Clamping jaw with correction function for yoke machining

A kind of jaw and function technology, applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of fine adjustment of movable jaws, insufficient lubrication, loosening, etc., to prevent clamping loosening, prolong service life, strengthen The effect of overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

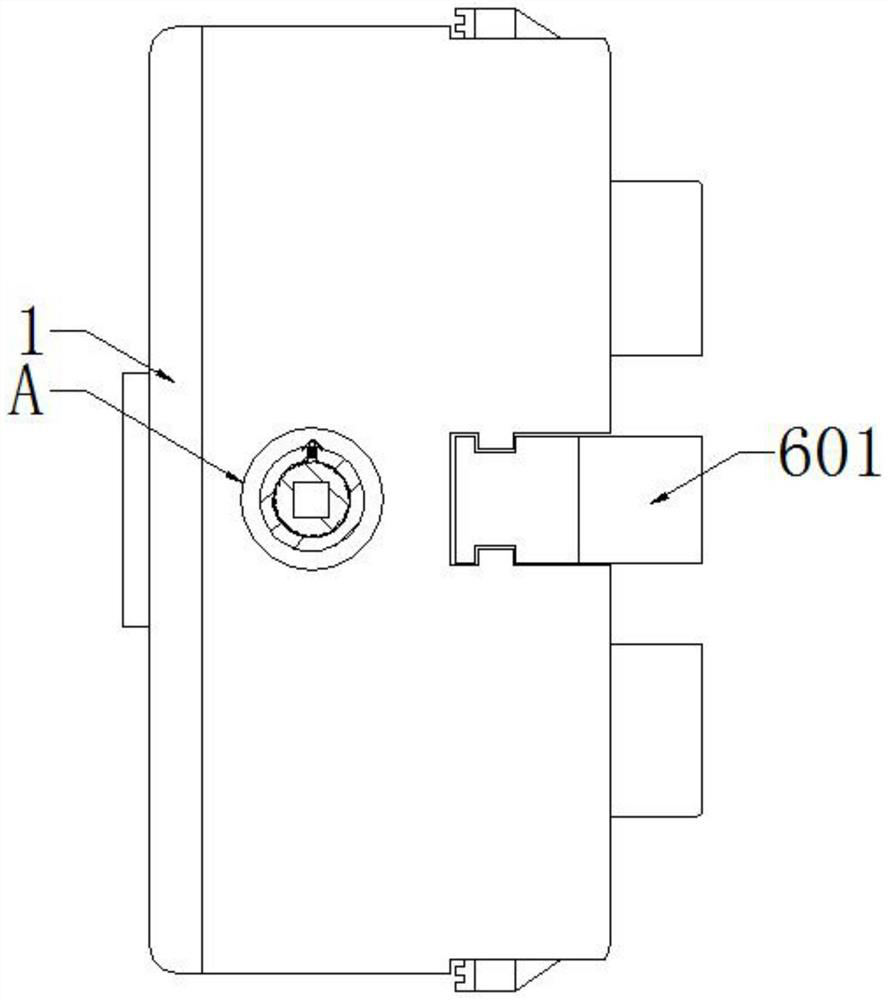

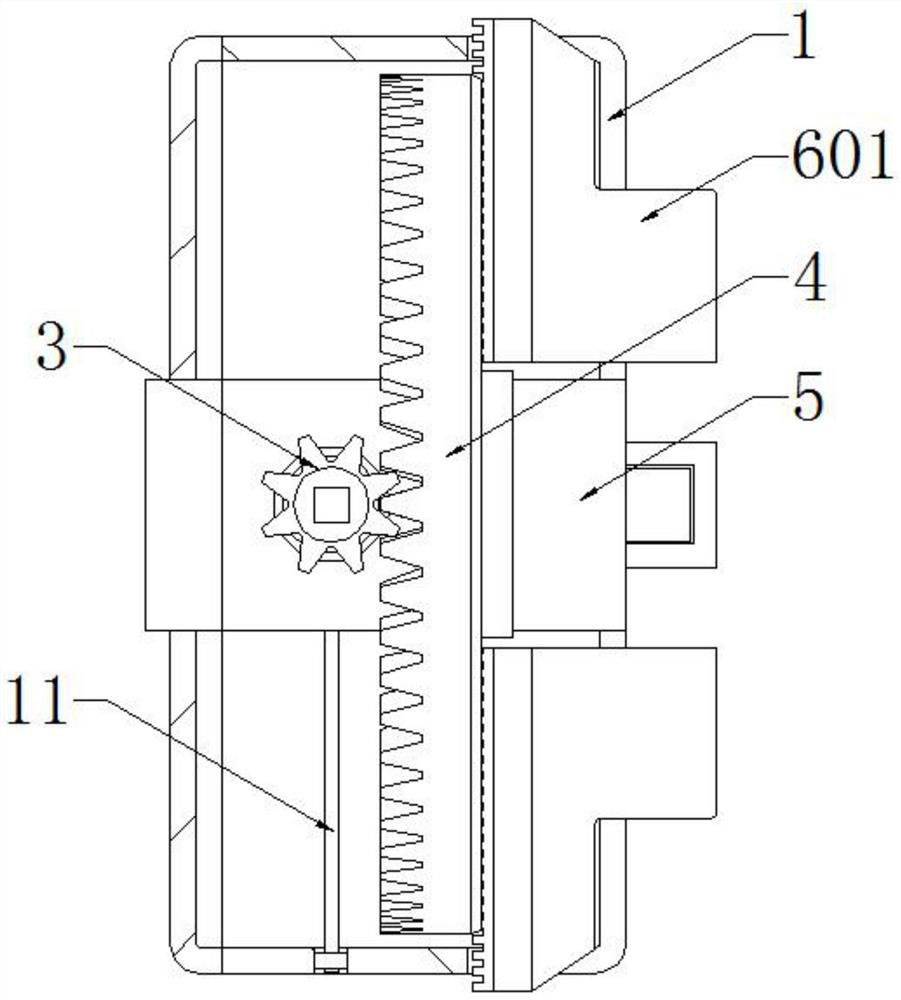

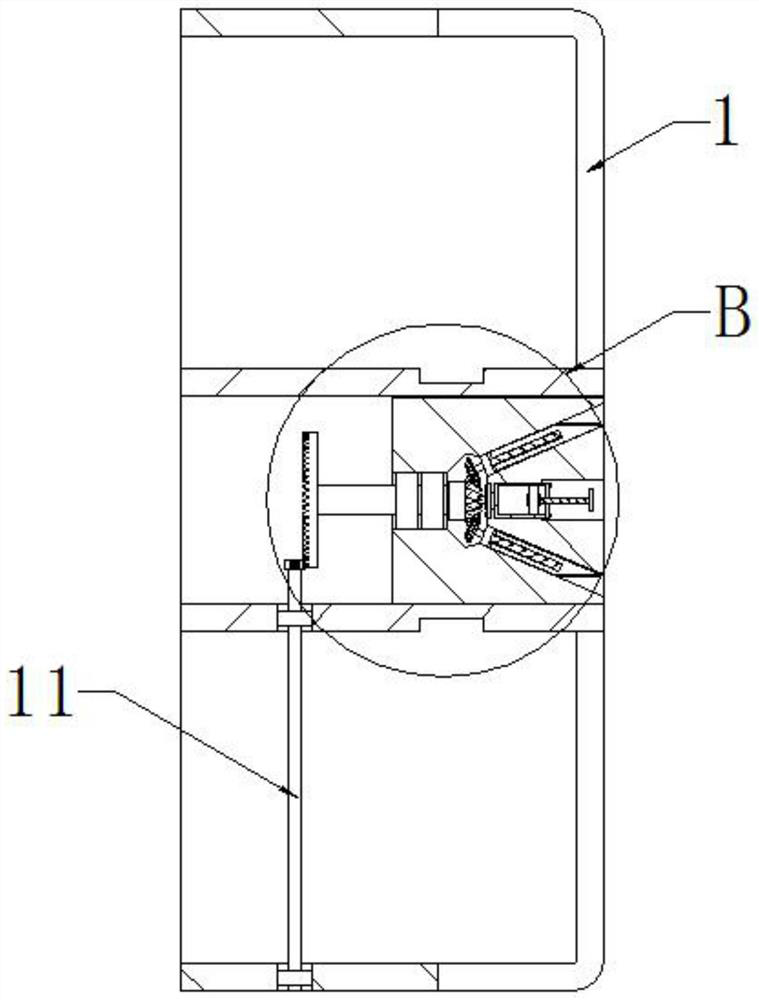

[0029] see figure 1 and Figure 4 , the present invention provides a technical solution: a clamping jaw with a correction function for yoke processing, comprising a chuck body 1 and a jaw assembly 6, the outer front end of the chuck body 1 is fixed with a self-locking assembly 2, and The self-locking assembly 2 includes a lock sleeve 201 , a rod sleeve 202 , a spring 203 and a boss pin 204 , the rod sleeve 202 is fixed inside the lock sleeve 201 , the spring 203 is arranged on the outside of the rod sleeve 202 , and the inner wall of the rod sleeve 202 is installed with The bump pin 204 and the rod sleeve 202 are elastically connected with the bump pin 204 through the spring 203, and the lower surface of the bump pin 204 is in close contact with the upper surface of the pinion bevel gear 3, and the center of the pinion bevel gear 3 and the lock sleeve 201 The centers of the circles coincide, the inner wall of the self-locking assembly 2 is provided with a small bevel gear 3, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com