Compressor oil pump system

A compressor pump and oil system technology, which is applied to pump components, mechanical equipment, variable capacity pump components, etc., can solve the problem of small passage area, affecting the movement range lubrication, poor oiling speed and poor pumping ability of pump oil, etc. problem, to achieve the effect of ensuring gas passage and bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

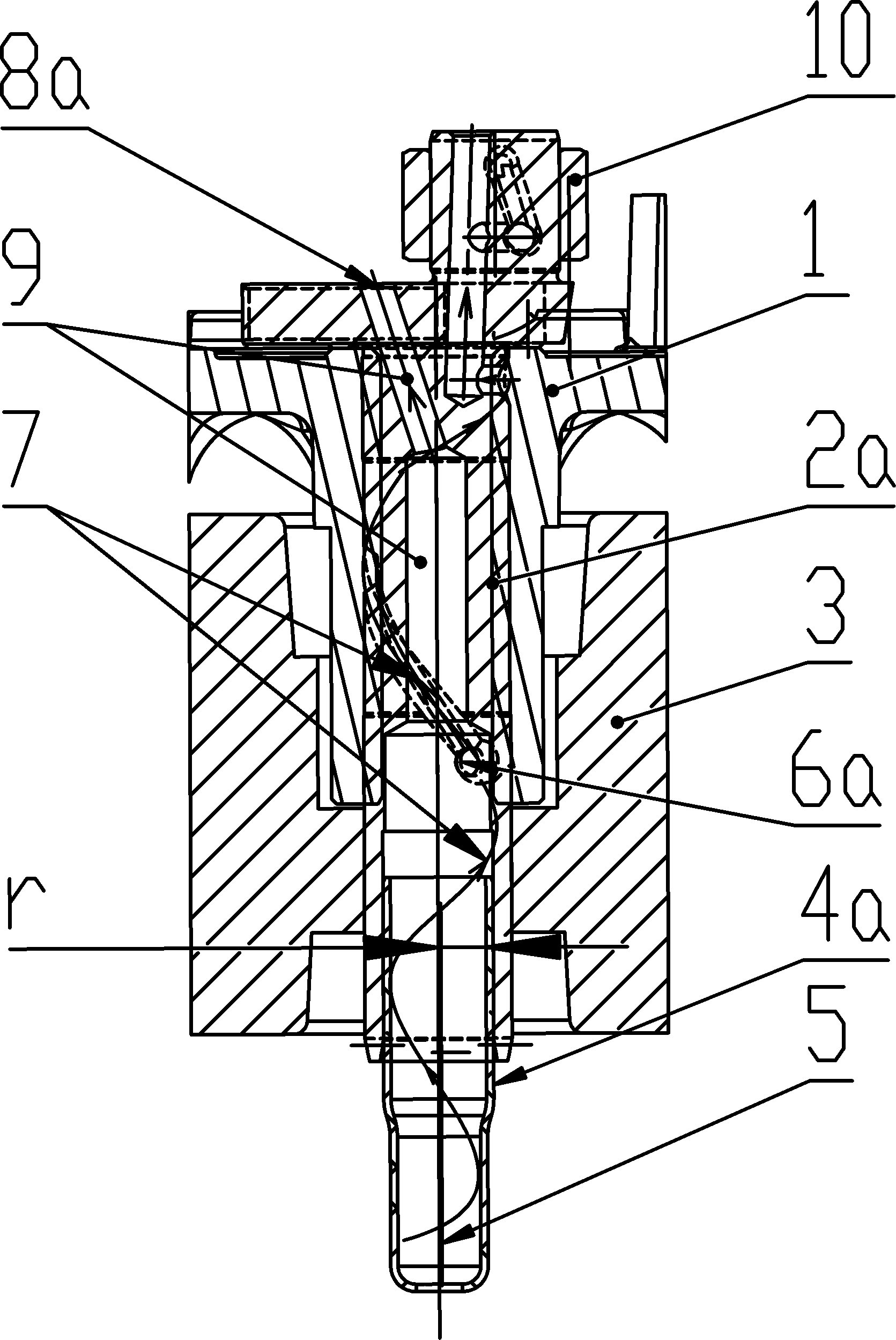

[0029] Such as image 3 , 6 , 7, the present embodiment is a compressor oil pump system with a reciprocating piston crankshaft-connecting rod mechanism, mainly including a crankshaft 2 and an oil suction pipe 4 built in the cylinder block 1 and rotor 3; the upper end of the crankshaft 2 is a solid The rod body part and the lower end are hollow oil guide pipes 13, and one (or multiple) helically extended oil grooves 7 are arranged on the outer surface of the solid rod body part. It communicates with the oil guide pipe, and the upper end of the oil groove 7 communicates with the crankshaft 2 top.

[0030] As a preferred solution, the oil-absorbing spacer 5 is embedded in the oil-suction pipe 4a with an interference fit, and there is a gap between the oil-suction spacer 5 and the air holes 8, so as not to block the passage of airflow.

[0031] The oil suction pipe 4 is a cylindrical tube with an inner hollow and open upper and lower ends, and is divided into an upper large-diam...

Embodiment 2

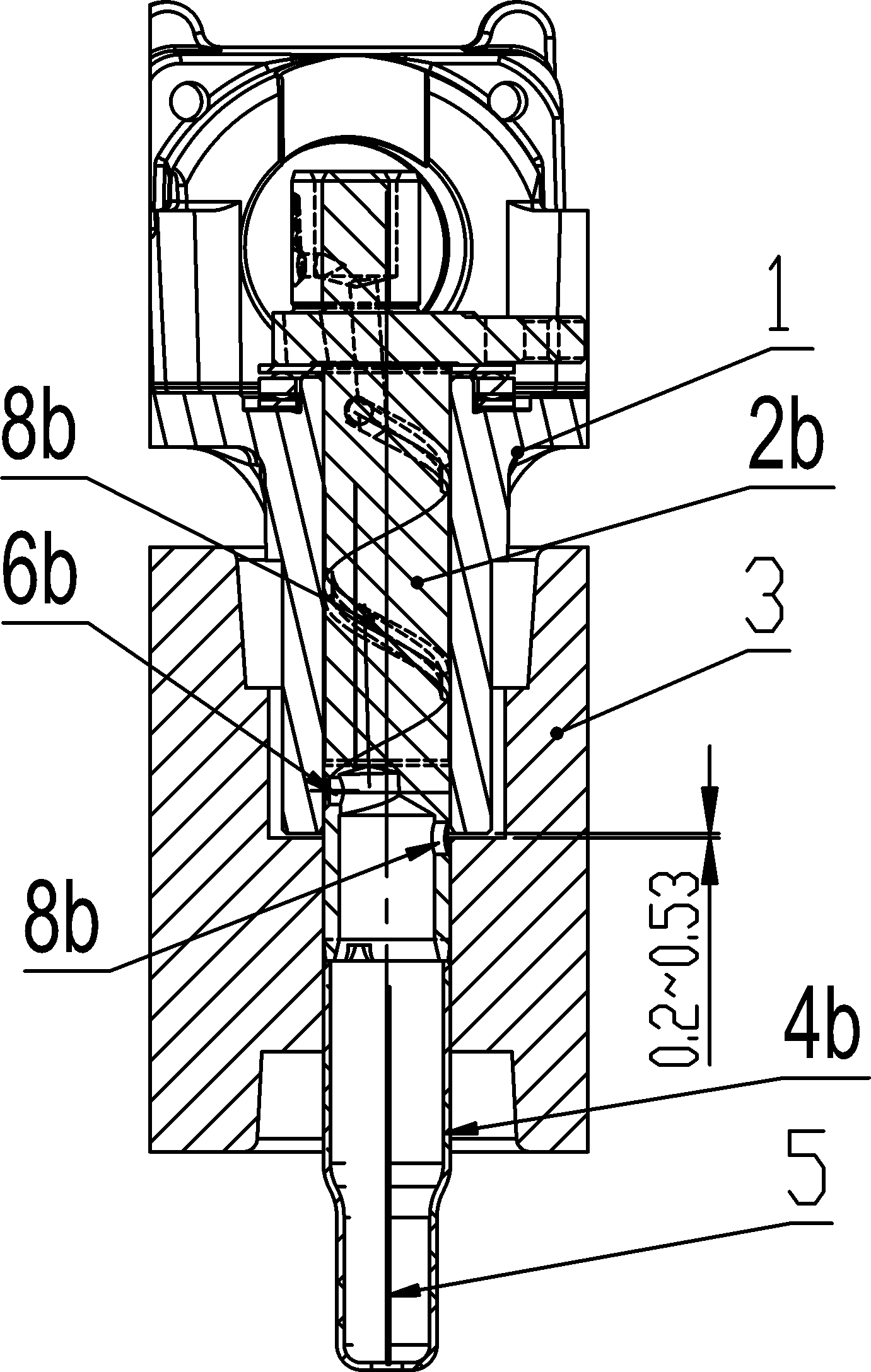

[0036] See attached Figure 4 , 6, 7. The main structure of the technical solution of embodiment two is basically the same as embodiment one; the difference is: the oil guide pipe 13 of the crankshaft 2 is in interference fit with the inner hole of the rotor 3; Hole interference fit; the oil guide pipe 13 and the large-diameter end 11 are butted in the inner hole of the rotor 3 to form an oil passage, such as Figure 4 shown.

[0037] The air hole 8 is still located below the lower end surface of the rotor 3 and above the oil surface during assembly, thereby ensuring that the air flow inside the oil pump system communicates with the external air pressure, thereby ensuring that the oil rises smoothly.

[0038] When working, the small-diameter end 12 of the lower part of the oil suction pipe 4 is partially submerged in the oil. When the crankshaft 2 and the oil suction pipe 4 rotate under the drive of the motor rotor 3, the centrifugal force pushes the oil to spiral on the inn...

Embodiment 3

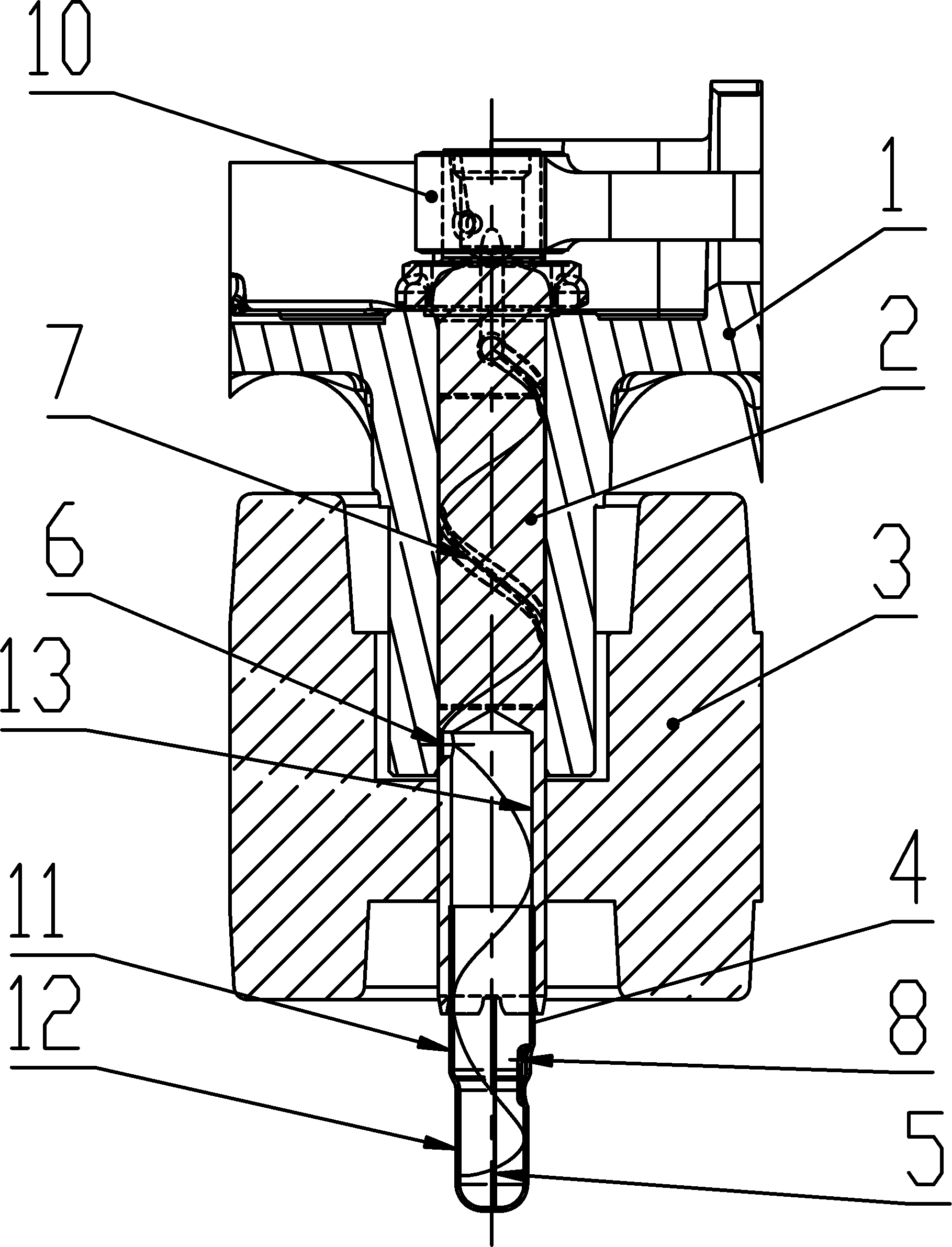

[0040] See attached Figure 5-7 The main structure of the technical solution of embodiment three is basically the same as that of embodiments one and two; the difference is that the large-diameter end 11 of the oil suction pipe 4 is sleeved on the outside of the lower end of the oil guide pipe 13 connected to the crankshaft 2, and at the joint Above, the oil guide pipe 13 of the crankshaft 2 has an interference fit with the inner hole of the rotor 3; the oil guide pipe 13 and the large-diameter end 11 are connected to each other to form an oil passage, such as Figure 5 shown.

[0041] The air hole 8 is still located below the lower end surface of the rotor 3 and above the oil surface during assembly, thereby ensuring that the air flow inside the oil pump system communicates with the external air pressure, thereby ensuring that the oil rises smoothly.

[0042] When working, the small-diameter end 12 of the lower part of the oil suction pipe 4 is partially submerged in the oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com