Stamping die used for sideward push

A technology of stamping dies and templates, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of large bending resistance, high mold cost, scratches on the surface of sheet metal, etc., to reduce bending resistance, bend Stable and reliable, simple structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

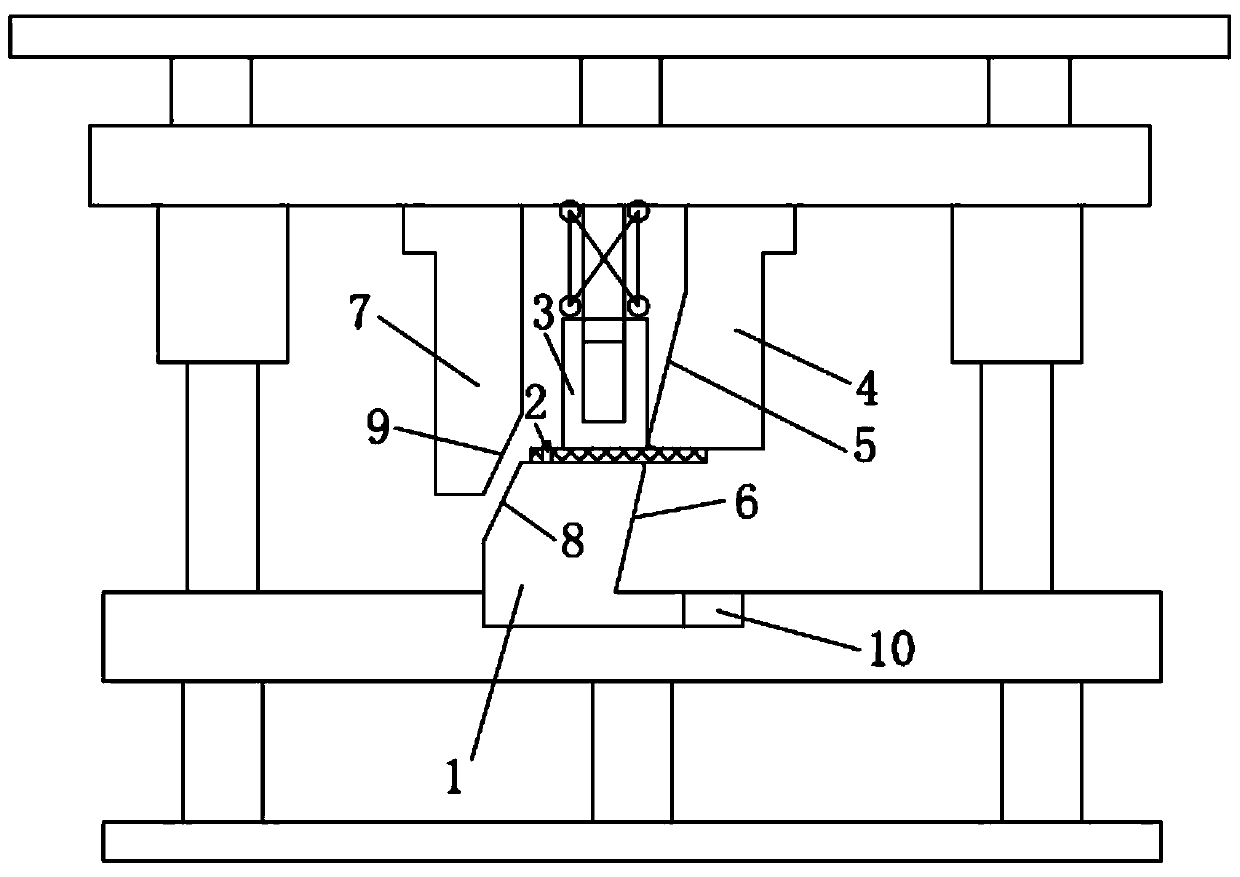

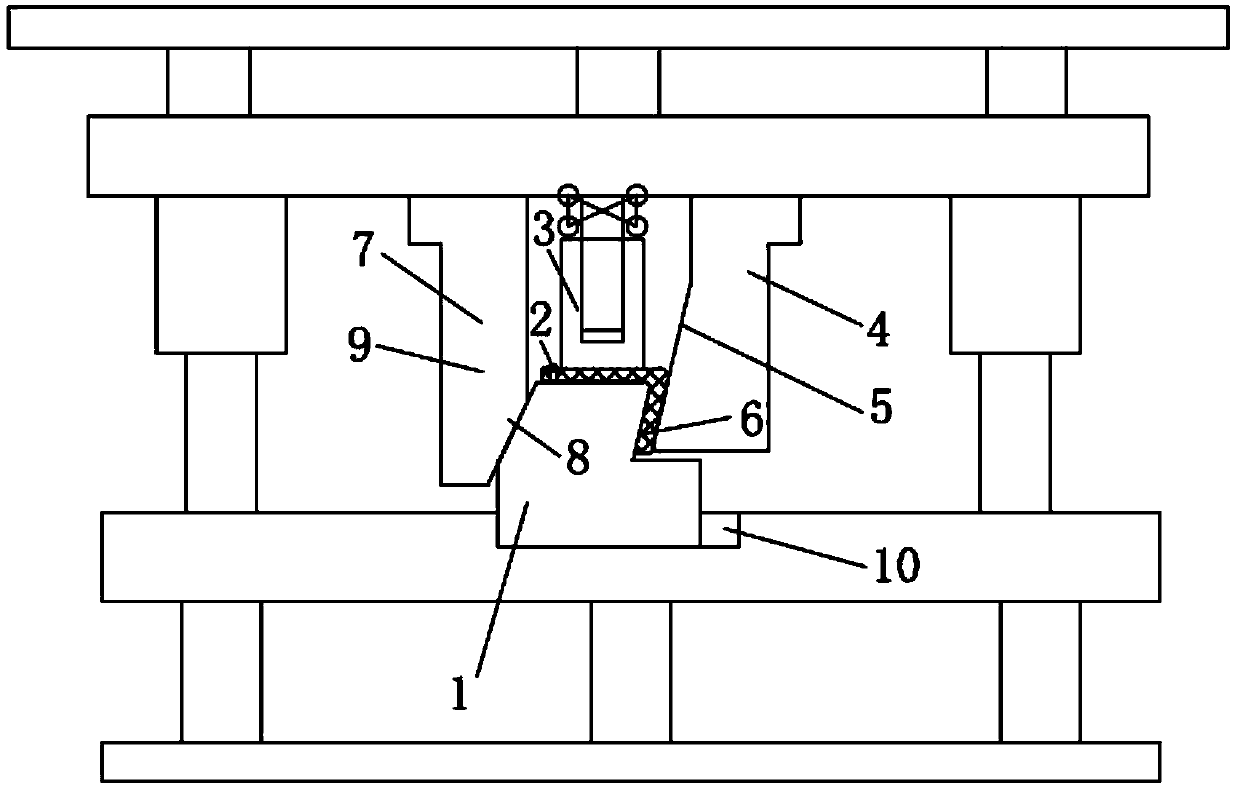

[0016] Attached below figure 1 And attached figure 2 The technical solutions of the present invention are further described through specific implementation methods.

[0017] A stamping die for side pushing, comprising an upper die and a lower die, an insert 1 is slidably fitted on the lower die, the upper surface of the insert 1 is provided with a positioning pin 2 for sheet metal positioning, the The upper mold above the inlet 1 is provided with an elastic pressure block 3 for pressing the sheet material. One side of the inlet 1 is provided with a first inclined wall 6. When the inlet is in the initial position, the first The upper end of an inclined wall 6 is aligned up and down with one side of the elastic briquetting block 3, and the upper die on one side of the elastic briquetting block 3 is provided with a punch 4 for sheet metal bending. One side is provided with a second inclined wall 5, the lower end of the second inclined wall 5 is in clearance fit with one side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com