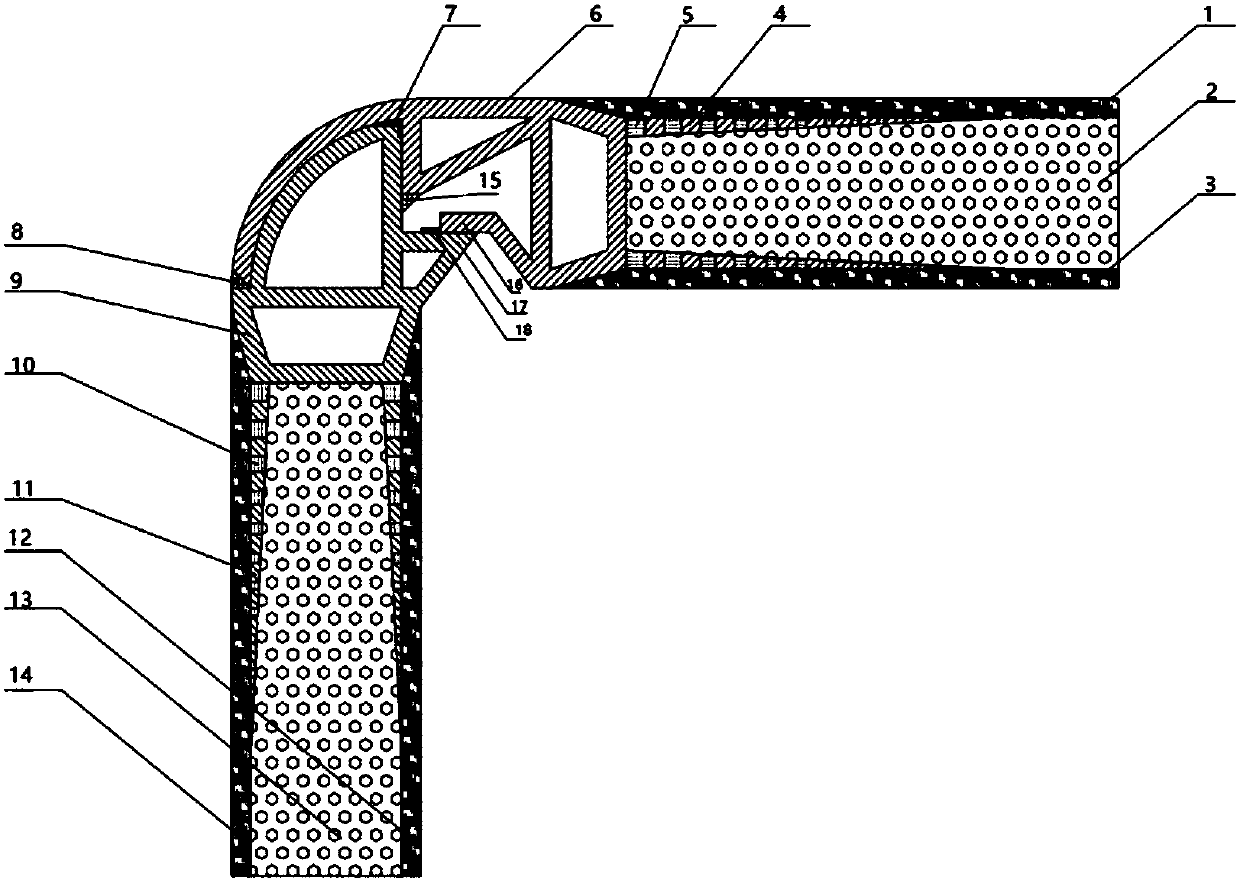

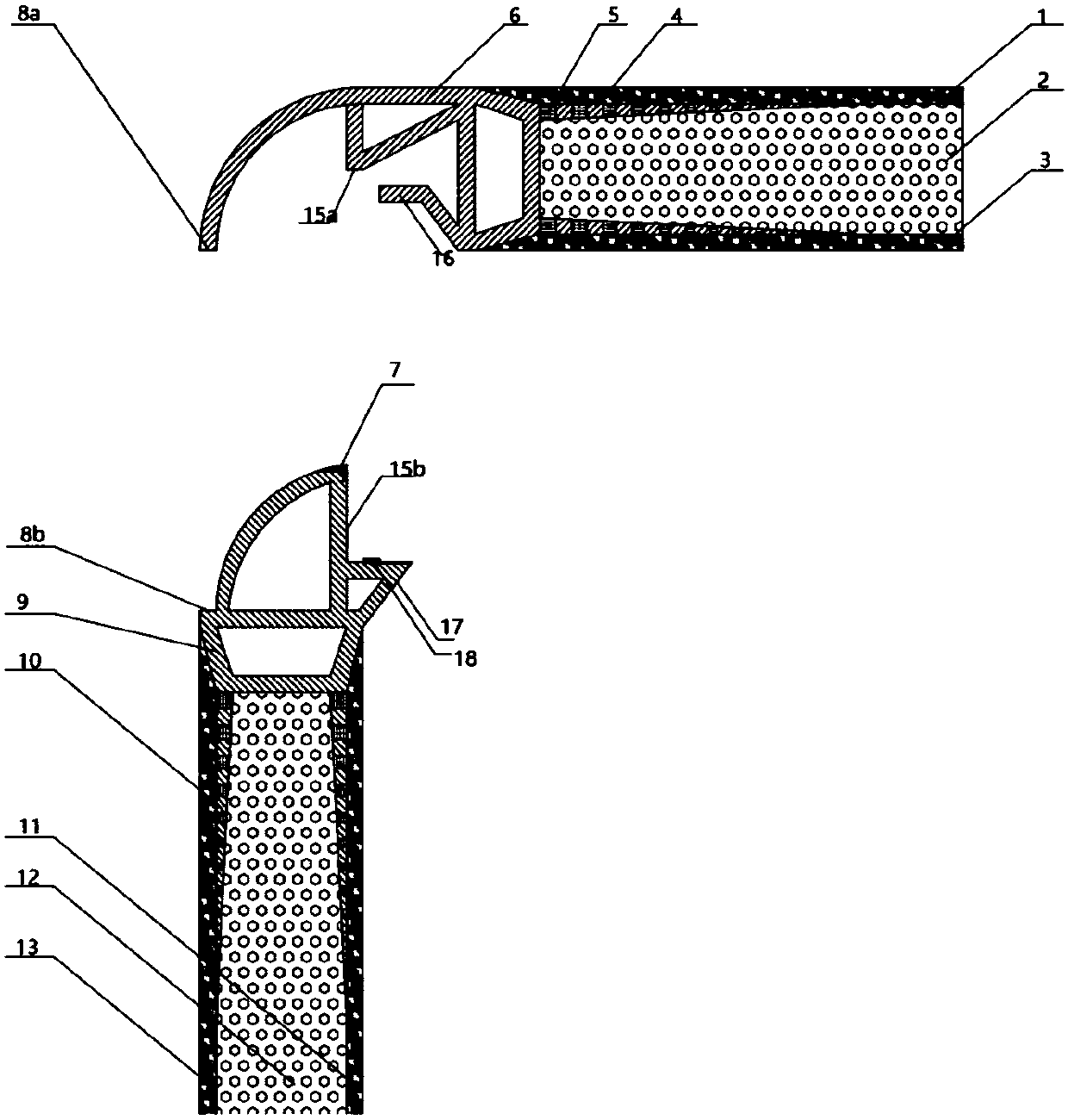

L-shaped composite material laminboard connecting structure with flexible metal connector

A technology of flexible joints and composite materials, applied in the direction of connecting components, layered products, mechanical equipment, etc., can solve problems such as damage to the integrity of composite material plates, stress concentration, etc., to facilitate laying and subsequent maintenance, reduce stress concentration, and alleviate The effect of structural quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0017] The pre-embedded metal plate of the metal connector is partially embedded between the sandwich foam and the composite material plate; using integrated molding technology, the composite material sandwich panel and the metal connector are solidified together; the structures of the two metal connectors are different; Lap two metal connectors together, then use glue and welding to reinforce. The embedded metal plate part of the metal connector is embedded between the sandwich foam and the composite material plate, using the co-cured wedge technology. The pre-embedded metal plate part of the metal connector has designed perforations on the surface of the metal plate, so that the composite material plate forms a nail-shaped protrusion at the perforation to increase the connection strength. The surface of the metal connector in contact with the composite material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com