Windproof roller shutter door

A rolling shutter door, rolling shutter shaft technology, applied in the direction of windows/doors, door/window protection devices, shutters/movable grilles, etc., can solve the technical solution of the wind resistance design of fast rolling shutter doors is not ideal, increase the winding diameter and top occupation The problems of space and complex processing technology of door curtains can achieve the effect of improving dynamic response ability, wind resistance and operation reliability, reducing motor power and inverter configuration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

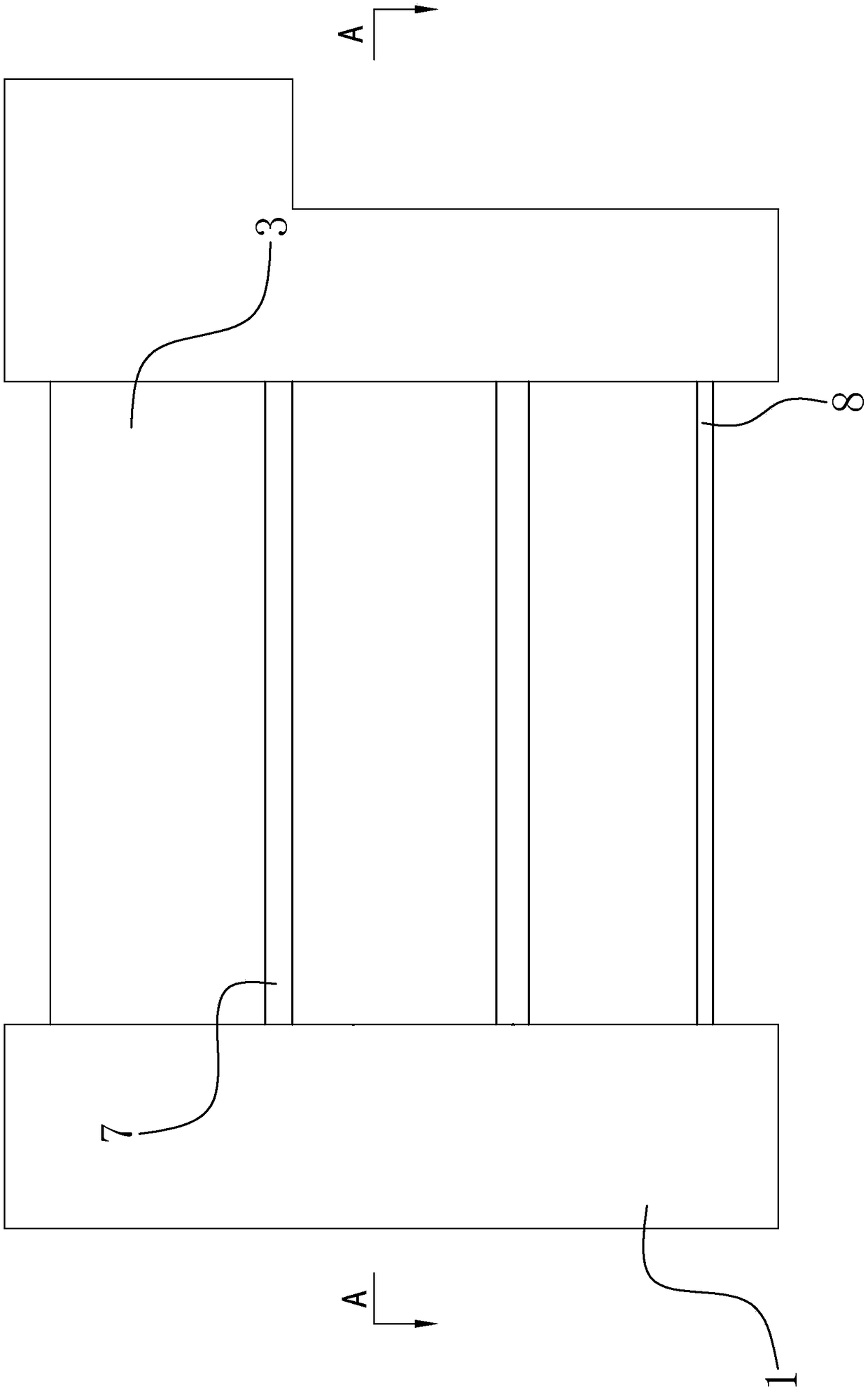

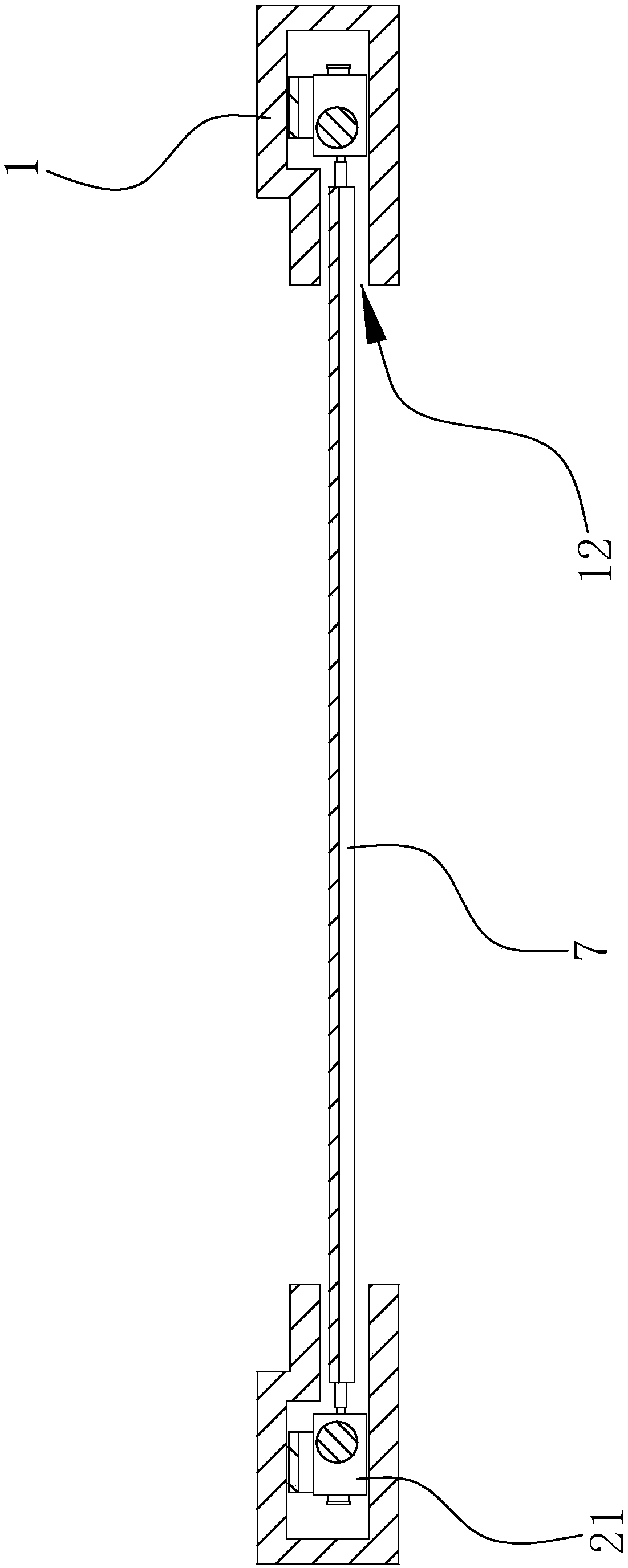

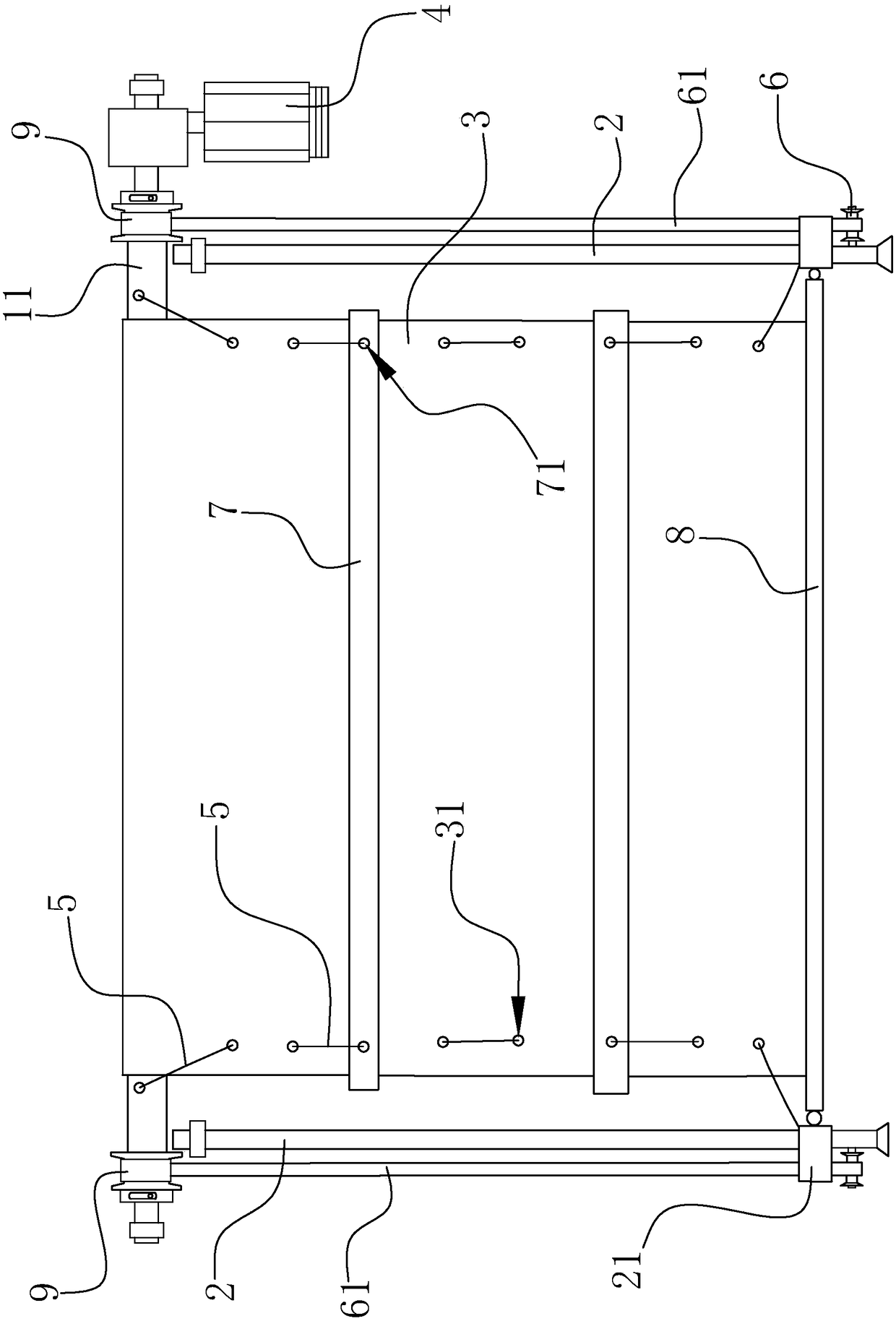

[0022] Such as Figure 1 to Figure 4 As shown, the wind-resistant rolling door of the present embodiment includes a rolling shaft 11 arranged on the top of the door frame, a soft door curtain 3 and a driving motor 4, and the driving motor 4 drives the rolling shaft 11 so that the door curtain 3 is wound. and unfolding, the two sides of the door curtain 3 below the roller shutter shaft 11 are respectively provided with columns 2, and the columns 2 are respectively provided with sliding sleeves 21 that can slide up and down relative to the column 2 through the transmission mechanism, and the sliding sleeves 21 are respectively connected with the door curtain. The corresponding bottoms of 3 are connected, and the transmission mechanism is linked with the driving motor 4. The left and right sides of the door curtain 3 are respectively provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com