Patents

Literature

58results about How to "Avoid pinch damage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

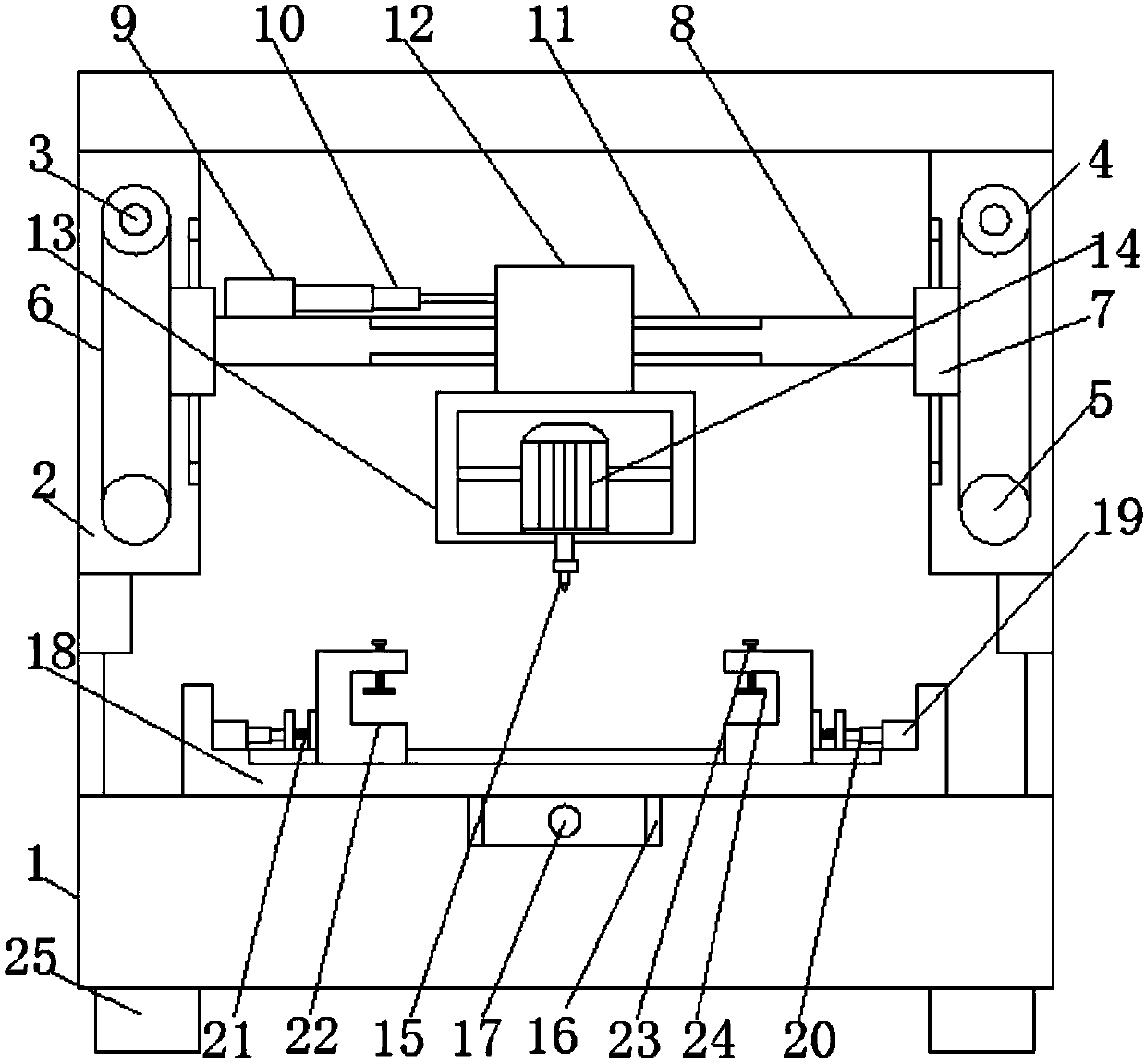

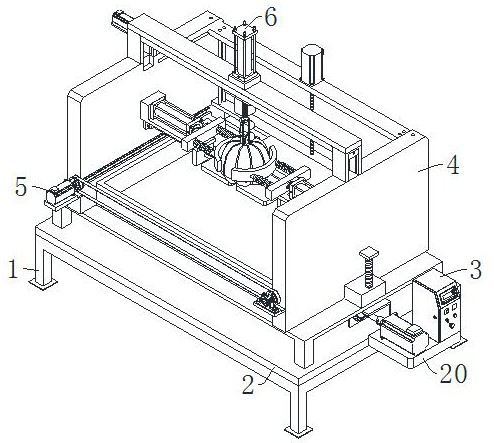

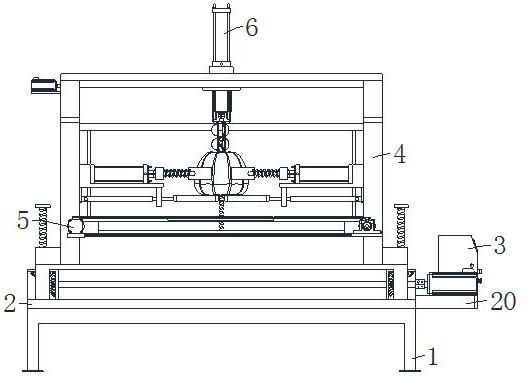

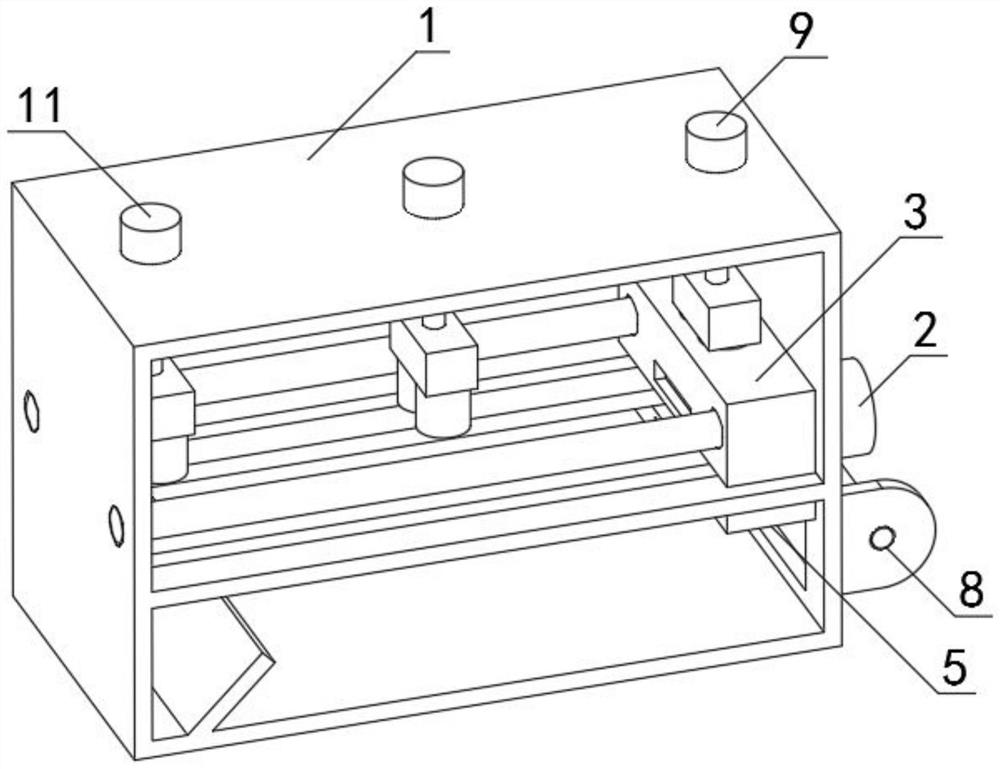

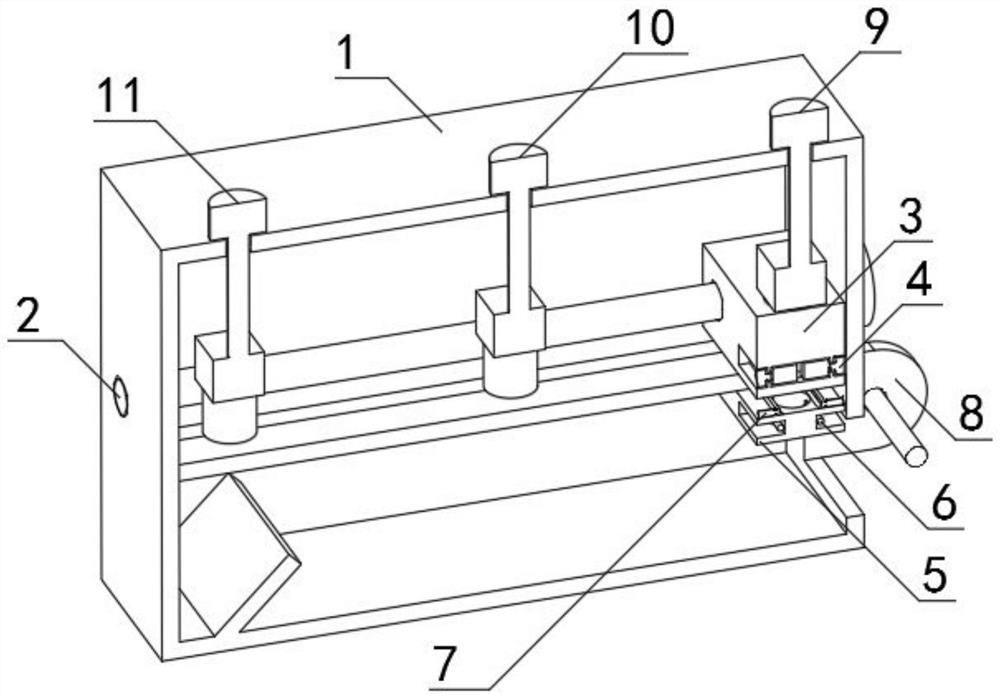

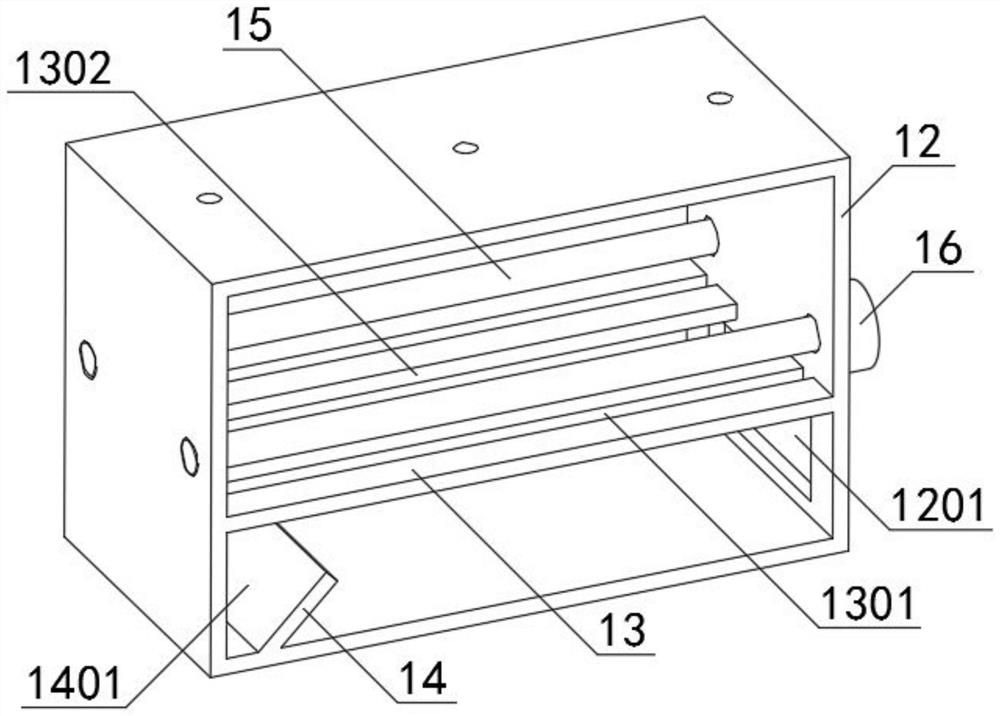

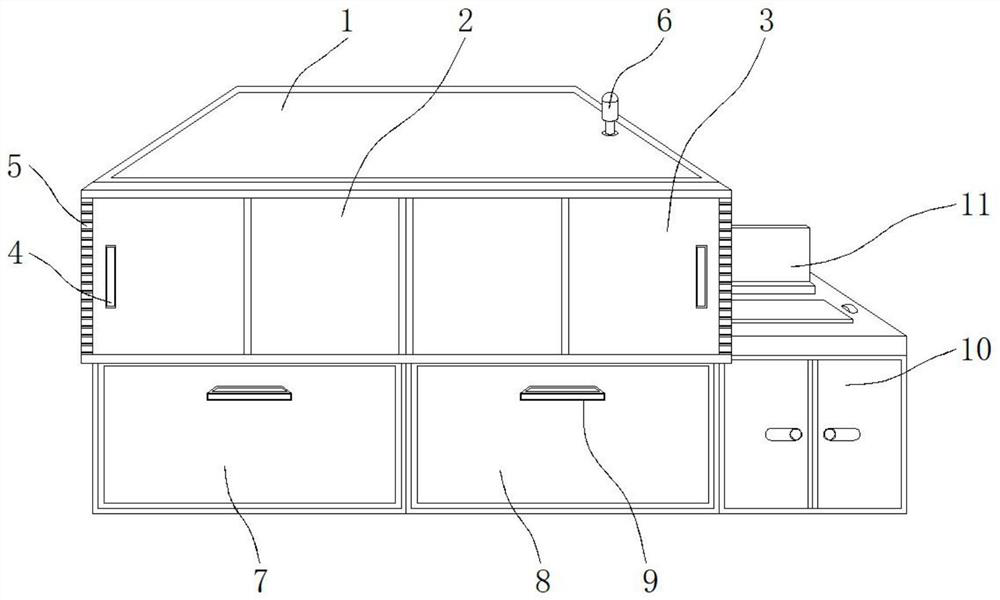

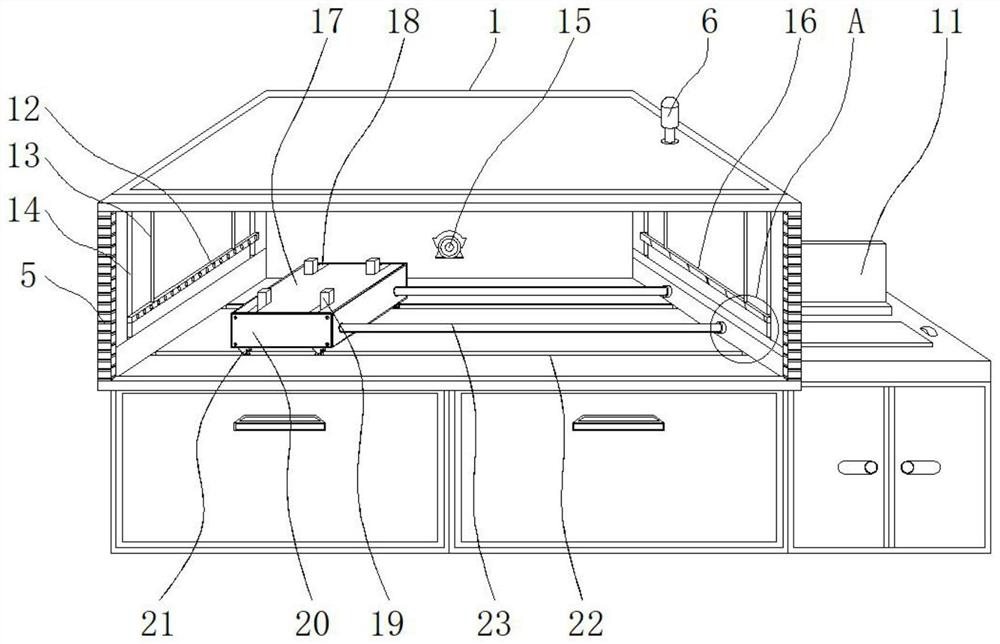

Steel structure drilling device

InactiveCN107824828AAvoid distortionAvoid stickingFeeding apparatusPositioning apparatusDrive wheelArchitectural engineering

The invention discloses a drilling device for a steel structure, which comprises a machine body. Both sides above the inner wall of the machine body are provided with organic casings. One motor, the output shafts of the two first motors are fixedly sleeved with driving wheels, the inner chambers of the two casings are provided with driven wheels, and belts are movably connected between the two driving wheels and the driven wheels, and the two belts Both of them are fixedly connected with fixed blocks, and the two fixed blocks are slidably connected to the inner wall of the through groove, and a support frame is fixedly connected between the two fixed blocks, and the left side of the top of the support frame is provided with a first cylinder. The invention solves the problem that the drill cannot be displaced laterally by adding a device for lateral movement to the drill, and achieves the purpose of the clamp device being able to move forward and backward by setting the turntable and the screw rod, and solves the problem that the existing steel structure drilling cannot be clamped at one time Problem with drilling multiple times.

Owner:余骆杨

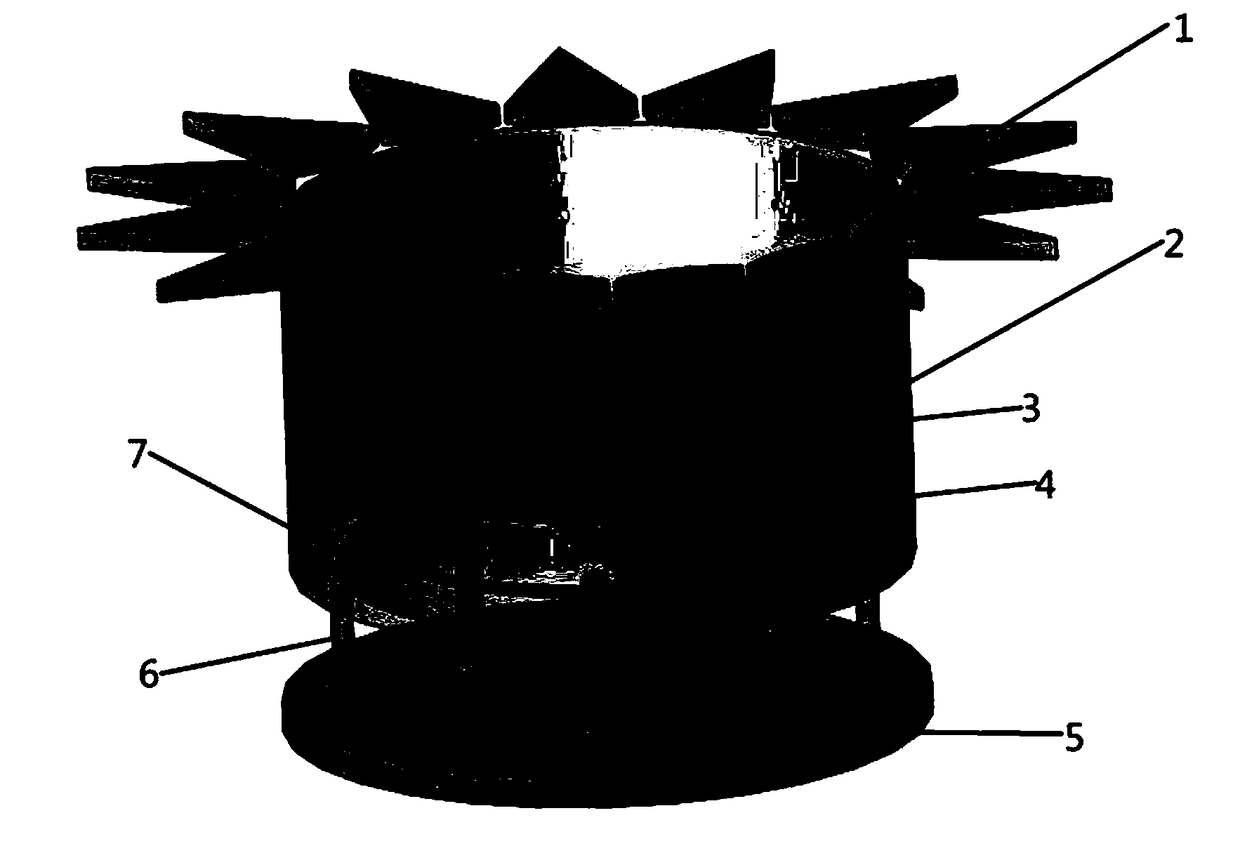

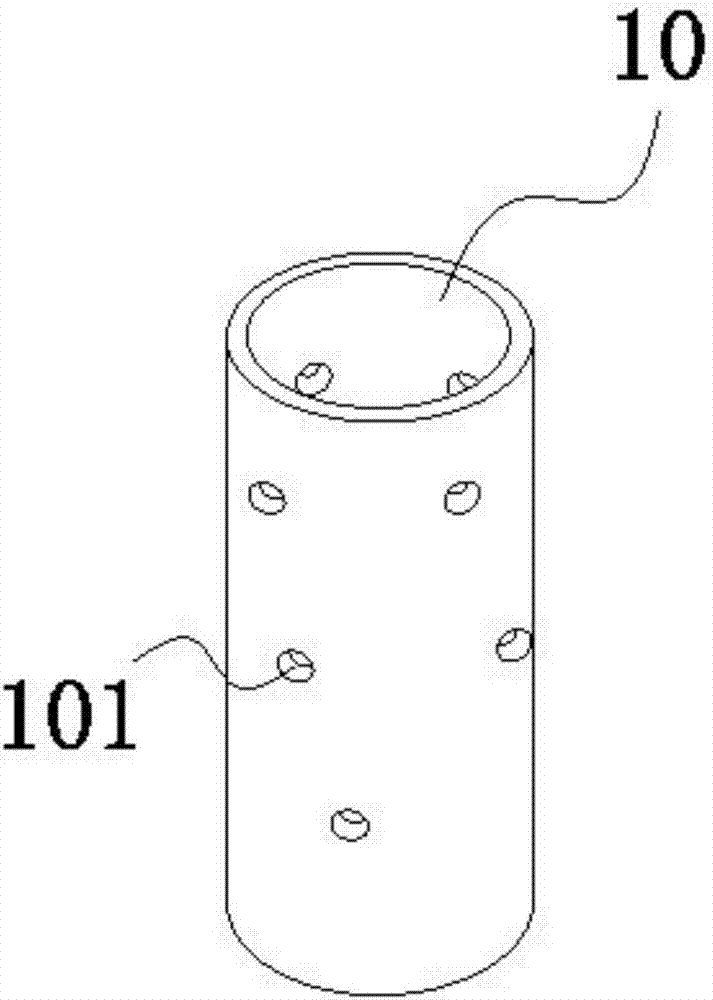

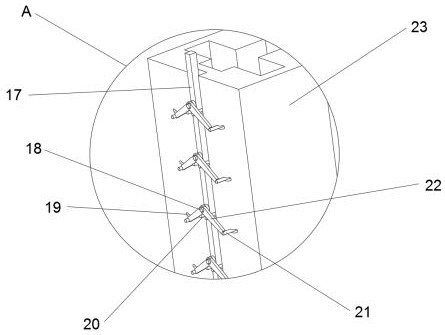

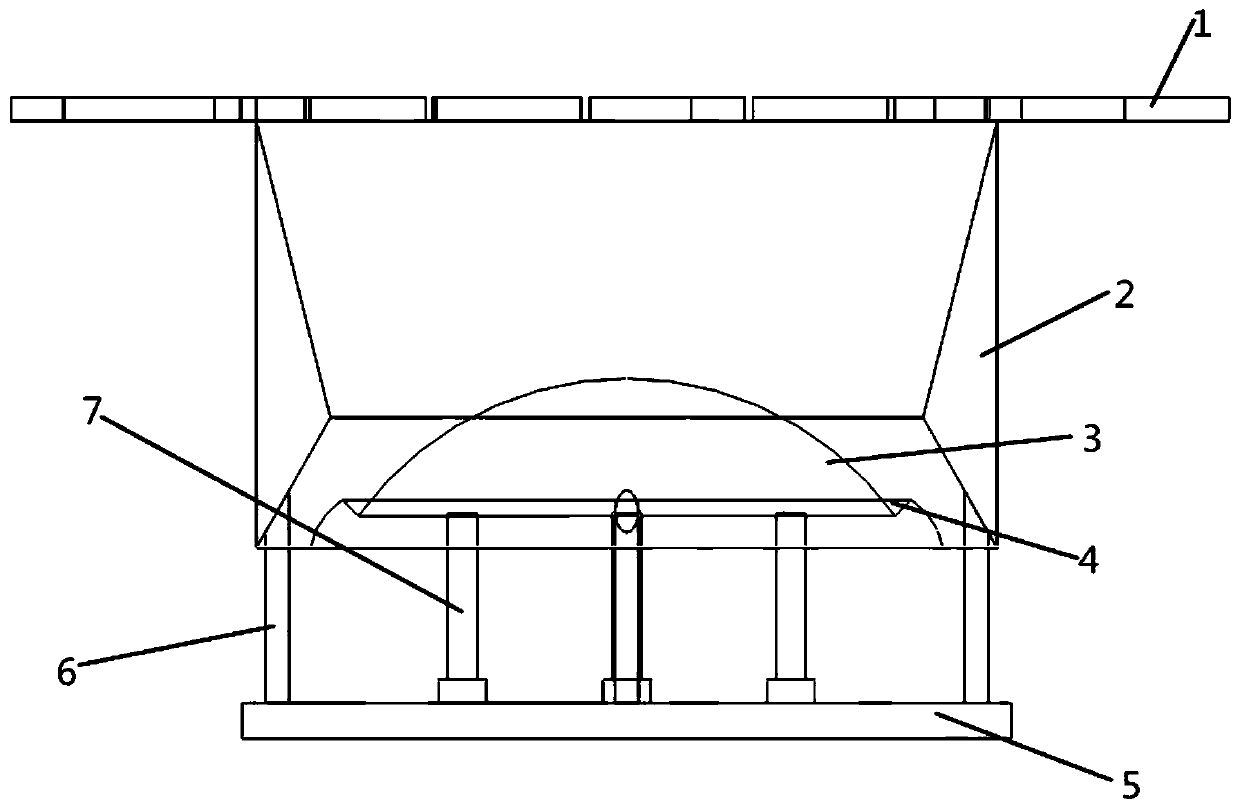

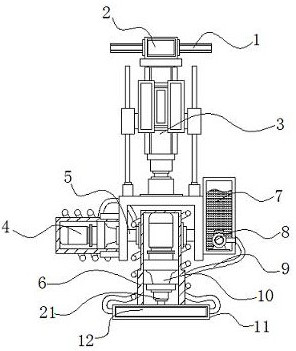

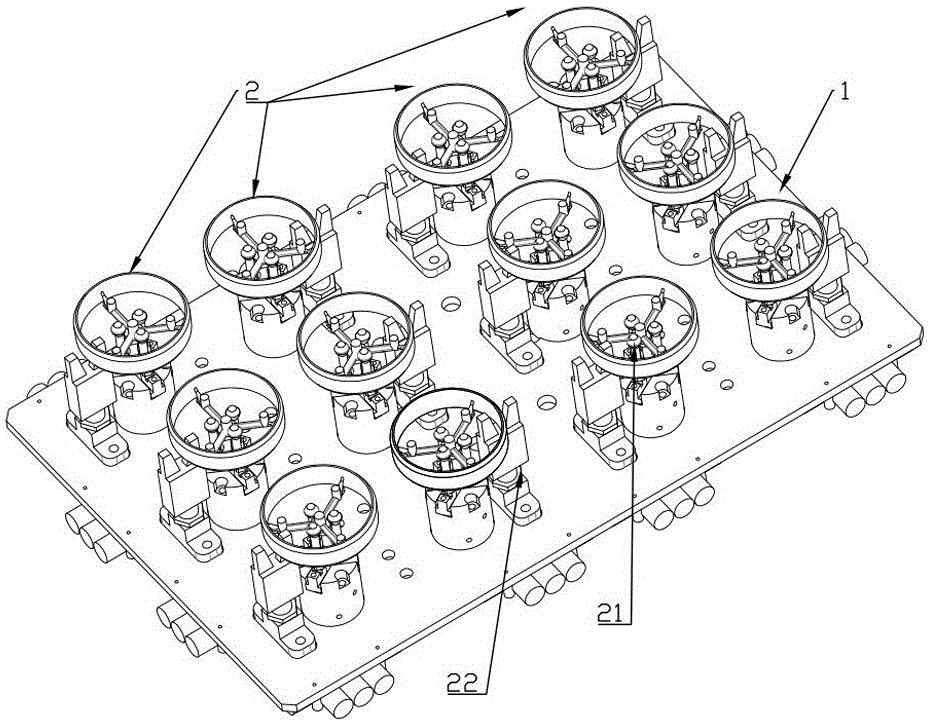

Multifunctional unmanned aerial vehicle stable-parking charging platform and method

ActiveCN108466567AEasy to fixSmall footprintCharging stationsElectric vehicle charging technologyUncrewed vehicleEngineering

The invention discloses a multifunctional unmanned aerial vehicle stable-parking charging platform and method. The multifunctional unmanned aerial vehicle stable-parking charging platform comprises abase and a hollow column body which is fixed to the base and internally provided with an upper hollow cone frustum and a lower hollow cone frustum, wherein the upper hollow cone frustum and the lowerhollow cone frustum are arranged in a coplanar mode. A hemisphere is embedded into the lower hollow cone frustum and internally provided with an unmanned aerial vehicle signal transferring device, anunmanned aerial vehicle state monitoring device and a wireless power supplying device. An annulus-shaped groove strip is arranged in the gap between the lower cone frustum and the hemisphere, and thewidth of the groove strip is consistent with or slightly larger than the diameter of an unmanned aerial vehicle take-off and landing wheel. The bottom of the hemisphere is connected with the base through a plurality of hydraulic columns. The occupied space of the structure of the stable-parking charging platform is greatly reduced, an unmanned aerial vehicle can be firmly fixed to the platform, and whether the unmanned aerial vehicle is in an ocean or on land, the situation that the unmanned aerial vehicle falls due to severe weathers such as heavy storm waves or the bumpy road conditions, andconsequently the loss is caused can be avoided.

Owner:WUHAN UNIV OF TECH

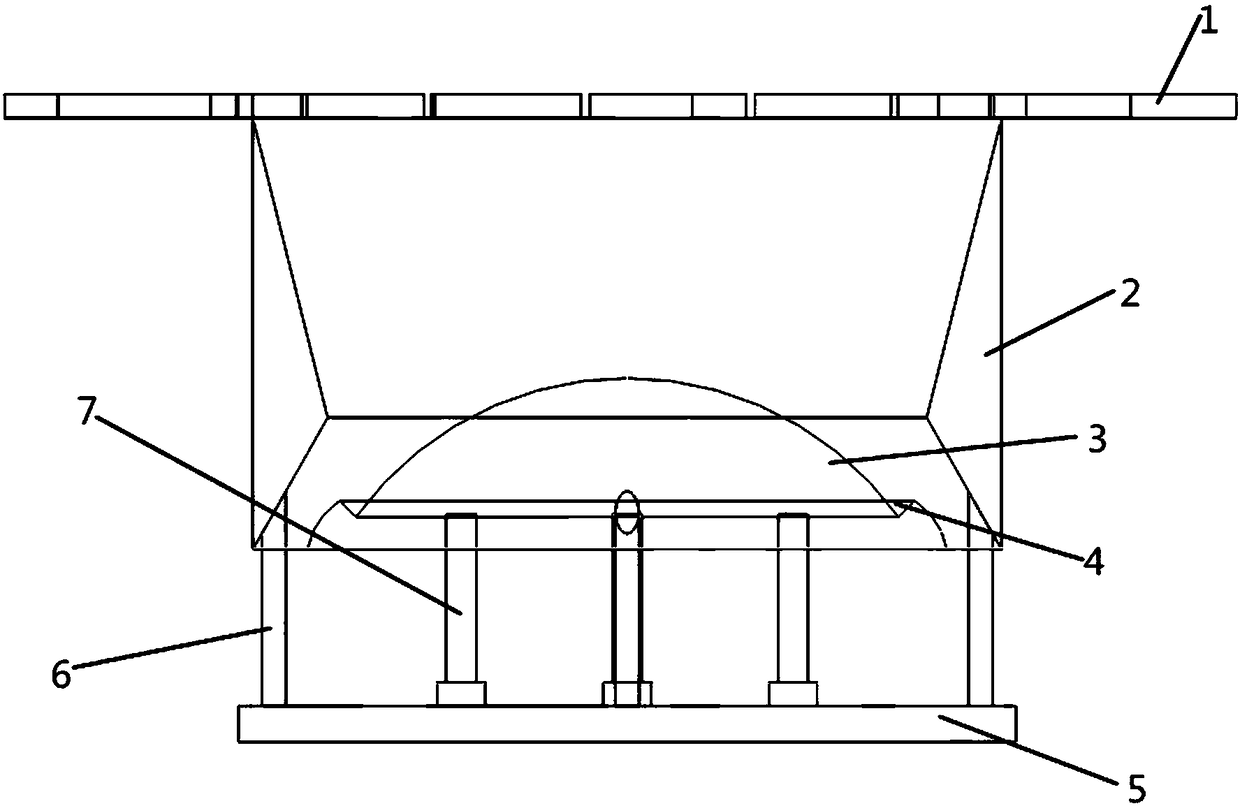

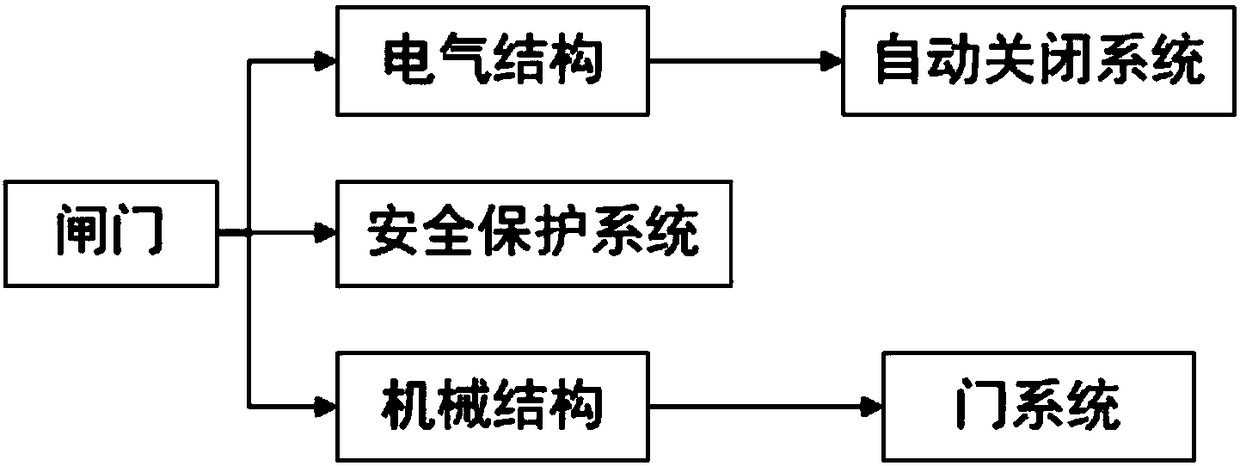

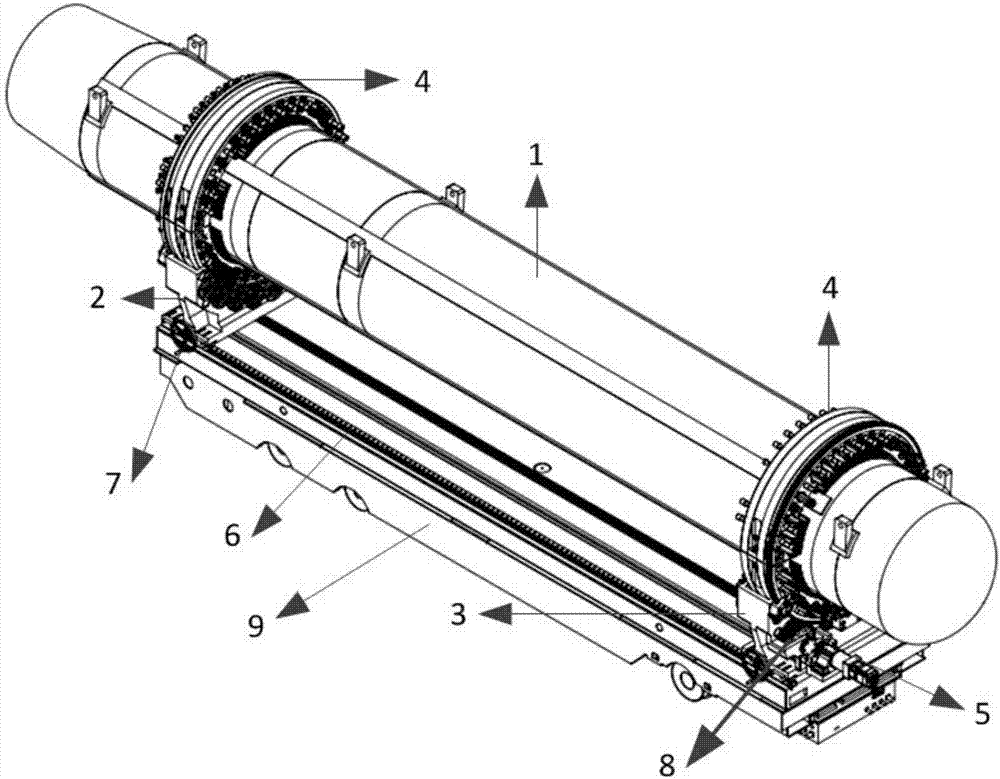

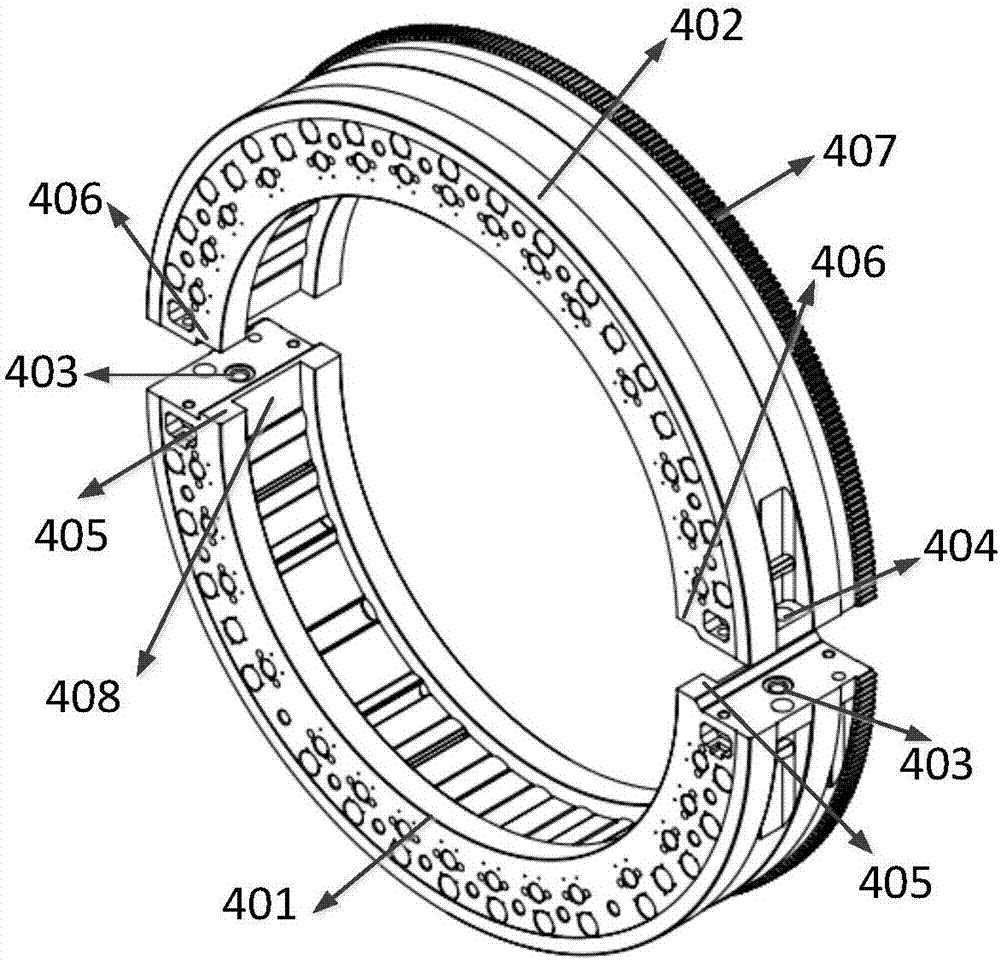

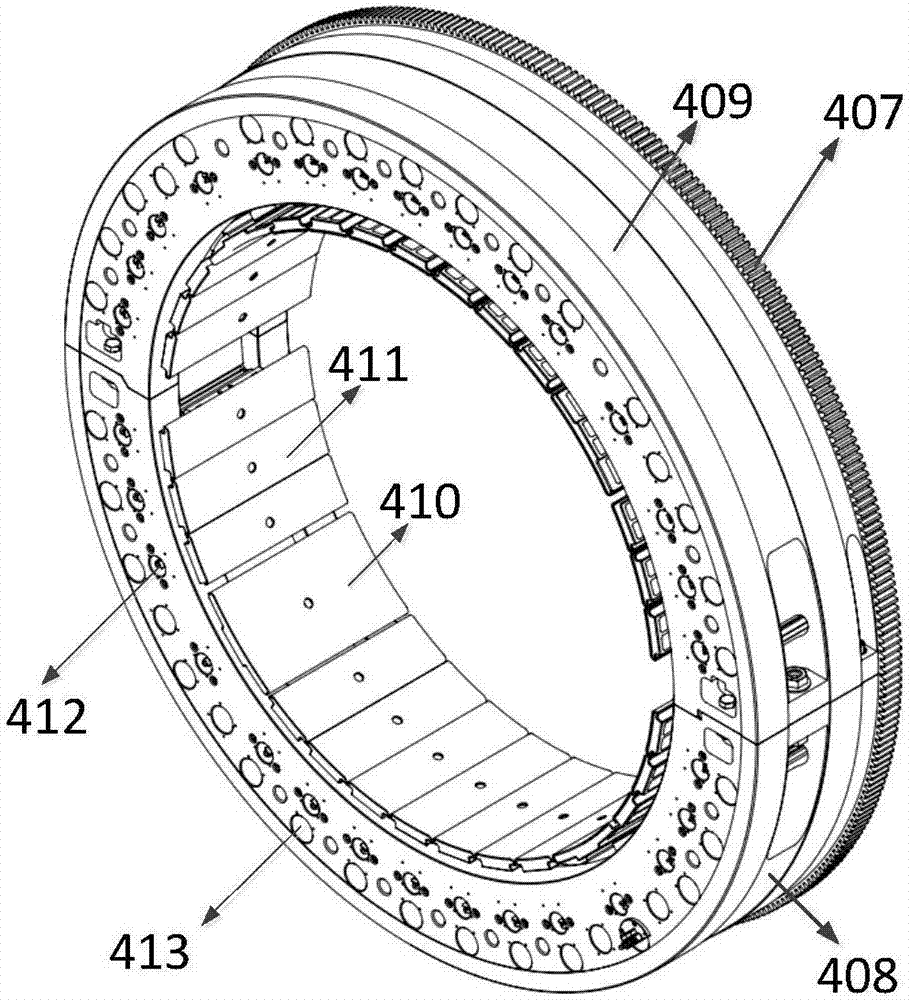

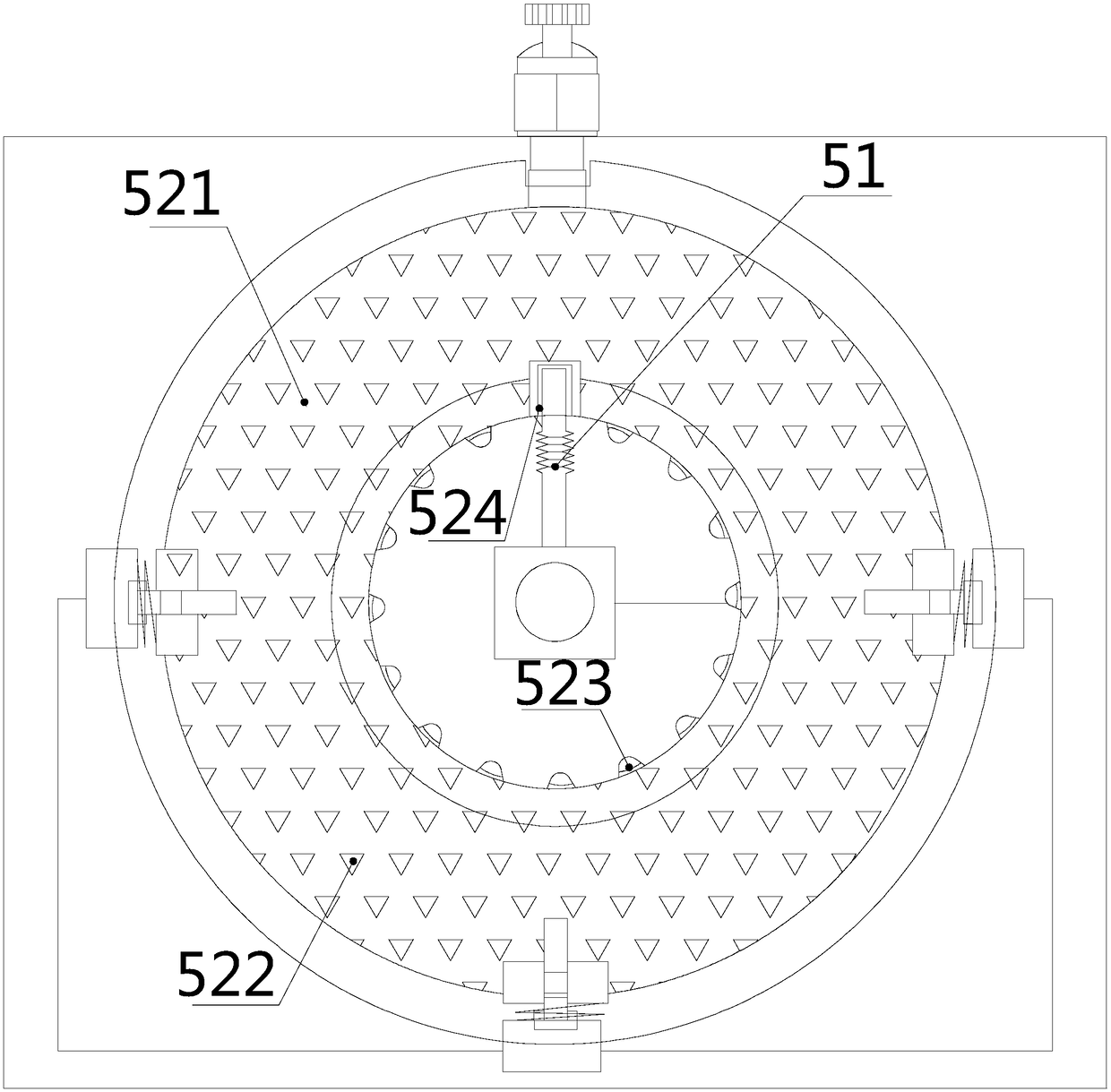

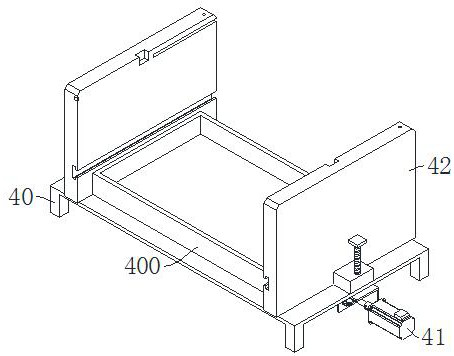

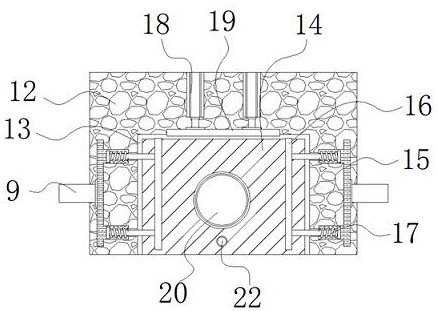

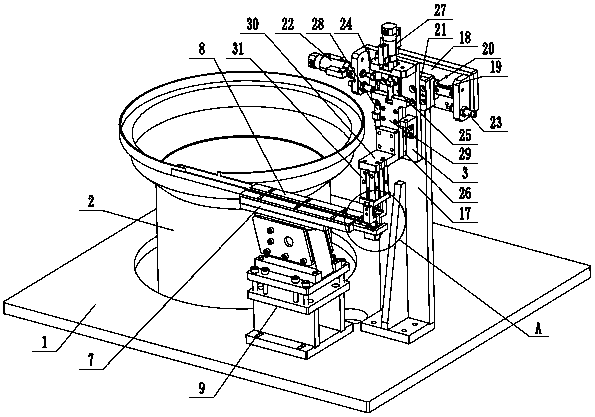

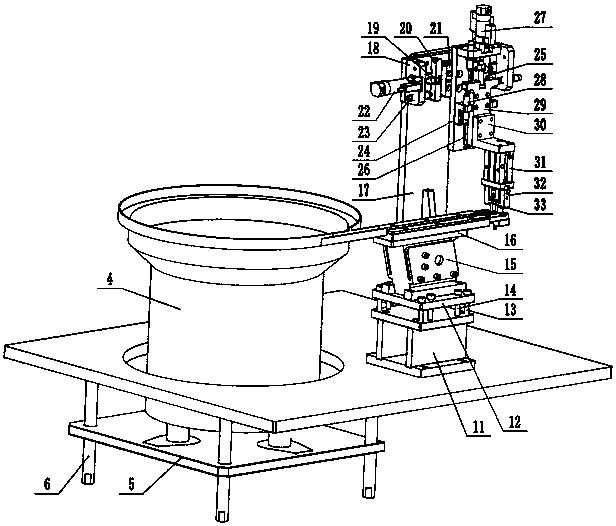

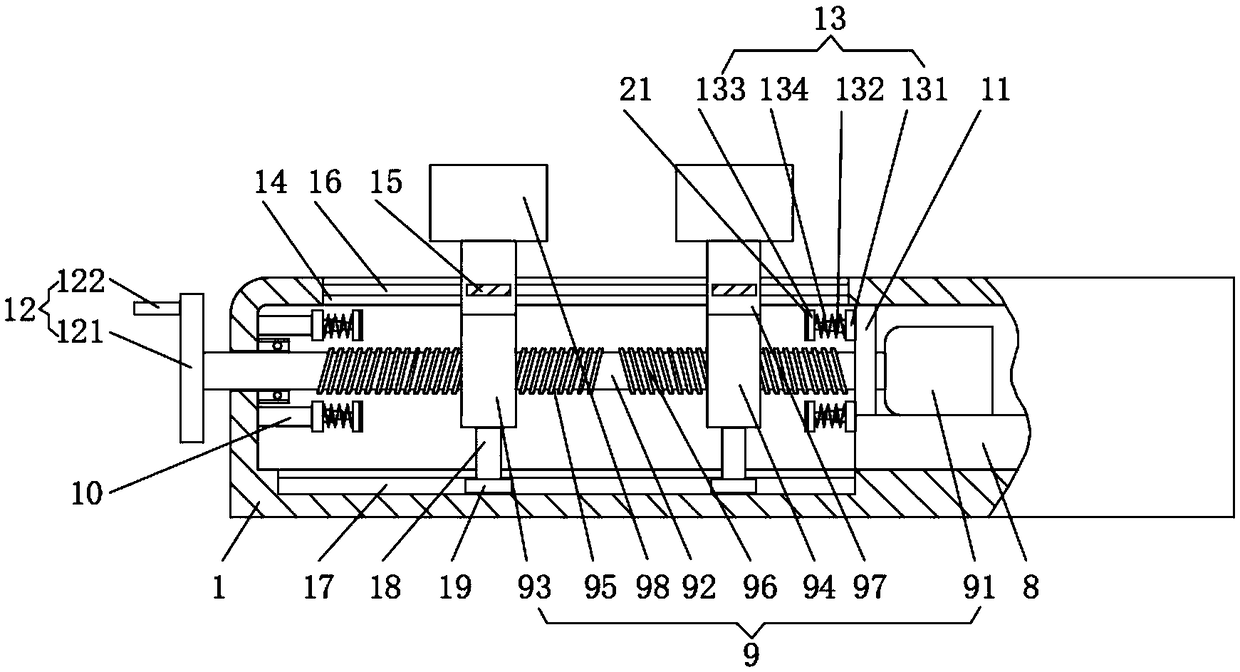

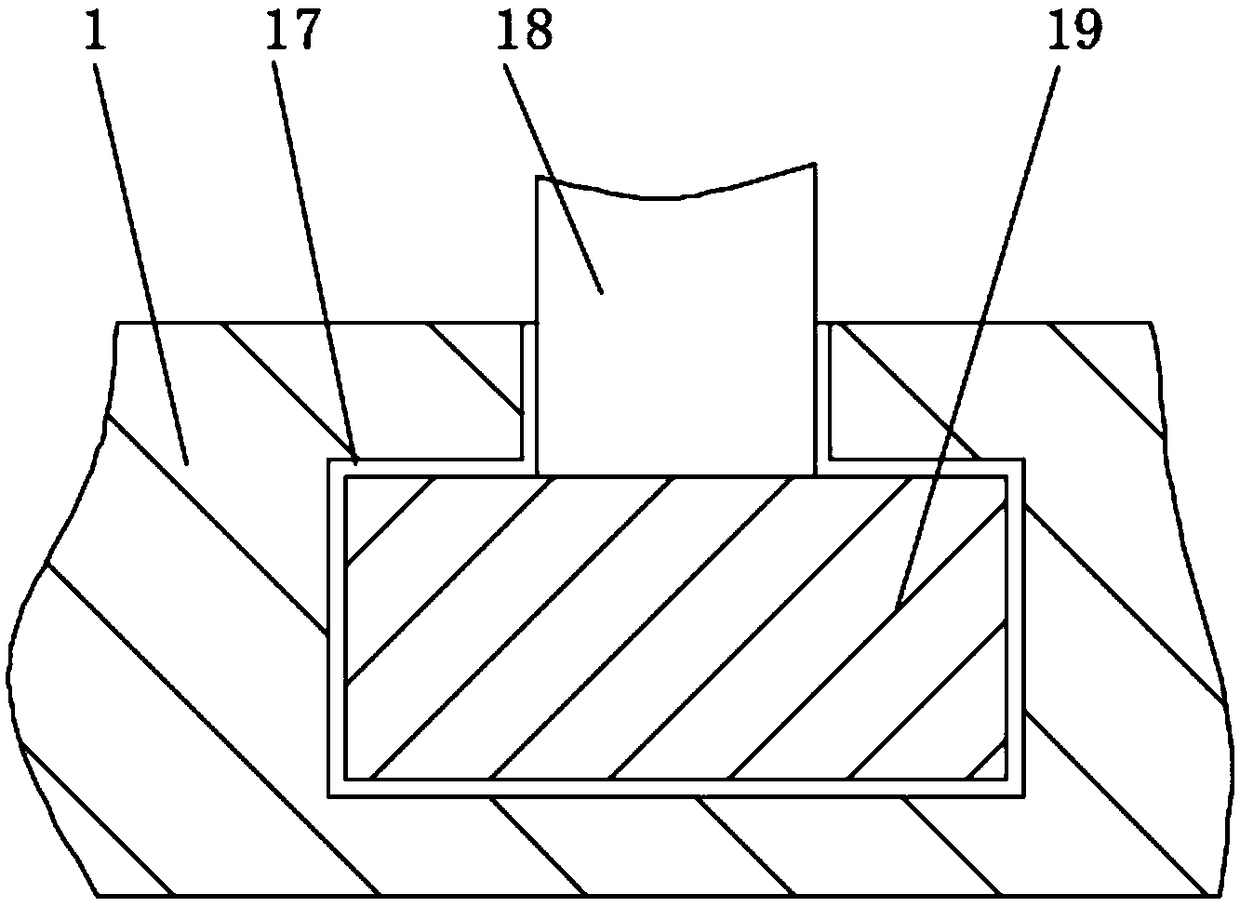

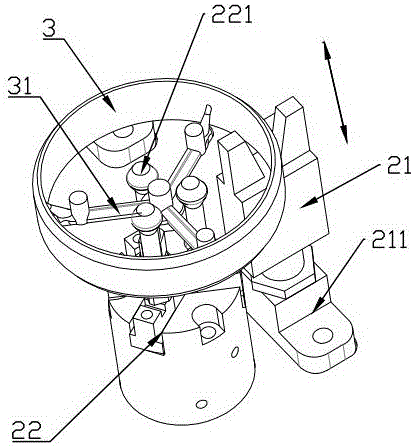

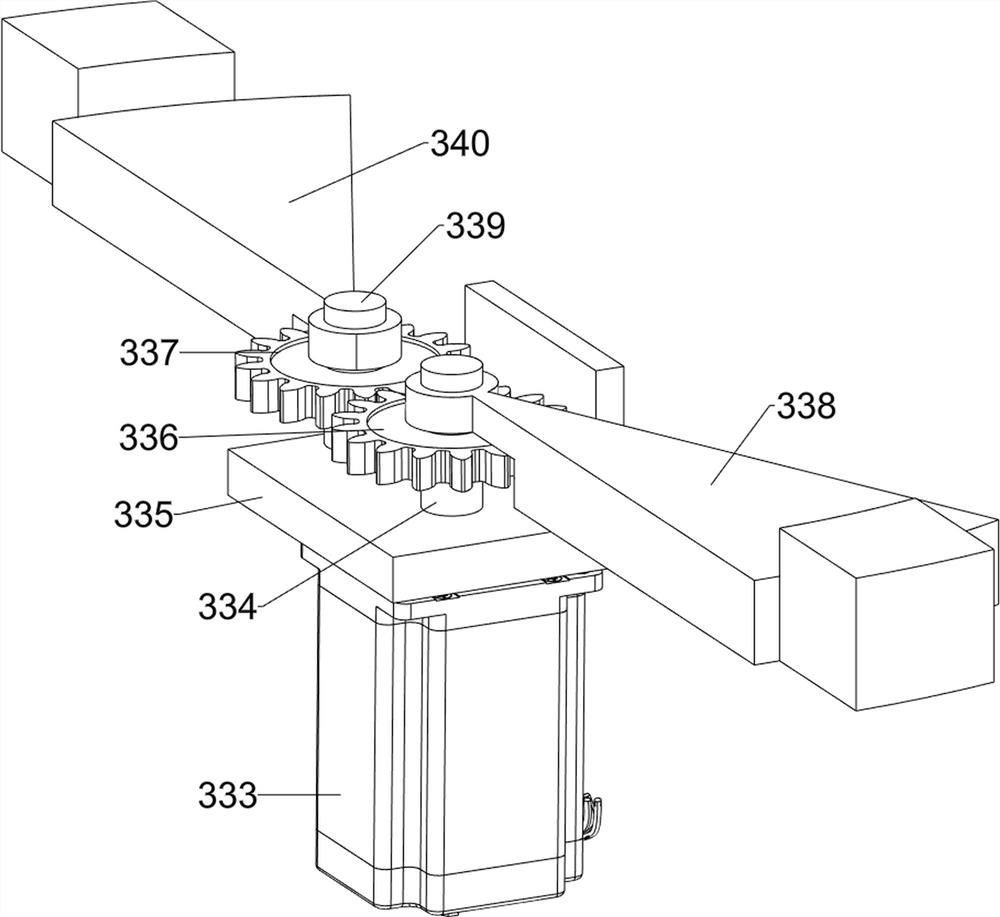

Clamping system and clamping method for large similar cylindrical workpieces

PendingCN107283191AAvoid collision and friction damageEasy and accurate clampingWork holdersPositioning apparatusPhysicsEngineering

The invention provides a clamping system for large similar cylindrical workpieces. The clamping system comprises at least two workpiece clamping devices; the workpiece clamping devices comprise first fixture bodies with semicircular structures and second fixture bodies; the first fixture bodies and the second fixture bodies are relatively connected to form a complete ring structure; and along the outer edge of the ring structure, transmission teeth engaged with external gears are arranged on the edges of the same side surfaces of the first fixture bodies and the second fixture bodies. The clamping system further comprises a bearing platform, and support bases arranged on the bearing platform in parallel; and a rotary driving device is arranged on one support base, and comprises a rotary driving mechanism and a driving gear connected with an output shaft end of the rotary driving mechanism. The invention further provides a clamping method for the large similar cylindrical workpieces. The clamping system has the advantages of safety, reliability, convenience in operation and high adaptability.

Owner:重庆真测科技股份有限公司 +1

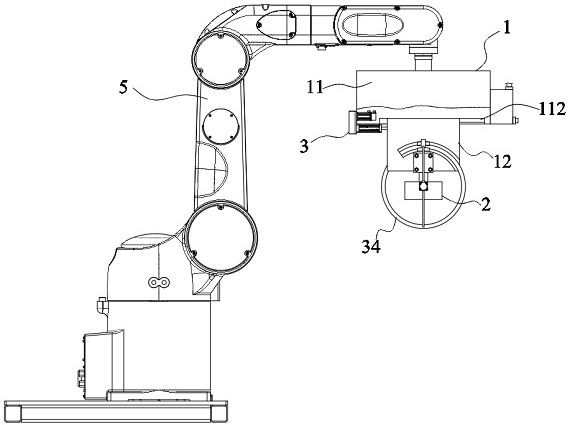

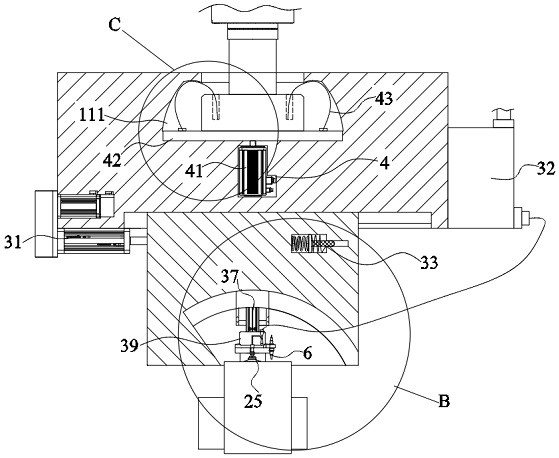

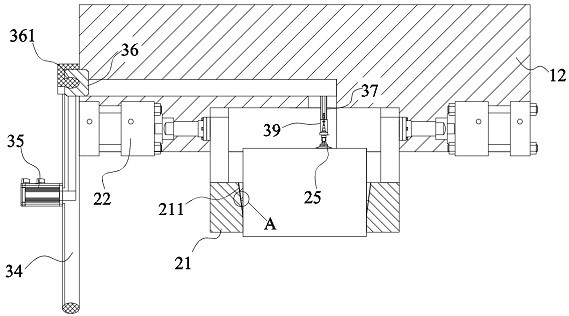

Integrated carrying device for carrying robot

ActiveCN114425768ASmall turning radiusPrevent affecting positioning accuracyProgramme-controlled manipulatorGripping headsMechanical engineeringElectrical and Electronics engineering

The invention discloses an integrated carrying device for a carrying robot, and relates to the technical field of integrated carrying devices, the carrying robot comprises a mechanical arm and the integrated carrying device, the integrated carrying device comprises a supporting device, a clamping device, a displacement device and a locking mechanism, the supporting device is connected with the clamping device, and the displacement device is connected with the supporting device. The supporting device is connected with the locking mechanism, the supporting device comprises a base and a carrying plate, the base is connected with the mechanical arm, the carrying plate is movably connected with the base, a material pushing groove is formed in the base, the carrying plate is movably connected with the material pushing groove, the mechanical arm is a main power driving mechanism, multi-degree-of-freedom displacement of the integrated carrying device is improved, and the supporting device is a main installation foundation. Other devices are installed, workpieces are clamped through the clamping device, objects are carried and displacement is adjusted through the displacement device, the base is installed and fixed through the mechanical arm, and automatic clamping is conducted through the locking mechanism.

Owner:常州捷仕特机器人科技有限公司

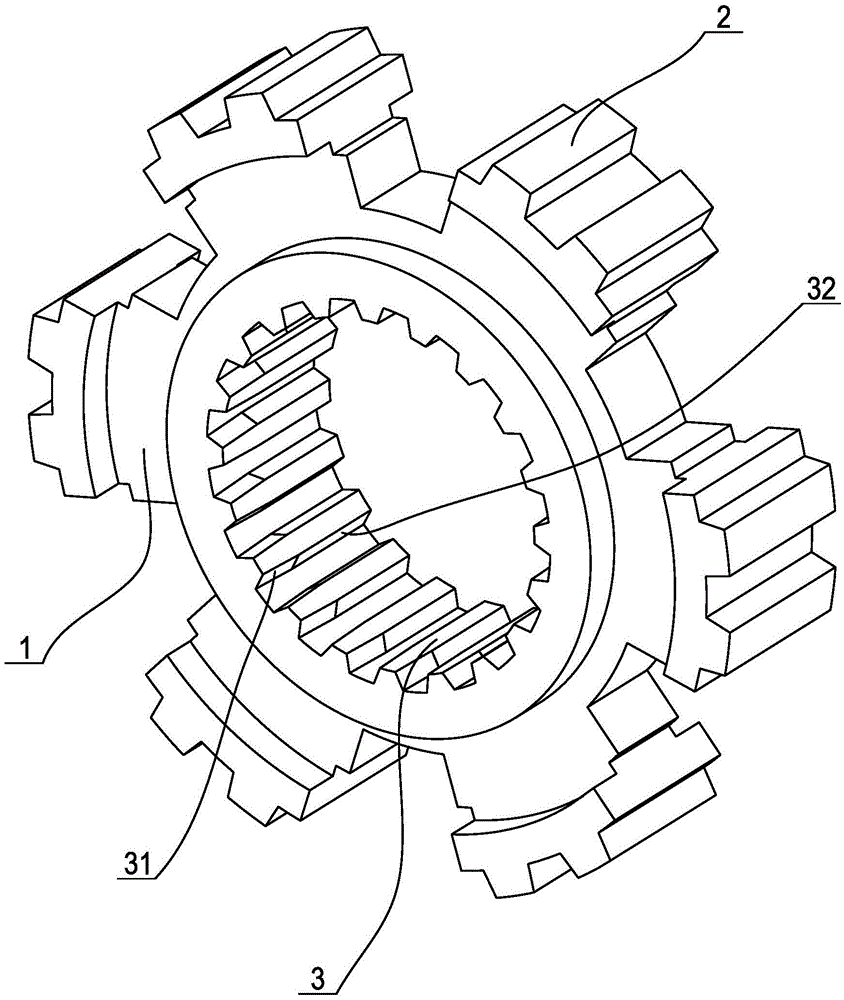

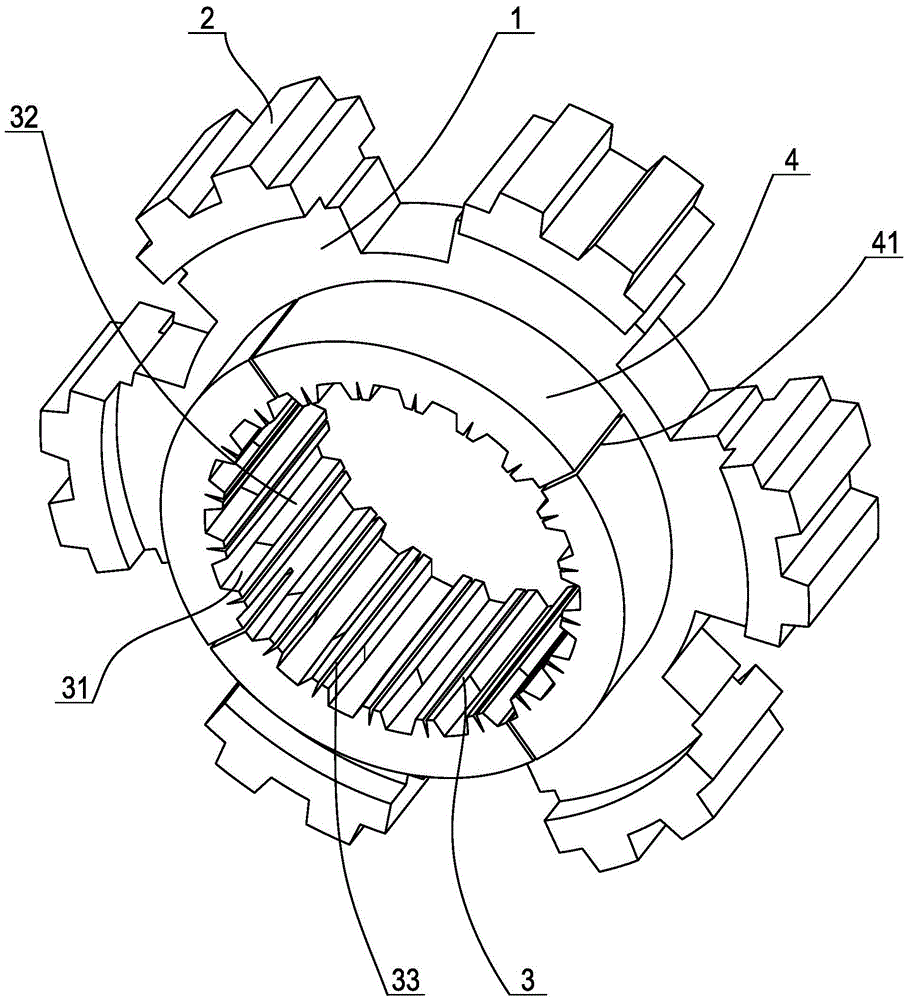

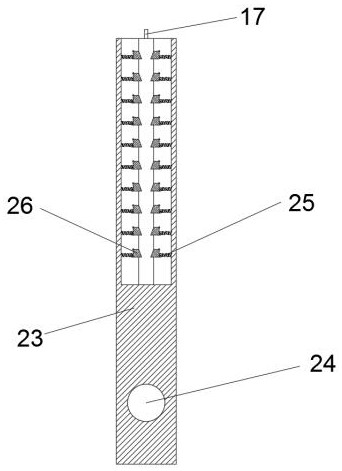

Powder metallurgy synchronizer gear hub

ActiveCN105697576AGood self-guiding centering effectAvoid pinch damageMechanical actuated clutchesPortable liftingDrive shaftPowder metallurgy

The invention discloses a powder metallurgy synchronizer gear hub which comprises a gear hub body, an outer gear hub spline on the outer side of the gear hub body, and an inner gear hub spline on the inner side of the gear hub body. The inner gear hub spline comprises a guide section close to the press-in end of the synchronizer gear hub, and a locating section away from the press-in end of the synchronizer gear hub. The reference circle tooth thickness of the guide section is gradually increased from the press-in end of the synchronizer gear hub to the joint of the guide section and the locating section, and the reference circle tooth thickness of the guide section and the reference circle tooth thickness of the locating section are in smooth transition. The reference circle tooth thickness, at the press-in end of the synchronizer gear hub, of the guide section is smaller than the width of a reference circle tooth groove of an outer spline of a transmission shaft. It can be ensured that the powder metallurgy synchronizer gear hub is automatically kept coaxial with the outer spline of the transmission shaft when mounted on the outer spline of the transmission shaft, it is effectively avoided that the thick side faces of teeth of an inner spline at the press-in end of the synchronizer gear hub are extruded to be damaged, and meanwhile power and torque can be stably transferred.

Owner:NINGBO SHANGZHONGXIA AUTOMATIC TRANSMISSION

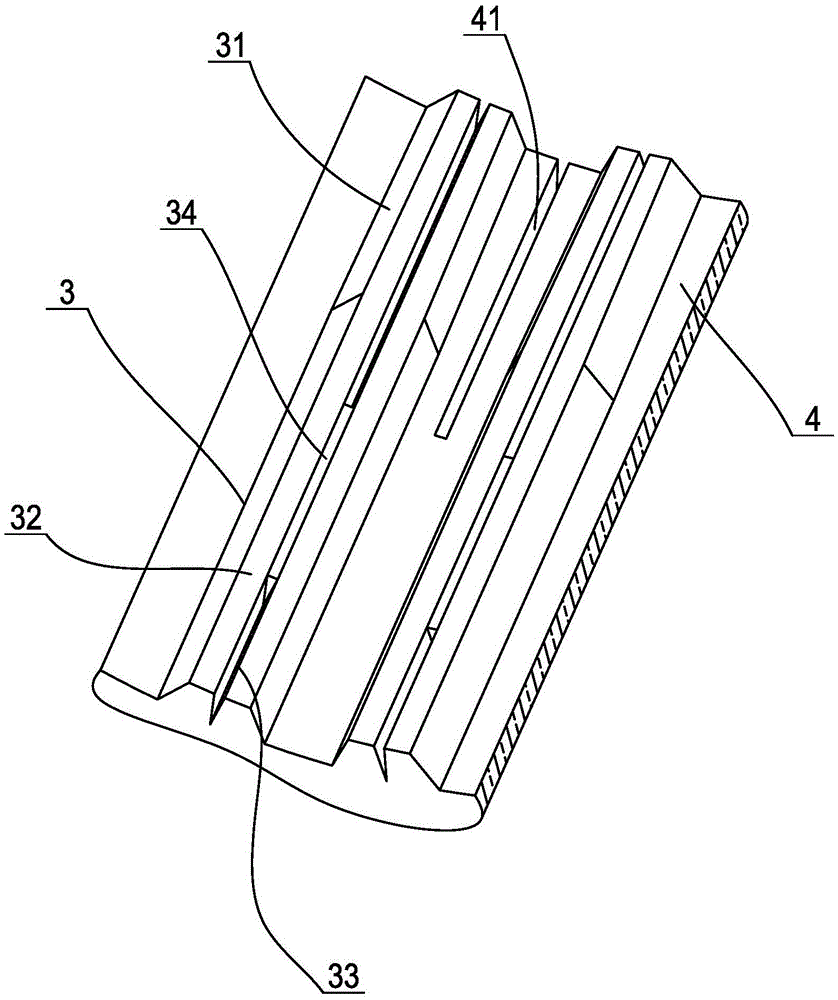

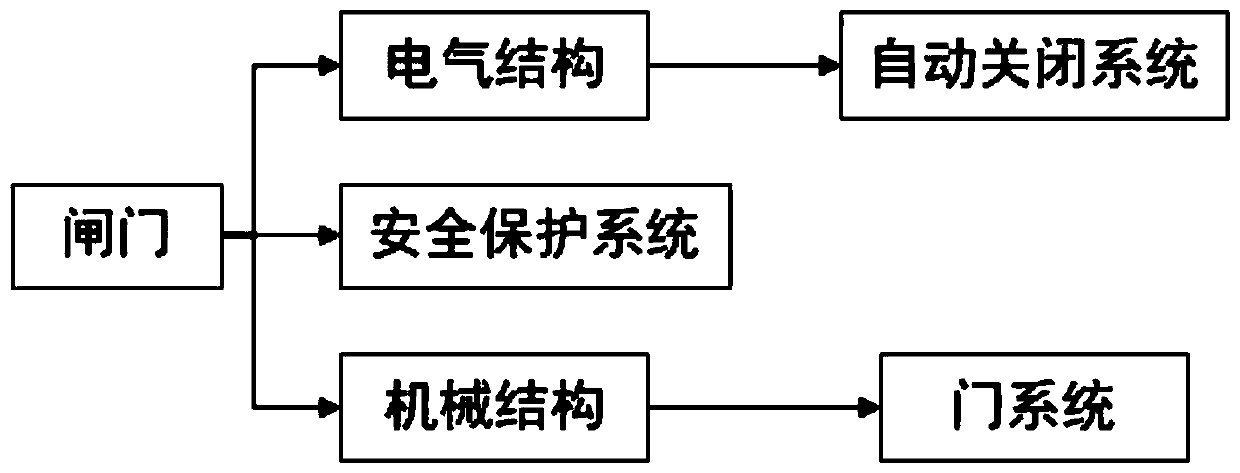

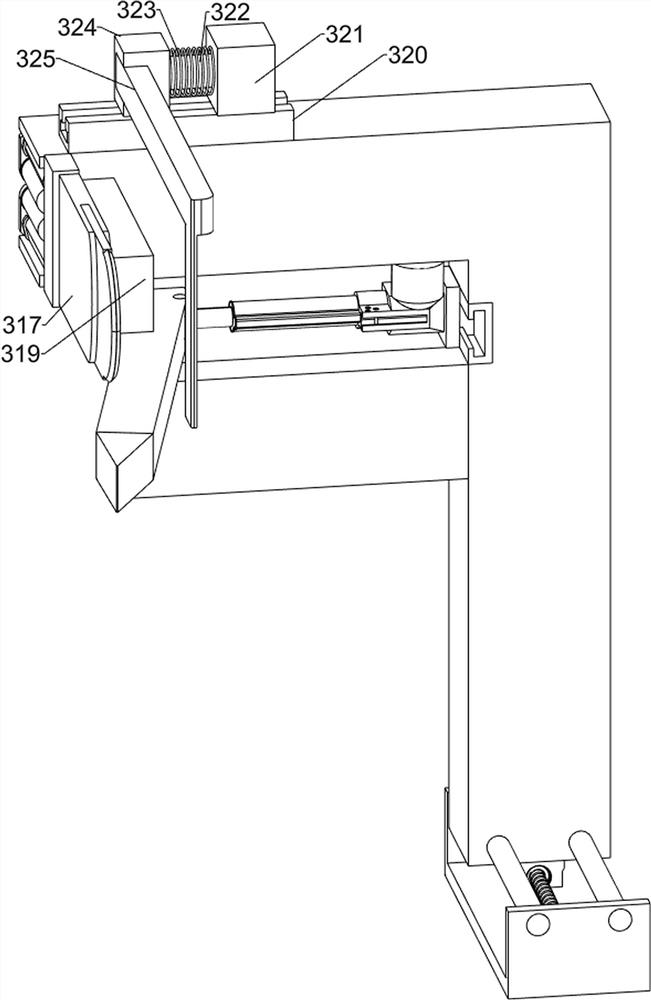

Processing grinder clamping device with damage-preventing pneumatic rubber ring used for wood clamping

InactiveCN108747820AClamping EliminationReduce manual operationsRevolution surface grinding machinesGrinding work supportsRubber ringEngineering

The invention discloses a processing grinder clamping device with a damage-preventing pneumatic rubber ring used for wood clamping. The processing grinder clamping device structurally comprises supporting frames, a power motor, a rotary operating box, a grinder rotary clamp, pneumatic clamping device, a middle end rolling clamp and a grinder table. The grinder rotary clamp is embedded in and rotationally connected with the lower portion of the right end of the rotary operating box. The pneumatic clamping device is mounted and arranged inside the grinder rotary clamp and matched with the grinder rotary clamp through gas. When wood enters the innermost position of the clamp, a pressing lever is pushed, an inflator pump is started, the rubber ring is inflated through a pipe and is made to expand to the two ends, since the rubber ring is in fastening connection with the wood and large-particle rubber with elasticity is arranged on the surface of the rubber ring, clamping damage of the surface of the wood can be prevented, when the rubber ring is stressed to the maximum extent, a protruding slide block on the rear portion of the rubber ring enables a circuit breaker to be started, electrical shutoff control is performed on the inflator pump through an electric wire, so that the rubber ring continues to be inflated, manual operation is reduced, an adjusting valve is ejected out of aclamp groove opening through the rubber ring, deflation can be performed through the valve when processing is completed, and clamping of the rubber ring to the wood is eliminated.

Owner:莆田市多迪贸易有限公司

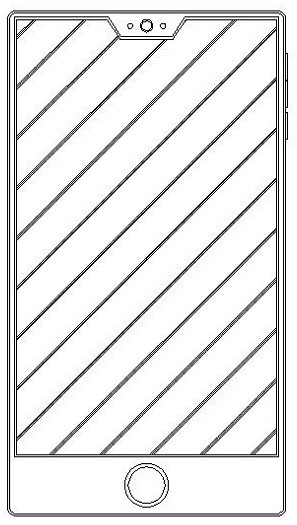

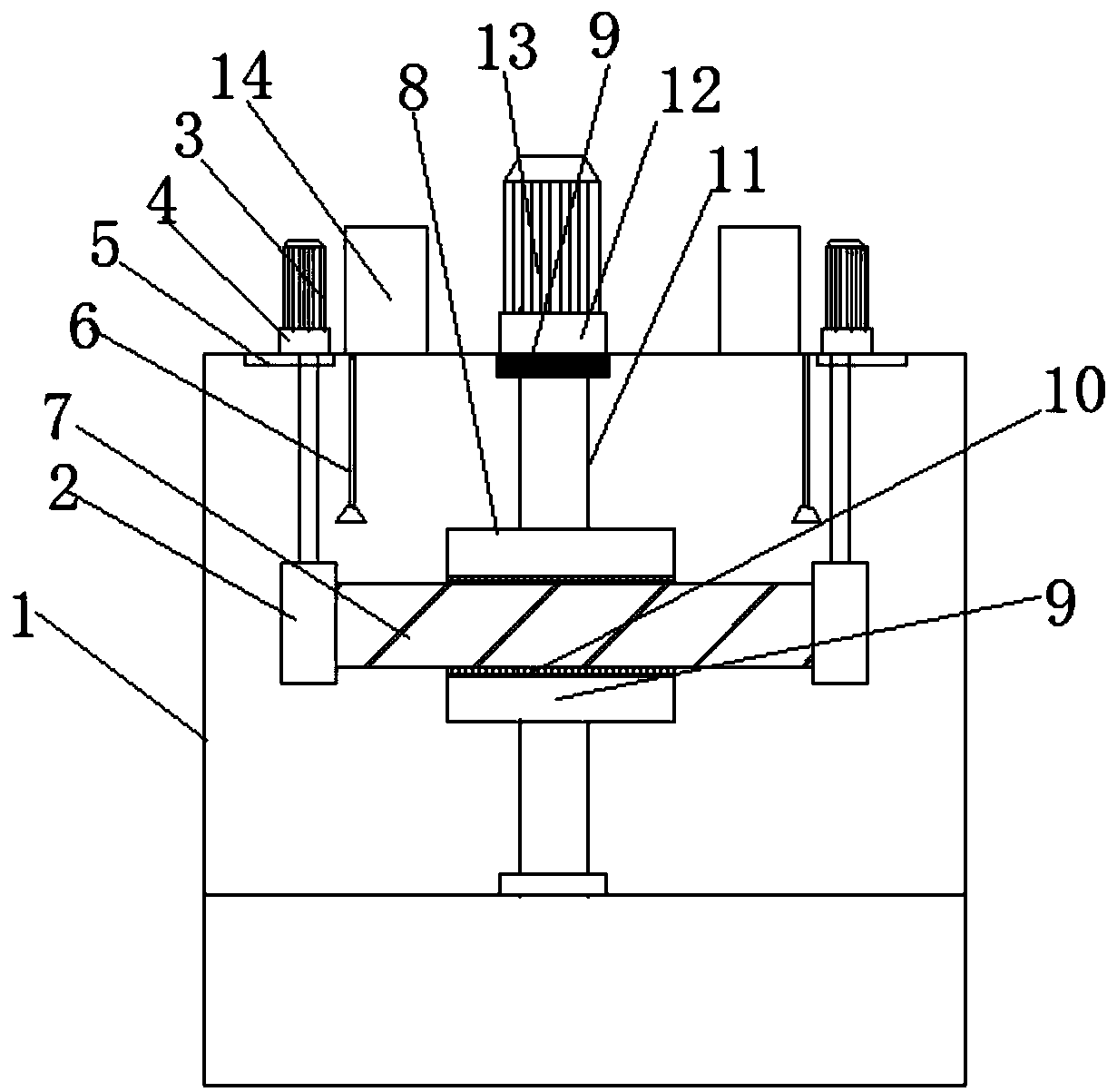

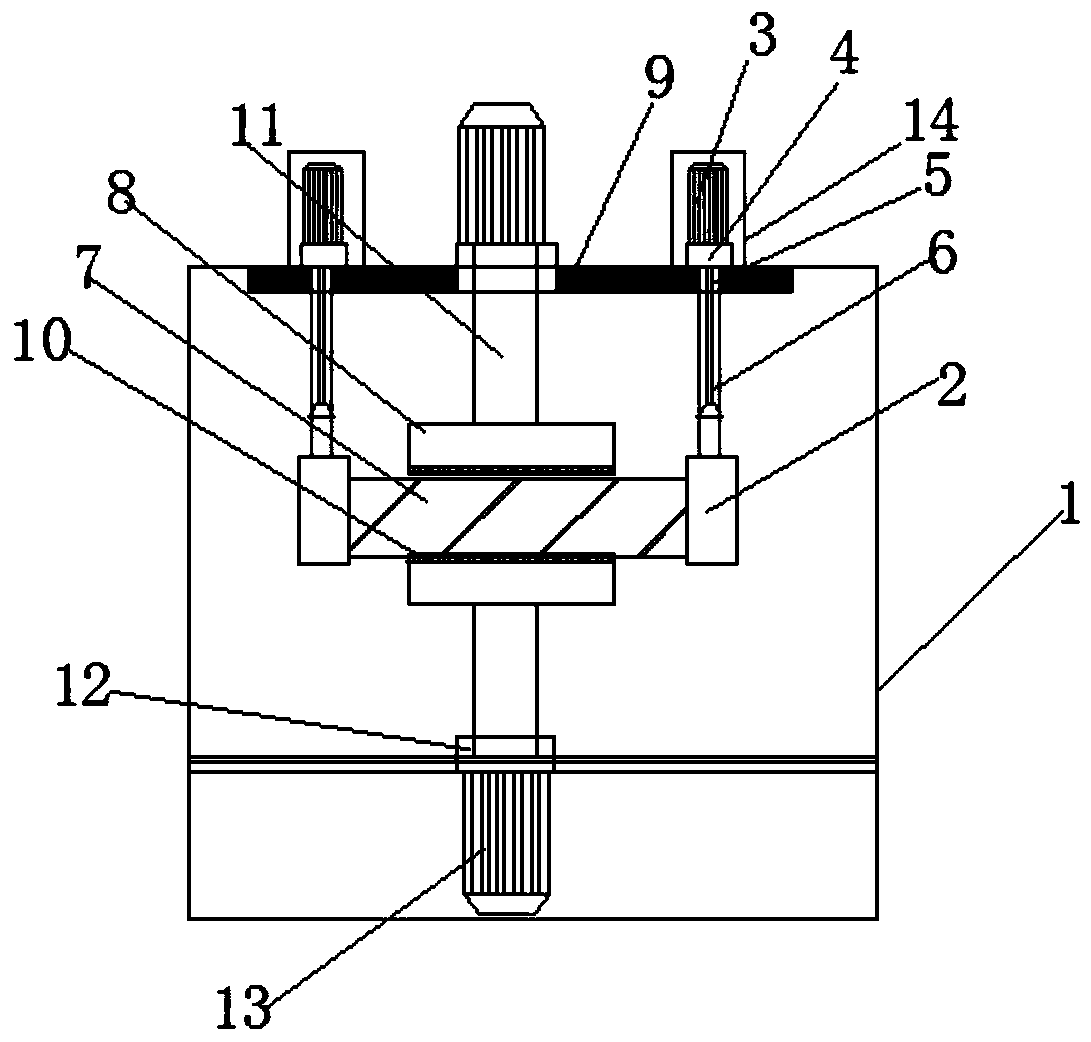

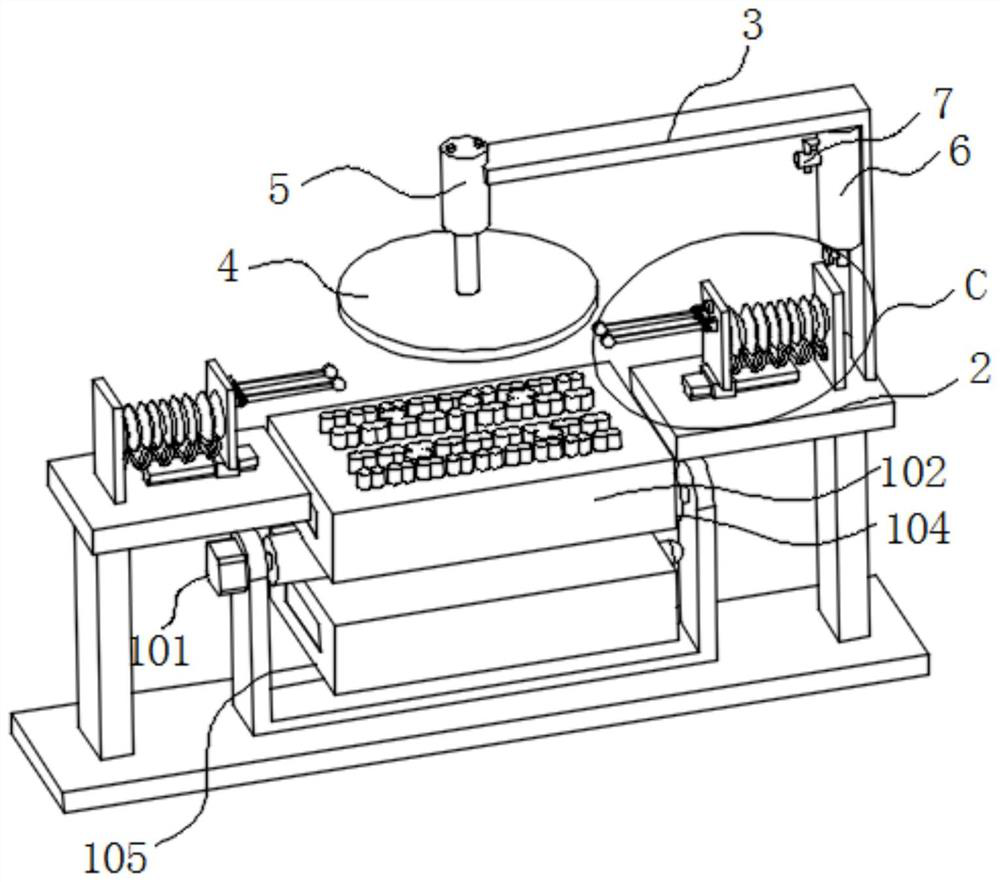

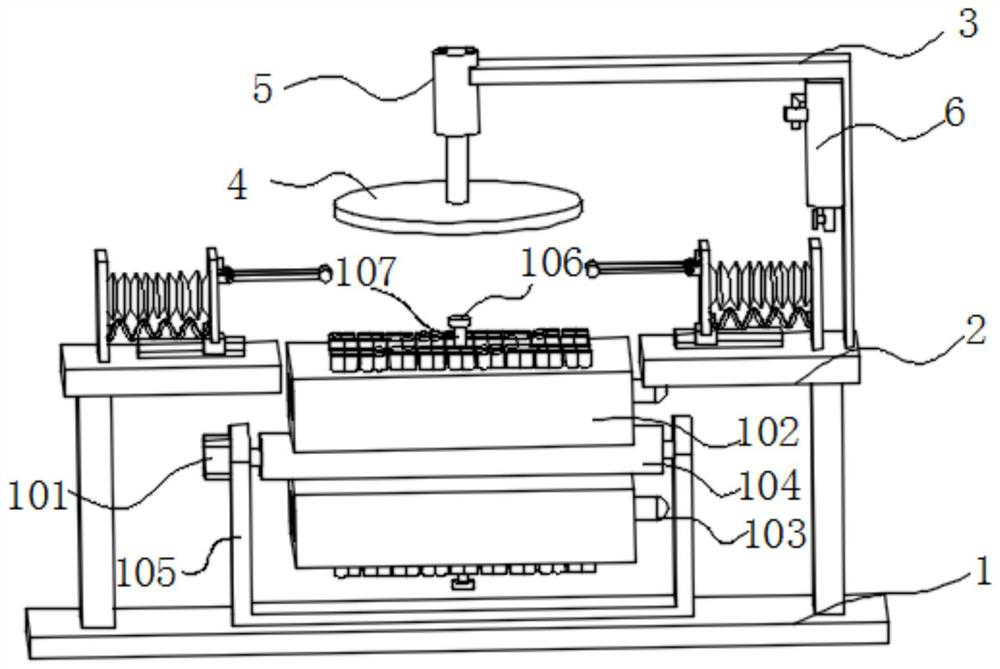

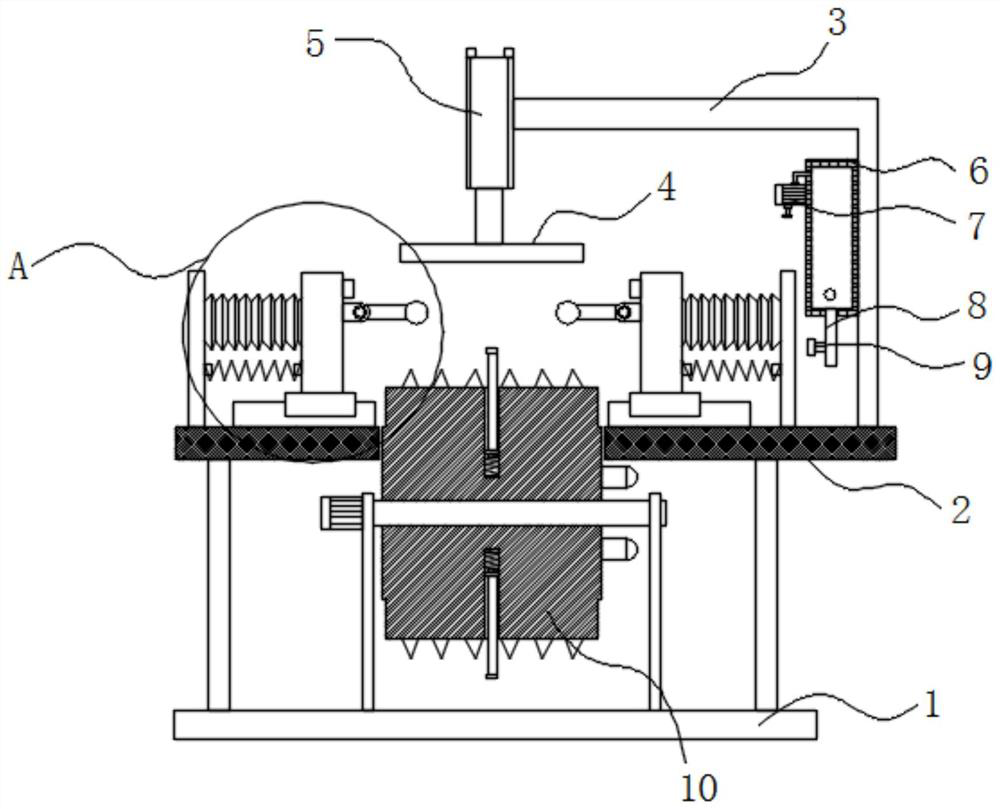

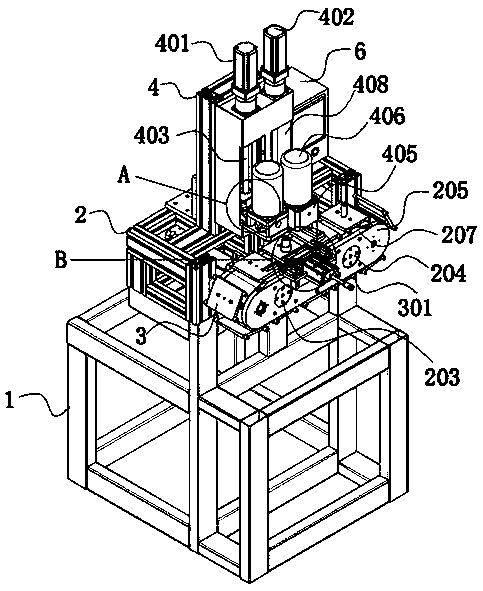

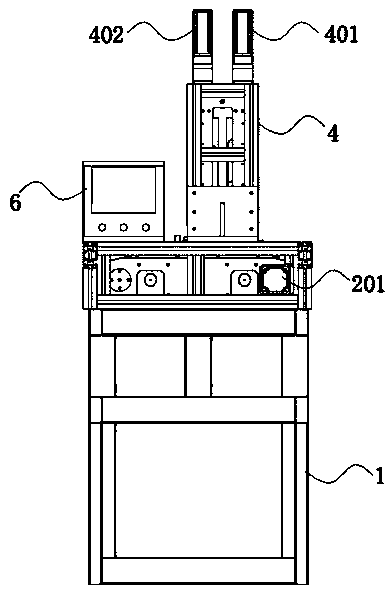

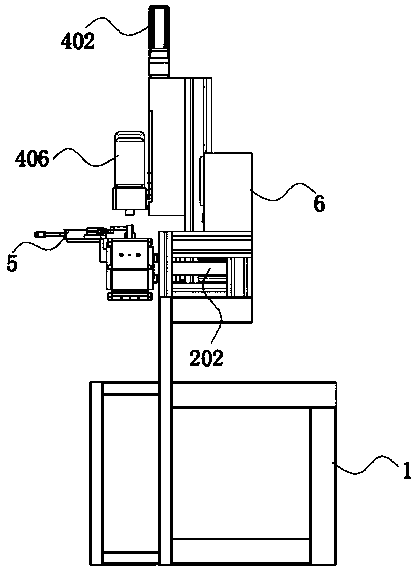

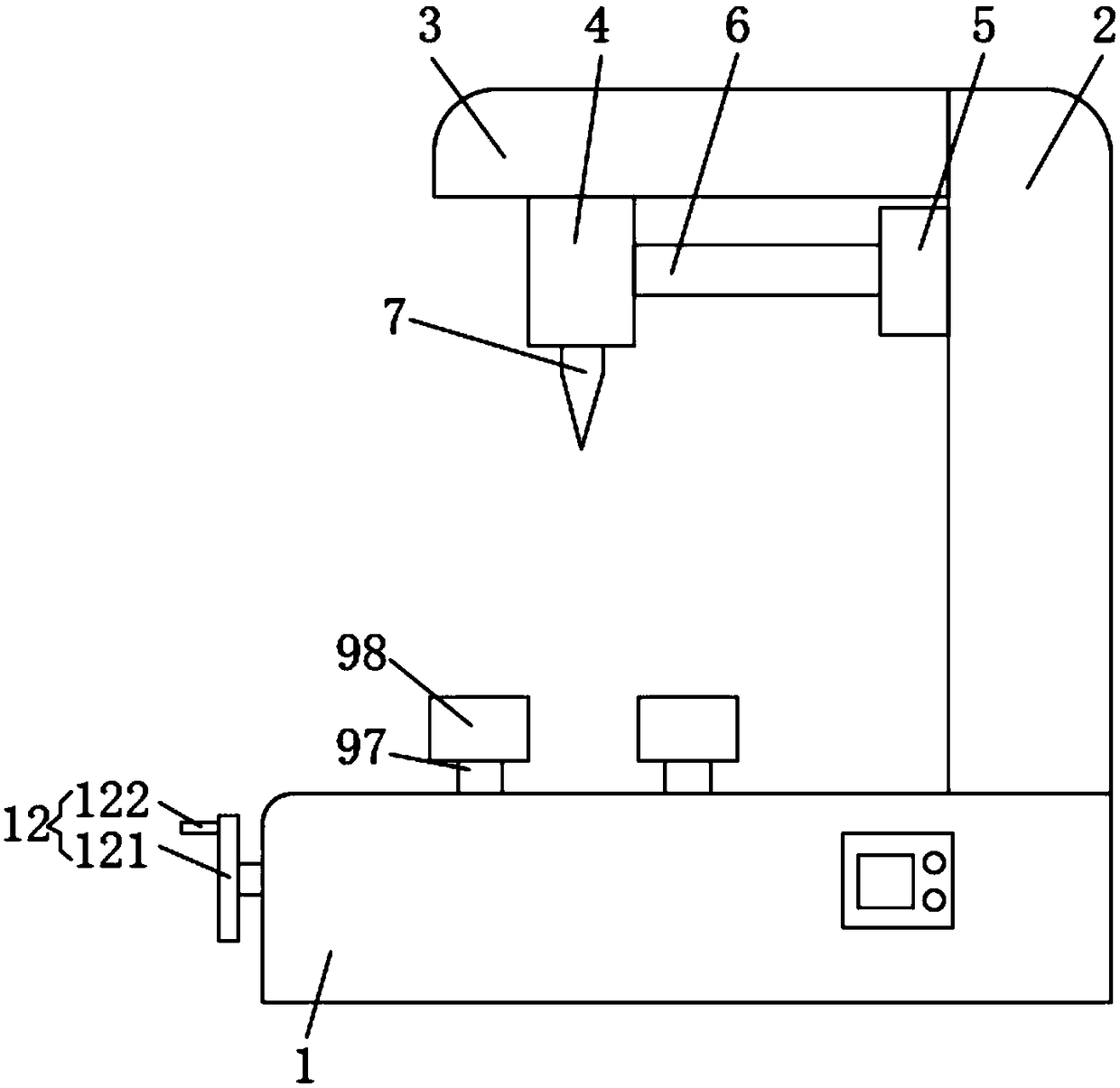

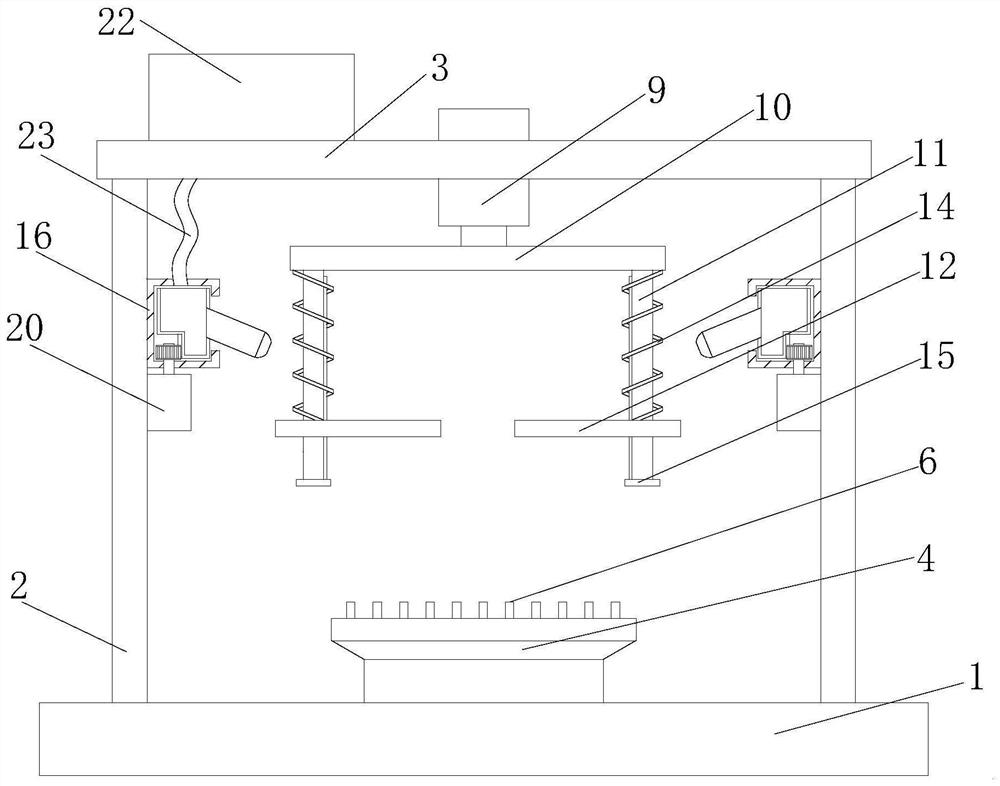

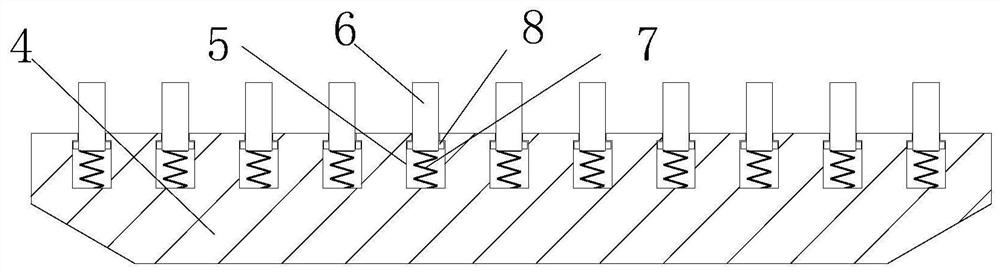

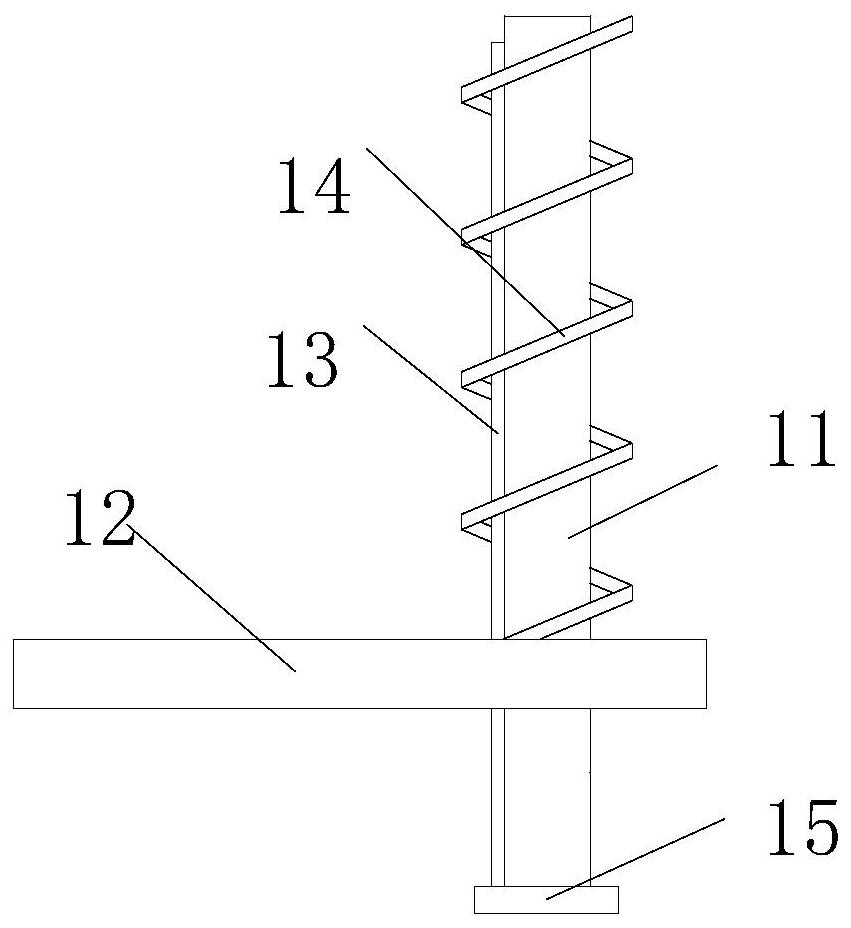

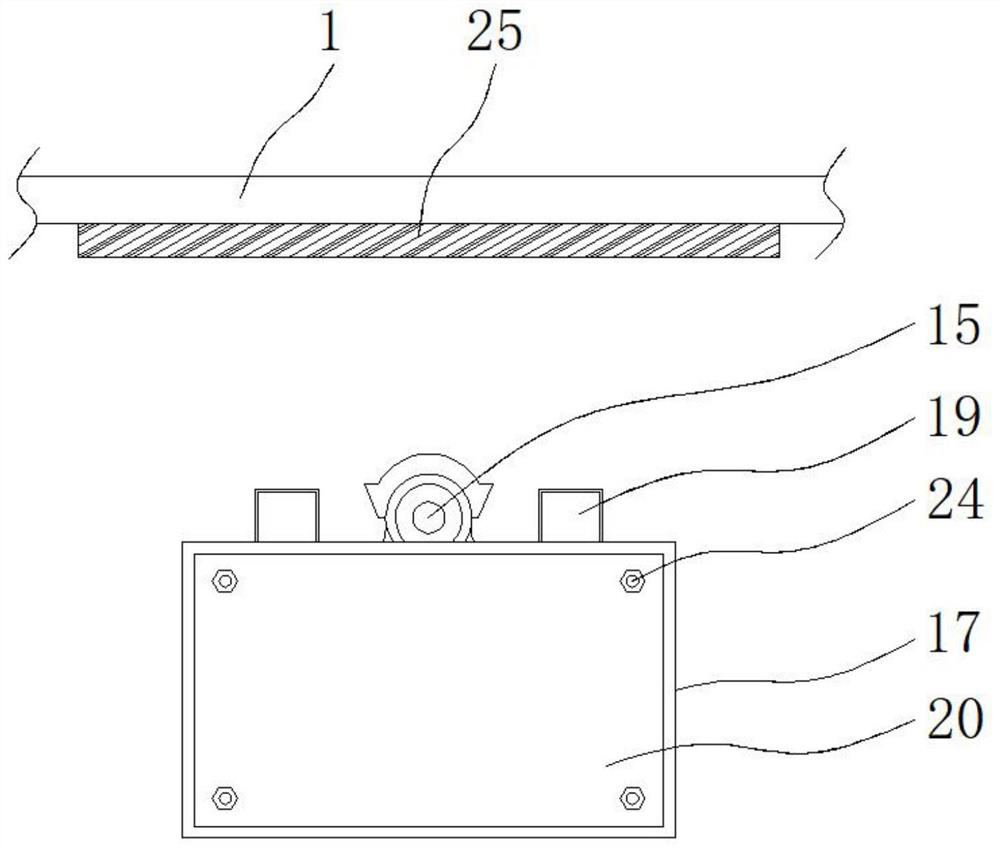

Mobile phone screen click detection equipment with limiting and clamping structure

InactiveCN112040053AEasy to detectReasonable structureSubstation equipmentComputer scienceMechanical engineering

Owner:重庆新禹智能科技有限公司

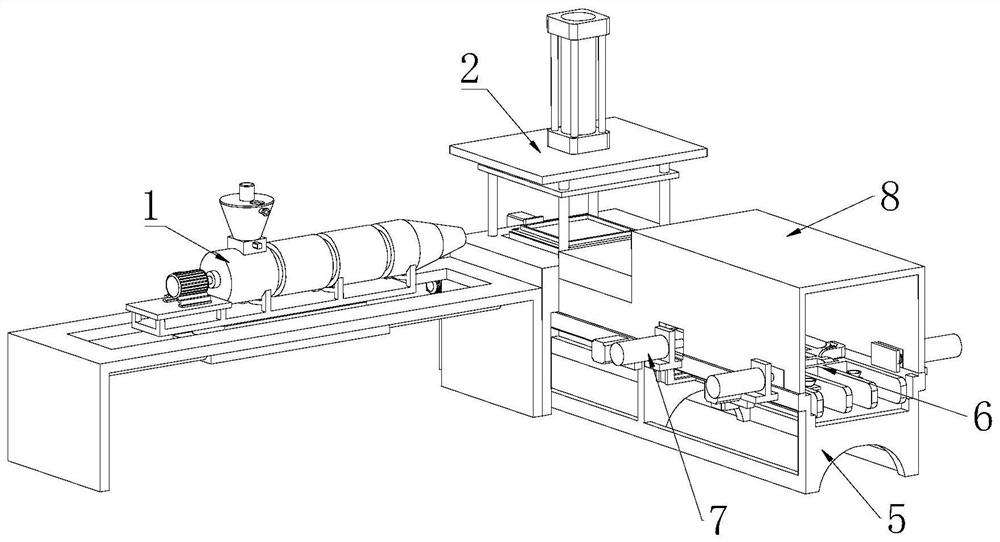

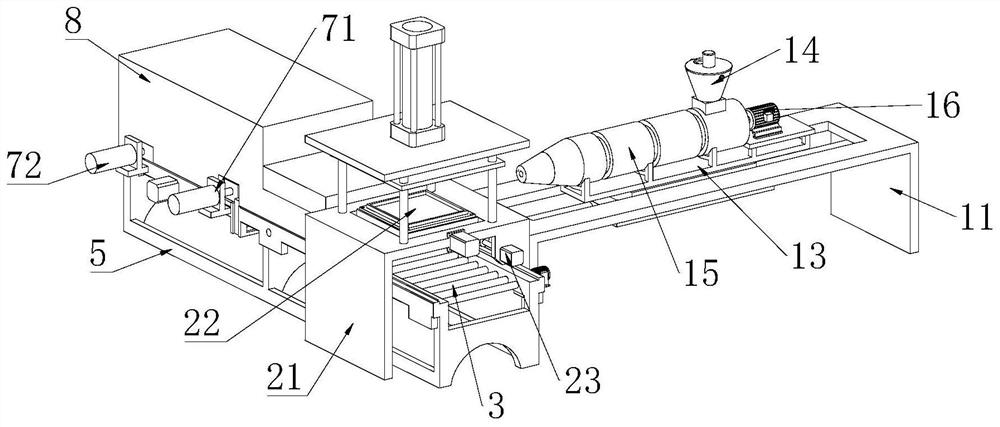

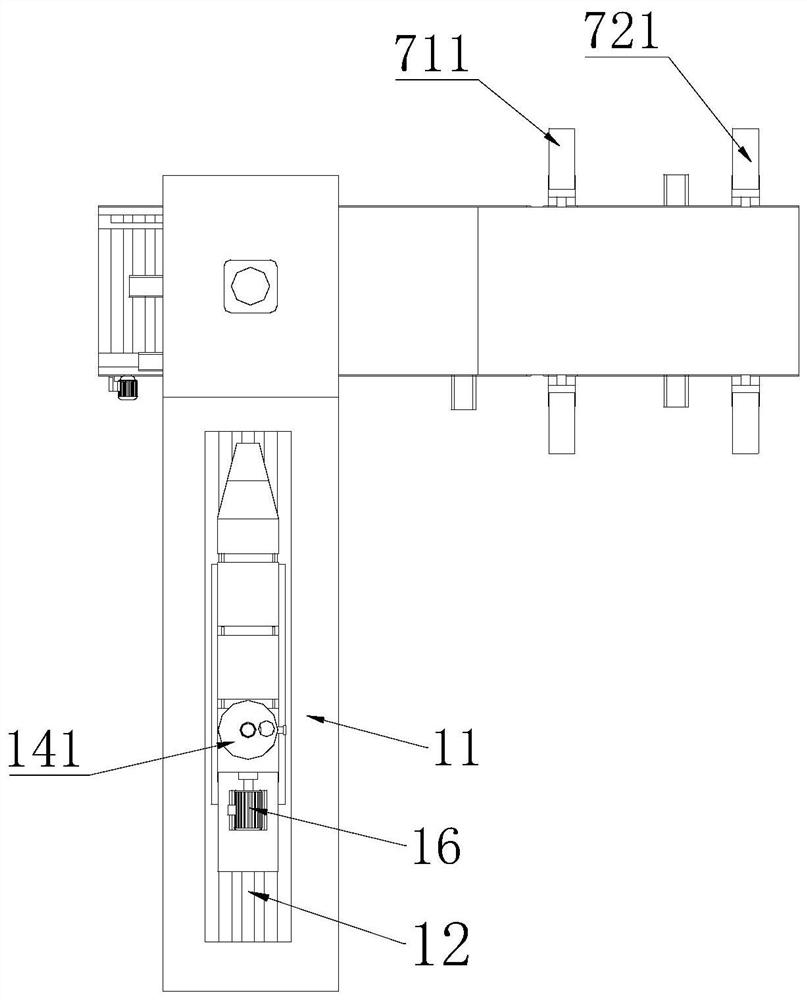

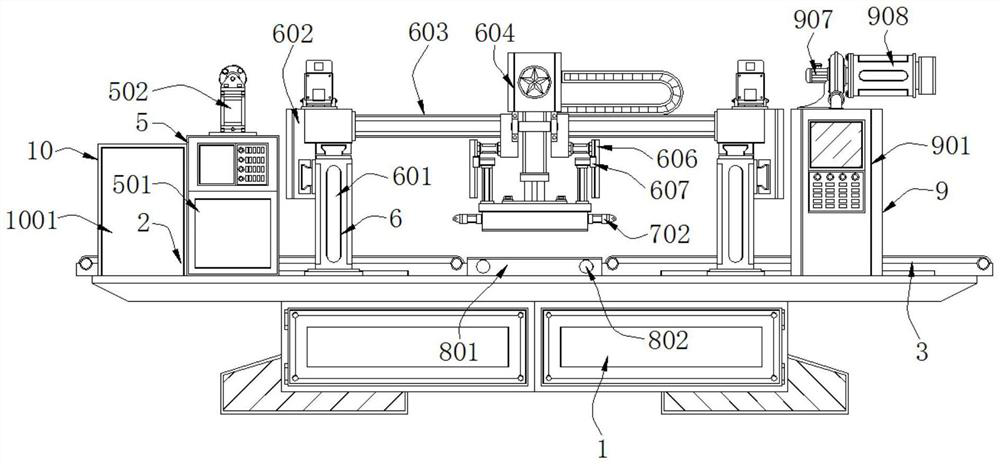

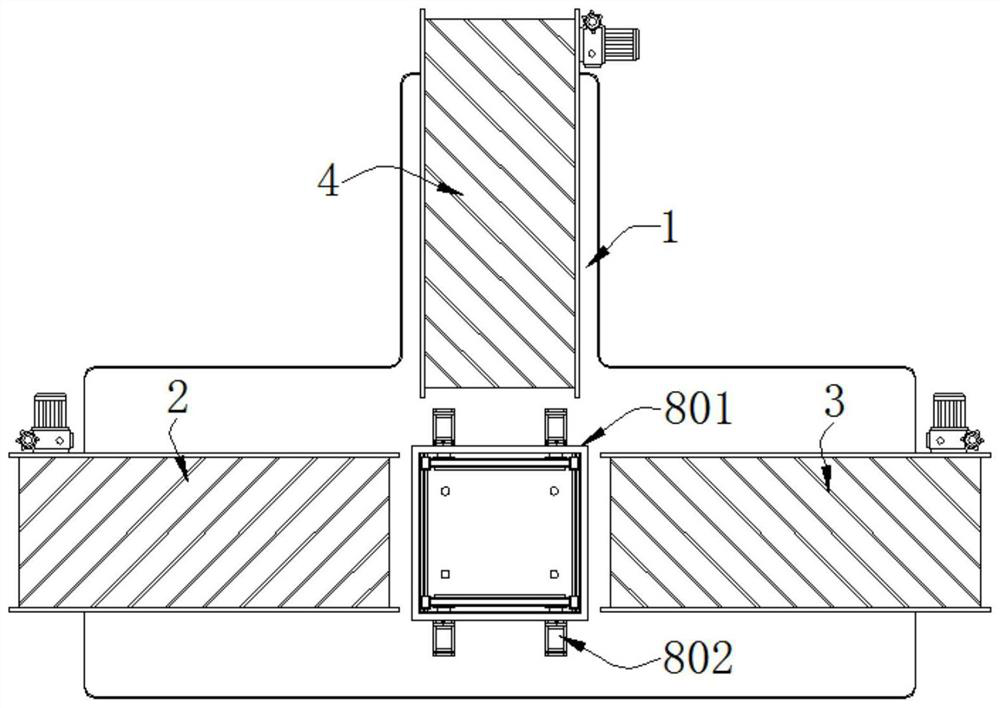

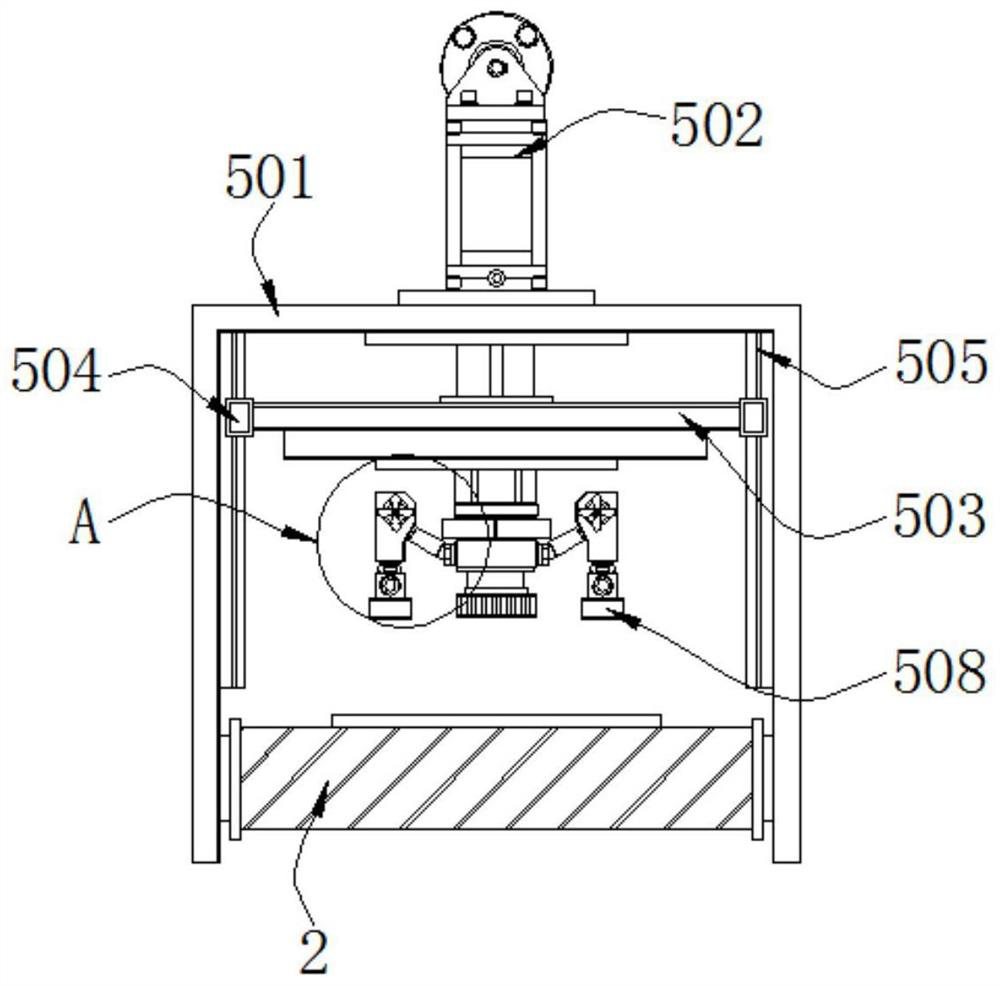

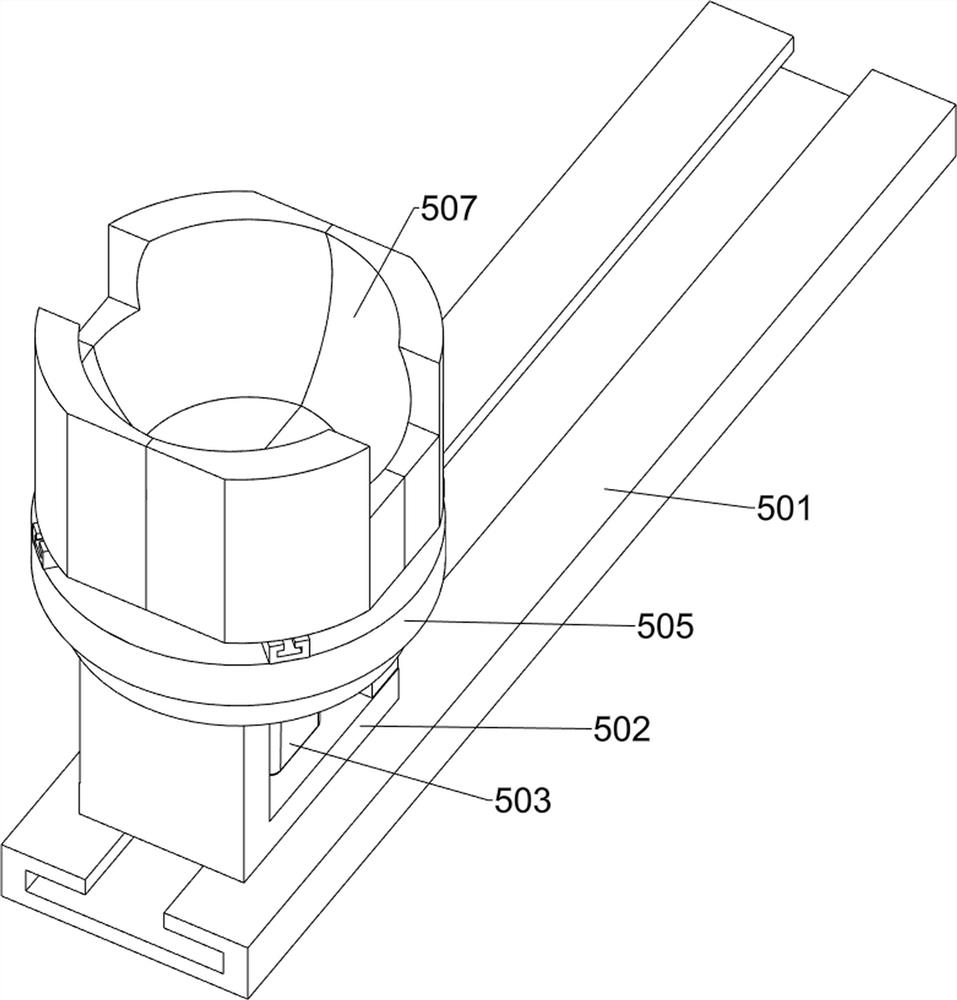

Glass injection molding mold and molding machine tool

ActiveCN113732866AMass productionRealize pressing automatic forming operationEdge grinding machinesGrinding drivesMolding machineSpiral blade

The invention relates to the technical field of glass processing, and provides a glass injection molding mold and molding machine tool. The glass injection molding mold and molding machine tool comprises a feeding mechanism, a molding mechanism, a conveying roller machine, a transition conveying mechanism, a support frame, a turn-over mechanism and a processing mechanism, wherein the feeding mechanism is arranged on one side of the molding mechanism; the conveying roller machine and the support frame are covered with a mounting cover plate; the feeding mechanism comprises a bearing table, a lead screw sliding table, a mounting support, a mixing assembly and an injection molding barrel; the bearing table is transversely arranged on one side of the molding mechanism; the lead screw sliding table is mounted at the inner top of the bearing table; the bottom of the mounting support is connected with the moving end of the lead screw sliding table; the injection molding barrel is fixed to the mounting support; a driving motor is arranged on the mounting support; a heater, a screw rod and a spiral blade are arranged in the injection molding barrel; the output end of the driving motor is connected with one end of the screw rod through a coupler; and the spiral blade is fixed to the screw rod.

Owner:JIANGSU HUIDA MEDICAL INSTR CO LTD

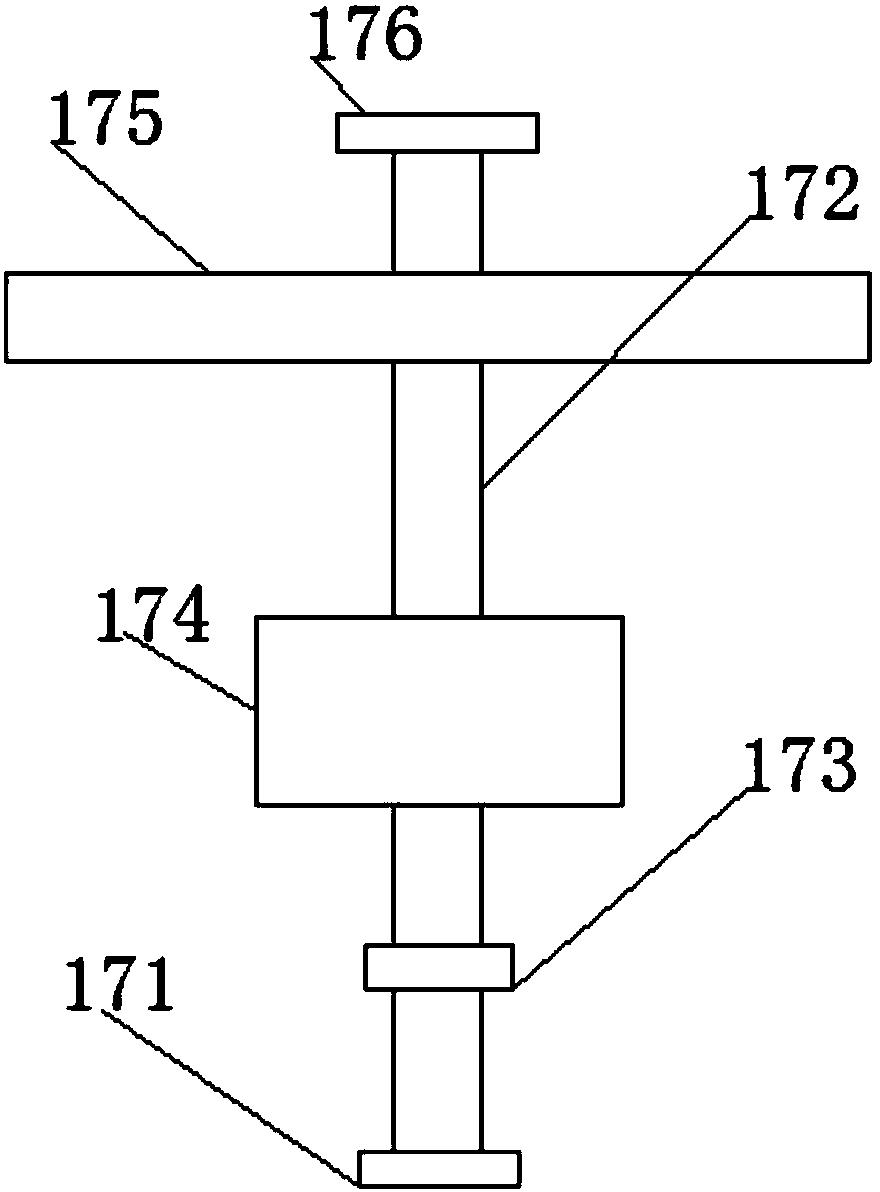

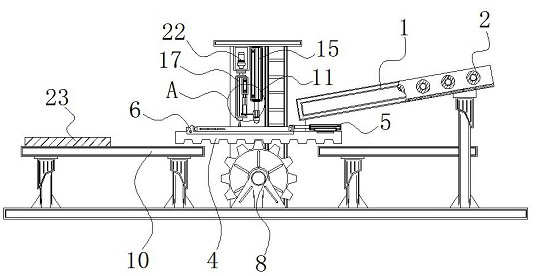

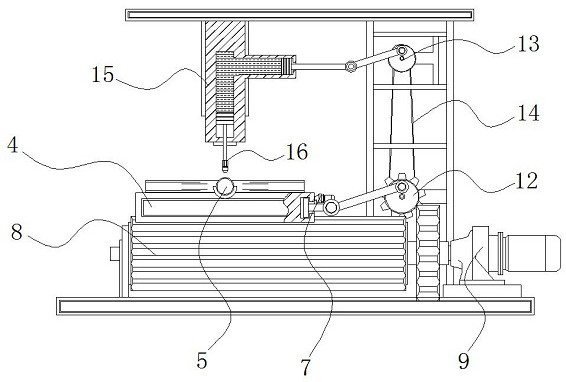

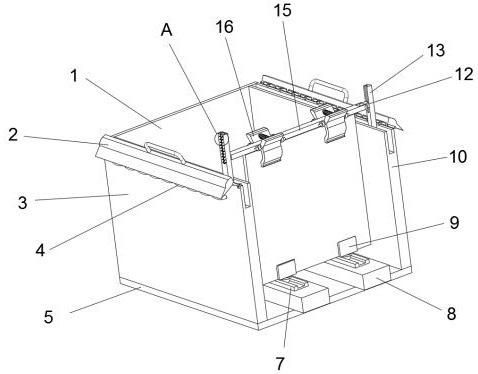

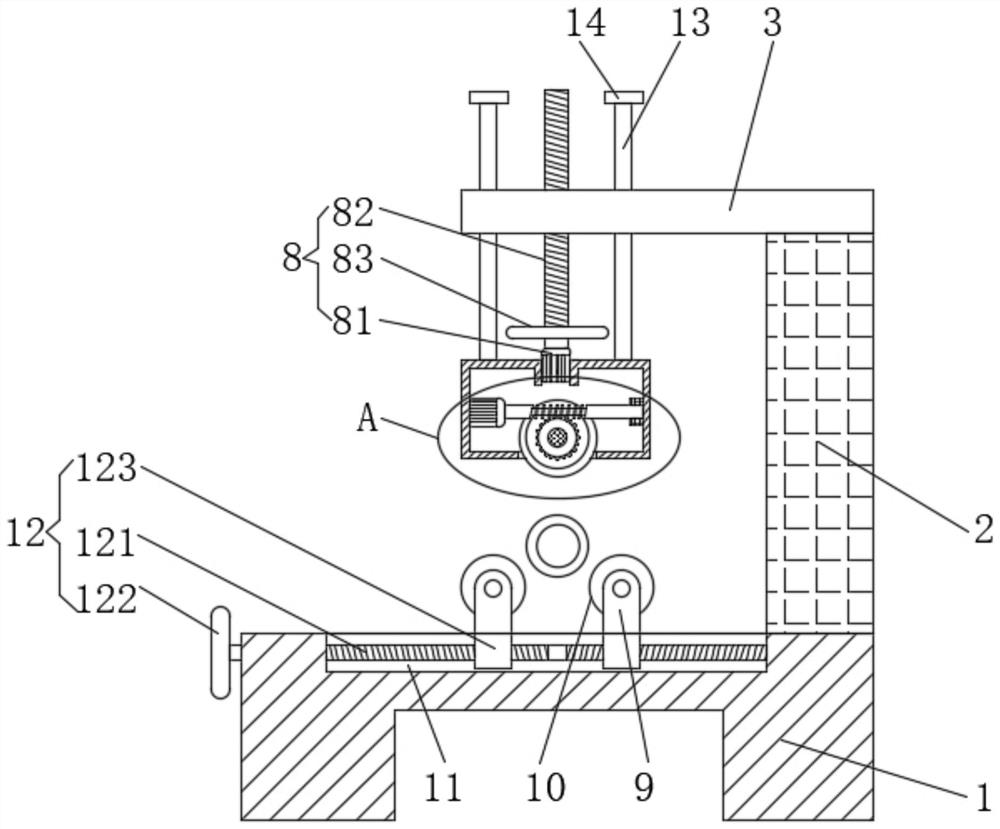

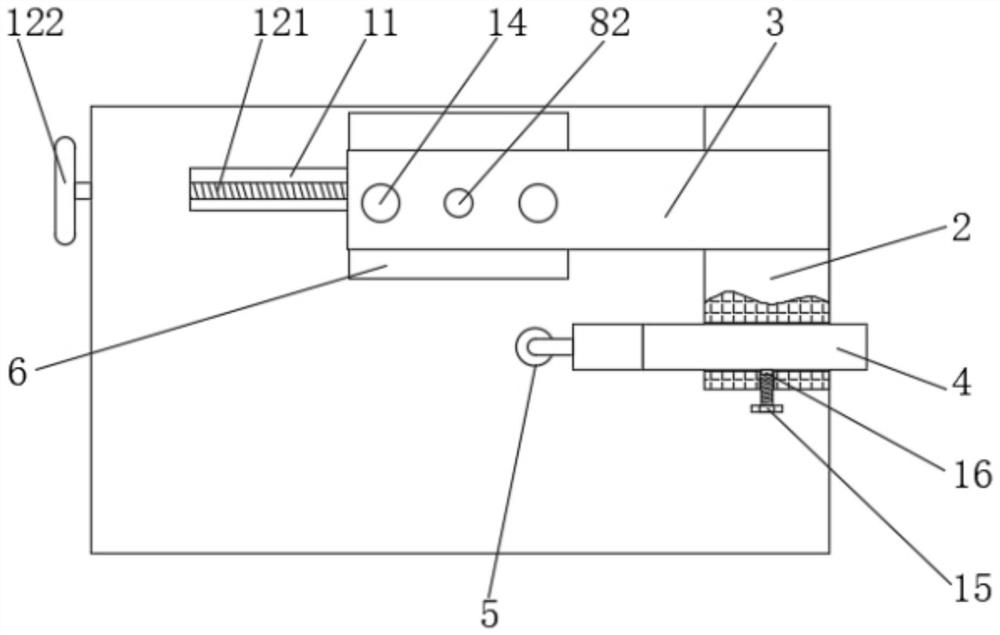

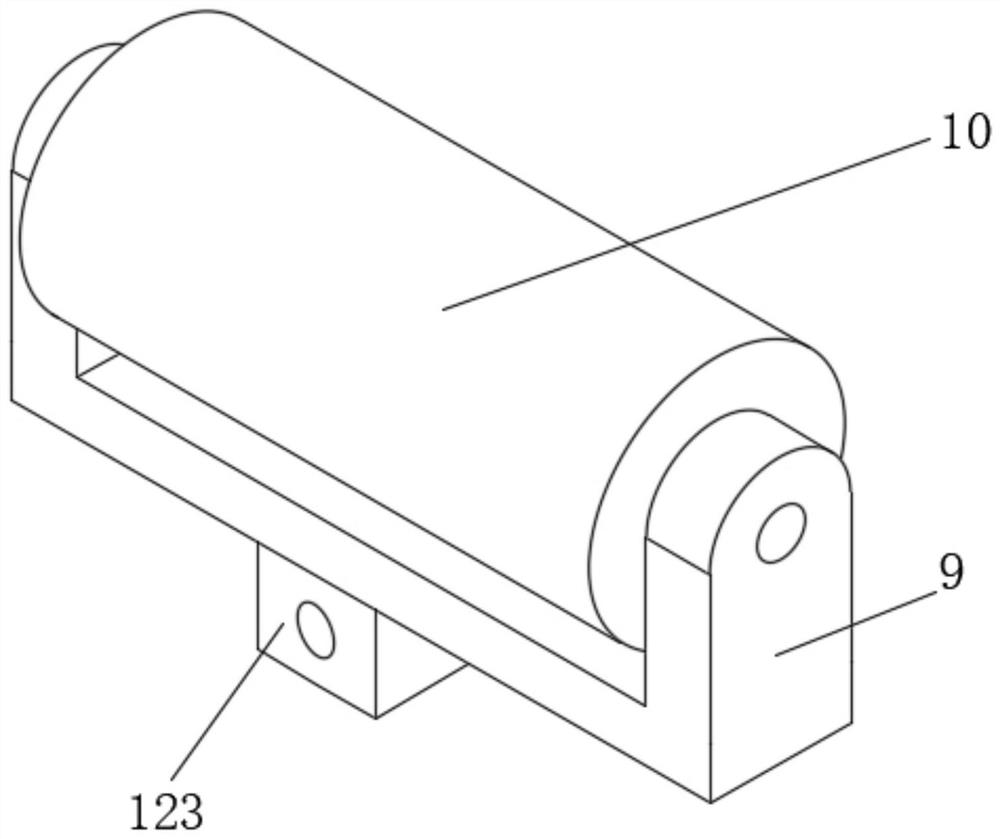

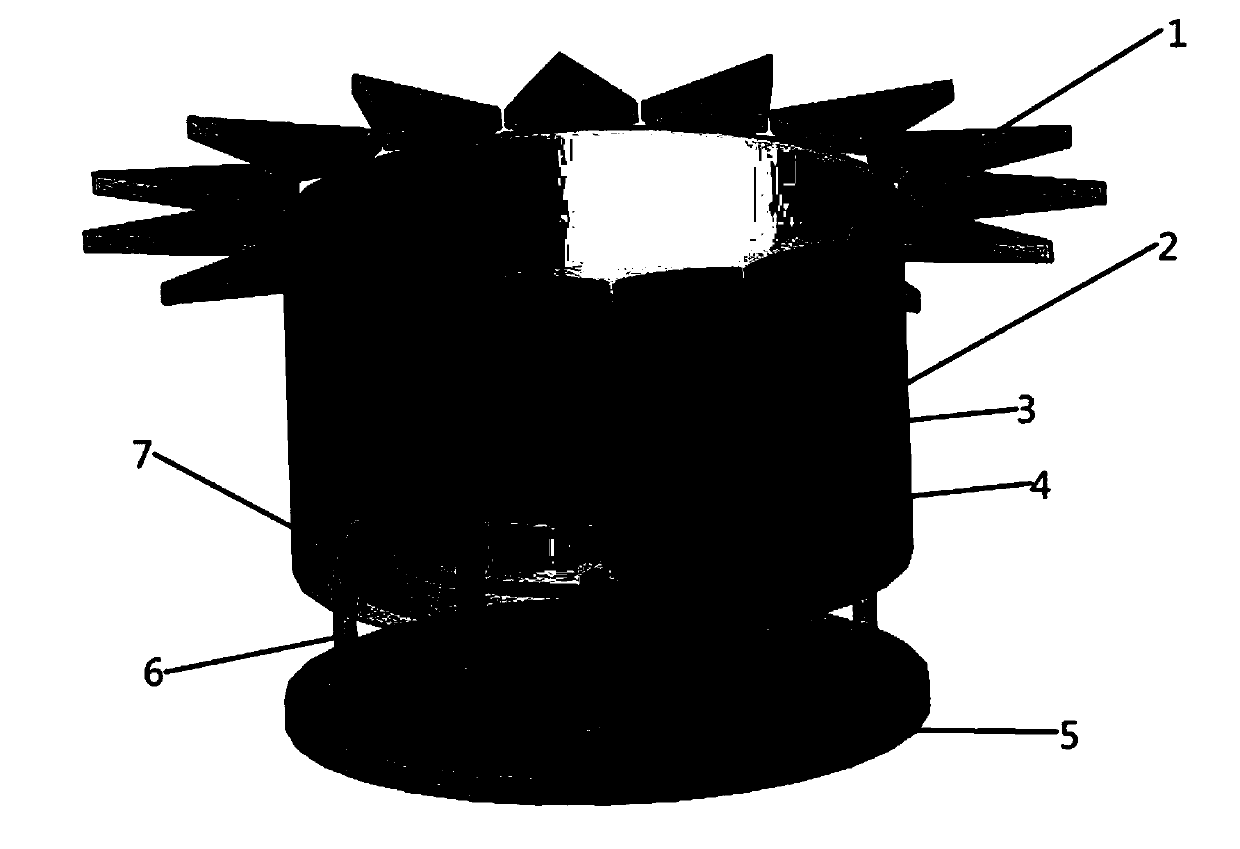

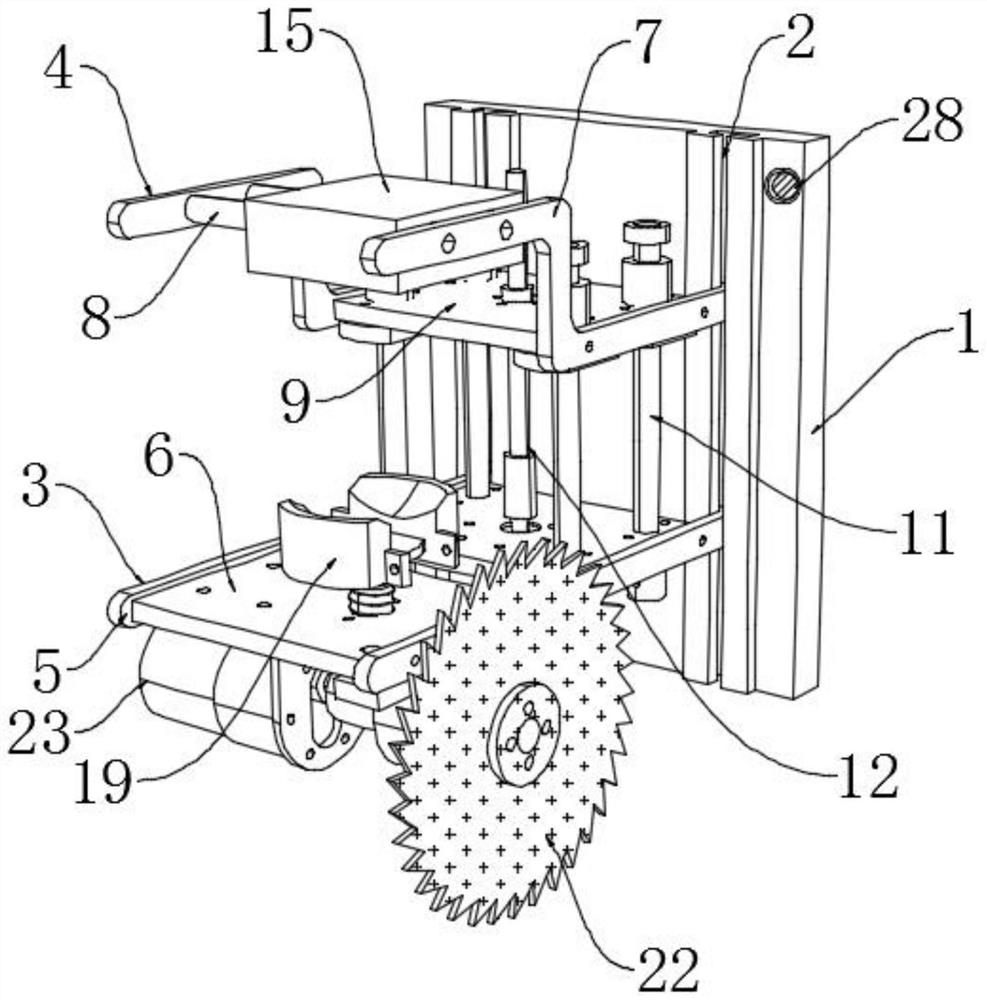

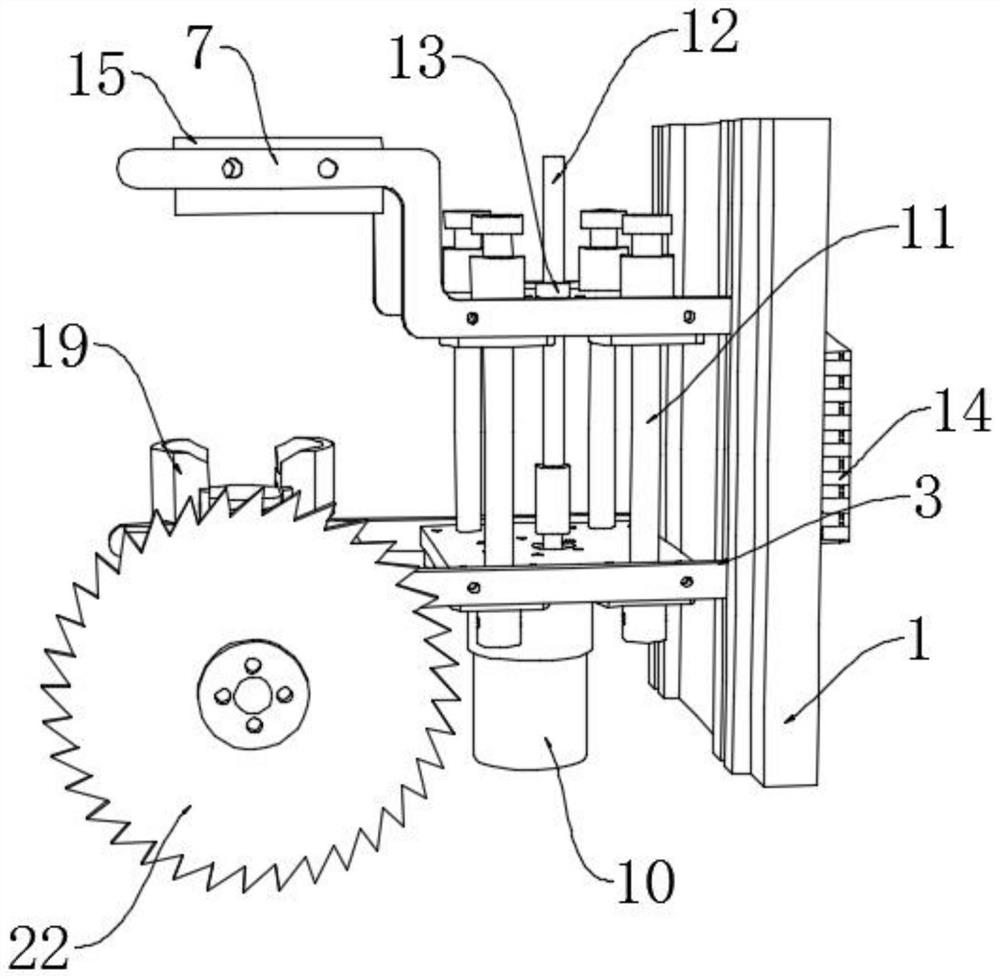

Working method of rough processing equipment for pumpkin pulp removal

InactiveCN112167641AEasy accessAvoid pinch damageFruit stoningFood treatmentProcess engineeringMechanical engineering

The invention relates to the technical field of pumpkin processing, in particular to a working method of rough processing equipment for pumpkin pulp removal. The rough processing equipment comprises abottom frame and a top plate, and further comprises a controller, a lifting mechanism, an adjusting mechanism and a pulp removal mechanism, wherein the top plate is fixedly arranged at the top of thebottom frame, an extension plate is fixedly arranged on one side of the top plate, the controller is arranged at the top of the extension plate, the lifting mechanism comprises a supporting frame, adriving assembly and two lifting assemblies, the adjusting mechanism comprises a horizontal moving assembly, a lifting-lowering assembly, two clamping assemblies and two carrying assemblies, and the pulp removal mechanism comprises a downward pressing assembly, a sliding assembly and a rotary cutting assembly. According to the working method, a pumpkin to be subjected to pulp removal is placed ontwo bearing plates, and the pulp removal processing can be performed on the pumpkin by controlling the controller, so that the operation is simple, safe and efficient, and accurate and controllable, and the processing efficiency of pumpkin pulp removal is greatly improved.

Owner:赵晓静

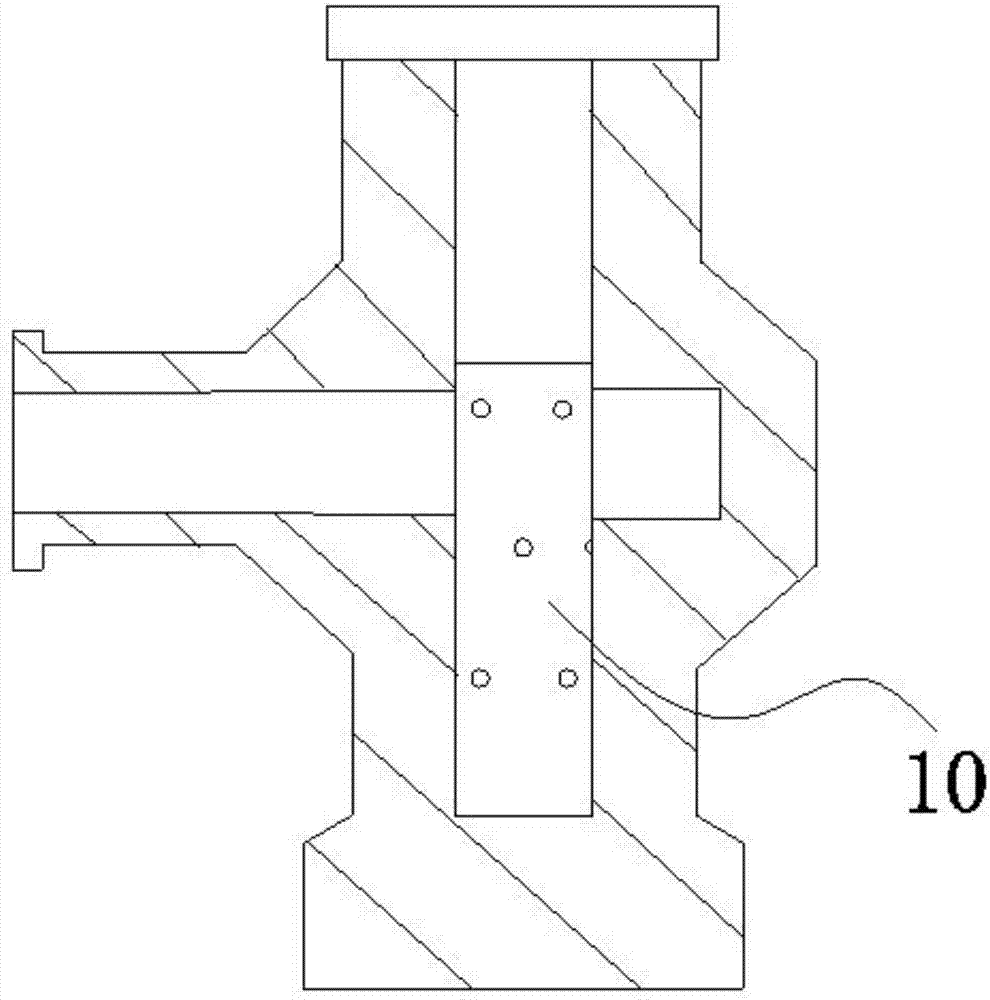

Machining device and method for hard alloy valve element of throttle valve

ActiveCN107538006AAvoid pinch damageReduce processing timeInternal combustion piston enginesThermal insulationStructural engineering

The invention provides a machining device and method for a hard alloy valve element of a throttle valve. The machining device is composed of an outer sleeve, an outer sleeve leakage-proof plate, a partition plate, an inner sleeve, an inner sleeve leakage-proof plate, a punching rod, a working box, a lower squeezing block and an upper squeezing block. The outer sleeve, the outer sleeve leakage-proof plate, the partition plate, the inner sleeve and the inner sleeve leakage-proof plate are sequentially placed on the lower squeezing block from outside to inside, the upper squeezing block is aligned with the axis of the inner sleeve and arranged above the inner sleeve, the working box is a thermal insulation box body, and a base is arranged below the interior of the working box; the lower squeezing block is installed in the middle of the base, a hand grab telescopic rod is arranged on the side face of the base, a hand grab extending to the position above the lower squeezing block is arranged at the top end of the hand grab telescopic rod, and a sliding rail is arranged at the top of the working box; and an upper squeezing block telescopic rod is installed below the sliding rail, the upper squeezing block telescopic rod can slide along the sliding rail, and the lower portion of the upper squeezing block telescopic rod is connected with the upper squeezing block. According to the design of the machining device and method adapting to the hard alloy valve element of the throttle valve, the purpose that a double-layer hard alloy valve element is manufactured is achieved.

Owner:SOUTHWEST PETROLEUM UNIV

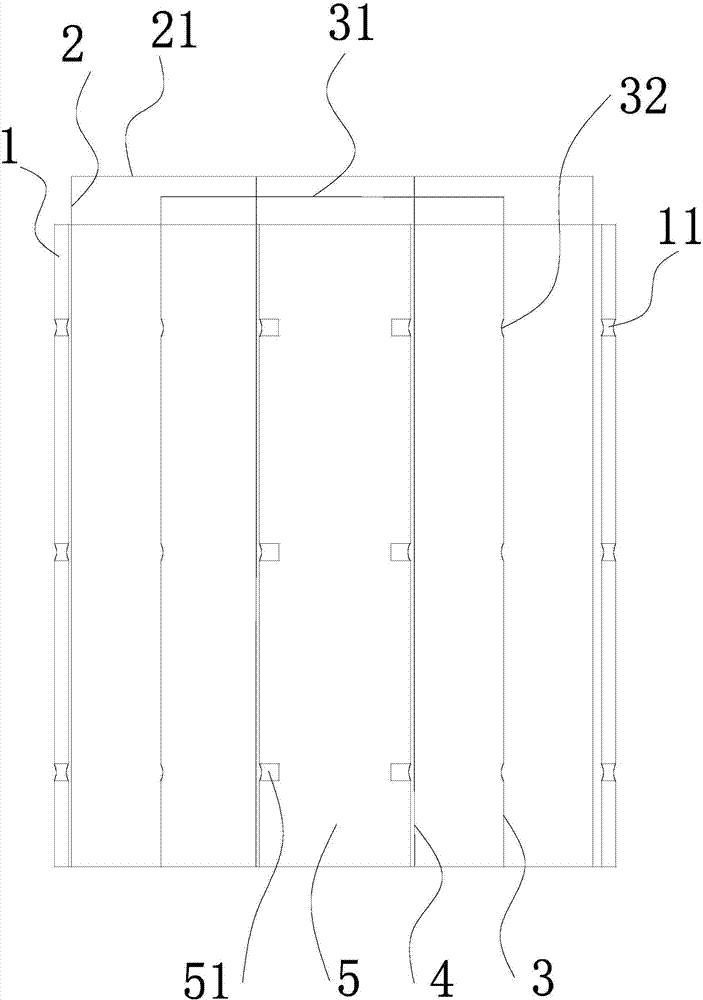

Marble slab clamping frame for background decoration for logistics transportation

ActiveCN111806854AReduce the burden onEasy to removeInternal fittingsLogistics managementBolt connection

The invention discloses a marble slab clamping frame for background decoration for logistics transportation. The marble slab clamping frame aims at solving the problem that time and labor are wasted when a marble slab is fixed and detached. According to the scheme, the marble slab clamping frame comprises a bottom plate, wherein the two sides of the outer wall of the top of the bottom plate are connected with a supporting plate I and a supporting plate II through bolts correspondingly, the outer wall of the top of the bottom plate is connected with a rear supporting plate through bolts, and the rear supporting plate is connected with the supporting plate I and the supporting plate II through bolts; and limiting mechanisms are fixed to the outer walls of the tops of the supporting plate I and the supporting plate II. According to the marble slab clamping frame for background decoration for logistics transportation, during fixing, a clamping rod is rotated, a clamping block is clamped in a supporting column I and is clamped at a designated clamping tooth, and a pressing rod and other original parts connected with the pressing rod are not affected; and when the marble slab is disassembled and taken out, the pressing rod is pressed, all the clamping teeth are pressed into the supporting column I at the same time through transmission clamps, then the clamping rod is moved out, andthe clamping device is conveniently disassembled, so that the device is not influenced by the size of the marble slab when fixing the marble slab, clamping and fixing are more flexible, and the burdenis relieved.

Owner:徐州新畅纺织有限公司

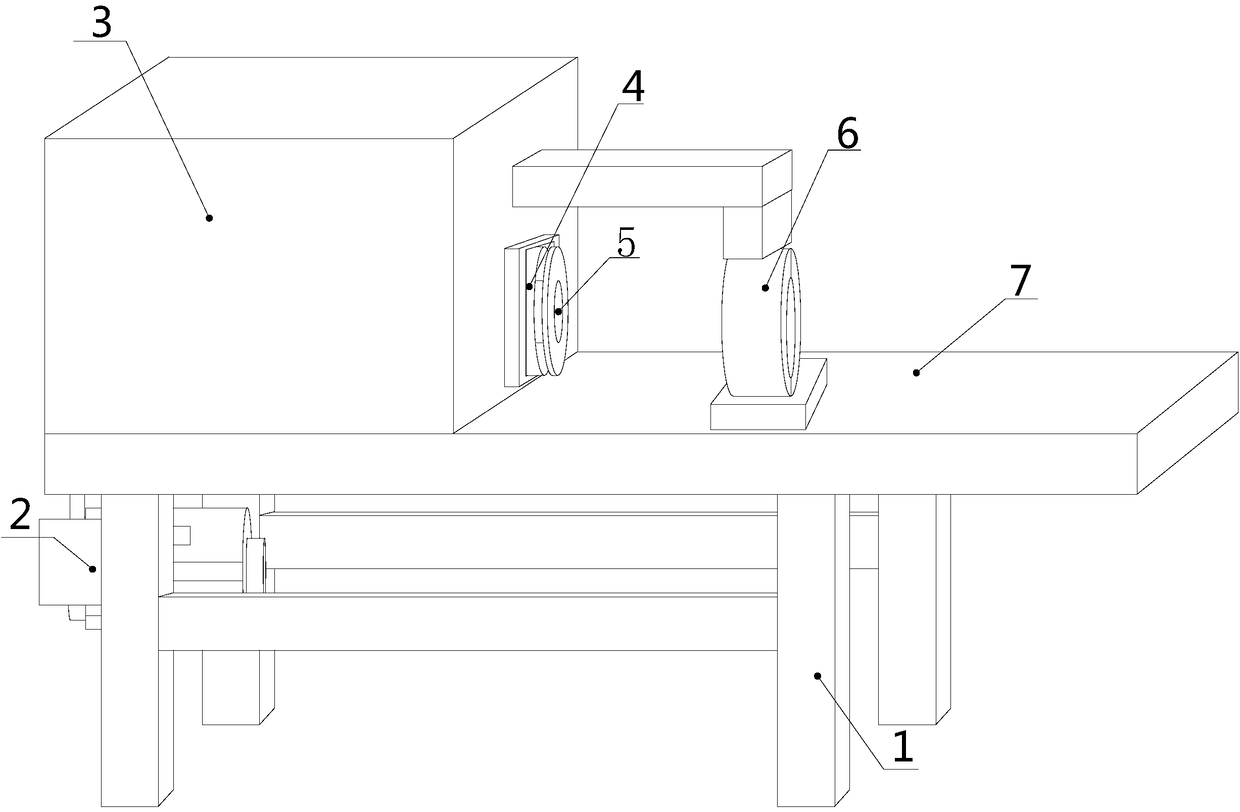

Edging device for glass production and processing

InactiveCN108942503AAvoid pinch damageImprove grinding efficiencyEdge grinding machinesGrinding work supportsSpray nozzleEngineering

The invention discloses an edging device for glass production and processing. The edging device for glass production and processing comprises a protection tank and grinding wheels, wherein the grinding wheels are fixedly arranged on the top part of an inner cavity of the protection tank; a No.2 sliding seat is fixedly arranged on the top part of the protection tank and the bottom part of the innercavity; a hydraulic rod is fixedly connected to one end of the No.2 sliding seat; trays are fixedly connected to one end of the hydraulic rod; rubber non-skid layers are fixedly connected to one sides of the trays; and glass is movably connected to one side of the grinding wheel. According to the edging device for glass production and processing provided by the invention, the glass between the trays is reversed in position through the operation of a No.2 motor, the other two sides of the glass are changed to the other side of the grinding wheel, and finally, No.1 sliding seats are moved to enable the grinding wheel to return so as to grind the other two sides; through arranging the No.2 motor and the trays, the sides of the glass can be automatically changed, so that the grinding efficiency and the quality are improved; and high-pressure spray nozzles are arranged on one side of the grinding wheel and can be used for spraying water for dedusting the side walls of the glass under the condition that water tanks supply water, so that the edging device for glass production and processing is suitable for widely use and popularization.

Owner:贵阳凤林方文科技有限责任公司

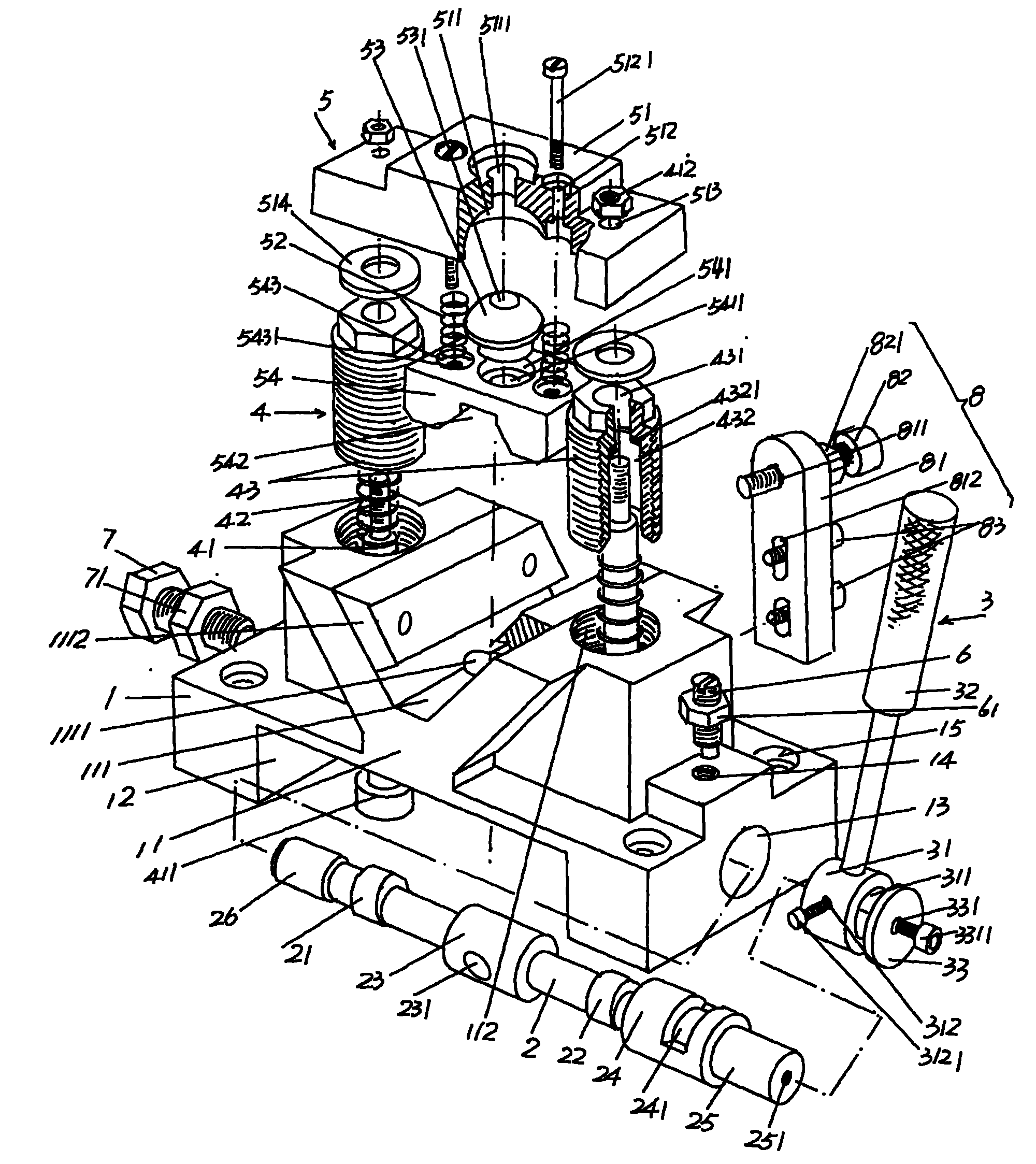

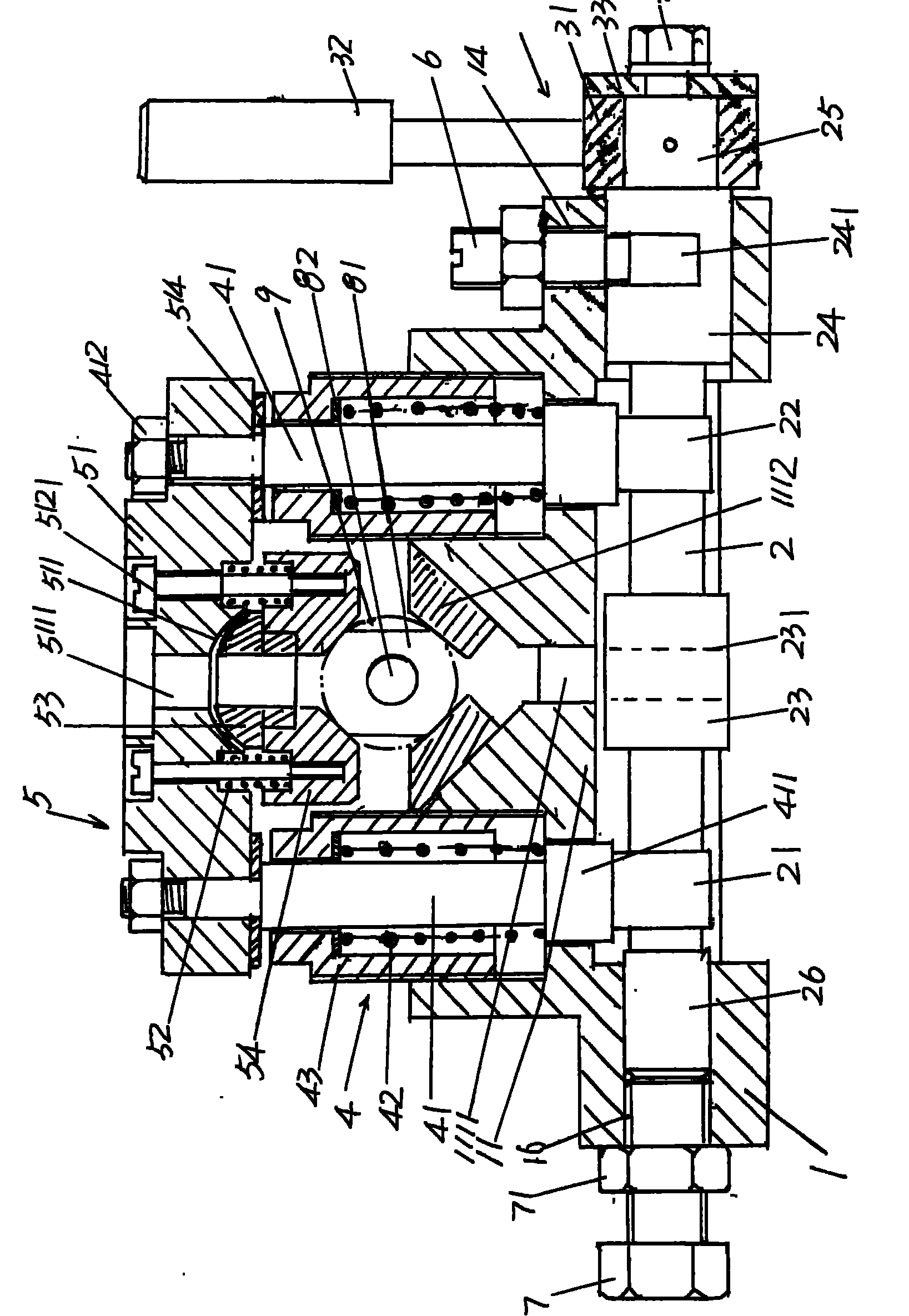

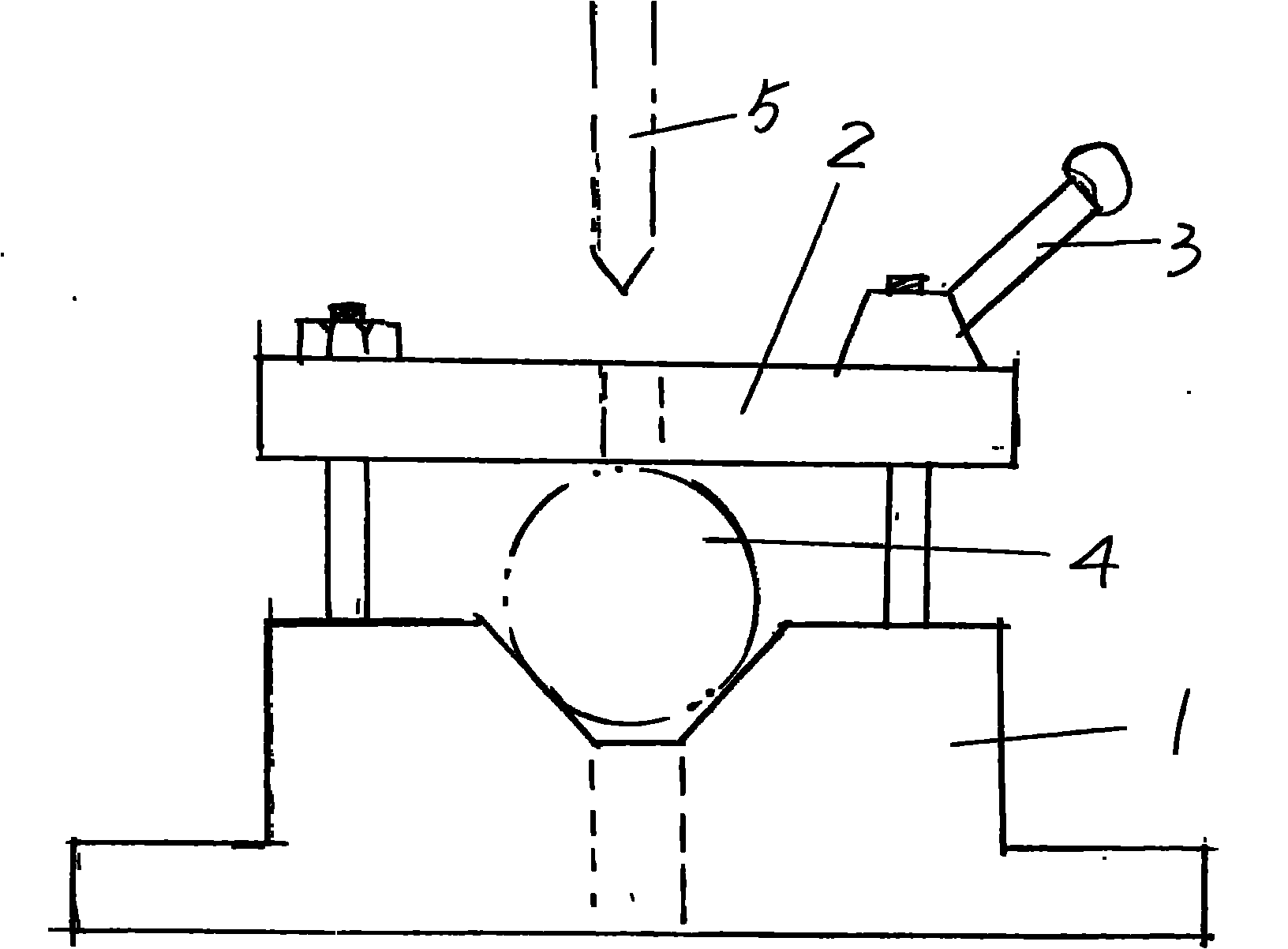

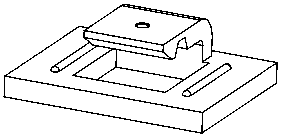

Clamp mechanism for processing piston pin hole of compressor

InactiveCN101695815BAvoid out of toleranceReliable clampingPositioning apparatusMetal-working holdersEngineeringCam

The invention relates to a clamp mechanism for processing a piston pin hole of a compressor, and belongs to the technical field of frock clamps. The clamp mechanism comprises a substrate, a cam shaft, a cam shaft control device, a pair of spherical pair lifting gears and a spherical pair hold-down gear, wherein the bottom of the substrate is provided with a cam cavity; the upper part of the substrate is provided with a workpiece seat; the workpiece seat is provided with a workpiece cavity; the bottom of the workpiece cavity is provided with a cutter through hole; both ends of the cam shaft are rotationally arranged on the substrate; the middle part of the cam shaft corresponds to the inside of the cam cavity; the cam shaft control device is linked with an end part of the cam shaft; the pair of spherical pair lifting gears corresponding to each other is arranged on the workpiece seat of the substrate and corresponds to both sides of the workpiece cavity; lower parts of the pair of spherical pair lifting gears extend into the cam cavity, are in contact with the cam shaft and are actuated by the cam shaft; and the spherical pair hold-down gear is linked with upper parts of the spherical pair lifting gears. The clamp mechanism for processing the piston pin hole of the compressor not only guarantees to reliably clamp a piston to avoid the piston moving about, but also avoids damaging the piston and avoids the deformation of a clamped position of the piston, and has convenient operation.

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

Polishing device used for mechanically machining accessories

ActiveCN112025532AFixing Fixture PolishingSupport for activitiesPolishing machinesGrinding drivesPolishingElectric machinery

The invention discloses a polishing device used for mechanically machining accessories. The polishing device comprises a working table. A fixing frame is fixedly connected to the right side of the topof the working table. A top plate is fixedly connected to the top of the fixing frame. A polishing motor is installed on the front side of the bottom of the left side of the fixing frame in a slidingmanner. A polishing head is fixedly connected to the output end of the polishing motor. An adjusting box is arranged at the bottom of the top plate. A uniform polishing transmission mechanism is fixedly connected to the left side of the inner wall of the adjusting box. According to the polishing device, by means of cooperative use of the working table, the fixing frame, the top plate, the polishing motor, the polishing head, the adjusting box, the uniform polishing transmission mechanism, a height adjusting mechanism, an adjusting frame, a supporting cylinder, a sliding groove and a horizontal adjusting assembly, the problems that an existing pipe polishing device clamps, fixes and polishes a pipe, the pipe cannot be moved during the polishing period, the one-time polishing area is reduced, the polishing position needs to be changed manually, and as a result, the polishing efficiency is low are solved, and the polishing device has the advantage of being high in polishing efficiency.

Owner:山东聊城中泰表业有限公司

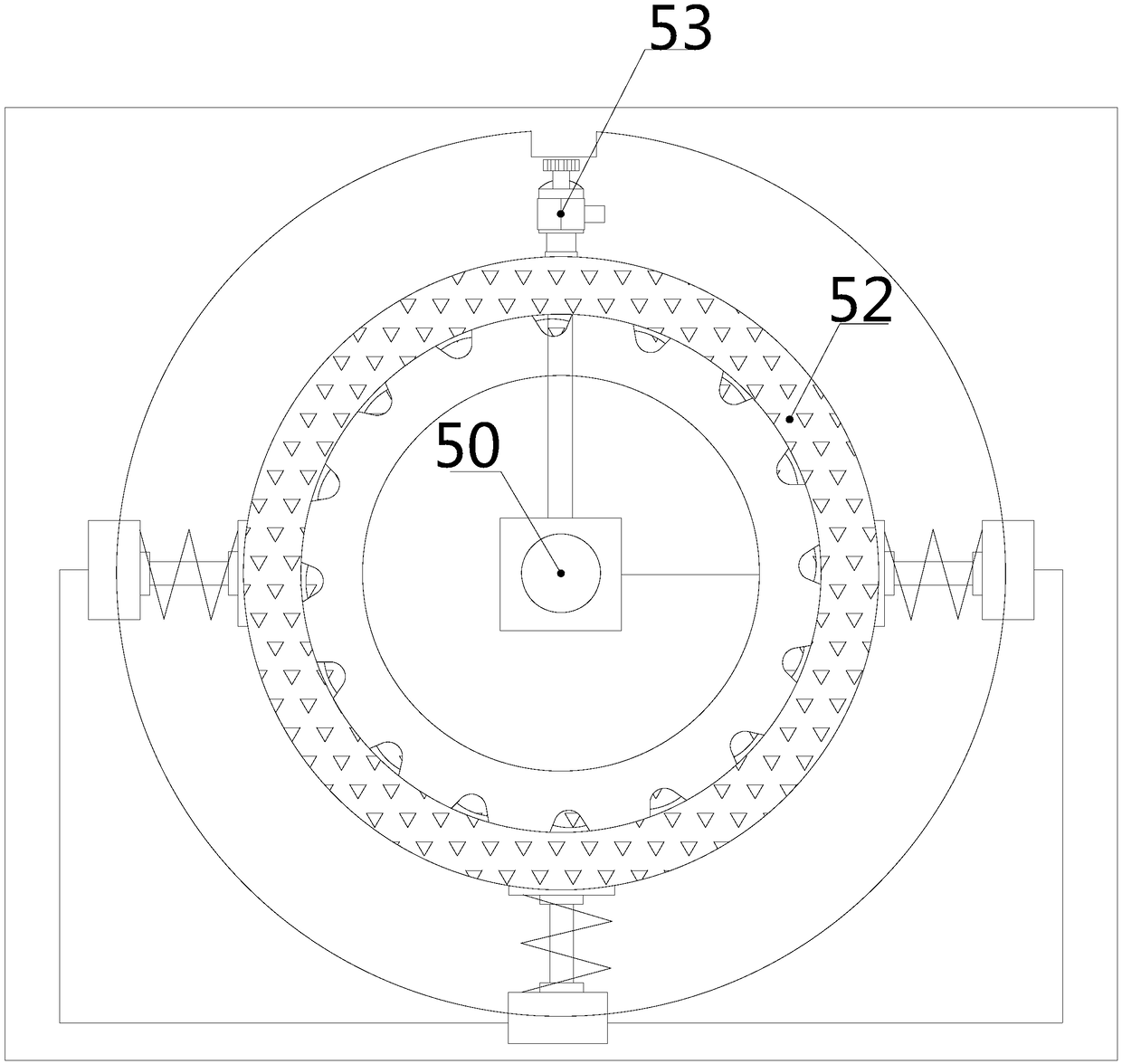

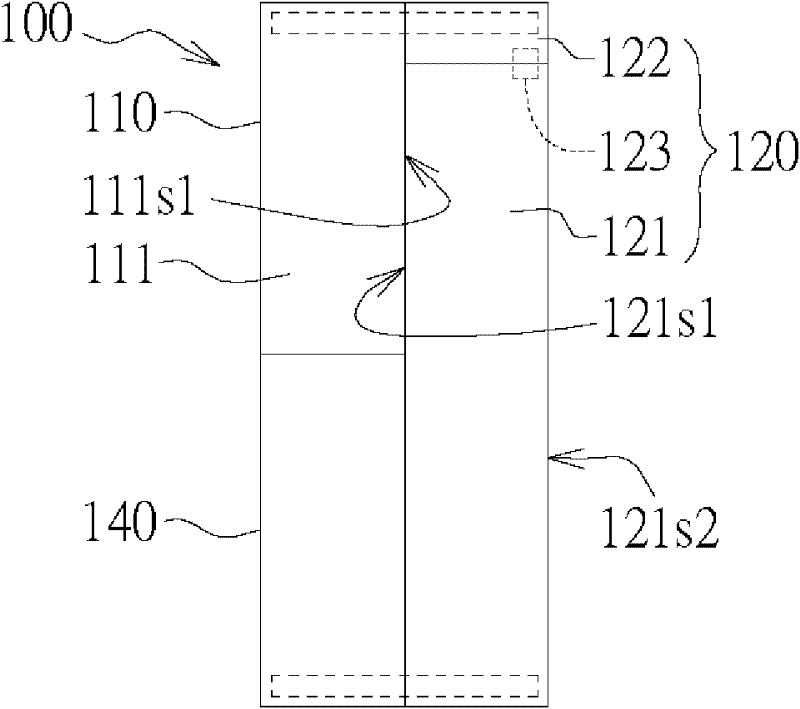

Wafer test equipment

ActiveCN114236337ARealize liftingAvoid pinch damageIndividual semiconductor device testingContinuous operationElectric signal

The invention belongs to the technical field of semiconductor processing, and particularly relates to wafer testing equipment which comprises a base and a mounting plate, the mounting plate is erected above the base, a rubber ball is in contact with a wafer, wafer lifting and air pump operation are achieved, air inlet of an air storage tank is achieved, air inlet of an air bag is achieved through a guide pipe, and after air inlet of the air bag, the air inlet of the air bag is closed. A sliding buckle is arranged at the bottom of the supporting plate, in the pushing process, the sliding buckle slides along a guide rail, center positioning of a wafer is achieved, after clamping, the two sides of the wafer make contact with a trigger button, extrusion of the trigger button is achieved, an electric signal is connected and received by a PLC processor, and air inlet operation is stopped; flexible extrusion and accurate positioning can be realized, clamping damage of a wafer is avoided, the feeding accuracy is ensured, abrasion under conventional calibration actions is reduced, the wafer is better protected, overturning discharging is realized, feeding is synchronously realized, continuous operation can be realized, and the detection efficiency is improved.

Owner:江苏威森美微电子有限公司

Multifunctional unmanned aerial vehicle parking stable charging platform and method

ActiveCN108466567BEasy to fixSmall footprintCharging stationsElectric vehicle charging technologyUncrewed vehicleEngineering

The invention discloses a multifunctional unmanned aerial vehicle stable-parking charging platform and method. The multifunctional unmanned aerial vehicle stable-parking charging platform comprises abase and a hollow column body which is fixed to the base and internally provided with an upper hollow cone frustum and a lower hollow cone frustum, wherein the upper hollow cone frustum and the lowerhollow cone frustum are arranged in a coplanar mode. A hemisphere is embedded into the lower hollow cone frustum and internally provided with an unmanned aerial vehicle signal transferring device, anunmanned aerial vehicle state monitoring device and a wireless power supplying device. An annulus-shaped groove strip is arranged in the gap between the lower cone frustum and the hemisphere, and thewidth of the groove strip is consistent with or slightly larger than the diameter of an unmanned aerial vehicle take-off and landing wheel. The bottom of the hemisphere is connected with the base through a plurality of hydraulic columns. The occupied space of the structure of the stable-parking charging platform is greatly reduced, an unmanned aerial vehicle can be firmly fixed to the platform, and whether the unmanned aerial vehicle is in an ocean or on land, the situation that the unmanned aerial vehicle falls due to severe weathers such as heavy storm waves or the bumpy road conditions, andconsequently the loss is caused can be avoided.

Owner:WUHAN UNIV OF TECH

Full-automatic waterproof plug penetrating crimping machine

ActiveCN113285326ANo manual operationImprove work efficiencyConnection formation by deformationStructural engineeringMachine

The invention belongs to the field of wire harness assembling equipment, and particularly relates to a full-automatic waterproof plug penetrating crimping machine, which comprises a crimping machine shell, driving assemblies, a movable seat, fixed assemblies, a connecting seat, a pushing assembly, a cutting assembly, a winding assembly, a straightening assembly, a sleeving assembly and a crimping assembly. The two sets of driving assemblies are mutually symmetrical, the driving directions are parallel, the two sets of driving assemblies are horizontally installed on the crimping machine shell, the driving ends of the two sets of driving assemblies are located in the crimping machine shell, the two ends of the movable seat are arranged on the driving ends of the two sets of driving assemblies in a transmission and sleeving mode respectively, and the two sets of fixing assemblies are opposite, and are arranged in the movable seat. Through cooperative use of the crimping machine shell, the driving assembly, the movable seat, the fixed assembly, the connecting seat, the pushing assembly, the cutting assembly, the winding assembly, the straightening assembly, the sleeving assembly and the crimping assembly, the crimping machine is fully automatic in the use process, manual operation is not needed, and the working efficiency is higher.

Owner:东莞市新波特电气有限公司

Mechanical clamping jaw with anti-pinch function for garment metal pendant detection

InactiveCN112265014AWith anti-pinch functionAvoid damageProgramme-controlled manipulatorMeasurement devicesElectric machineEngineering

The invention discloses a mechanical clamping jaw with an anti-pinch function for garment metal pendant detection, and relates to the technical field of garment metal pendant detection. The mechanicalclamping jaw specifically comprises a preset sliding rail and an adsorption clamping jaw assembly; the surface of the preset sliding rail is connected with an electric pulley; and the left side surface of the bottom of an electric telescopic rod is provided with a driving motor; one end of a motor rotating shaft penetrates through the side wall of the bottom of the electric telescopic rod and isconnected with a motor box at the same time; one side of a bidirectional water pump is connected with a water conveying hose; and the adsorption clamping jaw assembly is fixed to the bottom of the motor box. According to the mechanical clamping jaw with the anti-pinch function for the garment metal pendant detection provided by the invention, magnetic adsorption is adopted to clamp a pendant, thesurface of the pendant is prevented from being damaged due to uneven stress, the integrity of the pendant is kept, meanwhile, all faces of the pendant can make contact with an induction touch panel ata time, secondary clamping is not needed, the detection efficiency is improved, the structure is simple and reasonable, the production cost is low, and large-scale popularization is facilitated.

Owner:重庆数智源智能装备科技有限公司

Edge bending machine

The invention discloses an edge bending machine. The edge bending machine comprises a machine frame, wherein a fixing base is fixedly arranged at the top of the machine frame through a bolt, the interior of the fixing base is connected with a fixing shaft through a bearing, a fixing frame is fixedly arranged on one side of the fixing base through a bolt, a driving wheel and a driven wheel are fixedly arranged on the fixing frame, one end of the fixing shaft penetrates through the outer wall of the fixing base and is fixedly connected with a servo motor, and a touch screen is fixedly arranged on the fixing base. According to the machine, a conveying belt, a mold plate, a first thumb cylinder, a second thumb cylinder and a clamping block are arranged, so that the stability is high during conveying and fixing a paper tube, and the working continuity is improved; a positioning column and a limiting block are arranged, so that the processing and positioning accuracy of the paper tube is high; and a guiding plate and a roller are arranged, so that the conveying belt can be effectively prevented from deviating, the processing precision is improved, and the working efficiency is further improved.

Owner:东莞市威联数控设备有限公司

Electronic clamp feeding device

InactiveCN108357872AIngenious structureAchieve crawlingJigging conveyorsConveyor partsEngineeringLinear vibration

The invention provides an electronic clamp feeding device, and belongs to the technical field of electronic accessories. The electronic clamp feeding device comprises a machine frame bottom plate, a vibration feeding mechanism and an electronic clamp grabbing mechanism; a linear vibration material groove of the vibration feeding mechanism is installed on a vibration material groove supporting assembly, the left end of the linear vibration material groove is connected to a vibration feeding machine, and an electronic clamp pressing plate is installed on the two sides of the upper end of the linear vibration material groove; a linear vibration adjusting plate of the vibration material groove supporting assembly is installed on an I-shaped supporting base through connecting screws of the adjusting plate, and the linear vibration adjusting plate is further in threaded connection with vibration limiting screws; and a fixed material groove is formed in the right end of the linear vibration material groove, the electronic clamp grabbing mechanism is arranged on one side of the fixed material groove, and a grabbing clamping finger air cylinder of the electronic clamp grabbing mechanism isconnected to a grabbing first clamping finger and a grabbing second clamping finger. According to the electronic clamp feeding device, electronic clamps can be automatically and stably fed one by one,the electronic clamps are small in position deviation, structure is reasonable and compact, reliability is good, and the automation degree is high.

Owner:胡贤娟

Clamping-controllable fruit lossless picking end effector and control method thereof

PendingCN114097428ARealize the clamping force measurement workNot easy to dropProgramme control in sequence/logic controllersPicking devicesControl engineeringAgricultural engineering

The invention discloses a clamping-controllable fruit lossless picking end effector and a control method thereof, the clamping-controllable fruit lossless picking end effector comprises a sliding positioning seat, an interval adjusting assembly is mounted on the inner side of the sliding positioning seat, and a dynamic clamping assembly is additionally arranged on the interval adjusting assembly. By means of coordination and cooperation of all the assemblies and adjustment of the distance between the sliding rack component and the fixed rack component, dynamic adjustment can be effectively conducted on fruits of different sizes, the clamping force of subsequent fruits can be conveniently adjusted, and under cooperation of the dynamic clamping assembly, after the fruits are adjusted to reach the proper clamping force, the fruits can be conveniently clamped, and then the fruits can be conveniently clamped. According to the fruit clamping device, the distance measuring sensor works to measure the deformation quantity of the detection spring and transmits data to the PLC, the clamping force of fruits can be measured, meanwhile, the device has the effects of being adjustable in clamping force and adjustable in clamping range, in the specific use process, clamping of various fruits can be met, and the working efficiency is improved. Meanwhile, the clamping force of different fruits can be accurately adjusted and controlled, and nondestructive picking can be met.

Owner:GUANGDONG POLYTECHNIC OF IND & COMMERCE

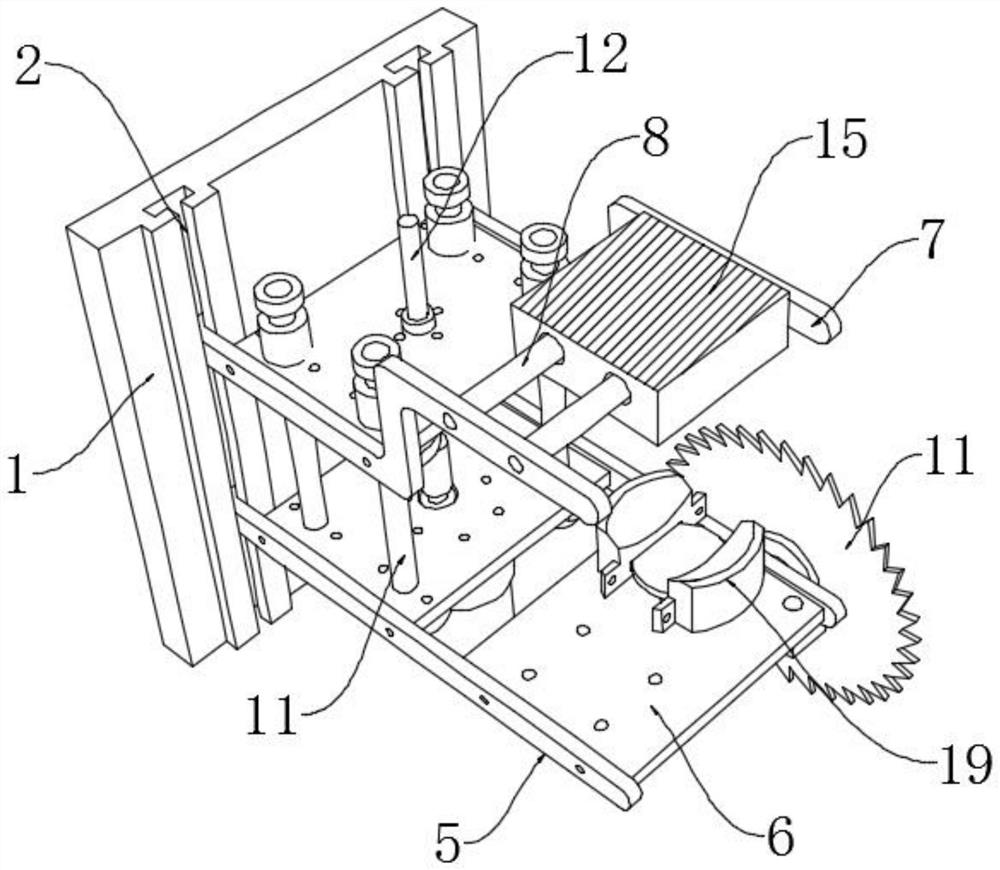

Intelligent production cutting device capable of automatically clamping

ActiveCN108972683ASolve the problem of poor automatic clamping effectImprove clamping effectMetal working apparatusShearing machine accessoriesDrive shaftArchitectural engineering

The invention discloses an intelligent production cutting device capable of automatically clamping. The intelligent production cutting device comprises a clamping box, wherein the right side of the top of the clamping box is fixedly connected with a supporting base; the left side of the top of the supporting base is fixedly connected with a transverse plate; the left side of the bottom of the transverse plate is fixedly connected with a protective cover; the left side of the top of the supporting base is fixedly connected with a drive motor; the output shaft of the drive motor is fixedly connected with a drive shaft through a shaft coupler; the left side of the surface of the drive shaft is in sleeve connection with a cutting blade; the right side of the bottom of the inner wall of the clamping box is fixedly connected with a fixed base; the top of the fixed base is fixedly connected with a clamping mechanism; the left side of the inner wall of the clamping box is fixedly connected with a fixed column; the left side of the top of the fixed base is fixedly connected with a supporting plate; the top of the supporting plate is fixedly connected with the top of the inner wall of the clamping box; the left side of the clamping box is equipped with a manual clamping mechanism; and the right side of the fixed column and the left side of the supporting plate are each fixedly connectedwith an anti-collision mechanism. The intelligent production cutting device capable of automatically clamping disclosed by the invention improves clamping precision and processing efficiency.

Owner:湖南明珠集团有限公司

Method for preparing and forming radial diffuser of large gas turbine

PendingCN113414450AStable and firmEasy to processPositioning apparatusMaintainance and safety accessoriesPhysicsGas turbines

The invention relates to the technical field of diffuser production, and discloses a method for preparing and forming radial diffuser of a large gas turbine. The large gas turbine comprises a mounting base, mounting plates are fixedly connected to the two sides of the top of the mounting base, a supporting plate is fixedly mounted at the tops of the mounting plates, a supporting assembly is arranged at the top of the mounting base, a hydraulic cylinder is fixedly mounted in the middle of the supporting plate, the output end of the hydraulic cylinder is fixedly connected with a fixing plate, covering and pressing assemblies are arranged on the two sides of the bottom of the fixing plate, an annular cooling assembly is arranged at one end of the mounting plate, and a cooling liquid box is fixedly mounted on one side of the top of the supporting plate. According to the manufacturing and forming method for the radial diffuser of the large gas turbine, it is guaranteed that firm clamping treatment can be conducted in the production process of the diffuser, clamping damage to raw materials of the diffuser can be completely eradicated in the clamping process, cooling treatment can be conducted in the machining treatment process of the raw materials of the diffuser, therefore, the quality of the diffuser can be improved, and damage to tools is also avoided.

Owner:山东优洛斯动力科技有限公司

Onboard chuck assembly of plastic ring injection mold

PendingCN106827399AAvoid pinch damageRealize automatic glue cuttingManufacturing engineeringElectrical and Electronics engineering

The invention discloses an onboard chuck assembly of a plastic ring injection mold. The onboard chuck assembly is connected to the tail end of a finished product discharge automatic mechanical arm of injection molding equipment and is characterized by comprising a bottom plate and two or more clamping jaw units connected to the bottom plate; any clamping jaw unit is provided with a rubber mouth chuck corresponding to the center of a plastic ring and a product chuck corresponding to the sidewall of the plastic ring; and all chucks are in bus connection with a controller of the injection molding equipment to do movement in time sequence. The onboard chuck assembly is applied to a demolding unit of the injection molding equipment and has the beneficial effects that injection molded parts are clamped through the rubber mouth chucks and the product chucks in time sequence, so that clamping damage of the chucks to products which are not shaped stably at the early stage of demolding is effectively avoided; automatic rubber cutting of products is realized through staggering of the two kinds of chucks, and the discharge efficiency of the products can be substantially improved.

Owner:SUZHOU INDAL PARK XIELI PLASTIC

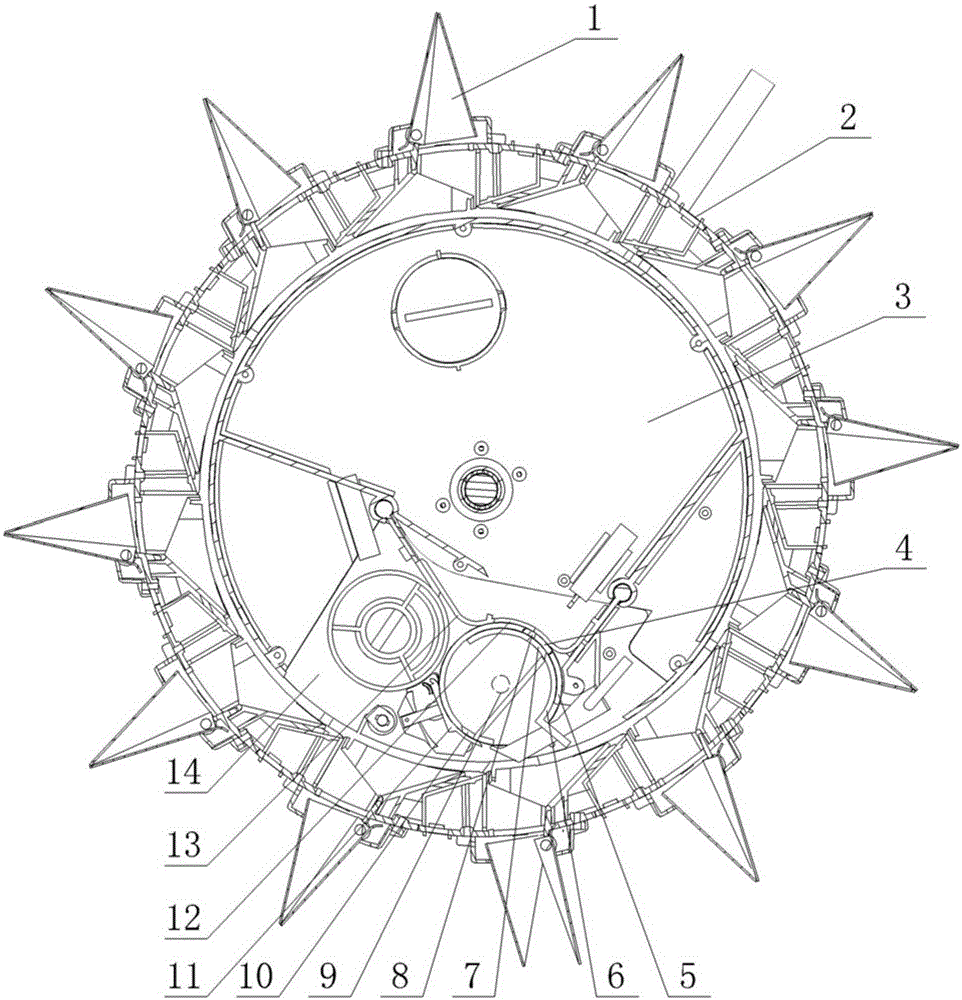

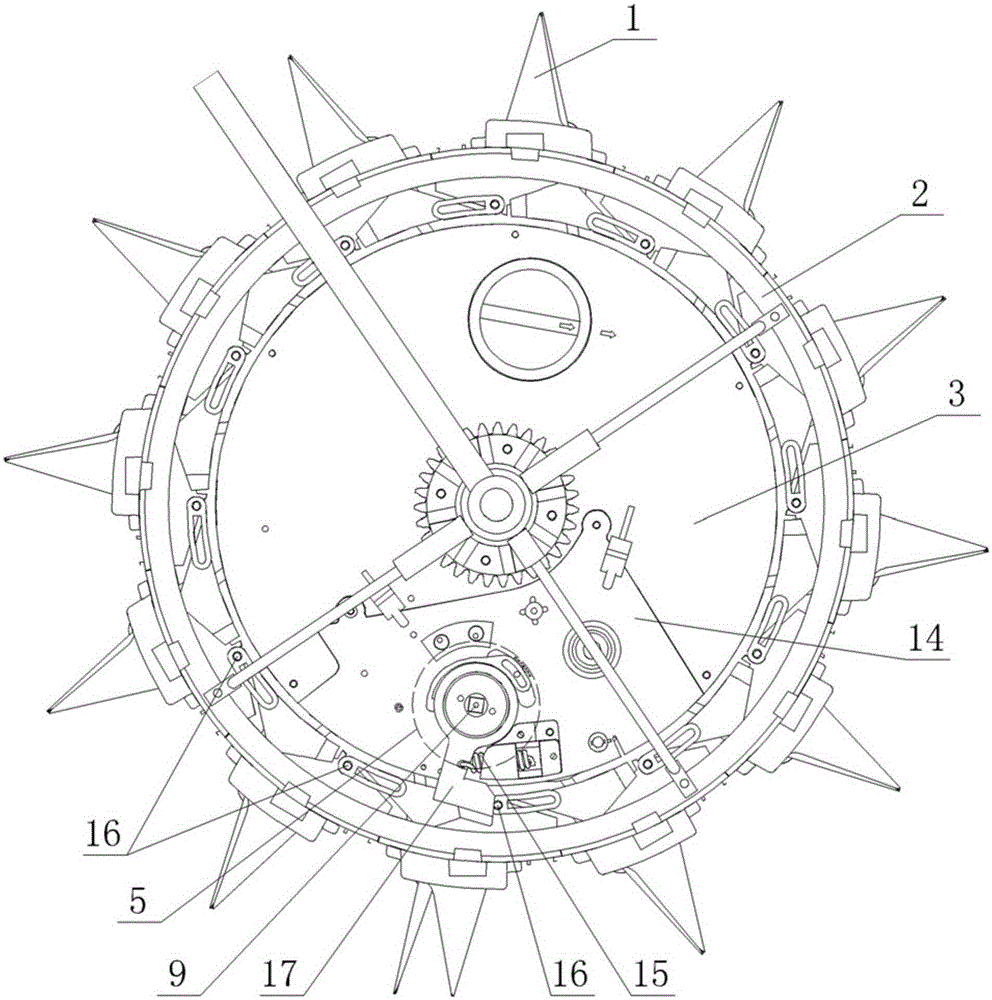

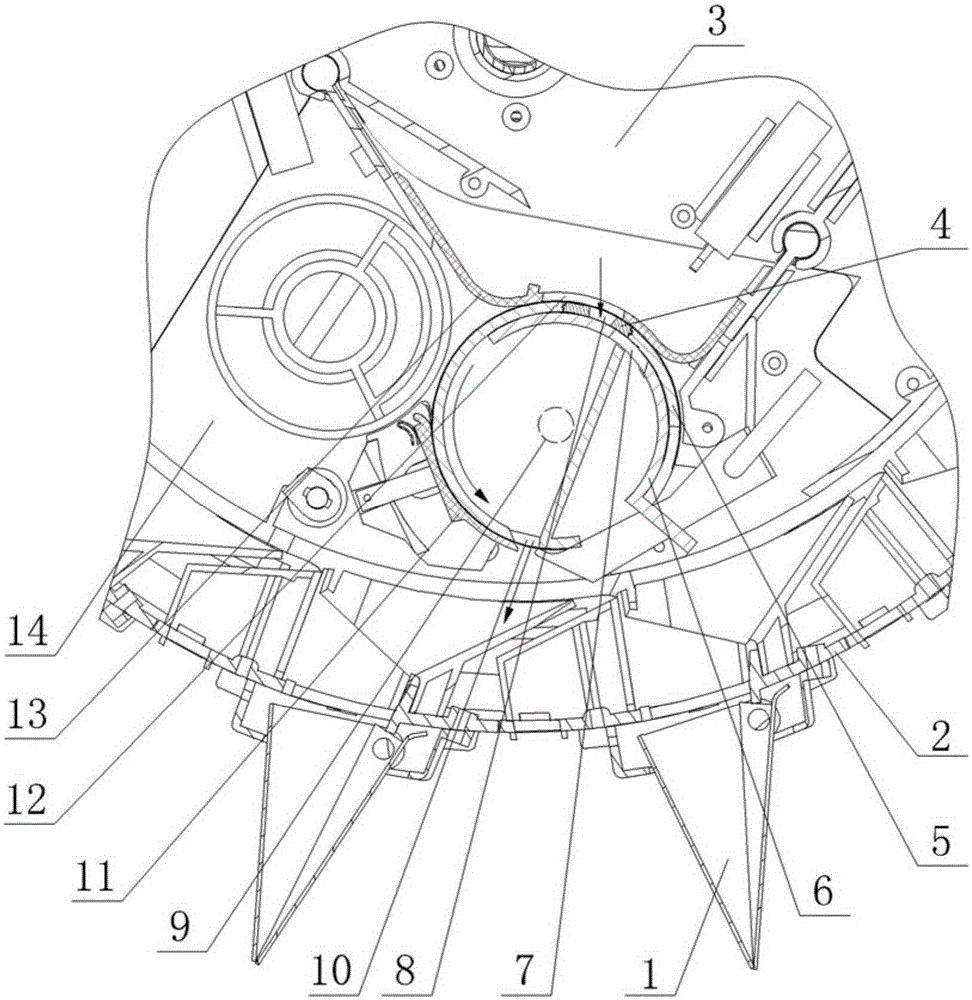

Seed lowering device of a hand-push seeder

The invention discloses a seed discharge device of a hand-pushed seeder. A seed box is arranged inside a shell and is rotationally connected with the shell; a seed discharge device is mounted at the bottom of the seed box; a seed taking wheel is arranged inside the shell of the seed discharge device; two hinging points of the seed taking wheel are respectively a first hinging point and a second hinging point; a swinging arm is arranged at one end of the seed taking wheel; a first baffle is arranged inside the seed taking wheel; a seed leaking hole is formed in the first baffle; a seed taking hole is formed in the seed taking wheel; a seed discharge hole is formed below the seed taking wheel; the seed discharge hole and the seed leaking hole are communicated with each other; a second baffle covers the lower end surface of the seed taking wheel; when the seed taking wheel is positioned at the first hinging point, the seed taking hole of the seed taking wheel is internally communicated with the seed box; the seed discharge hole in the seed taking wheel is communicated with a duckbilled inlet in the shell; when the seed taking wheel is positioned at the second hinging point, the seed taking hole of the seed taking wheel is communicated with the seed leaking hole, and the seed discharge hole of the seed taking wheel is opposite to the second baffle; a shifting rod is mounted on the side surface of the shell. The seed discharge device of the hand-pushed seeder, which is disclosed by the invention, is capable of seeding small-size seeds, and is reliable to use.

Owner:董兆伟

Transfer device with clamping protection structure for display screen production

PendingCN114590588AQuality assuranceAvoid damageConveyorsCleaning using toolsEngineeringProduction quality

The invention discloses a transfer device with a clamping protection structure for display screen production, and relates to the technical field of display screen production, the transfer device comprises a placement seat and a transfer assembly, a feeding conveying belt is arranged in the middle of the left side of the upper end of the placement seat, and a good product conveying belt is arranged in the middle of the right side of the upper end of the placement seat; a defective product conveying belt is arranged in the middle of the rear end of the upper end of the placement base, and a detection assembly used for display screen appearance detection is arranged on the left side of the upper end of the placement base. Through mutual cooperation of a plurality of assemblies, when the display screens are transferred, appearance detection and power-on testing can be conducted on the display screens, the production quality of the display screens is ensured, classified conveying can be conducted on the display screens subjected to detection and testing, classified conveying of good products and defective products is achieved, and the production efficiency is improved. The actual using effect of the display screen transfer device is improved, meanwhile, the good clamping and protecting effect is achieved, and the situation that the display screen is damaged in the clamping and transferring process is avoided.

Owner:江苏雅驹新材料实业有限公司

Self-attaching type separation equipment for inonotus obliquus serving as health-care medicinal material

PendingCN114287295ARealize cutting and pickingAvoid stickinessCultivating equipmentsMushroom cultivationMedicinal herbsMedicine

The invention relates to the field of health-care medicines, in particular to self-attaching type separation equipment for a health-care medicinal material inonotus obliquus. The inonotus obliquus picking machine solves the technical problems that inonotus obliquus grows on a birch, the inonotus obliquus is different in height position, the contact face of the inonotus obliquus and the birch is arc-shaped, and when a knife is used for linearly cutting and picking on the side face, the inonotus obliquus is possibly damaged by cutting the inonotus obliquus, and the picked inonotus obliquus is incomplete. According to the technical scheme, the self-attaching type separation equipment for the inonotus obliquus serving as the health-care medicinal material comprises a first trolley, first wheels, a cutting mechanism and the like; two groups of first wheels are mounted on two sides below the first trolley; and a cutting mechanism is mounted on the first bracket. According to the inonotus obliquus cutting and picking device, the cutting mechanism is designed, inonotus obliquus of different sizes can be cut and picked, the angle adjusting function is achieved, the inonotus obliquus cutting device can be attached to the cutting face of inonotus obliquus on a birch for cutting, bark on the birch is pressed, and the loose cortex layer on the birch is prevented from being attached to the cutting face of the inonotus obliquus during cutting.

Owner:牛玉兰

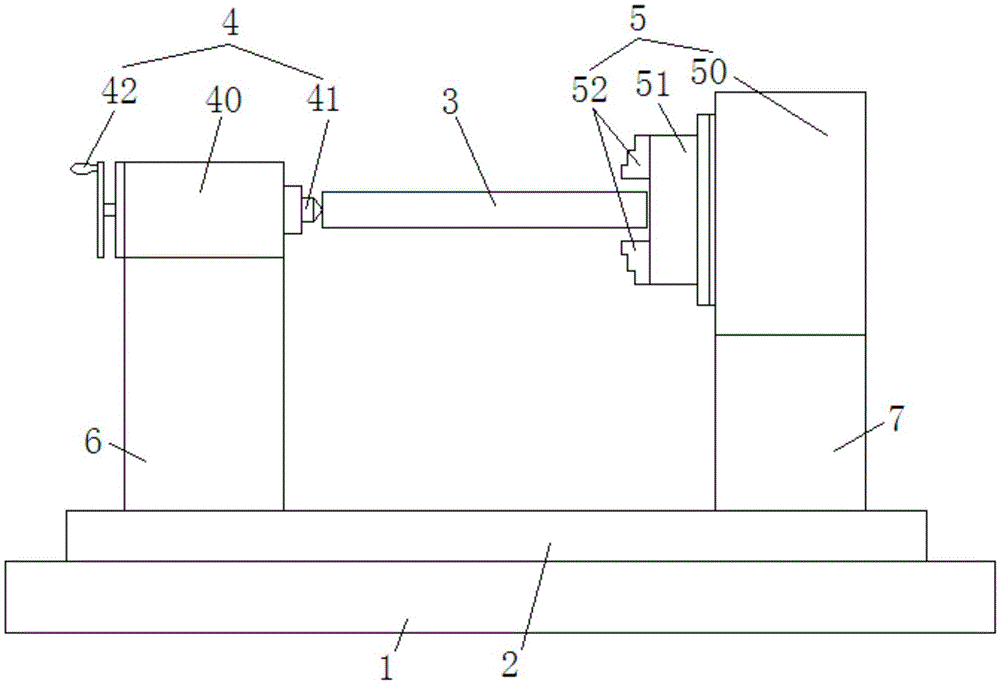

Throat liner machining equipment

InactiveCN105619635AReduce vibrationAvoid pinch damageWorking accessoriesStone-like material working toolsNumerical controlThroat

The invention relates to throat liner machining equipment. The throat liner machining equipment comprises a numerically-controlled machine tool, wherein the numerically-controlled machine tool comprises a saddle; a backing plate is arranged on the upper surface of the saddle; a first fixture and a second fixture are connected and arranged on the backing plate; the second fixture comprises a second fixed support seat; a rotating table is rotationally connected to one side facing the first fixture, of the second fixed support seat, and a clamping element is arranged on the rotating table; the first fixture comprises a first fixed support seat; an ejection rod capable of stretching out towards the direction of the second fixture to eject the end surface of one end departing from the second fixture, of a workpiece, is arranged on the first fixed support seat; during machining, one end of the workpiece is fixed on the clamping element, and the other end of the workpiece is tightly ejected through the ejection rod, thus vibration between a spindle of the numerically-controlled machine tool and the workpiece is reduced, and clamping damages to a drilling part of the workpiece are also avoided; and by using the numerically-controlled machine tool, accuracy during machining is ensured, in addition, the workpiece is driven to transversally move and rotate through the transversal movement carried out through the backing plate and the rotation of the rotating table, and accuracy control is facilitated, thus the production efficiency is improved.

Owner:黄泗平 +2

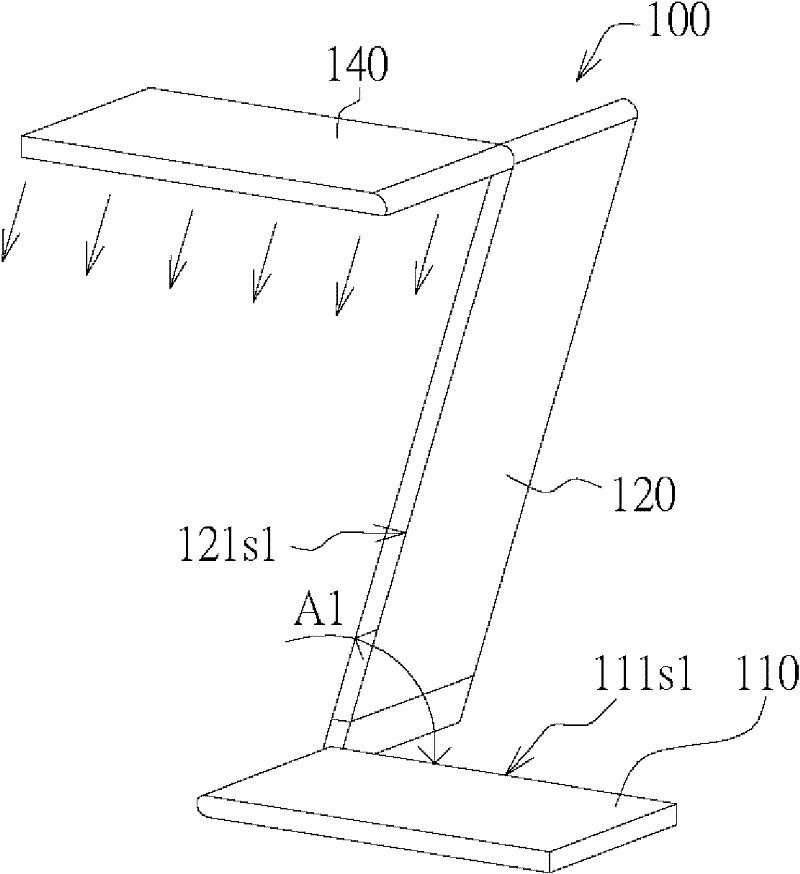

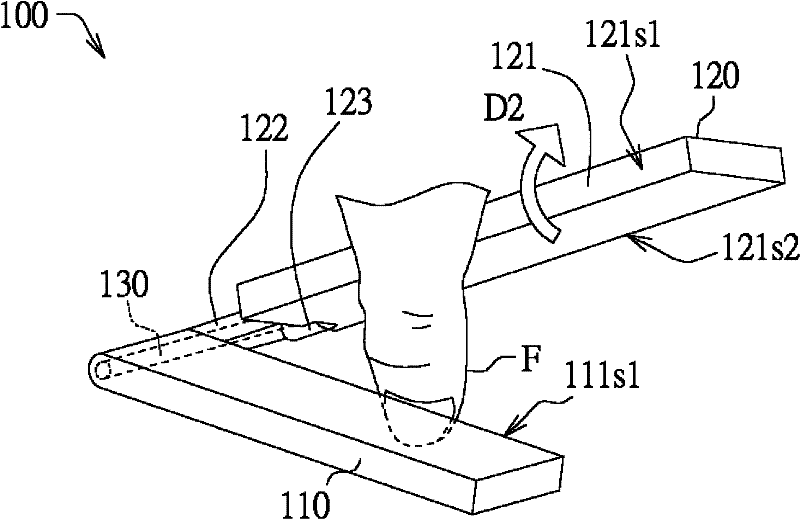

Lighting device

InactiveCN102305365AAvoid pinchingAvoid pinch damageLighting support devicesFree standingEffect lightEngineering

Owner:广州环球电器有限公司

Appearance detection equipment with clamping damage prevention structure for vehicle solar photovoltaic panel

InactiveCN112615588AImprove adsorption capacityAffect healthPhotovoltaic monitoringPhotovoltaic energy generationEngineeringWaste material

The invention relates to appearance detection equipment with a clamping damage prevention structure for a vehicle solar photovoltaic panel. The appearance detection equipment comprises a machine body and a camera, wherein a fixed door is arranged in the middle of the front end of the machine body, a movable door is arranged on the outer side of the fixed door, a handle is arranged on the surface of the movable door, and a magnetic attraction strip is arranged at a front end of the side face of the movable door; a display lamp is arranged at an upper end of the machine body, a storage box is arranged on the left side of the front end of the lower portion of the machine body, a waste box is arranged on the right side of the storage box, a pull handle is arranged on the surface of the waste box, a containing cabinet is arranged on the right side of the machine body, and a computer is arranged at the upper end of the containing cabinet. The appearance detection equipment with the clamping damage prevention structure for the vehicle solar photovoltaic panels is provided with the abutting columns, the solar photovoltaic panels between the abutting columns are effectively and tightly clamped and fixed by the abutting columns under the elasticity of the rear springs, and the contact surface with the solar photovoltaic panels is reduced as much as possible; and the solar photovoltaic panel is prevented from being clamped and damaged due to the fact that the solar photovoltaic panel is clamped and fixed.

Owner:西藏易华路信息技术服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com