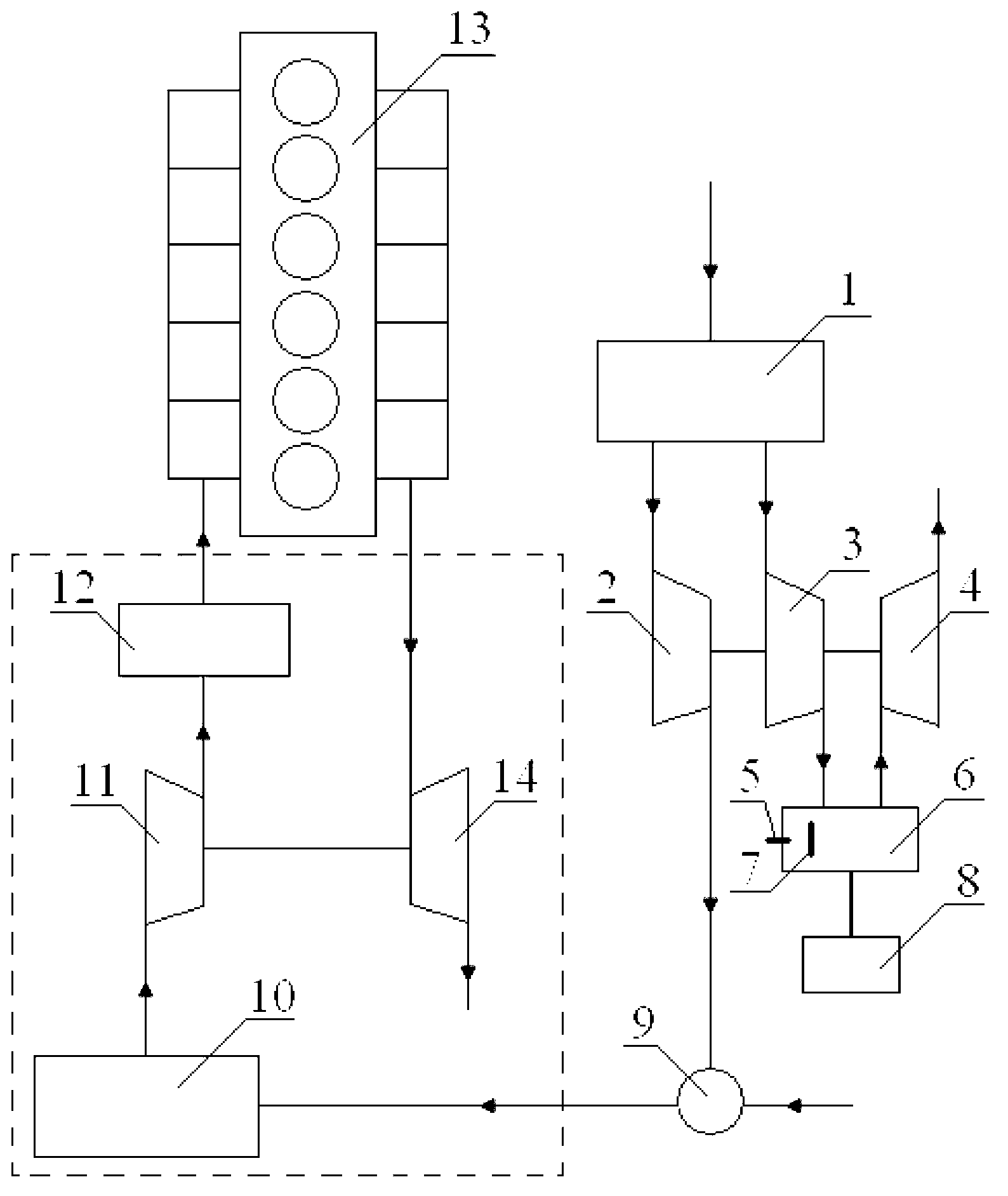

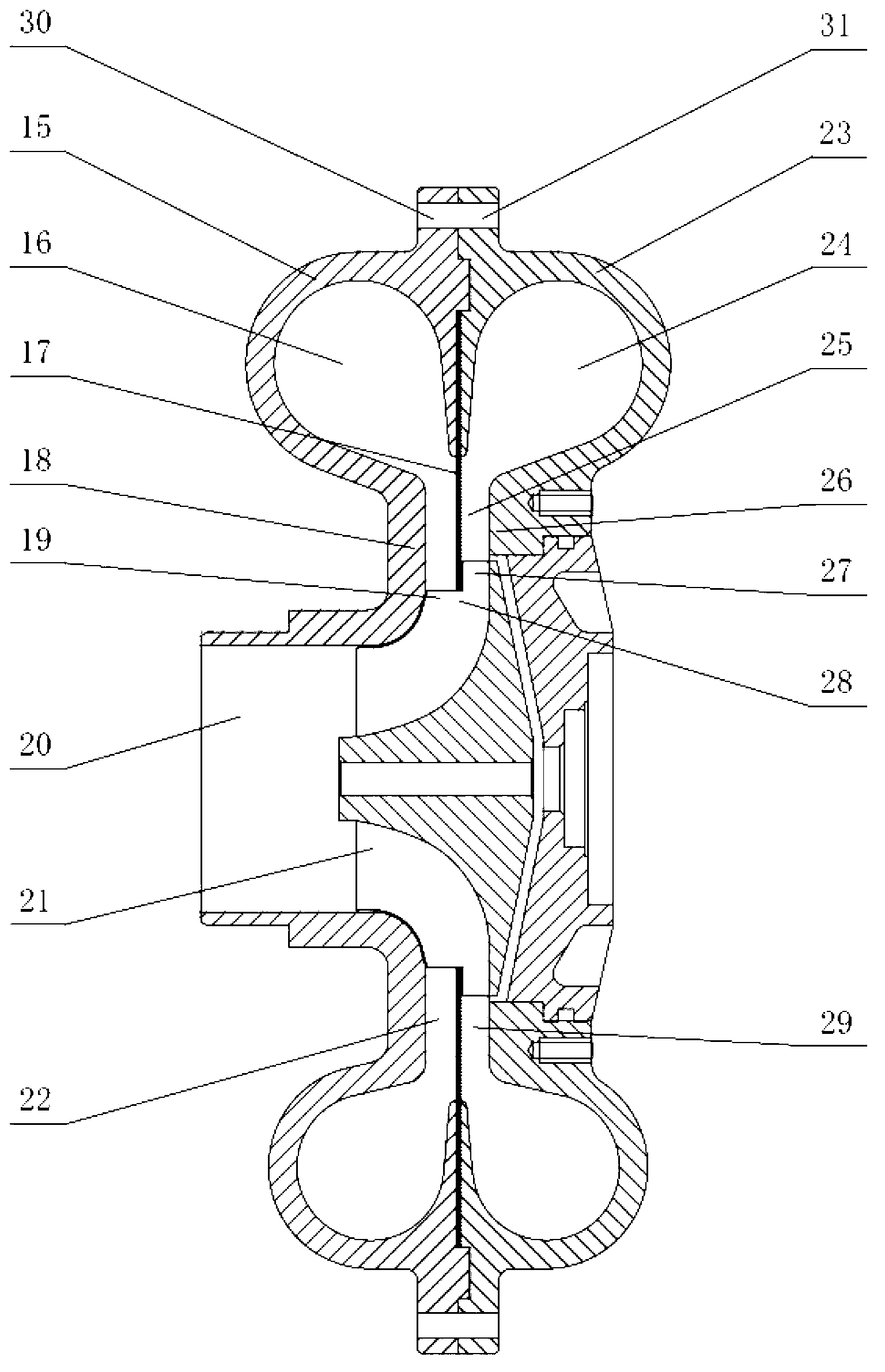

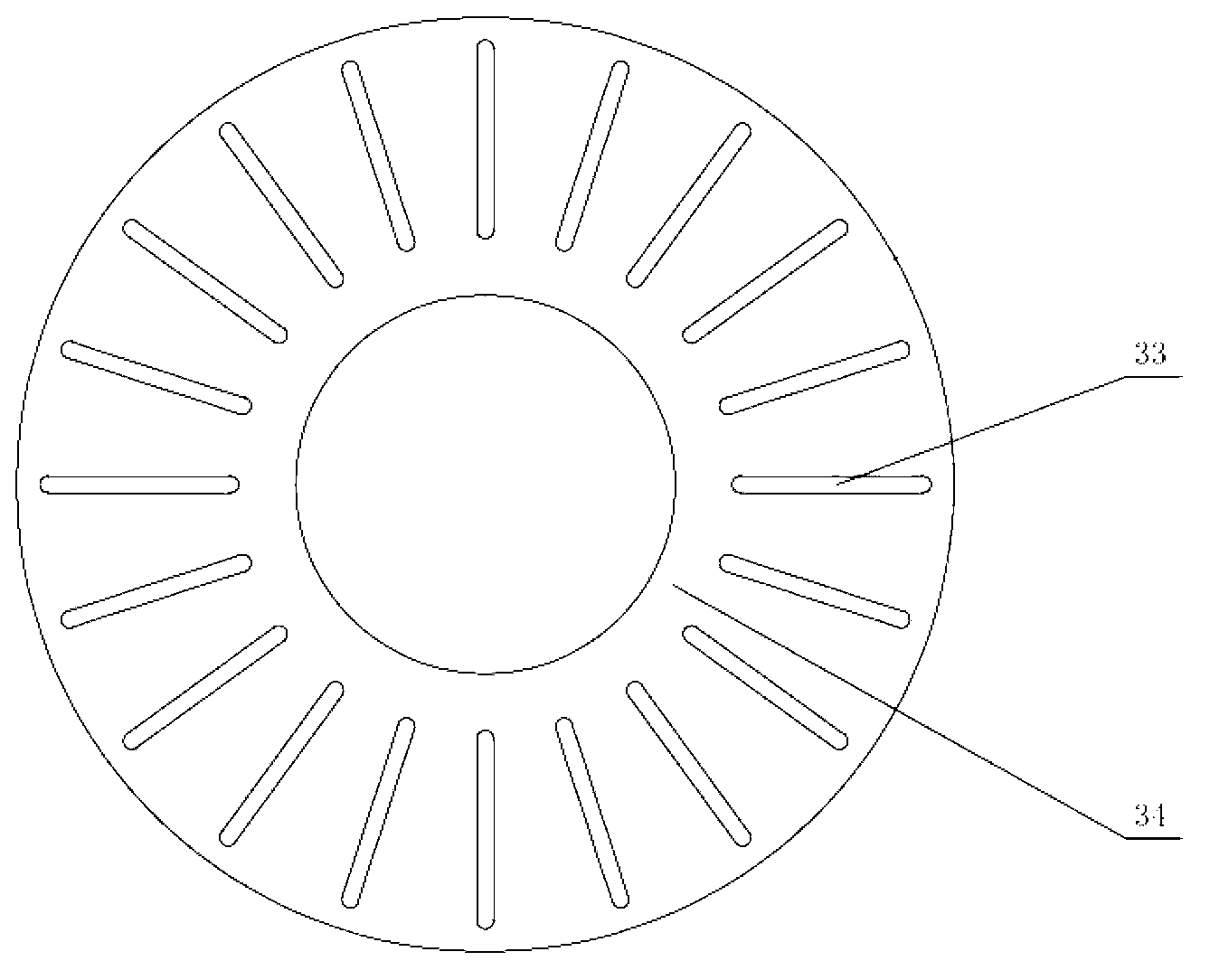

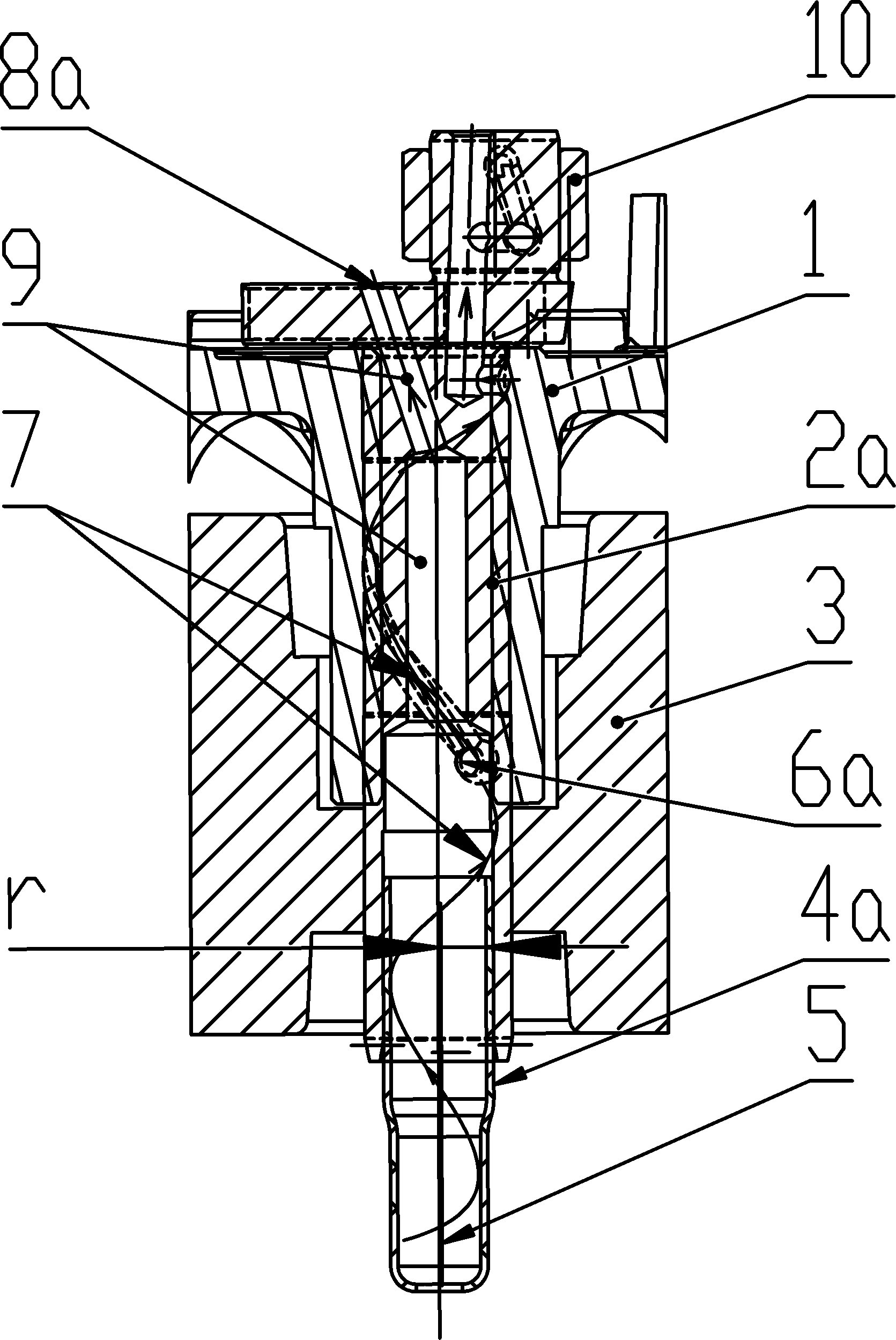

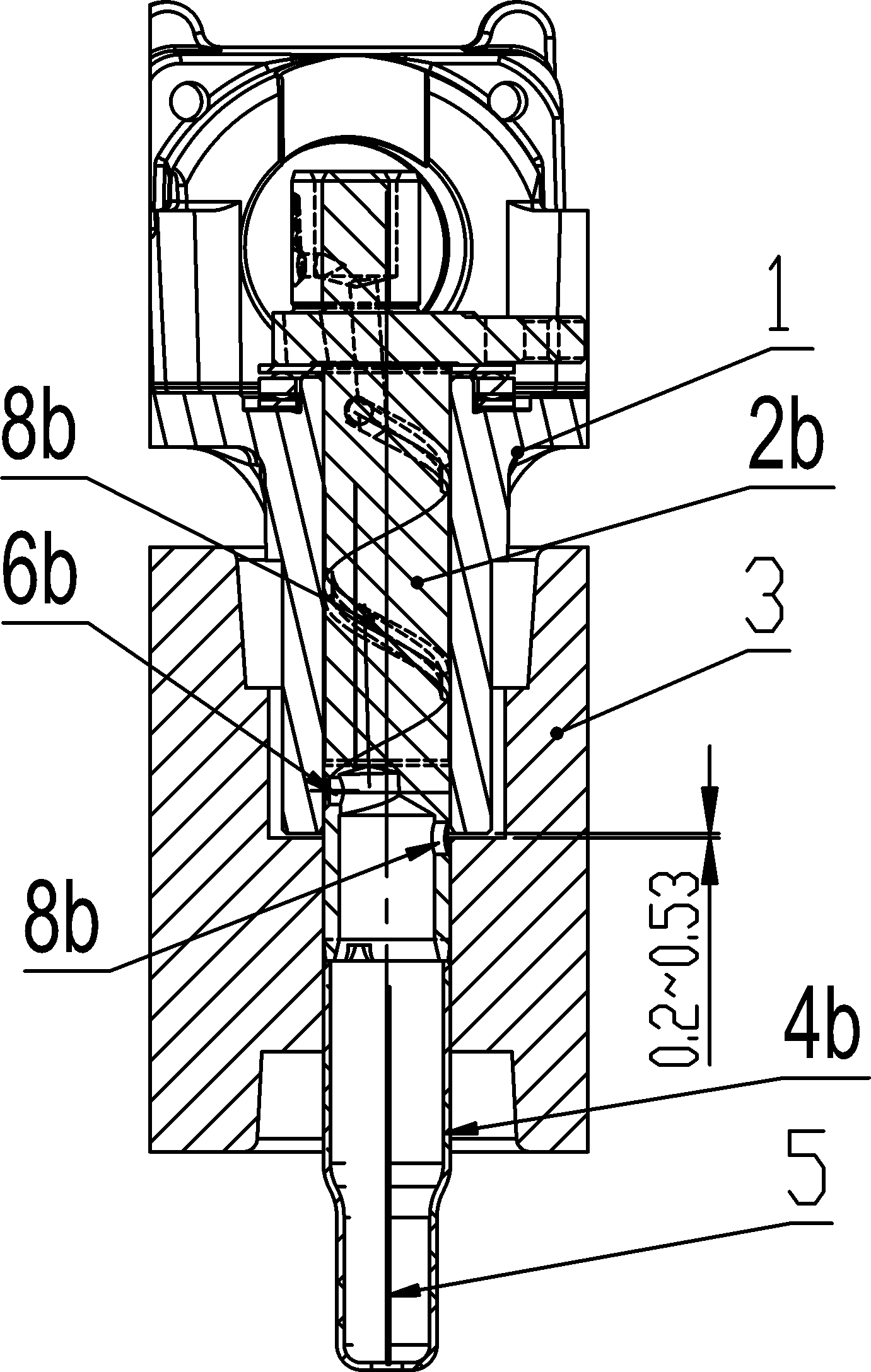

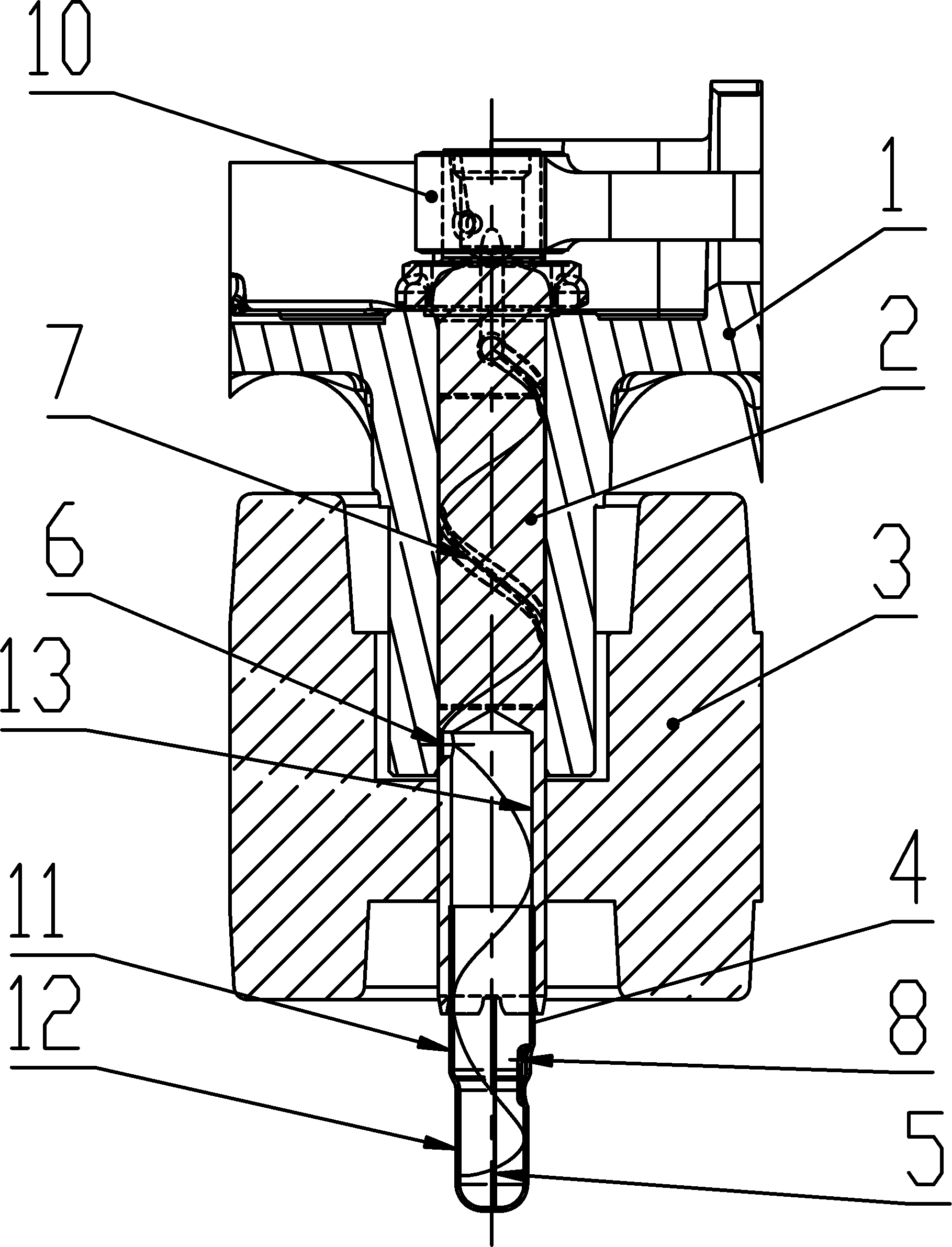

Centrifugal compressor used for generating two different pressure ratios

InactiveCN102840169AImprove balanceReduced bending resistancePump componentsPumpsEngineeringInternal combustion engine

The invention relates to a centrifugal compressor used for generating two different pressure ratios. The centrifugal compressor belongs to the technical field of a supercharging of an internal combustion engine and comprises a front shell of a compressor, a rear shell of the compressor, an annular splitter plate and step-shaped centrifugal compressor impellers. A compressor air inlet and a compressor front air collecting runner volute are arranged on the front shell of the compressor, a compressor back air collecting runner volute is arranged on the rear shell of the compressor; the compressor front air collecting runner volute is connected with the compressor back air collecting runner volute by adopting a bolt, and the annular splitter plate is arranged between the compressor front air collecting runner volute and the compressor back air collecting runner volute; a pressure enlarging passage consisting of the compressor front air collecting runner volute and the compressor back air collecting runner volute is divided into two parts by the annular splitter plate, thereby forming a dual-runner vaneless diffuser; step shaped centrifugal compressor impellers are arranged at the inner parts of the front shell of the compressor and the rear shell of the compressor; the outlets of the impellers are provided with big and small diameters, so that the outlets of the impeller are formed to be in a ladder shape. By using one compressor, two compressed airs with different pressure ratios is generated; the centrifugal compressor is applicable to the condition required to generate the compressed air with two pressure ratios simultaneously.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

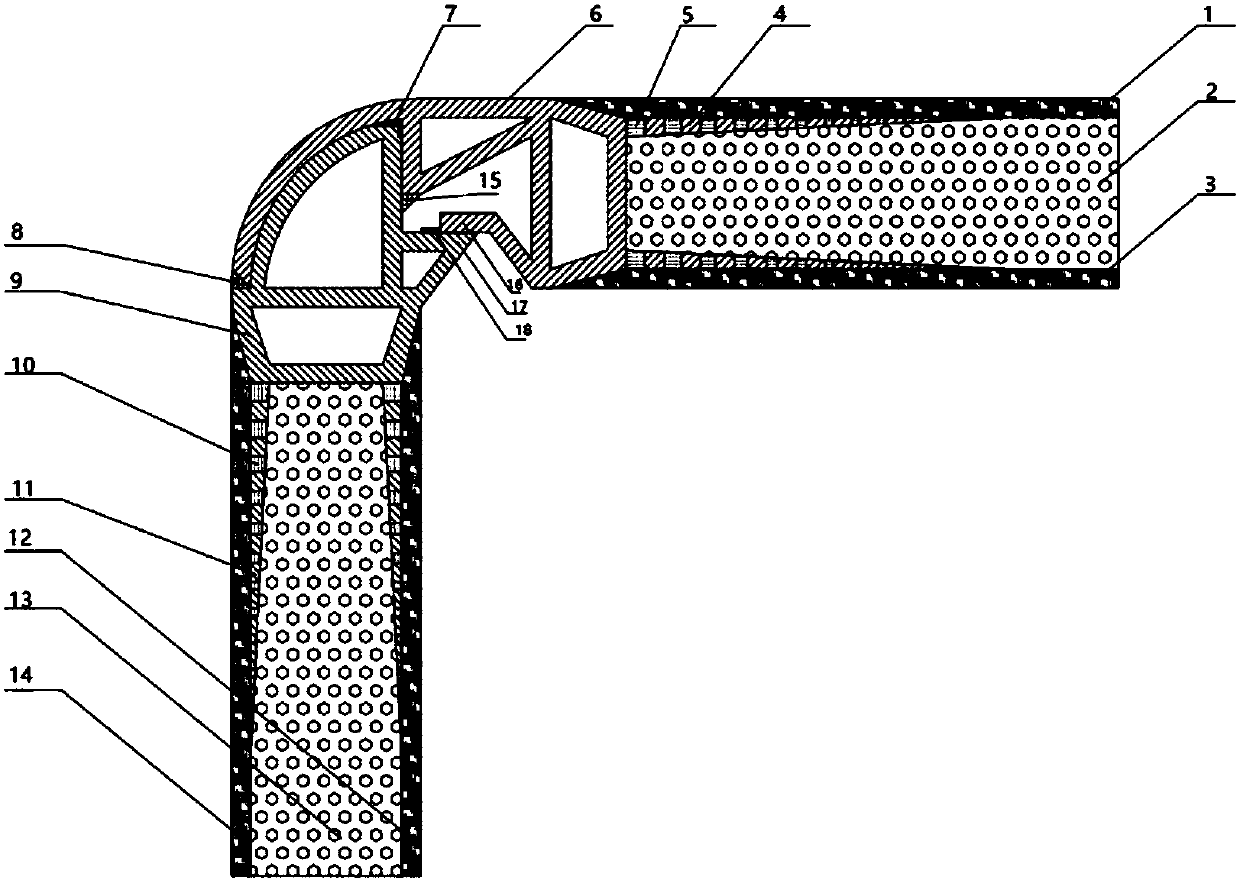

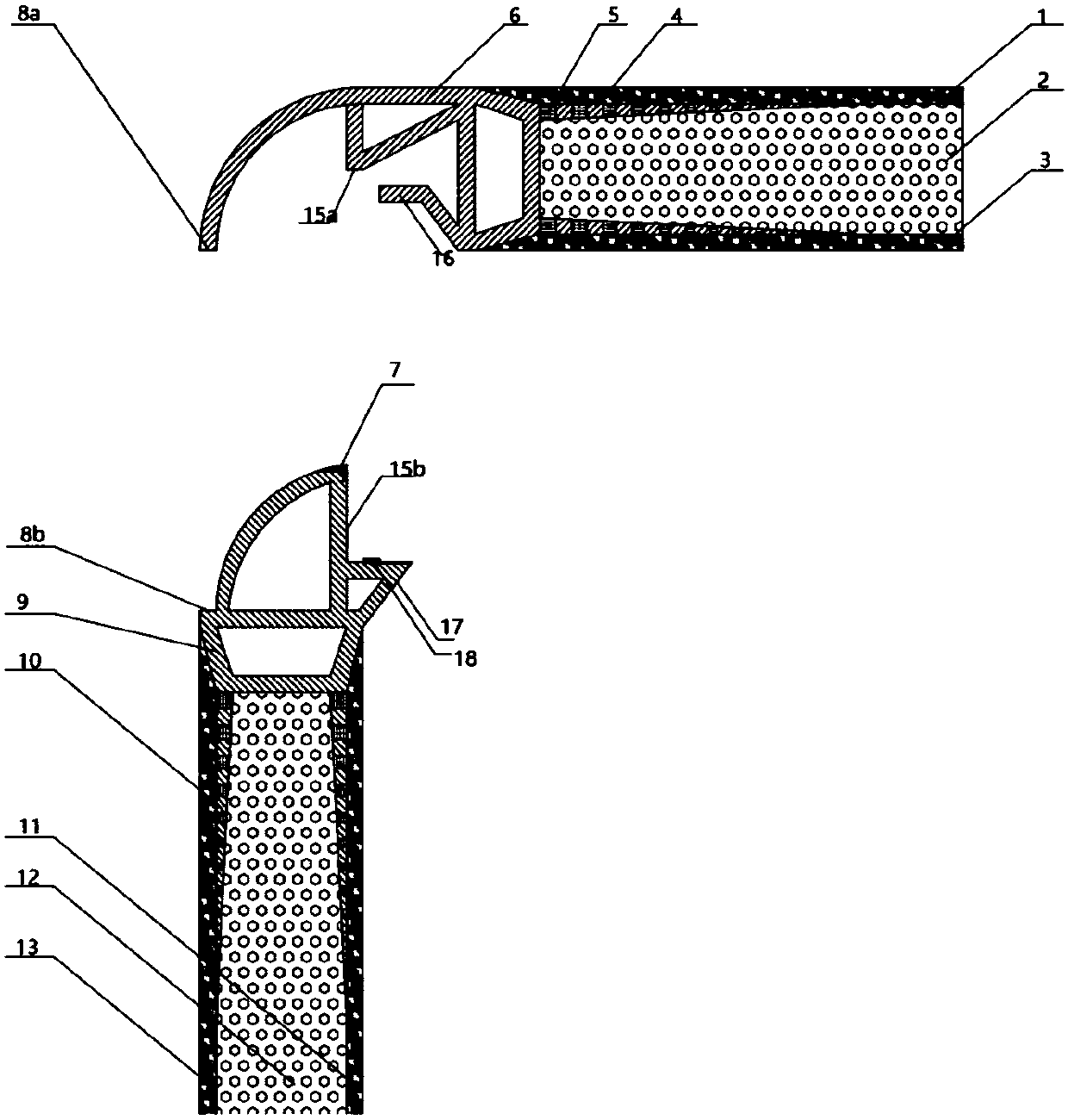

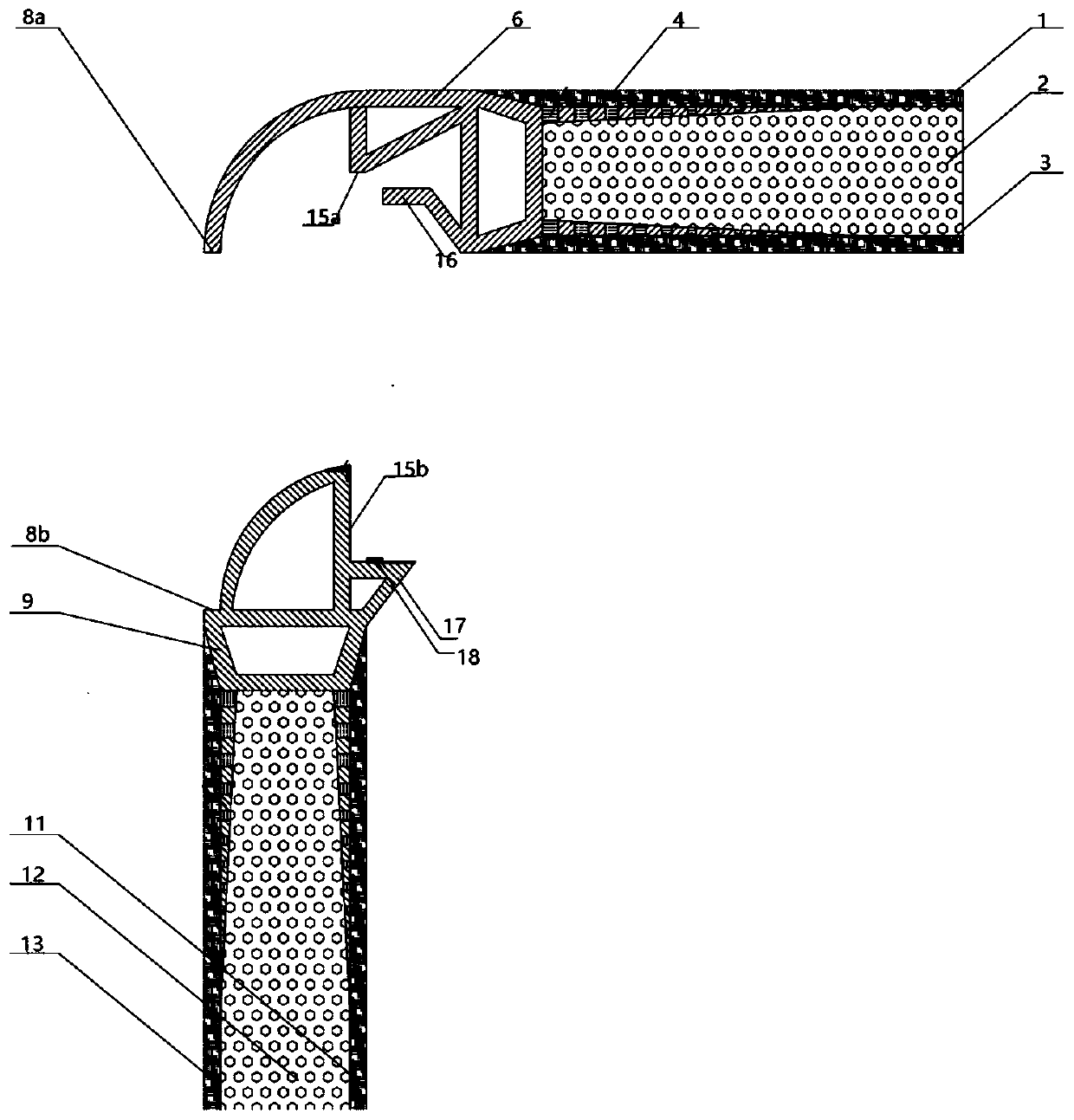

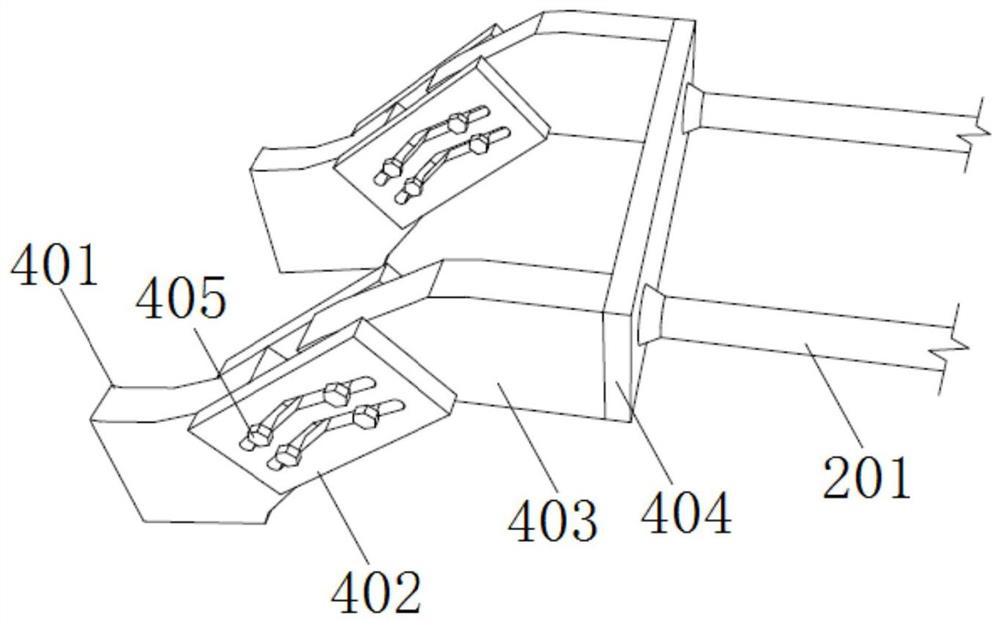

L-shaped composite material laminboard connecting structure with flexible metal connector

ActiveCN107901518AGood bending resistanceReduce manufacturing stepsLayered productsFastening meansLaminated compositesMetal

The invention provides an L-shaped composite material laminboard connecting structure with a flexible metal connector. The structure comprises foamed laminated composite material plates and metal connecting parts, wherein pre-buried metal plate parts of the metal connecting parts are embedded between laminated foams and composite material plates; composite material laminboards and the metal connecting parts are cured together by using an integral molding technique. Due to adoption of adjustable flexible connectors, the assembling stress is effectively reduced, and flexible assembling is achieved; the pre-buried metal plate parts are designed as a forked tail structure, so that the concentrated stress at the connecting parts of the metal plates and the composite material plates is effectively reduced; the connecting parts are of circular arc-shaped design, so that the bending strength is improved; due to a co-curing technique, composite material openings and the like are avoided, and the integrity of the composite material plates is ensured; a relatively large space is reserved in the metal connecting parts, so that convenience can be brought to pipeline laying and later maintenance. The structure is applicable to mechanical connection of composites material laminboards and other structures of large-size structures.

Owner:HARBIN ENG UNIV

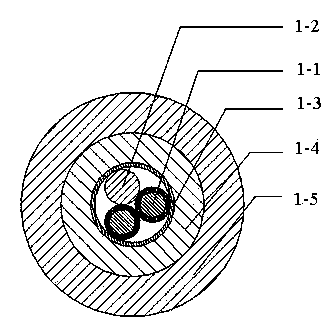

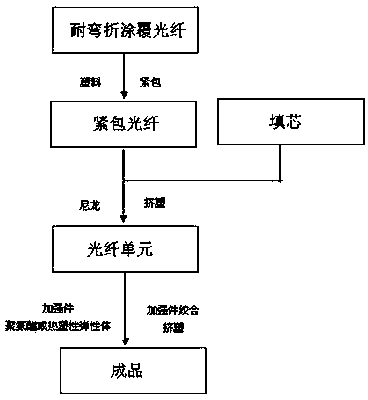

Novel foldable light emergency cable and implementation method thereof

ActiveCN103713368AIncrease production speedCompact and stable structureFibre mechanical structuresStructural engineeringElectrical and Electronics engineering

The present invention relates to an emergency cable. The problem to be solved is to overcome the problems of the prior art to provide a novel folding lightweight cable and implementation of emergency, in terms of mechanical, environmental and other emergency with existing conventional cable performance is not reduced, the improved performance of the cable resistance to bending and reduced cable diameter and the reduced cable weight. The emergency cable is characterized in that said two optical fibers and a cable used for filling in the 'SZ' twist and simultaneously extruding an outer layer of nylon fiber unit; outer diameter of the optical fiber unit is 0.6mm-2.0mm; in uniformly twisted around reinforcement fiber unit and at the same time strengthening the outer layer of the outer sheath extrusion. The present invention is made of an emergency cable reasonable structure, excellent performance, not only can reduce the outer diameter of the cable is not reduced under the premise of guaranteed performance and reduce the weight of the cable, and can improve the resistance to bending of the cable, and higher productivity.

Owner:CHINA ELECTRONICS TECH GRP NO 23 RES INST

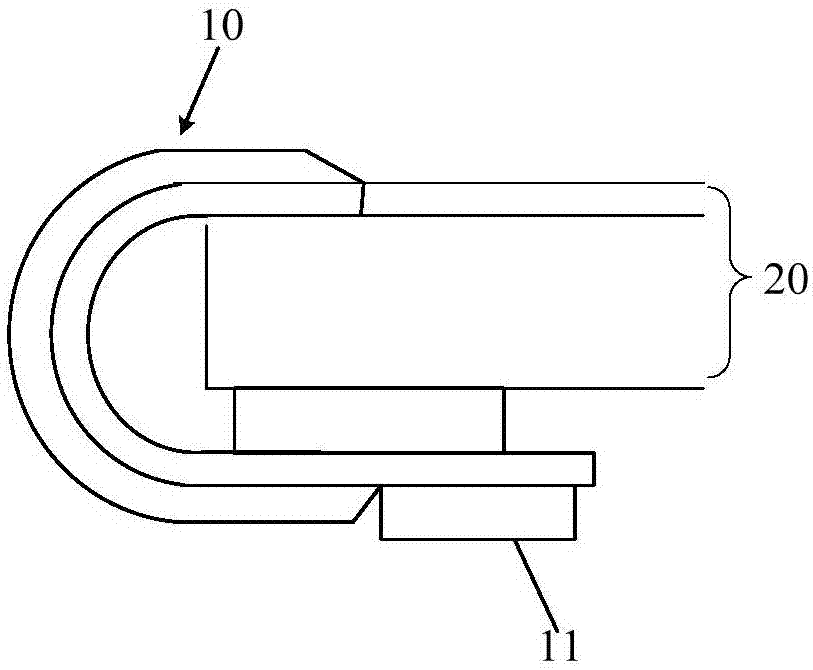

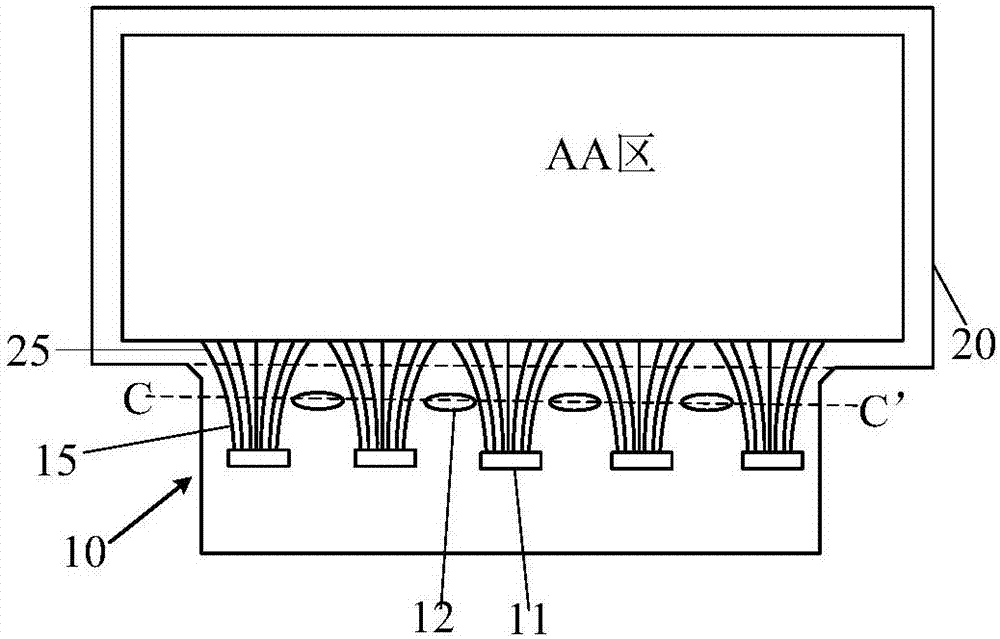

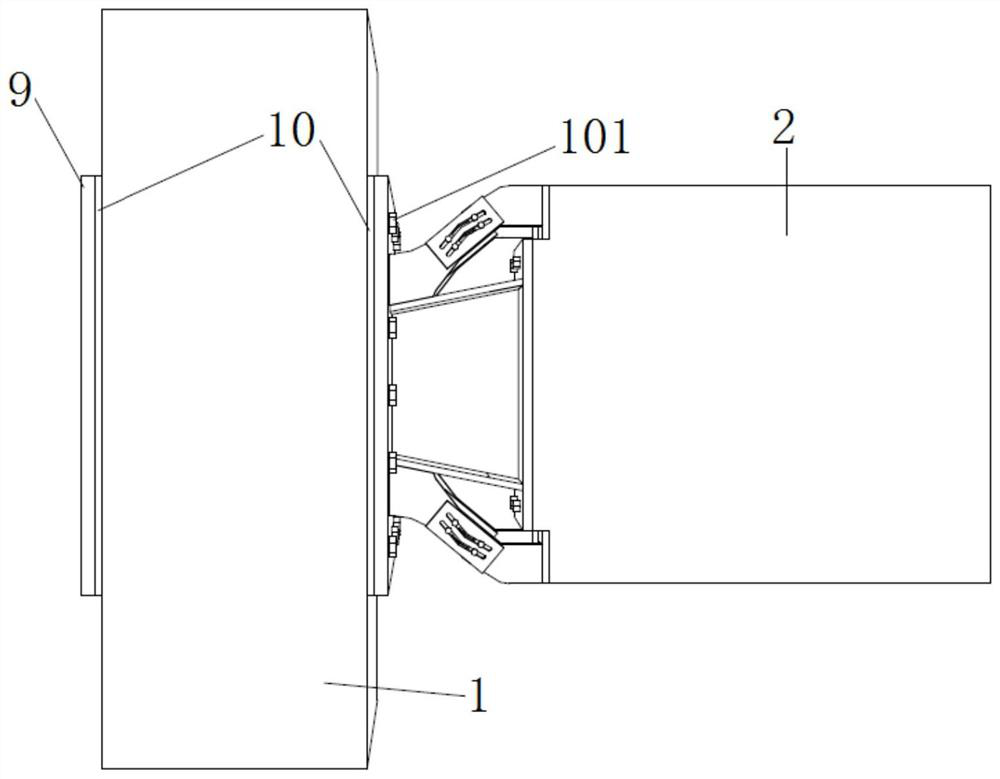

Driving circuit board and displaying device

ActiveCN107546252AEasy to bendReduced bending resistanceStatic indicating devicesPrinted circuit aspectsElectricityDisplay device

The invention provides a driving circuit board. The driving circuit board is applied to a displaying device. The displaying device board comprises a displaying substrate, the displaying substrate comprises a displaying area and a lead area located around the displaying area, and the lead area is provided with a lead which extends from the displaying area; one end of the driving circuit board is used for being electrically connected with the lead of the lead area, the driving circuit board can be bent, and the other end of the driving circuit board is located at the side, deviating from the light emergence direction, of the displaying substrate; the driving circuit board is provided with through holes running through the driving circuit board, and the through holes are located on the bending portion of the driving circuit board. Correspondingly, the invention further provides the displaying device. The driving circuit board is easier to bend, and therefore a narrow frame of the displaying device is easily achieved.

Owner:BOE TECH GRP CO LTD +1

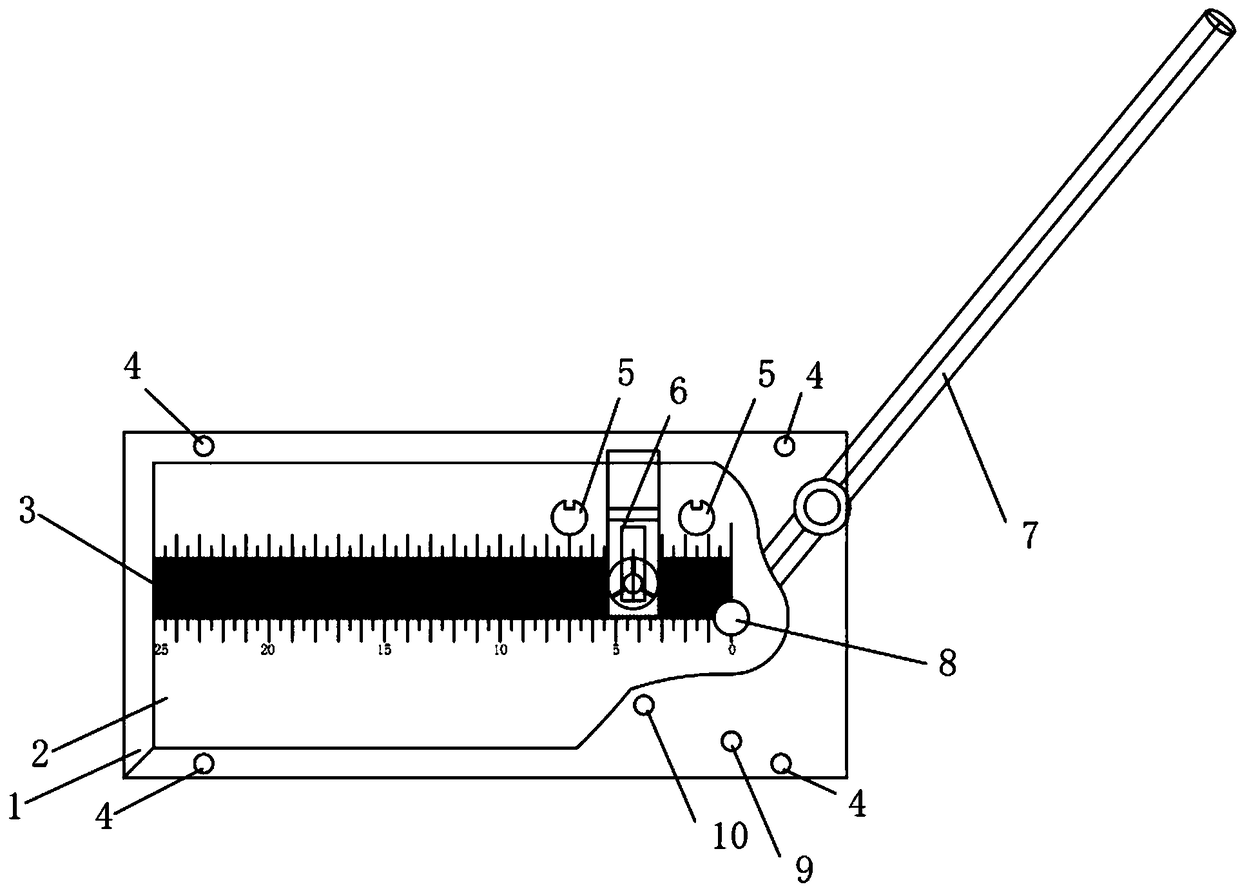

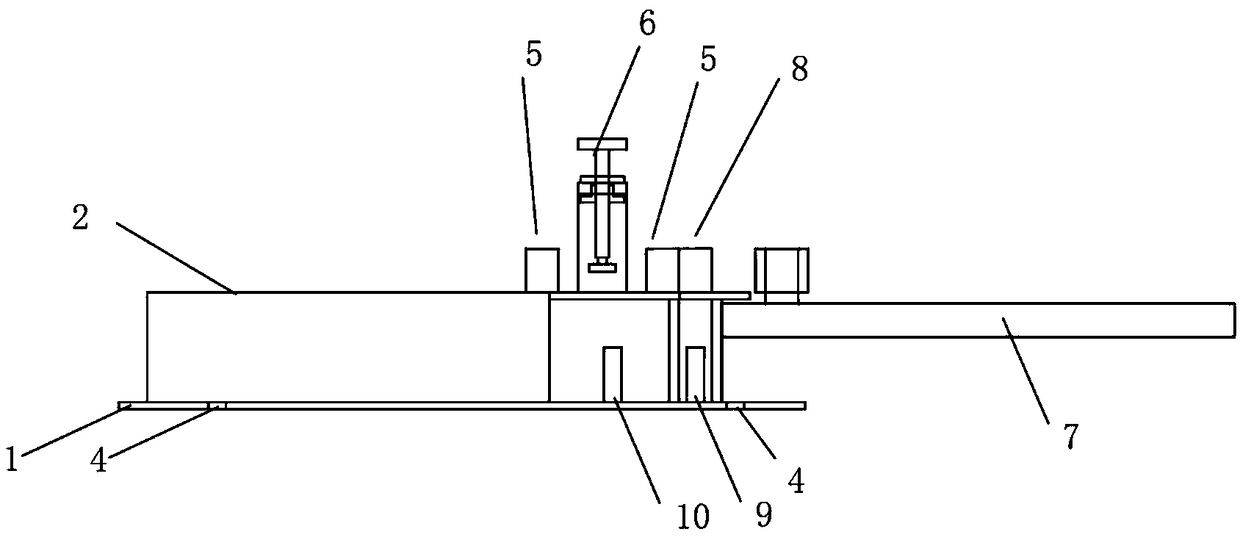

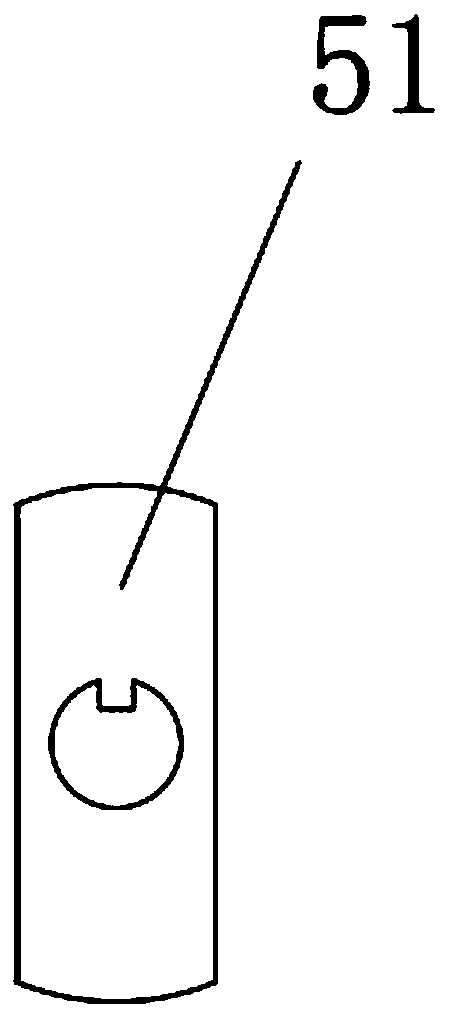

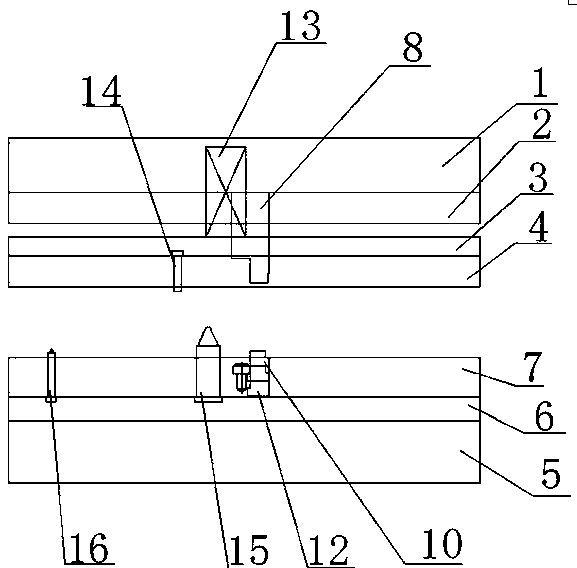

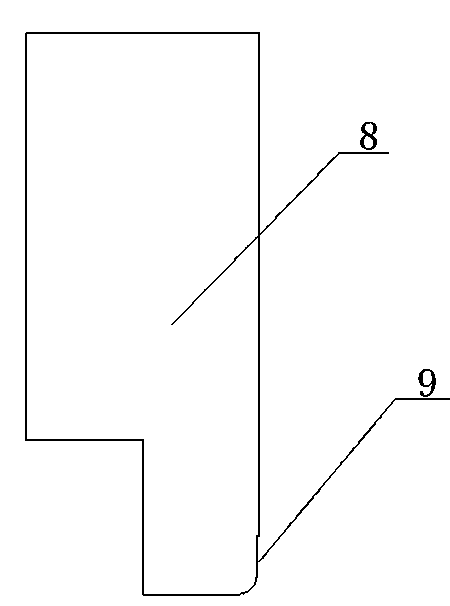

Manual reinforcing steel bar bending tool and operation method thereof

The invention relates to a manual reinforcing steel bar bending tool and an operation method thereof. The manual reinforcing steel bar bending tool comprises an operating floor base and an operation table, wherein the operating table is arranged above the operating floor base and is connected with the operating floor base through a connecting plate arranged in the vertical direction. The manual reinforcing steel bar bending tool is characterized in that a positioning column, a presser and a bending circle center positioning column are arranged on the operation table; and a spanner is arrangedbetween the operating floor base and the operation table. The manual reinforcing steel bar bending tool provided by the invention is simple in structure and convenient to operate; the reinforcing steel bar bending efficiency and the reinforcing steel bar bending accuracy are improved; the presser is arranged on the reinforcing steel bar operation table, and the reinforcing steel bar is fixed whenbeing bent, so that the precision of the length of a hook is ensured; and the presser can move in a long hole at a flat plate suspension section according to the position of the reinforcing steel bar,and a pressing plate can freely rotate along the axis of a screw rod and cannot rotate on the surface of the reinforcing steel bar along with the rotating of a hand wheel, so that the influence of pressing on the physical property and the mechanical property of the reinforcing steel bar is reduced.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

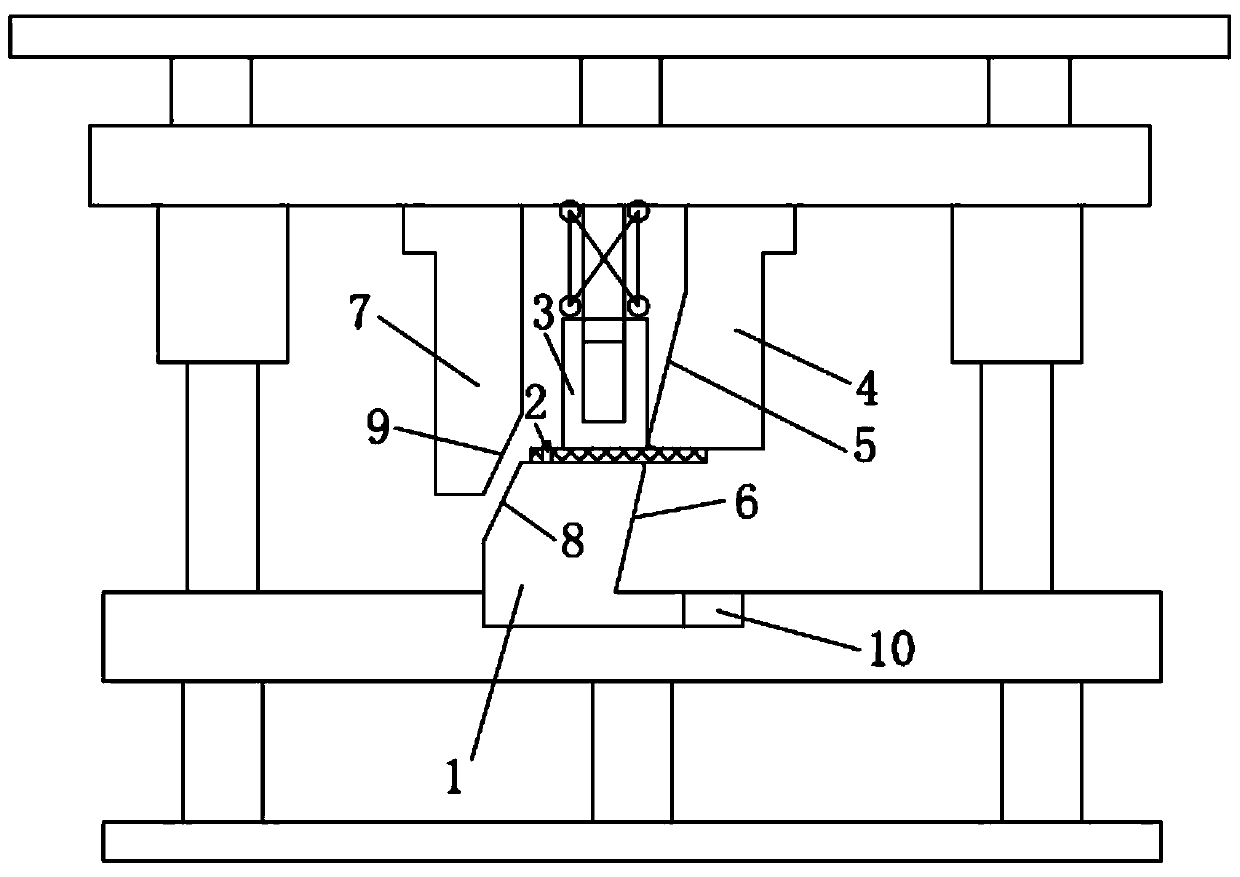

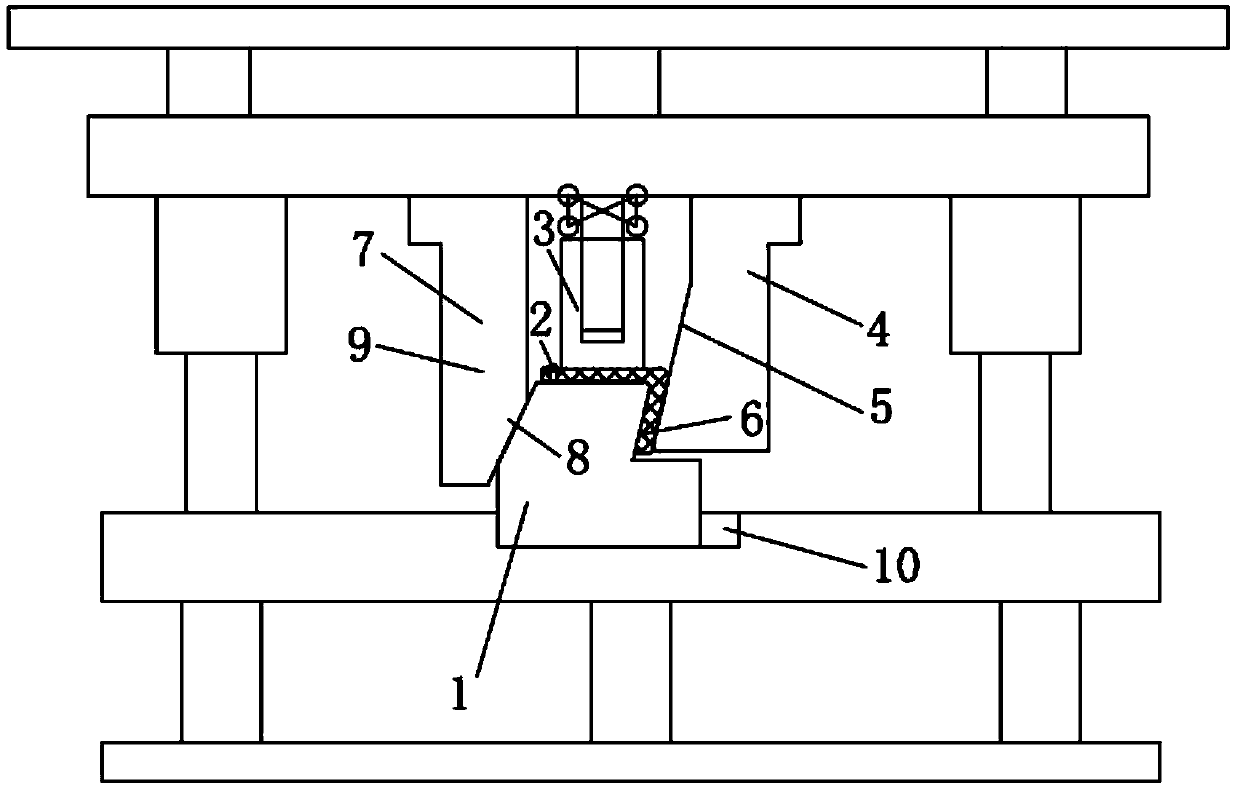

Stamping die used for sideward push

InactiveCN103990709AReduced bending resistanceSimple structureShaping toolsEngineeringMechanical engineering

The invention discloses a stamping die used for sideward push. An elastic pressing block is arranged above an insert core. A first inclined wall is arranged on one side of the insert core. When the insert core is in the initial position, one end of the first inclined wall and one side of the elastic pressing block are aligned in the vertical direction. A punch pin is arranged on one side of the elastic pressing block. A second inclined wall is arranged on one side of the punch pin. The second inclined wall and the first inclined wall are parallel to each other. A third inclined wall is arranged on the other side of the insert core. A push rod is arranged above the third inclined wall. A fourth inclined wall parallel to the third inclined wall is arranged at the bottom of the push rod. Due to the first inclined wall, a bent edge used for conveniently bearing force is formed on the top of the insert core, and meanwhile enough bending space is reserved for a bent piece. Due to the second inclined wall, bending resistance between the punch pin and a plate is reduced. Due to the third inclined wall and the fourth inclined wall, the insert core can slide towards one side of the punch pin in the die assembly process so that a bent angle smaller than 90 degrees can be formed. The stamping die is simple in structure, stable and reliable in bending and capable of effectively reducing bending resistance.

Owner:昆山电子羽电业制品有限公司

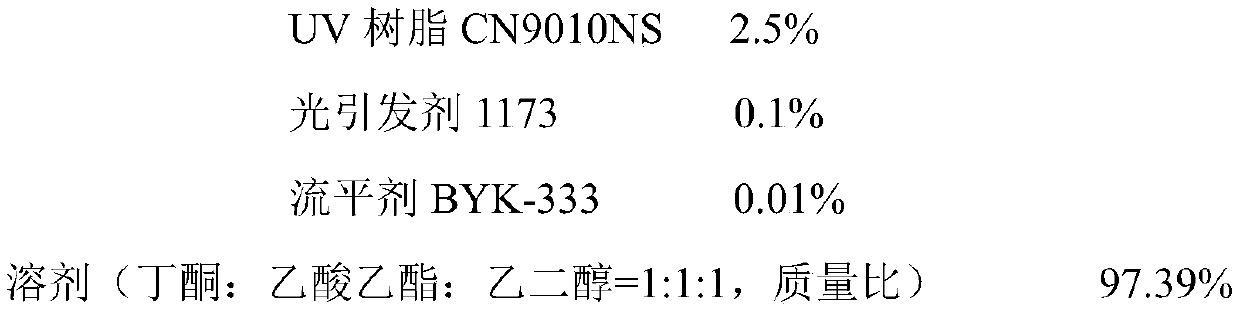

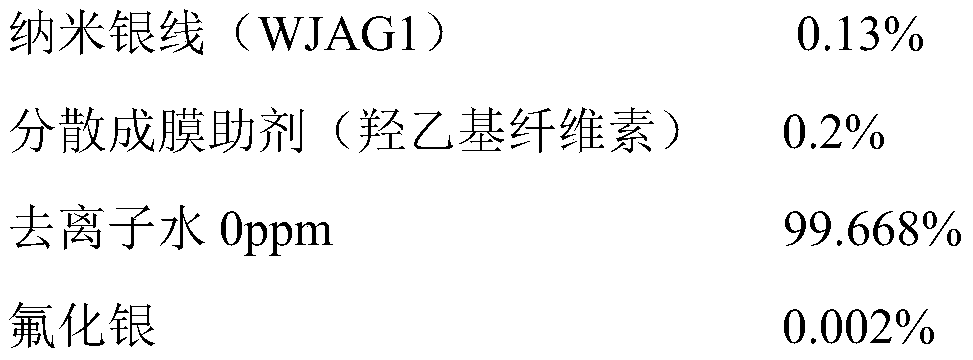

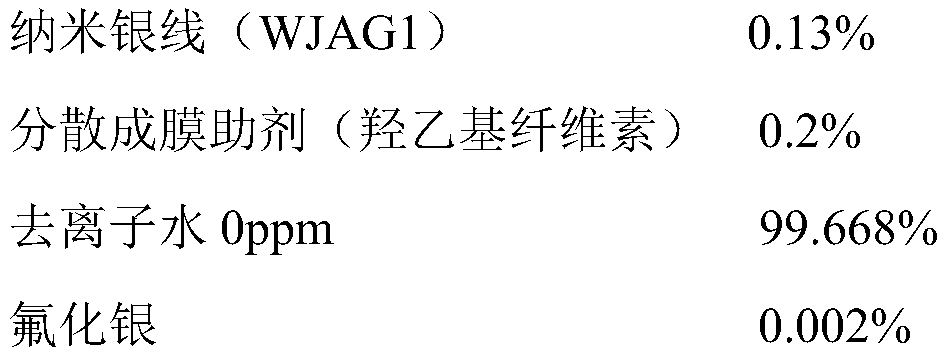

Nano silver wire flexible transparent conductive film with high lapping efficiency and excellent bending resistance

ActiveCN110444318AImprove efficiencyImprove bending resistanceConductive layers on insulating-supportsInsulated cablesUv protectiveTransparent conducting film

The invention discloses a nano silver wire flexible transparent conductive film with high lapping efficiency and excellent bending resistance. The flexible transparent conductive film is prepared by firstly coating the surface of a substrate with nano silver wire conductive ink to form a conductive layer, then coating the surface of the conductive layer with an optimization liquid for optimization, and finally coating the surface of the optimized conductive layer with a UV protective liquid to form a UV protective layer. The nano silver wire surface PVP of the flexible transparent conductive film of the invention is removed, and the nano silver wire network nodes are soldered so that it requires a small number of nano silver wires to prepare the conductive film. The obtained conductive film has excellent optical performance, low square resistance, and excellent bending resistance, and is suitable for large-size display and flexible display.

Owner:合肥微晶材料科技有限公司

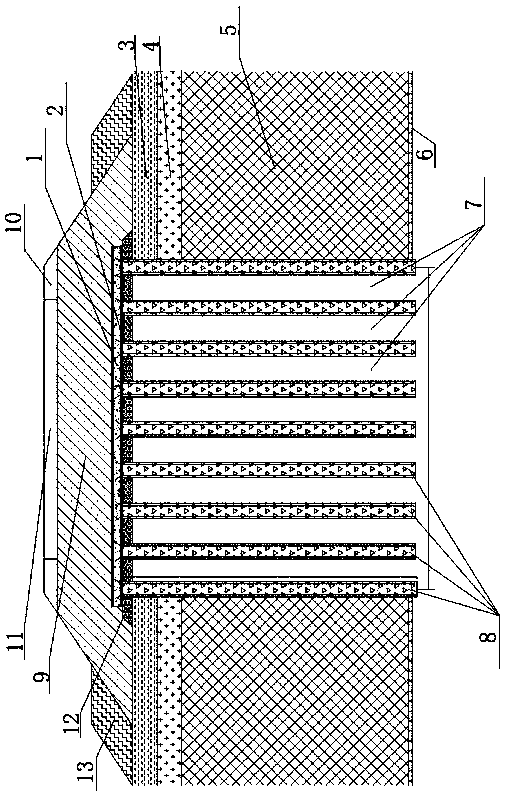

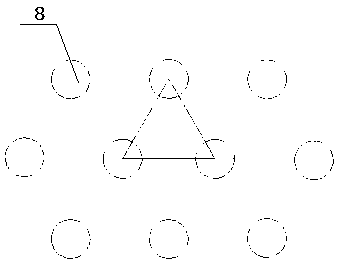

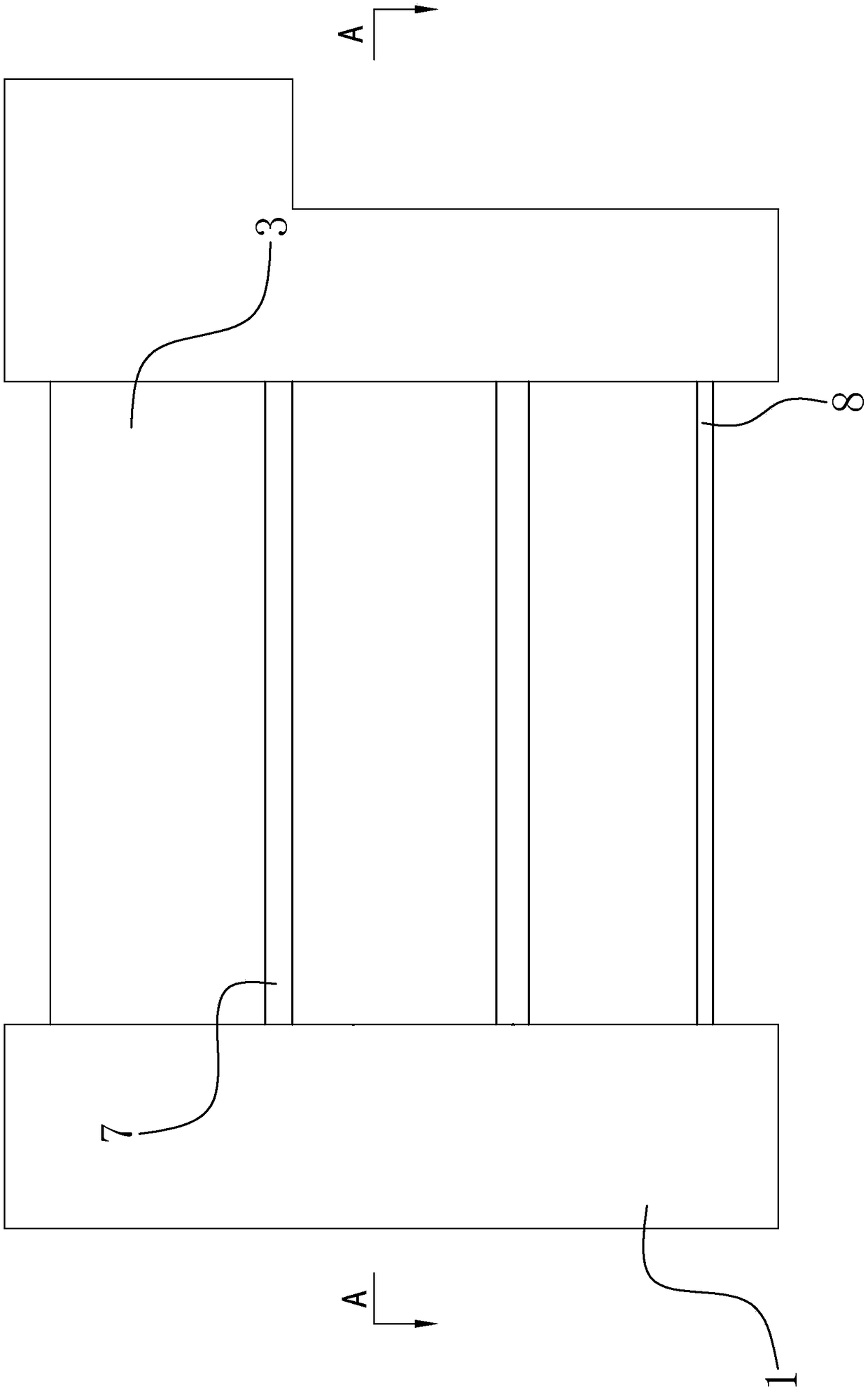

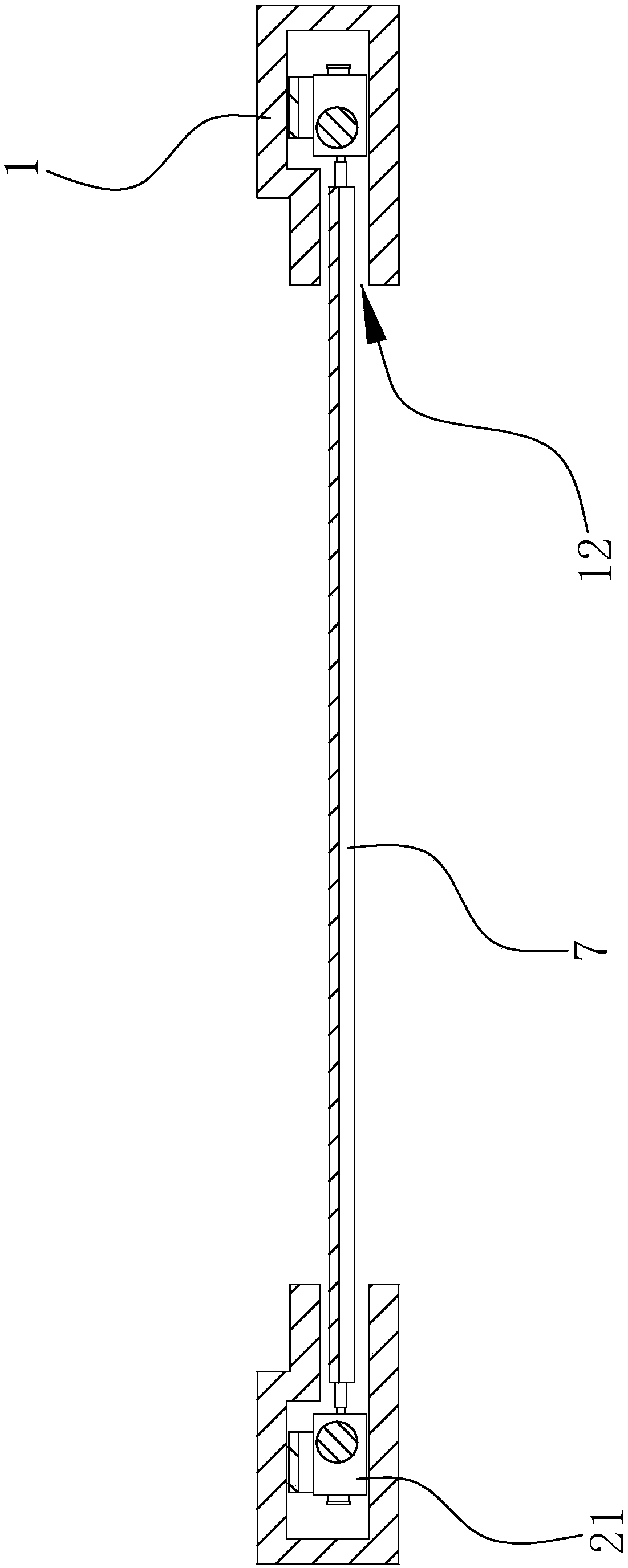

High-latitude high-temperature permafrost area highway raft plate-pile composite foundation and construction method

InactiveCN108265735AQuality assuranceEnsure safetyProtective foundationBulkheads/pilesPermafrostHigh latitude

The invention provides a high-latitude high-temperature permafrost area highway raft plate-pile composite foundation and a construction method. In the prior art, the hydration heat generated by CFG piles during construction would have a large effect on permafrost around the piles and therefore the lateral restraint would be obviously reduced after the permafrost melts, so that the bearing abilityof the CFG piles would be obviously affected. The high-latitude high-temperature permafrost area highway raft plate-pile composite foundation comprises a foundation; the foundation comprises a group of prefabrication piles (8); inter-pile soil (7) is arranged between each two adjacent prefabrication piles; the lower portions of the prefabrication piles pass through humus (3), peat soil (4) and a high-temperature permafrost layer (5) sequentially and are located on a pile foundation force holding layer (6); the tops of the prefabrication piles extend into a raft plate (1); an XPS thermal insulation plate (2) is arranged under the raft plate and a cotton-padded mattress cushion layer (12) is arranged under the XPS thermal insulation plate. The invention is applied to the high-latitude high-temperature permafrost area highway raft plate-pile composite foundation and the construction method.

Owner:LONGJIAN ROAD & BRIDGE +1

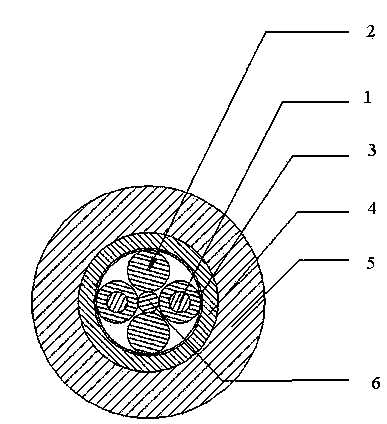

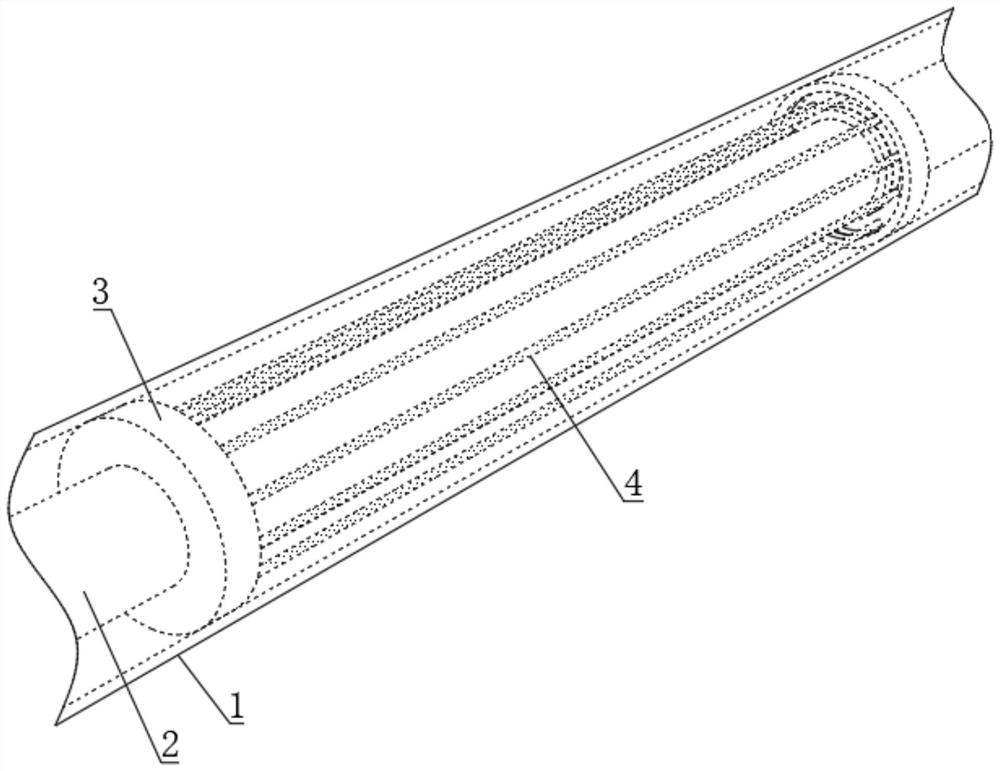

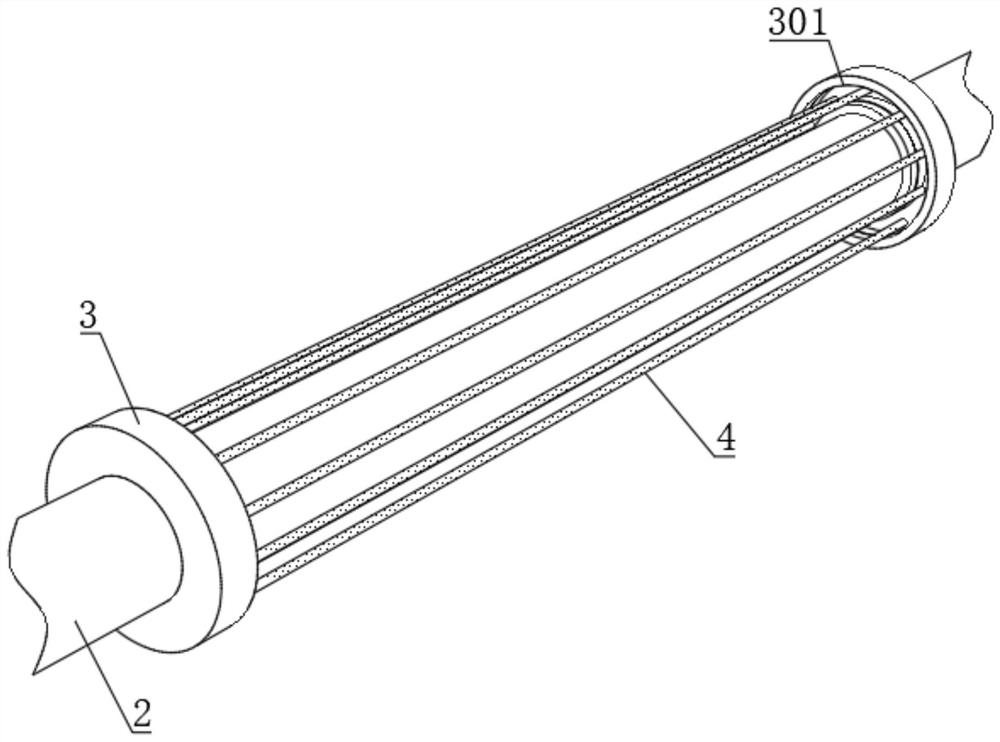

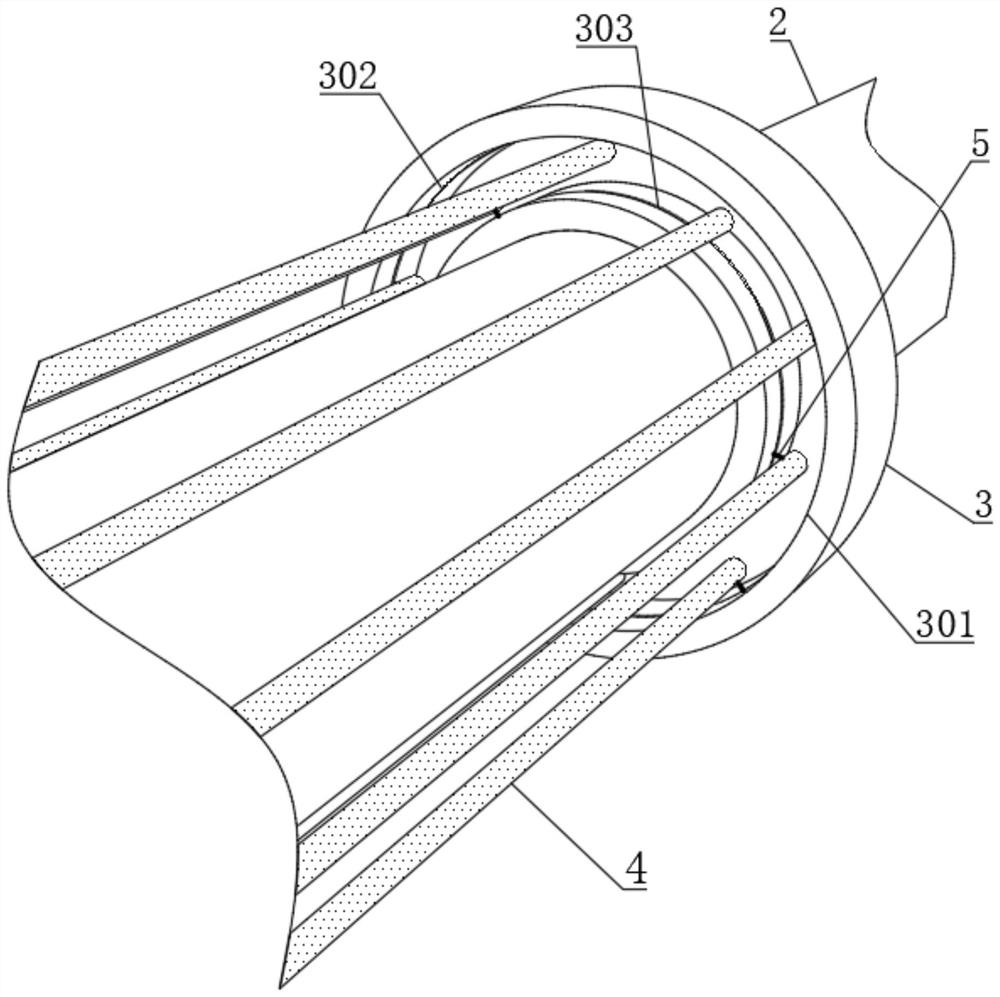

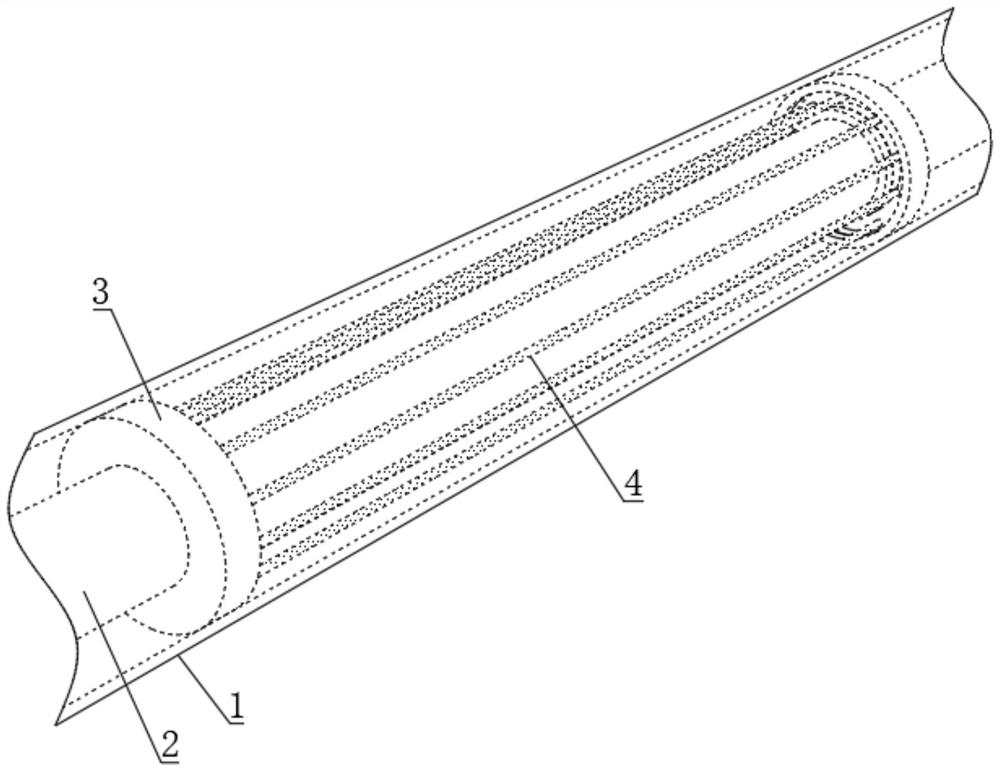

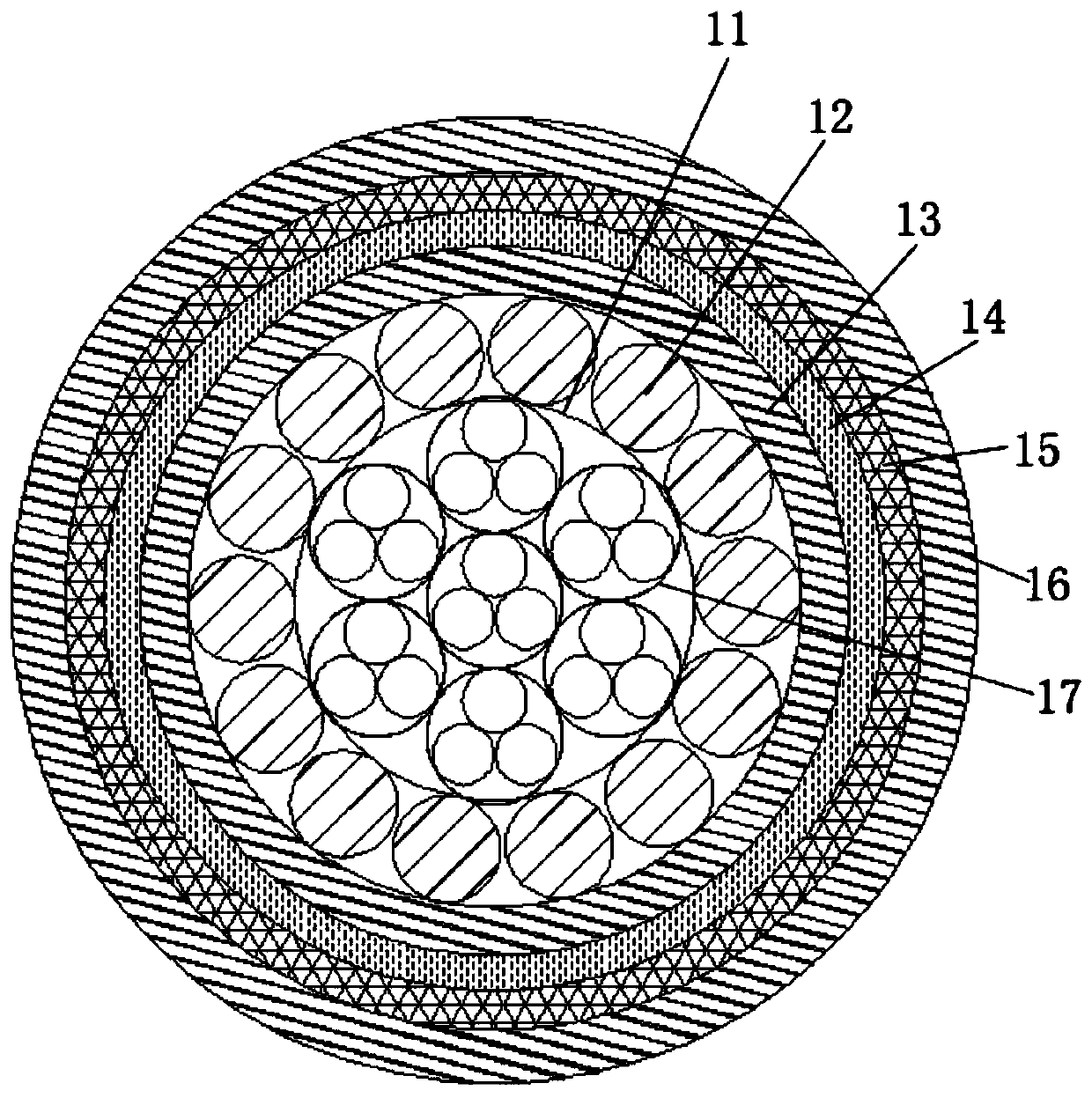

Self-adaptive multi-directional anti-bending cable

ActiveCN112927843AReduces bending damageImprove bending abilityFlexible cablesFlexible conductorsStructural engineeringBending force

The invention discloses a self-adaptive multi-directional anti-bending cable, and belongs to the field of cables. An anti-bending lead screw sleeve is arranged between a sheath and a cable core, when the self-adaptive multi-directional anti-bending cable is subjected to bending force in any direction, and the sheath and the cable core are bent, a plurality of anti-bending elastic rods which are originally uniformly and dispersedly arranged are limited by the lengths of the anti-bending elastic rods, the plurality of anti-bending elastic rods gradually move near the bending point and are gathered at the bending point to jointly provide acting force for the cable core to resist bending, so that the cable has relatively high bending resistance, and when external bending force disappears, the plurality of anti-bending elastic rods are automatically dispersed to provide resilience force for the sheath and the cable core to recover a linear shape, and therefore, the linear state can be recovered more quickly and effectively, and the bending damage degree of the cable core can be reduced. In addition, when external bending force reaches a relatively high degree, the anti-bending elastic rods automatically release gas outwards, so that the anti-bending performance of the anti-bending elastic rods is reduced, the anti-bending elastic rods have certain flexibility, and the cable adapts to relatively large external acting force.

Owner:沧州会友线缆股份有限公司

Flexible printed circuit board and mobile terminal

ActiveCN105636351AImprove flexibilityReduced bending resistancePrinted circuit aspectsElectrical connection printed elementsSignal routingComputer terminal

The invention provides a flexible printed circuit board and a mobile terminal. The flexible printed circuit board comprises a substrate layer, a circuit layer and a covering film. The circuit layer is arranged on the substrate layer and comprises non-bending parts and a bending part. The bending part is provided with multiple signal wirings and multiple grounding wirings. The signal wirings are parallelly arranged. The length directions of the signal routing wires are parallel to the opposite direction of the non-bending parts. The grounding wirings are parallelly arranged. The lengths directions of the grounding wirings are perpendicular to the length directions of the signal wirings. The stress directions of the parallelly-arranged signal wirings are consistent with each other and are mutually dispersed, so bending resistance force imposed by each of the signal wirings on the bending part is reduced. There is no stress effect between the adjacent grounding wirings, so no bending resistance force is imposed on the bending part and flexibility of the flexible printed circuit board is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Bending and stamping die

The invention discloses a bending and stamping die. The bending and stamping die comprises an upper die base, an upper padding plate, an upper clamp plate, an upper die plate, a lower die plate, a lower padding plate and a lower die base, wherein a bending punch is fixedly installed at the lower end of the upper die base, the bending punch sequentially passes through the upper padding plate and the upper clamp plate and then is matched with the upper die plate, a bending wall is arranged on one side of the bending punch, an insert core is arranged on the lower die plate, an enter groove is formed in one side of the insert core, the enter groove is aligned at the bending wall, a limiting block is arranged on the lower portion of the insert core, and the limiting block is fixedly installed on the lower die plate through a screw. The bending and stamping die is reasonable in structure and simple to operate, guarantees stability and reliability of bending, uses special structure of the bending punch, reduces bending resistance during the bending process, and reduces failure rate of work pieces, caused by abrasions during the bending process.

Owner:KUNSHAN HUANGJIA PRECISION MOLD

High-strength thick glass substrate and preparation method thereof

InactiveCN107721155AImprove flexural strengthReduce melting effectGlass shaping apparatusOptical propertyHigh intensity

The invention discloses a high-strength thick glass substrate which comprises the following raw materials in percentage by weight: 56-63 percent of SiO2, 6-8 percent of Al2O3, 2-6 percent of B2O3, 8-9percent of CaO, 3-5 percent of MgO, 13-15 percent of Na2O, 1-3 percent of K2O, 0-1 percent of Sb2O3 and 0.1-1 percent of a clarifying agent. The invention further discloses a preparation method of the high-strength thick glass substrate. The high-strength thick glass substrate prepared by the preparation method disclosed by the invention is high in mechanical and optical properties, good in melting effect and low in processing difficulty.

Owner:株洲醴陵旗滨玻璃有限公司 +1

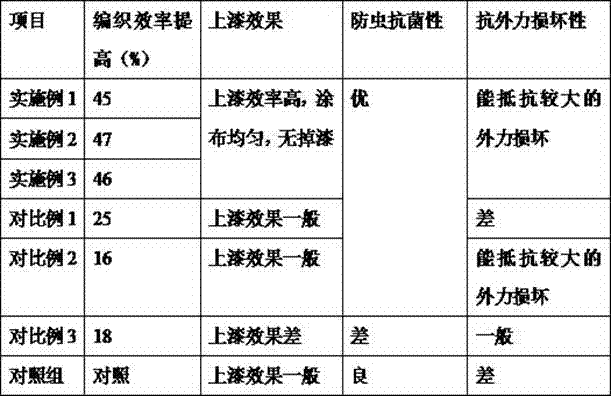

Vitex negundo treatment method for weaving

ActiveCN106985235AUniform irradiationImprove toughnessWood treatment detailsReed/straw treatmentFiberUltimate tensile strength

The invention relates to the technical field of processing of weaved crafts and discloses a vitex negundo treatment method for weaving. The vitex negundo treatment method comprises the following steps: (1) vitex negundo is pretreated after being harvested, so that part of the water content of the vitex negundo can be eliminated when the vitex negundo is naturally sun-dried, the toughness of the vitex negundo can be enhanced, and the damage to the vitex negundo can be reduced when the sun-dried vitex negundo is trimmed; (2), the pretreated vitex negundo is softened under the action of steam, so that not only can the skin of the vitex negundo be removed conveniently, but also the orientation of the aggregation structure of internal fibers can be improved, the tensile strength can be improved, the bending resistance can be reduced, and the toughness of the vitex negundo can be improved in the further load-bearing process; (3), the improved vitex negundo is put into a soak solution, so that not only can the mechanical property stabilizing effect be achieved, but also the varnishability of the vitex negundo can be improved due to components in the soak solution, and the soak solution has the antimicrobial and mothproof efficacy; and (4), the physically and chemically treated vitex negundo is dried and adjusted, so that the perfect processing performance can be achieved

Owner:阜南县环宇柳木工艺制品有限公司

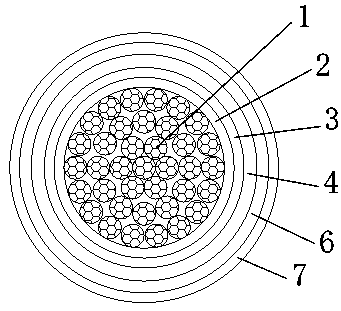

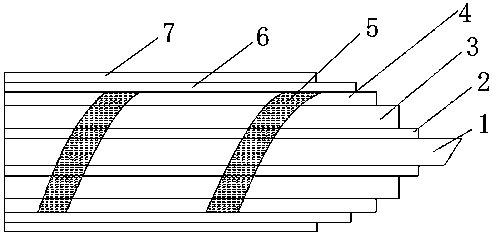

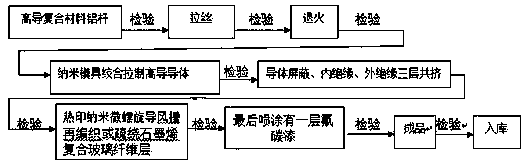

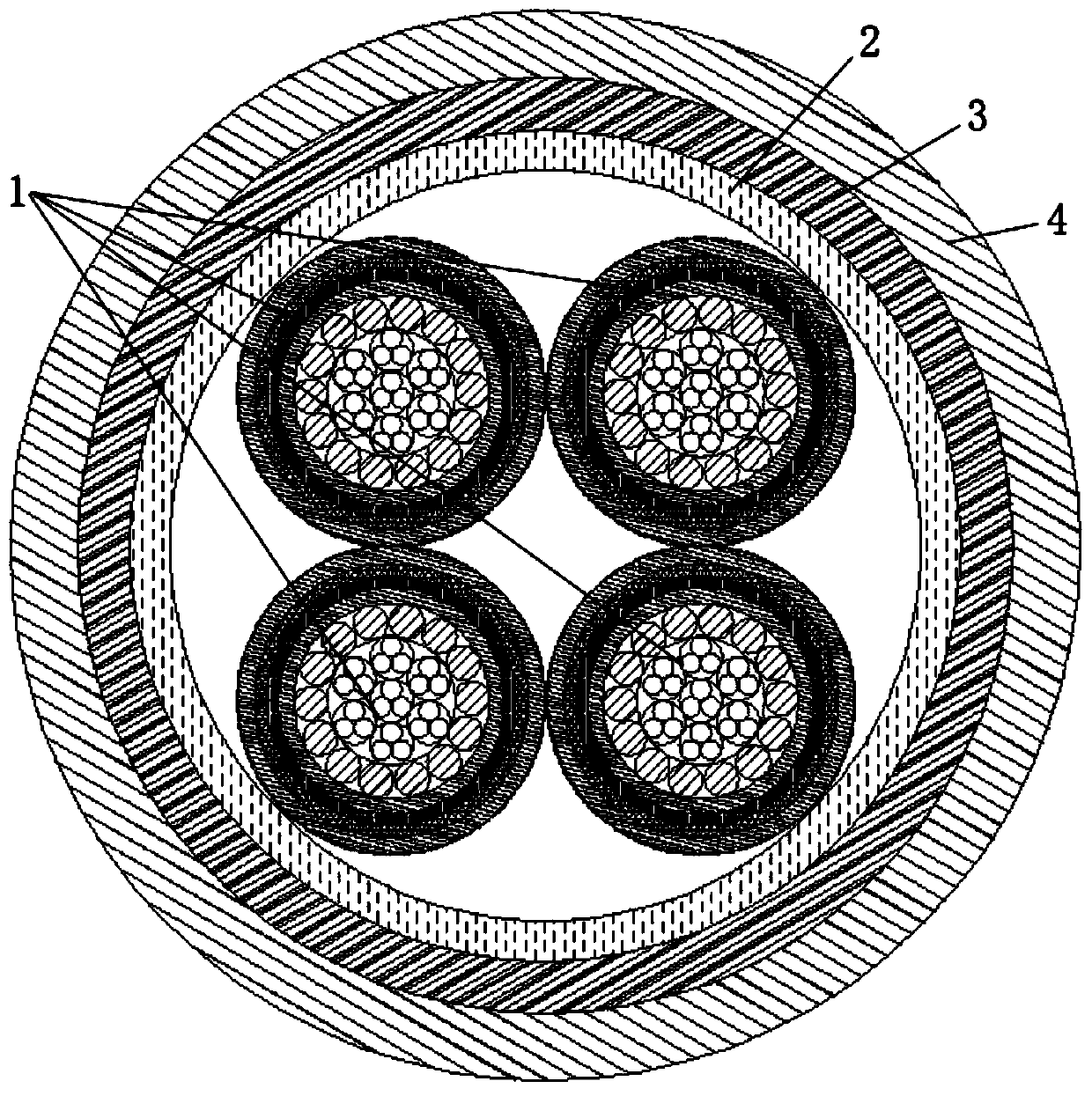

10kV graphene composite shielding low-noise weather-proof anti-interference overhead insulated cable

InactiveCN108520802AHigh strength mechanical propertiesHigh current requirementClimate change adaptationPower cables with screens/conductive layersLow noiseCross-linked polyethylene

The invention discloses a 10 kV graphene composite shielding low-noise anti-interference overhead insulated cable, comprising a highly conductive composite aluminium conductor. The highly conductive composite aluminium conductor is composed of 37 highly conductive composite aluminium wires of a diameter of 2.54 mm by four-layer intertwisting in a "1+6+12 +18" structure mode; a graphene composite semiconductive shielding layer, a crosslinked polyethylene internal insulating layer and a modified weather-proof insulation external insulating layer are extruded outside the highly conductive composite aluminium conductor in common; and an outer surface of the modified weather-proof insulation external insulating layer is provided with a nanometer micro-spiral air guide groove by thermal printingand then a graphene composite glass fibre layer is arranged through extrusion weaving or sparse winding, and a layer of fluorocarbon paint is sprayed outside the graphene composite glass fibre layer.The 10 kV graphene composite shielding low-noise anti-interference overhead insulated cable has the advantages of high electric strength, high temperature resistance, high thermal stability, high anti-interference performance, high humidity resistance, good embrittlement resistance and weather aging resistance, and thus the service life of the cable is greatly prolonged, and the safety of the cable is greatly improved.

Owner:WUXI CITY HENG HUI CABLE

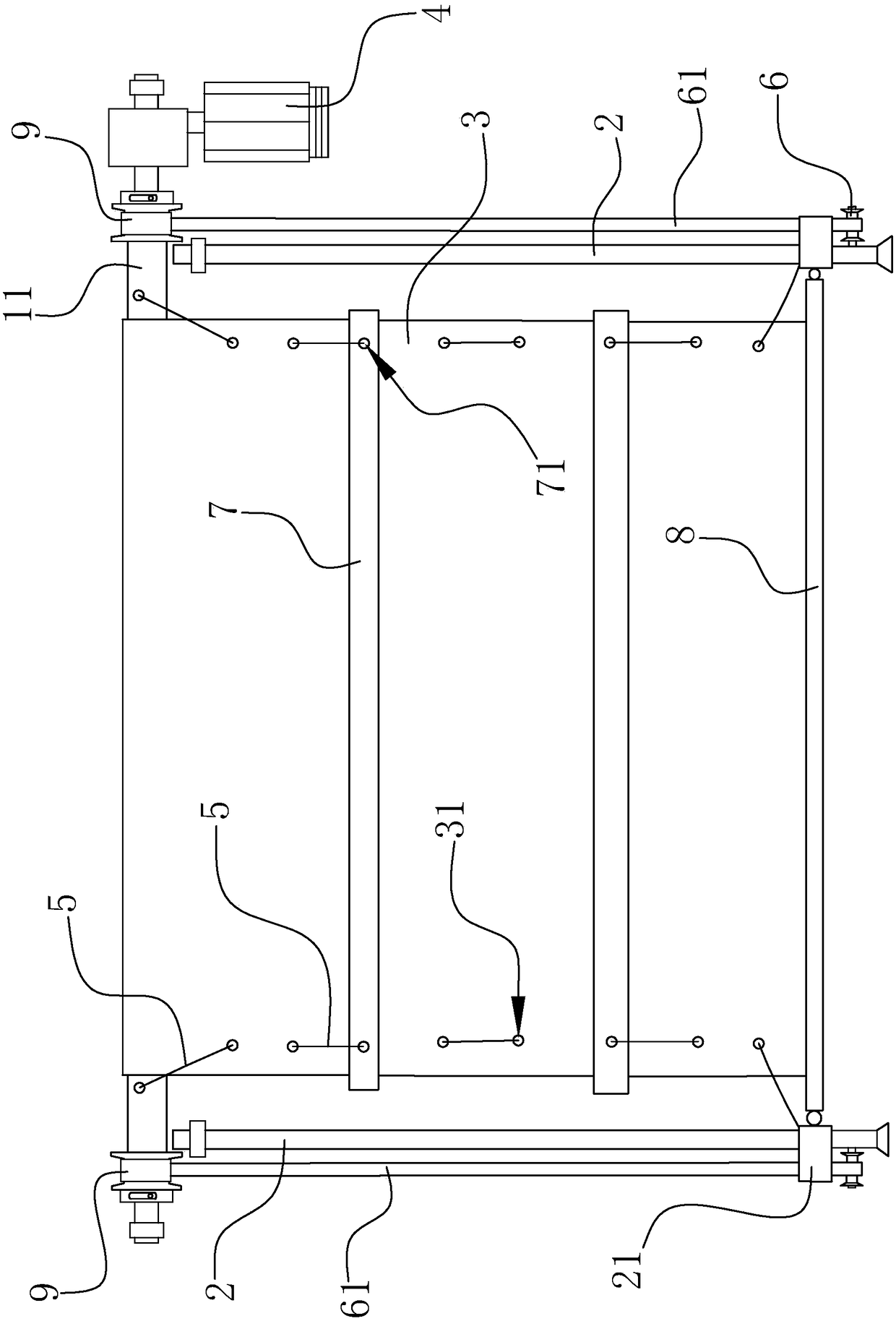

Windproof roller shutter door

InactiveCN108166910AImprove overall rigidityDynamic Vibration Cancellation CapabilityShutters/ movable grillesWeight problemElectric machinery

The invention relates to a windproof roller shutter door. The windproof roller shutter door comprises a roller shutter shaft arranged at the top of a door frame, a soft door curtain and a drive motor.The drive motor drives the roller shutter shaft to wind and unfold the door curtain. Two sides of the door curtain below the roller shutter shaft are correspondingly provided with vertical columns. Each vertical column is correspondingly provided with a sliding sleeve which can slide up and down relative to each vertical column through a transmission mechanism. The sliding sleeve is correspondingly connected with the corresponding bottom of the door curtain. A transmission mechanism is linked with the drive motor. Threading holes arranged at intervals on the upper and lower sides are correspondingly formed in the left and right sides of the door curtain, and tensioning ropes are inserted in the threading holes on each side of the door curtain. The upper ends of the tensioning ropes pass through the corresponding threading holes at the upper part of the curtain correspondingly and are connected with the corresponding position of the roller shutter shaft, and the lower ends of the tensioning ropes pass through the corresponding threading holes at the lower part of the door curtain correspondingly and are connected with the corresponding sliding sleeve. The windproof roller shutter door has the advantages that an integrated support system which is capable of hardness and softness is used, wind resistance and operational reliability are greatly improved; a rope lifting method is used, has no weight problem, and has a lighter dead weight.

Owner:宁波中令清洁技术有限公司

Low-pressure injection molding method for power capacitor shell

ActiveCN107972224AImprove pass rateIncrease elasticityChemical industryDomestic articlesEnvironmental resistanceAntioxidant

The invention relates to a low-pressure injection molding method for a power capacitor shell. The low-pressure injection molding method comprises the following steps of: sequentially putting isotaticpolypropylene homopolymer, modified waste plastic shell powder, talcum powder, silicon micro powder, fluororubber, a nucleating agent and an antioxidant into a mixer to uniformly mix to obtain a material mixture; and putting the material mixture into a hopper of a low-pressure injection molding machine, melting and plastifying the material mixture in the hopper of the low-pressure injection molding machine in each region of a screw, injection-molding the material mixture into a mould cavity of a mould, injecting glue in sequence according to a time quantum, opening the mould after mould cooling, ejecting and taking out products. According to the low-pressure injection molding method disclosed by the invention, modified waste plastic shell powder is utilized to substitute part of isotatic polypropylene homopolymer, so that recycling of a waste polypropylene capacitor shell is realized, and therefore, the low-pressure injection molding method is energy-saving and environmentally friendly, does not reduce elasticity and bending resistance of finished products, and further enables a qualification rate of the finished products to be 98.5%.

Owner:HUANGSHAN SHENGE ELECTRONICS TECH

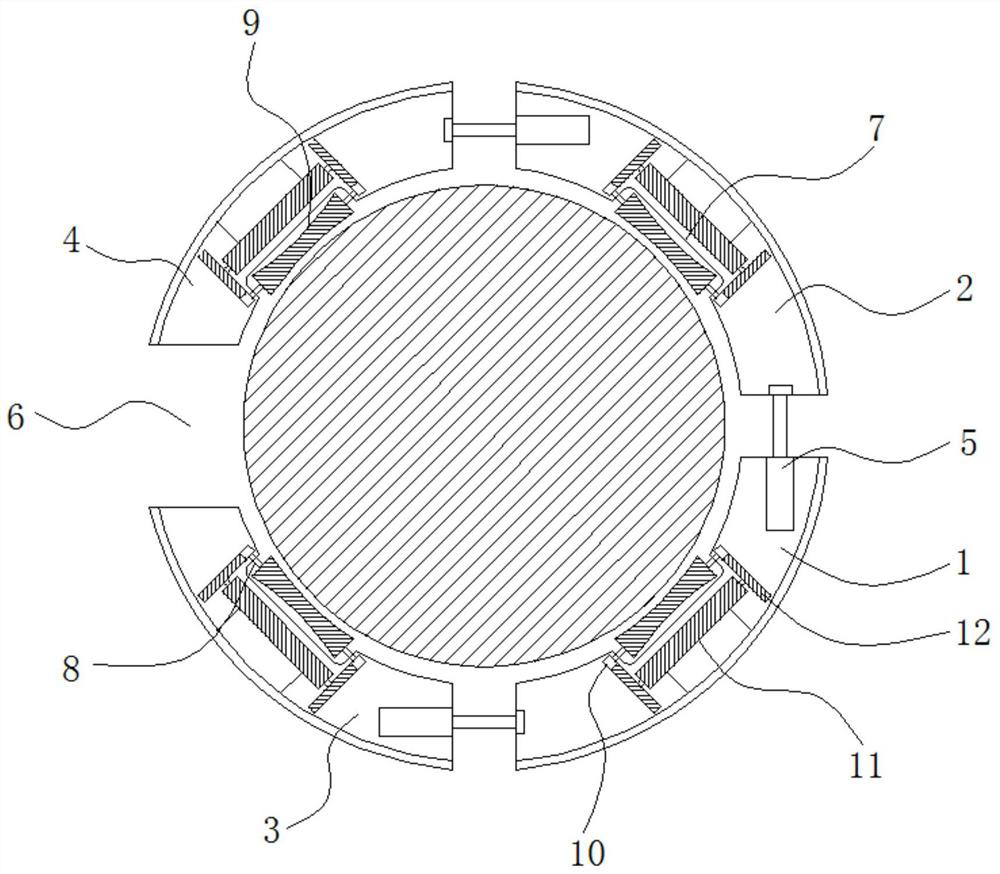

Pollution inspection robot used for underwater pipeline

ActiveCN112682701AEasy to turn and steerWalking smoothlyGeneral water supply conservationCommunication cablesEnvironmental geologyStructural engineering

The invention discloses a pollution inspection robot used for an underwater pipeline. The pollution inspection robot at least comprises three robot housings which integrally arranged to be circular ring shaped housing structures, wherein each robot housing comprises a first housing, a second housing, a third housing and a fourth housing correspondingly, the first housing is provided with an arc-shaped housing structure with a radian of 90 degrees, the first housing and the second housing are the same in arc length, and the third housing and the fourth housing are the same in arc length. The inspection robot disclosed by the invention consists of multiple robot housings, and each robot housing is of the circular-ring shaped housing structure, so that underwater pipelines can be correspondingly clamped into the circular ring shaped housings; and adjacent robot housings are connected through a waterproof spring tube, so that on one hand, communication waterproof communication cables can be correspondingly mounted, on the other hand, each robot housing is conveniently turned and steered, and thus, the integral structure smoothly travels on the pipeline.

Owner:WUXI INST OF ARTS & TECH

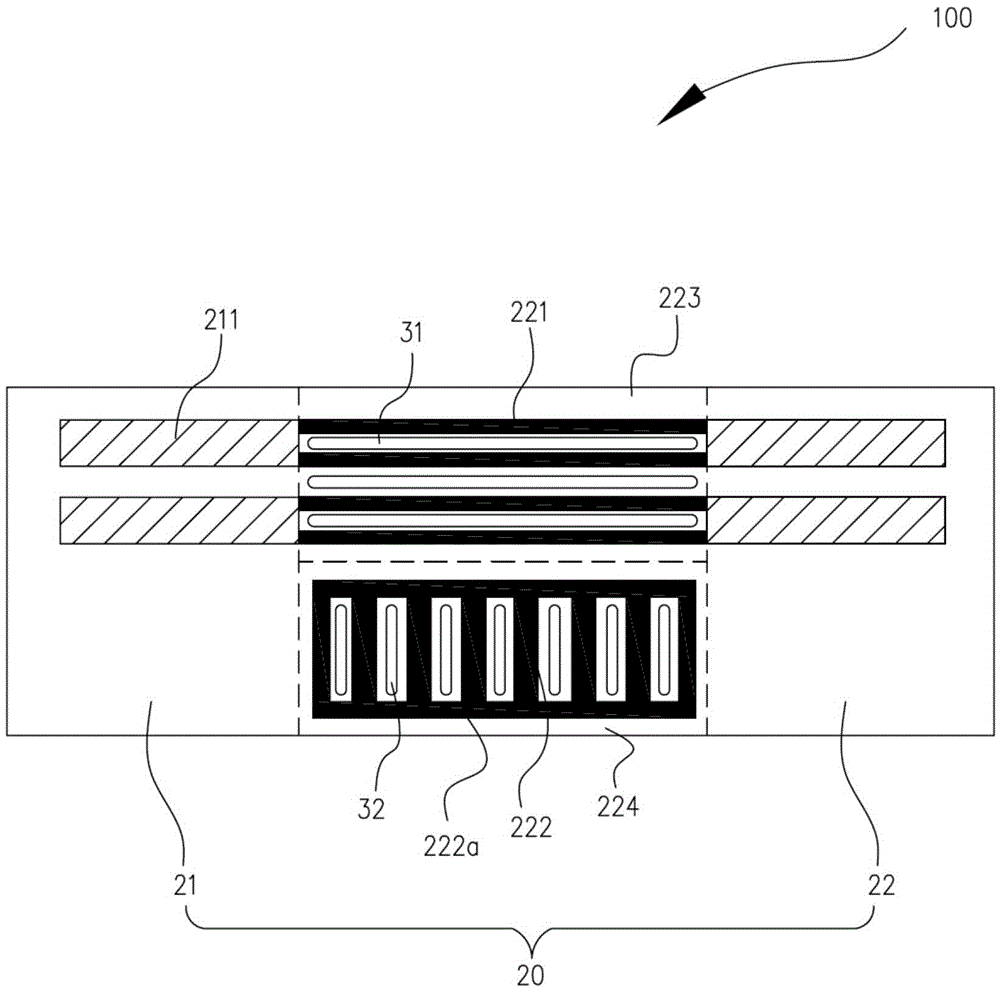

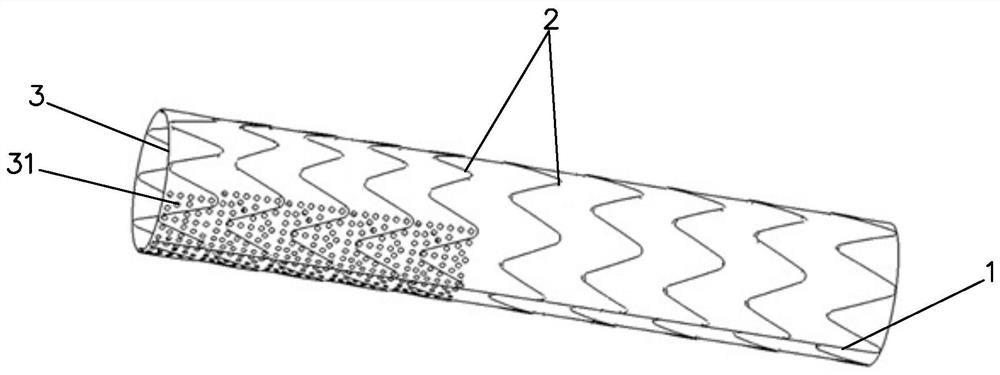

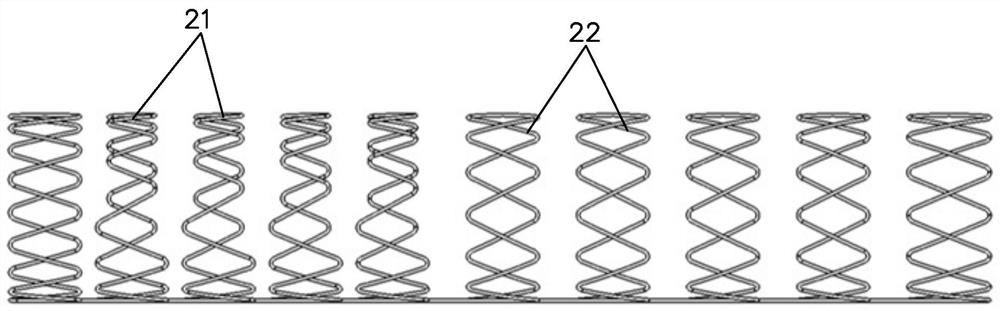

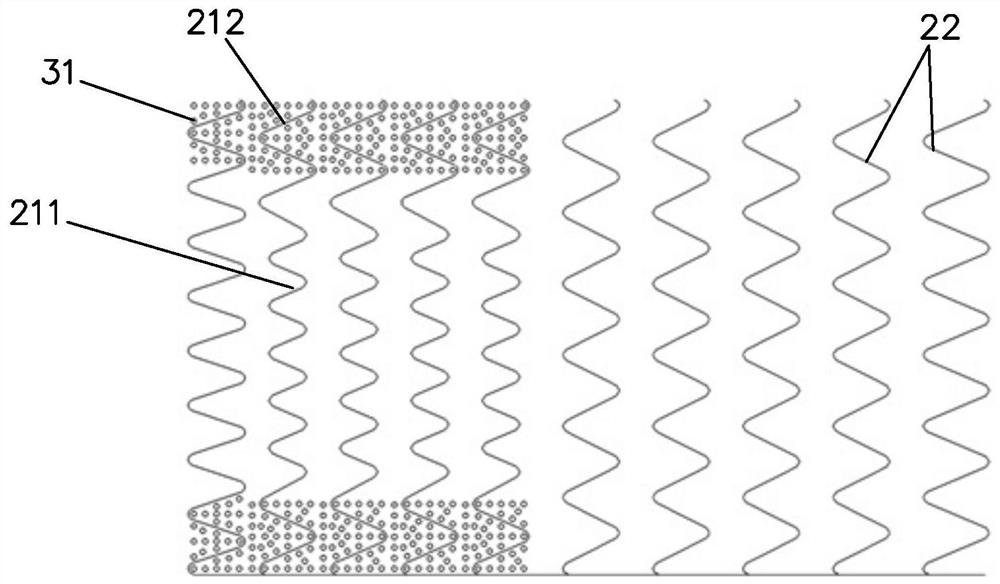

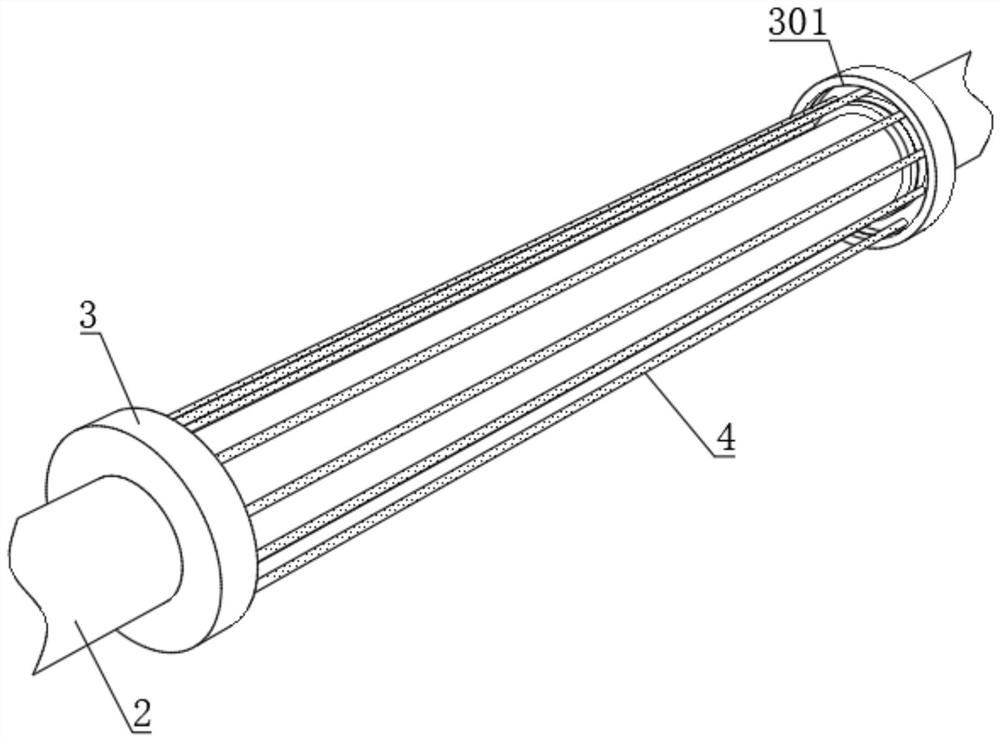

Novel covered intravascular stent used for aortic arch

PendingCN112022430AGood anchoring effectImprove safety and reliabilityStentsBlood vesselsThird aortic archBiomedical engineering

The invention discloses a novel covered intravascular stent used for the aortic arch. The novel covered intravascular stent comprises a keel, a plurality of wave loops and a covering membrane, whereinthe plurality of wave loops are independently distributed along the length direction of the keel and are fixedly connected to the keel; the covering membrane covers the outer surfaces or the inner surfaces of the wave loops to form a pipe stent structure; and the front part of the covering membrane is provided with a plurality of through holes. The front part of the keel is provided with high andlow wave loops, and therefore, the flexibility of the front part of the pipe stent is improved; and then, after the stent is released in the aortic arch, the stent structure parts of the high and lowwave loops on the aortic arch can be perfectly fit to the aortic wall, so that a bend on the aortic arch can be effectively fit, in addition, through round hole cutting seams on the covering membrane, blood flow velocity and blood pressure in an aortic aneurysm can be lowered so as to form a thrombus creation environment, in addition, the blood flow volume of upper three branches can be guaranteed, and treatment safety and reliability can be improved.

Owner:GUANGDONG UNIV OF TECH

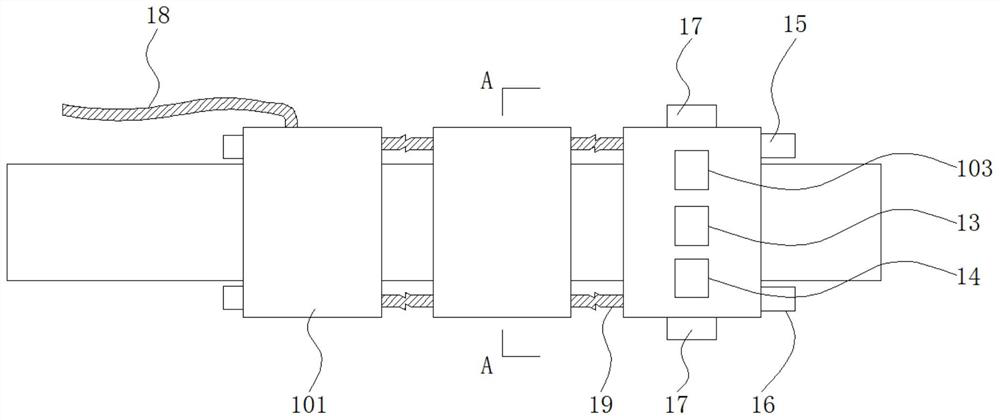

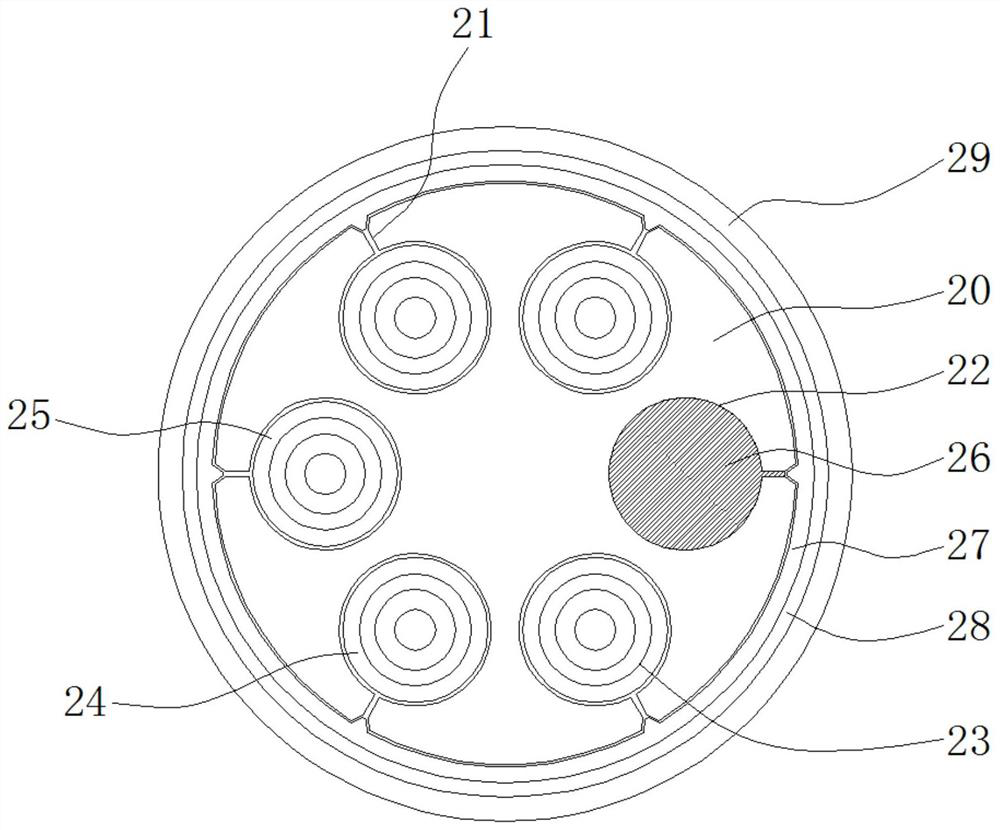

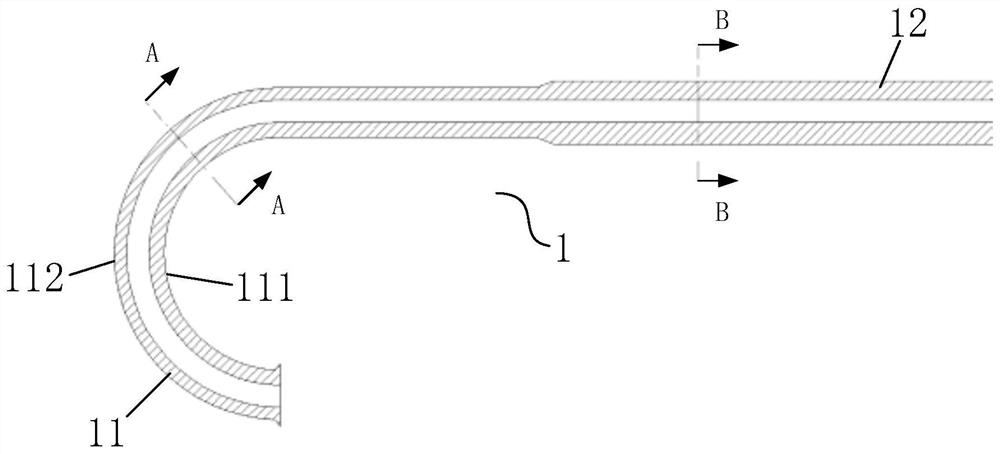

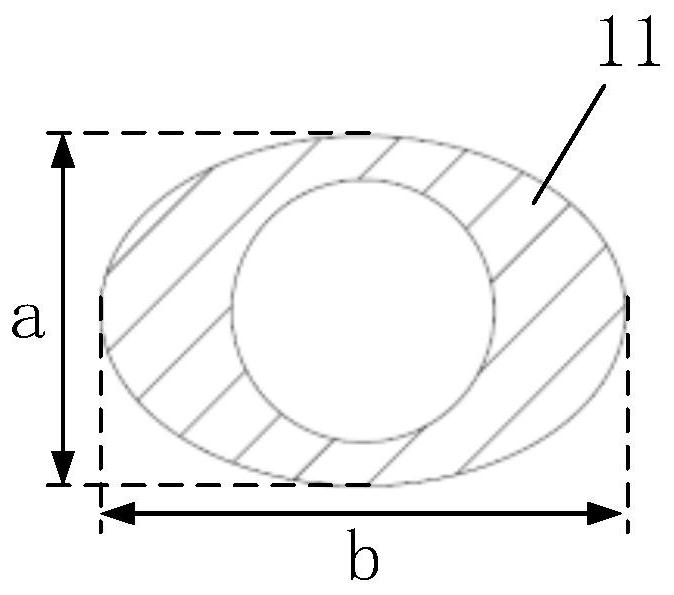

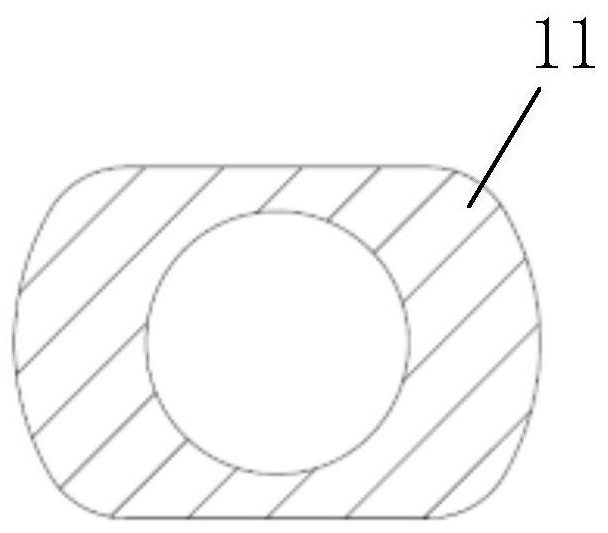

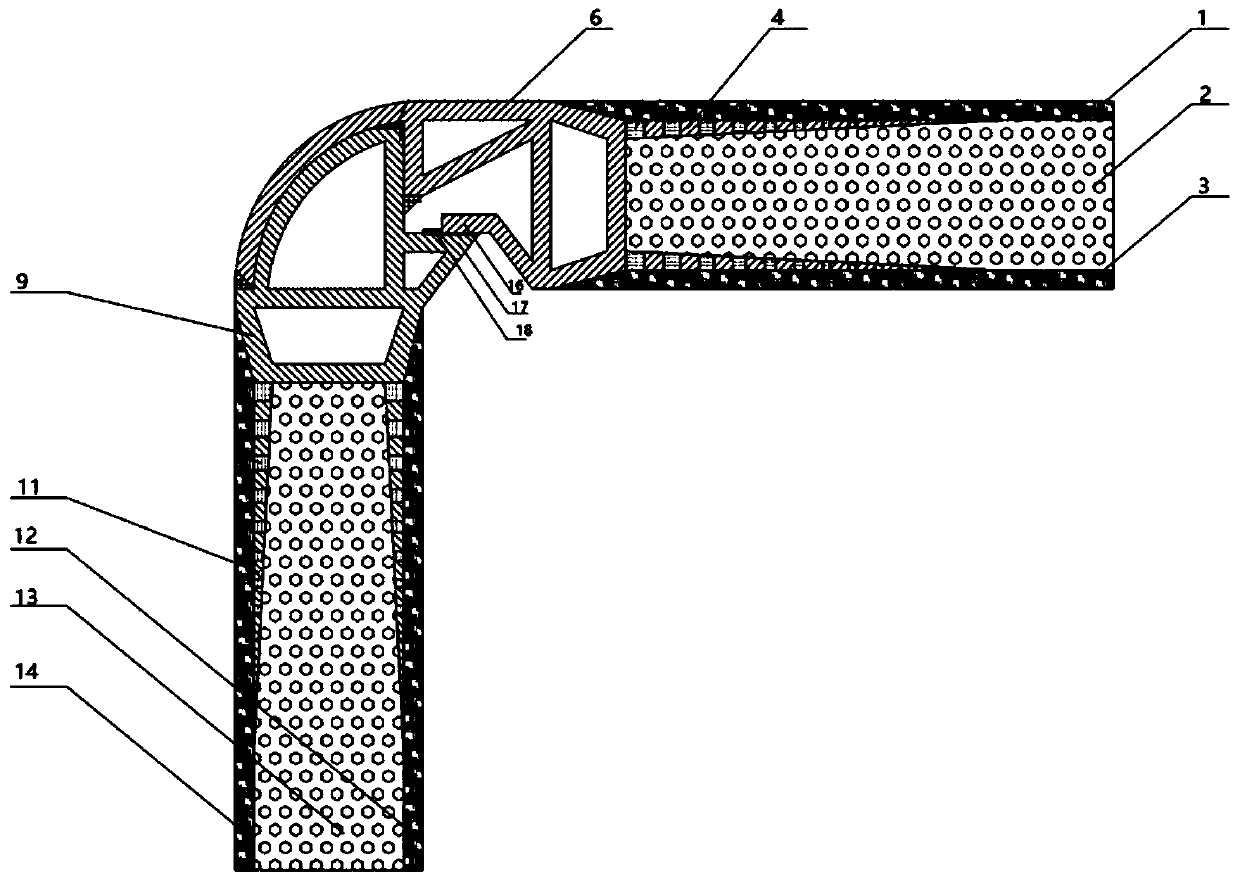

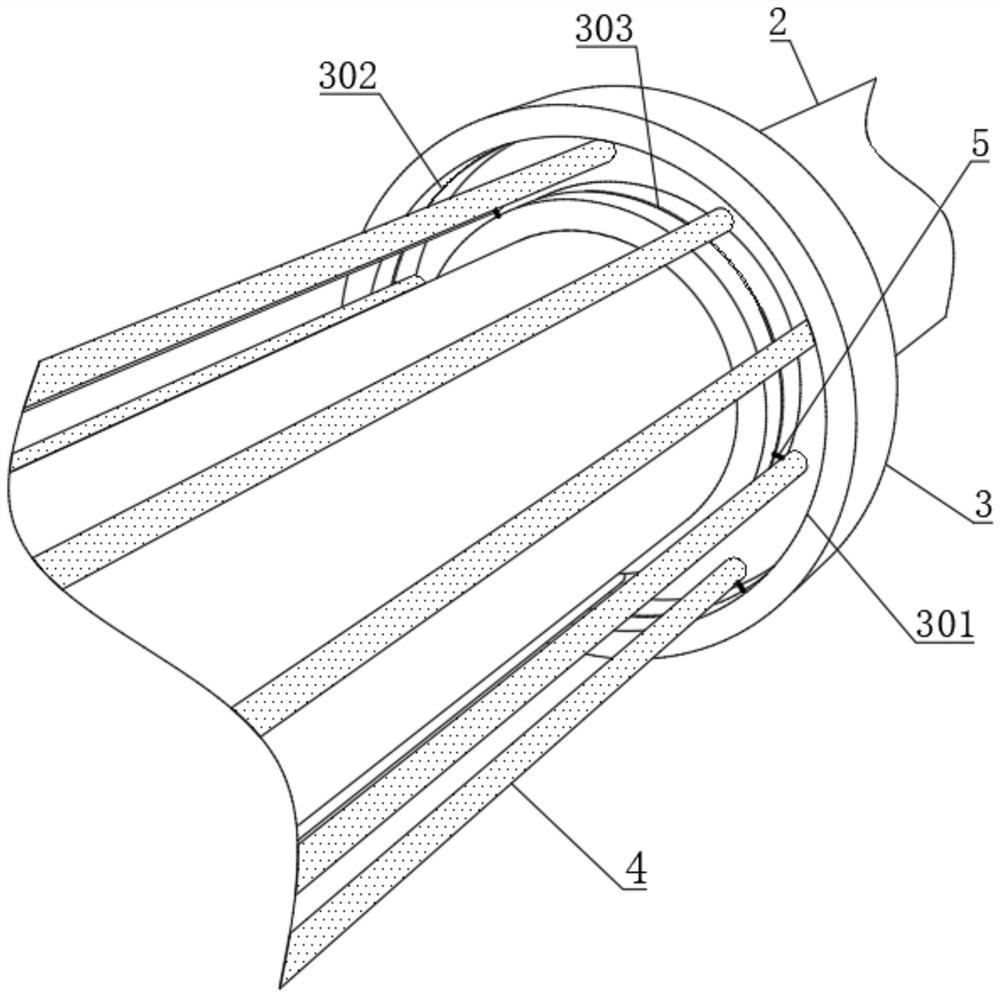

Catheter conveying system

ActiveCN112914793AReduce wall thicknessIncrease wall thicknessHeart valvesCatheterMechanical engineering

The invention relates to a catheter conveying system. The catheter conveying system comprises an inner tube, wherein the inner tube comprises a straight section part and a turning part, one end of the turning part is fixedly connected with one end of the straight section part, the cross section of the turning part is in the shape that the wall thickness in the bending direction is smaller than the wall thickness perpendicular to the bending direction, and the cross section of the turning part can be in an oval shape or an oval-like shape. According to the application, by changing the shape of the turning part, the wall thickness of the turning part in the bending direction is reduced, so that the turning part has relatively low bending resistance, and the turning part can conveniently pass through the main bend of a blood vessel; and in addition, the wall thickness of the turning part in the direction perpendicular to the bending direction is relatively large, and compared with the straight section part, the sectional area reduction amount is smaller or not reduced, so that it can be guaranteed that the whole inner tube still has higher tensile failure resistance, and the bend passing capacity can be effectively improved.

Owner:KINGSTRONBIOCHANGSHU CO LTD

Touch substrate, manufacturing method thereof, and touch screen using the touch substrate

ActiveCN104020890BAvoid scratchesNot easy to damageInput/output processes for data processingCross-linkResin matrix

A touch control substrate, comprising: a transparent substrate; a conductive layer arranged on one side of the transparent substrate, the conductive layer includes a cured transparent photosensitive resin matrix and conductive nanowires embedded in the cured transparent photosensitive resin matrix, and the conductive nanowires are formed by cross connection Conductive grid; the conductive layer is patterned to form a plurality of touch electrodes. The above-mentioned touch substrate has good electrical conductivity. The invention also provides a manufacturing method of the touch substrate and a touch screen using the touch substrate.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

A connection structure of L-shaped composite sandwich panels with metal flexible joints

ActiveCN107901518BReduce frictionReduce displacementLayered productsFastening meansLarge sizeTail structure

The invention provides an L-shaped composite material laminboard connecting structure with a flexible metal connector. The structure comprises foamed laminated composite material plates and metal connecting parts, wherein pre-buried metal plate parts of the metal connecting parts are embedded between laminated foams and composite material plates; composite material laminboards and the metal connecting parts are cured together by using an integral molding technique. Due to adoption of adjustable flexible connectors, the assembling stress is effectively reduced, and flexible assembling is achieved; the pre-buried metal plate parts are designed as a forked tail structure, so that the concentrated stress at the connecting parts of the metal plates and the composite material plates is effectively reduced; the connecting parts are of circular arc-shaped design, so that the bending strength is improved; due to a co-curing technique, composite material openings and the like are avoided, and the integrity of the composite material plates is ensured; a relatively large space is reserved in the metal connecting parts, so that convenience can be brought to pipeline laying and later maintenance. The structure is applicable to mechanical connection of composites material laminboards and other structures of large-size structures.

Owner:HARBIN ENG UNIV

An adaptive multi-directional anti-bending cable

ActiveCN112927843BReduces bending damageImprove bending abilityFlexible cablesFlexible conductorsClassical mechanicsEngineering

The invention discloses an adaptive multi-directional bending-resistant cable, which belongs to the field of cables. The invention arranges a bending-resistant screw sleeve between the sheath and the cable core. When the invention is subjected to bending force in any direction, it will cause When the sheath and the cable core are bent, the originally uniformly dispersed elastic rods will gradually move to the vicinity of the bending point due to their own length limitations, and gather at the bending point to jointly provide the cable core with resistance to bending. force, so that the present invention has greater bending resistance, and when the external bending force disappears, a plurality of bending elastic rods will automatically disperse, providing the sheath and cable core with resilience to restore the linear shape, making the present invention The invention restores the straight state faster and more effectively, reducing the bending damage of the cable core. In addition, when the external bending force reaches a higher strength, the bending-resistant elastic rod automatically releases gas outwards, reducing its own bending resistance. It has a certain degree of flexibility, so that the present invention can adapt to larger external force.

Owner:沧州会友线缆股份有限公司

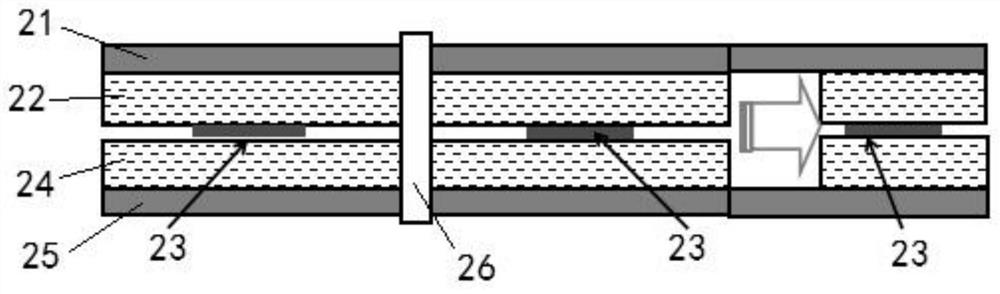

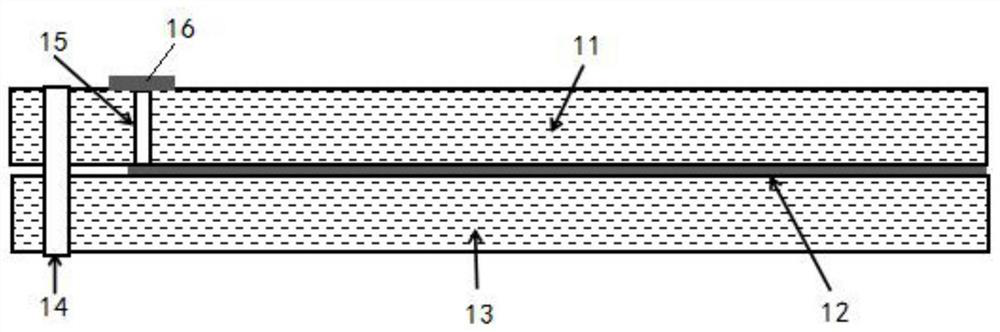

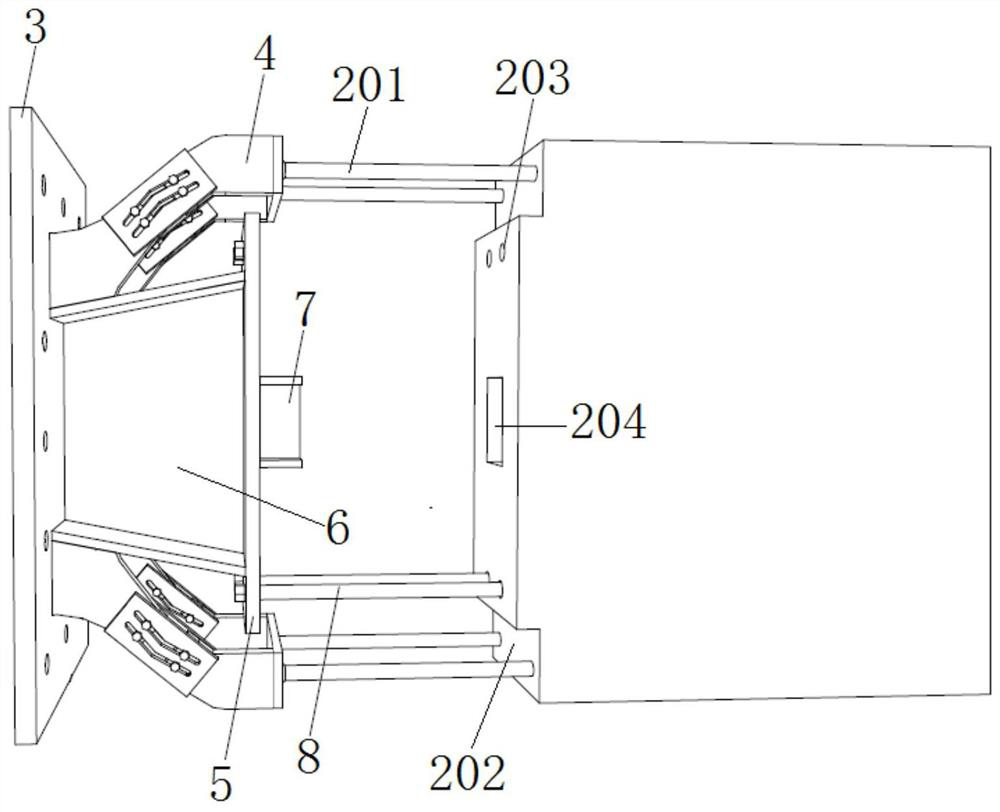

Flexible light and thin multichannel transmission line

The invention provides a flexible light and thin multi-channel transmission line. The transmission line comprises a plurality of layers of transmission line ports, a middle conduction line and a plurality of layers of transmission line ports; a middle conducting layer comprises a first metal layer, a first dielectric layer, a middle wiring layer, a second dielectric layer and a second metal layer which are arranged in sequence, and a first metalized through hole penetrating through each layer; the multi-layer transmission line port comprises a third dielectric layer connected with the first dielectric layer, a port wiring layer connected with the middle wiring layer, a fourth dielectric layer connected with the second dielectric layer, a metalized grounding hole penetrating through each layer, a first metalized connecting hole which penetrates through the third dielectric layer and is connected with the port wiring layer, and a bonding pad which is connected with the first metalized connecting hole. Compared with a traditional transmission line, the transmission line has the advantages of being easy to integrate, suitable for multi-channel transmission, low in insertion loss, low in reflection loss, low in profile, bending resistance, low in hygroscopicity and the like. The method is suitable for big data communication requirements of MIMO technology and informatization communication, and has a wide application prospect.

Owner:江苏嘉华通讯科技有限公司

A self-resetting beam-column energy-dissipating connector and its construction method

ActiveCN113529945BImprove shear resistanceGood self-resetting performanceProtective buildings/sheltersShock proofingClassical mechanicsStructural engineering

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Tensile high-frequency multi-core cable and preparation method thereof

PendingCN111462936AHigh tensile strengthGood flexibilityCable conductor constructionCable insulation constructionTinningElectrical conductor

The invention discloses a tensile high-frequency multi-core cable and a preparation method thereof. The cable comprises a cable core formed by twisting a plurality of coaxial cable cores, a fluororesin wrapping tape layer, a copper-plastic composite tape wrapping shielding layer and an outer sheath, wherein the coaxial cable core comprises an inner conductor and a cable core body formed by concentrically twisting a plurality of PFA resin filling wires, an inner insulating layer, a metal winding shielding layer, a metal weaving shielding layer and an outer insulating layer sequentially coat theouter portion of the wire core body, the inner conductor is formed by twisting plural strands of wires, the stranded wire is formed by crossly and spirally twisting a plurality of tinned copper monofilaments with a diameter of 0.02-0.03 mm, the metal winding shielding layer is formed by spirally winding copper alloy wires in one direction, the metal weaving shielding layer is formed by spirally winding and weaving double-layer tinned copper wires in opposite directions, and the double-layer tinned copper wires are coated with lubricating oil. The cable has good tensile strength, flexibility,bending resistance and torsion resistance, and is not easy to break, small in high-frequency signal attenuation and durable in use.

Owner:浙江物产中大线缆有限公司 +1

Compressor oil pump system

ActiveCN102364101BAvoid blockageGuaranteed unobstructedPositive displacement pump componentsPositive-displacement liquid enginesStomaMechanical engineering

The invention relates to an oil pumping system of a compressor. The oil pumping system mainly comprises a crankshaft arranged in a cylinder seat and a rotor, and an oil suction pipe connected with the lower end of the crankshaft, wherein the upper end of the crankshaft is a solid rod body and the lower end of the crankshaft is a hollow oil guide pipe; a spirally extending oil groove is formed on the outer surface of the solid rod body; an oil hole by which the oil groove is communicated with the oil guide pipe is formed at the lower end, connected with the oil guide pipe, of the oil groove; the oil suction pipe is a cylindrical pipe with a hollow inner part, and openings are formed at the upper end and the lower end of the cylindrical pipe; at least one air hole is formed in the oil suction pipe; the surface or the curved surface where the air hole is formed is inwards contracted relative to the cylindrical surface of the oil suction pipe; and during assembly, the air hole is positioned below the lower end face of the rotor and above the oil level. By the structure, the problem of unsmoothness, caused by a small gap between the end face of an axial hole of the cylinder seat and a counter bore of the rotor, of an air channel can be solved completely; furthermore, as the air channel does not extend towards the upper end of the crankshaft and the upper end of the crankshaft is the solid rod body, the anti-bending capacity of the crankshaft when the diameter of the crankshaft is reduced and the smoothness of the air channel can be guaranteed.

Owner:黄石东贝压缩机有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com