Tensile high-frequency multi-core cable and preparation method thereof

A multi-core cable, high-frequency technology, applied in communication cables, insulated cables, cable conductor structures, etc., can solve problems such as poor high-frequency signal transmission characteristics, wire core or shielding disconnection, and unstable shielding effect. The effect of improving noise shielding properties, increasing tensile strength, and increasing tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

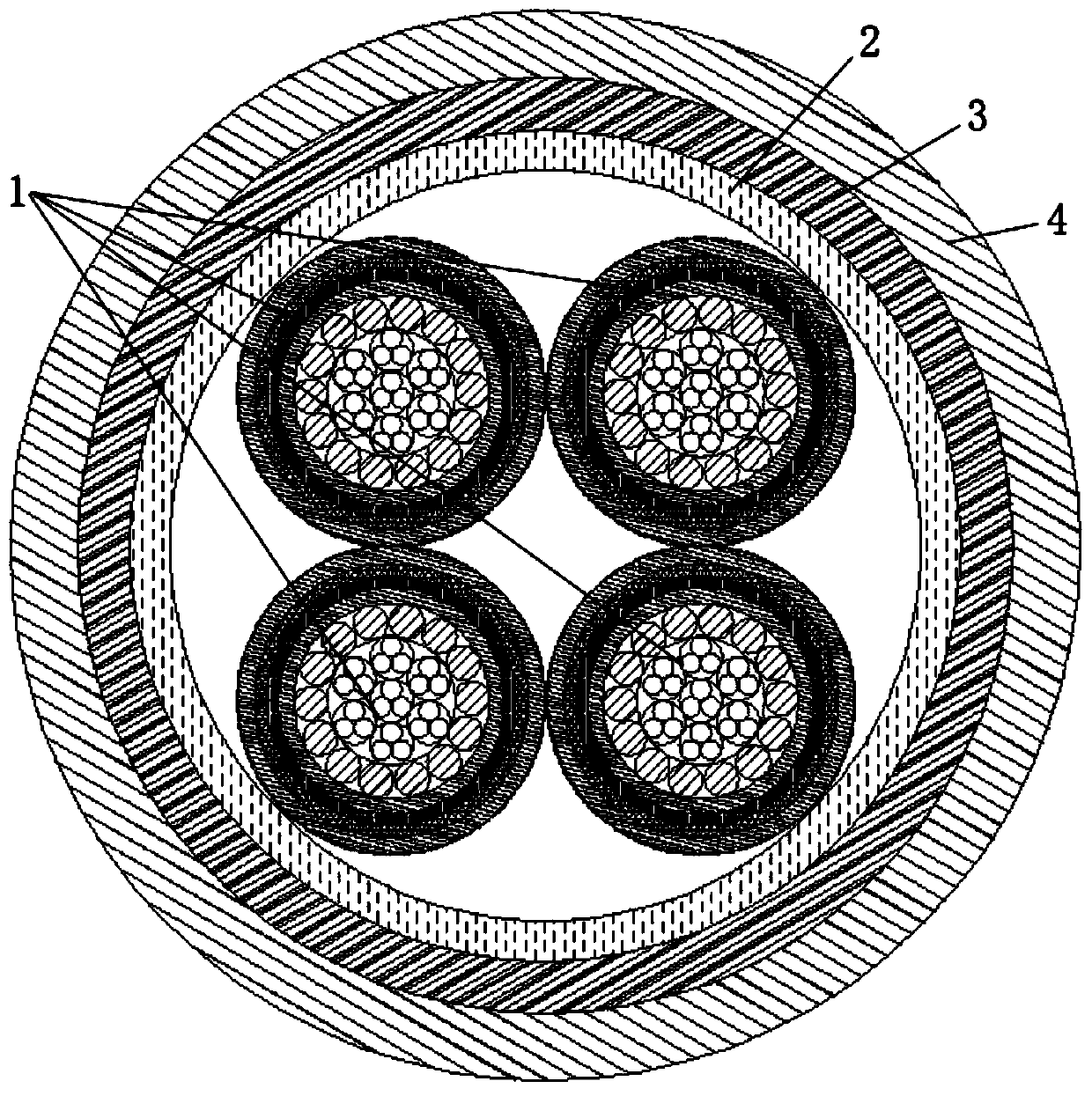

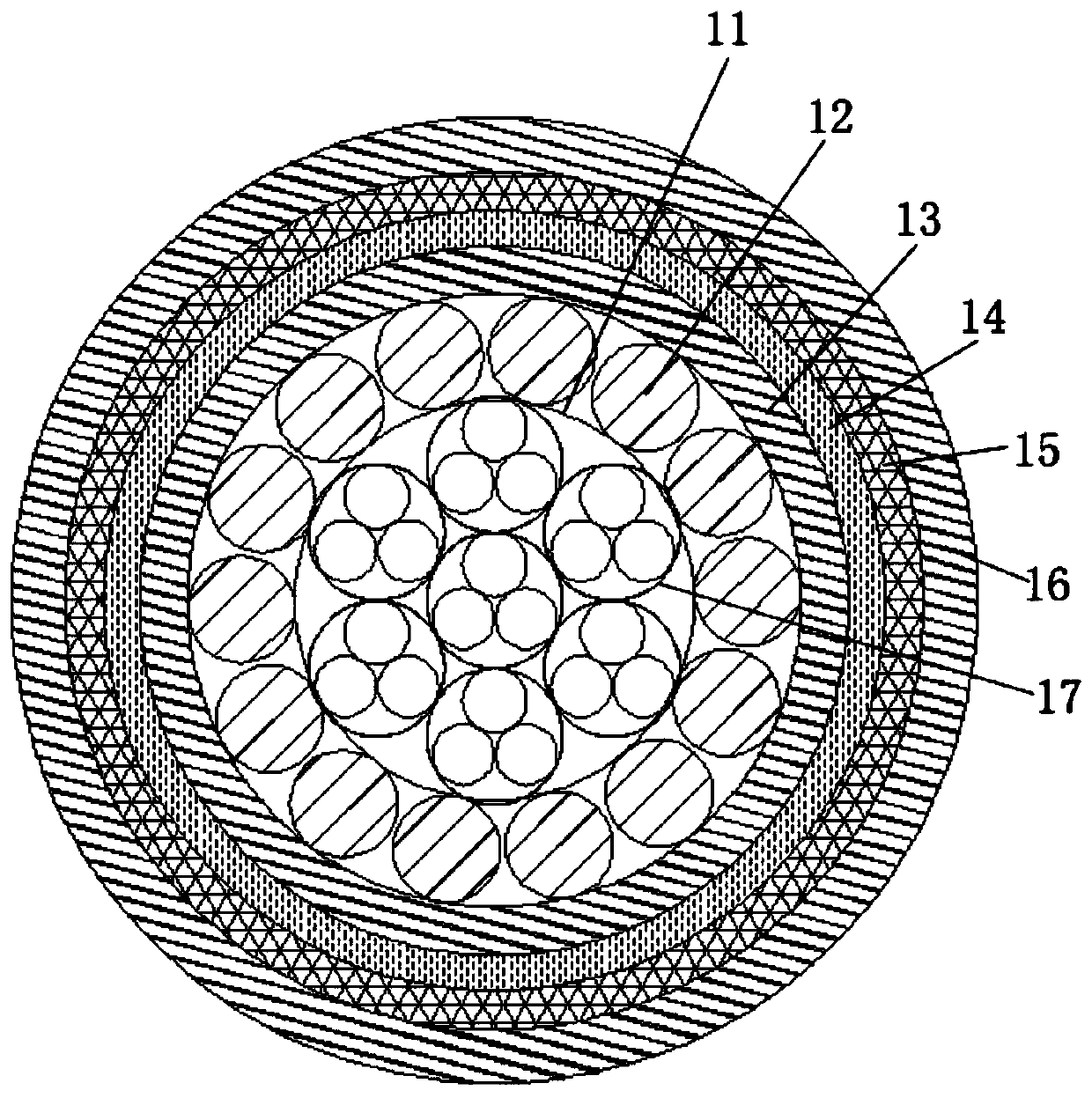

[0031] Such as figure 1 As shown, the stretch-resistant high-frequency multi-core cable of the embodiment of the present invention includes several coaxial cores 1 twisted to form a cable core, such as figure 2 As shown, the coaxial core 1 includes a core body formed by concentrically twisting an inner conductor 11 and a plurality of PFA resin filled wires 12, and the inner conductor 11 is formed by multiple strands 17. In this embodiment, It is formed by twisting seven strands, preferably, the outer diameter of the strands is 0.04mm to 0.15mm. The strand 17 is composed of a number of tinned copper monofilaments with a diameter of 0.02 mm to 0.03 mm, which are cross-helically twisted. Preferably, the strands are composed of three to five tin-plated copper monofilaments, which are cross-helically t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com