Intelligent production cutting device capable of automatically clamping

An intelligent production and automatic clamping technology, applied in shearing devices, accessories of shearing machines, metal processing, etc., can solve the problem of reducing clamping accuracy and processing efficiency, poor clamping effect, and increasing operation risk. and other problems, to achieve the effect of good clamping effect, easy and fast clamping, and improved clamping accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

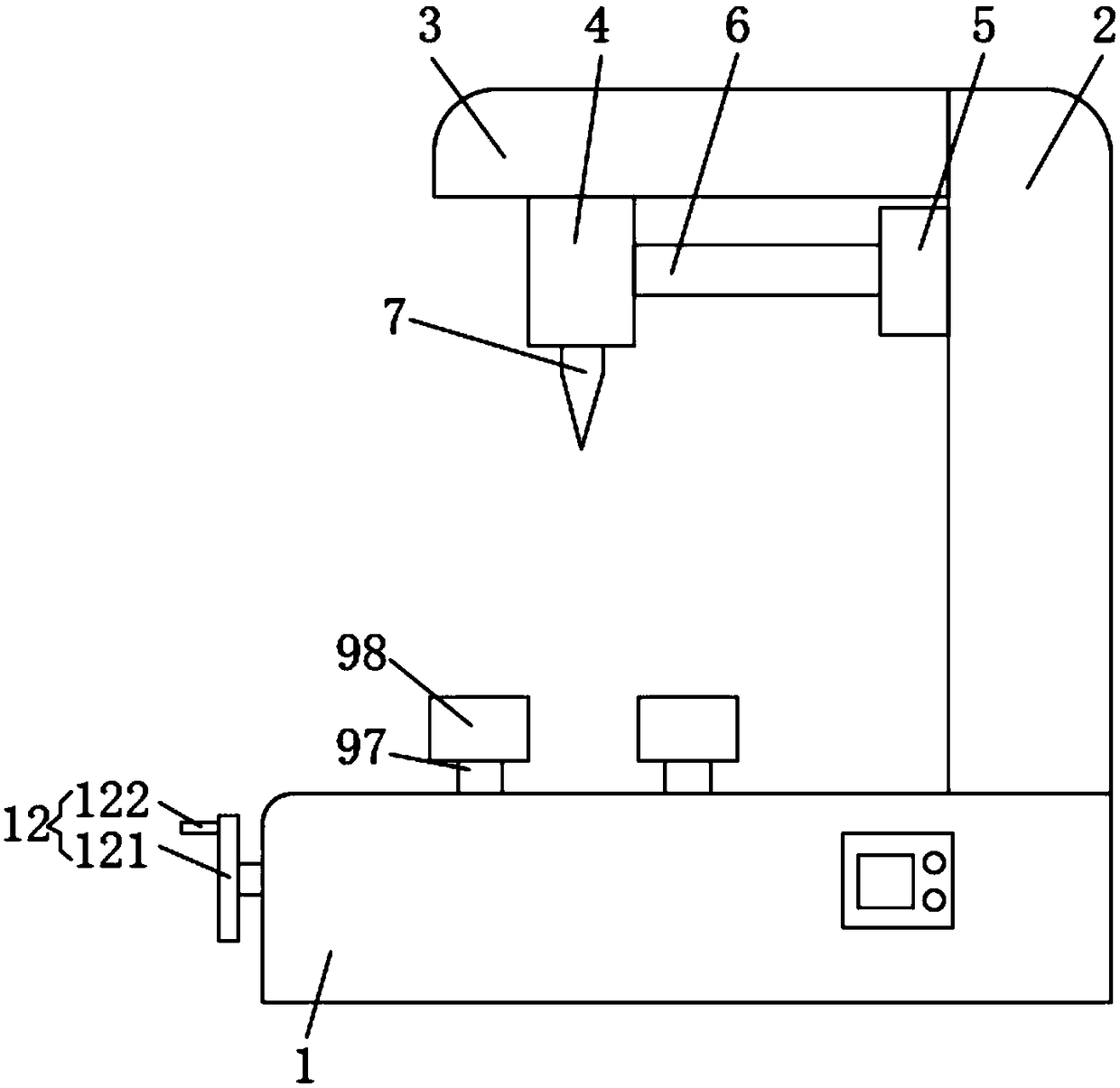

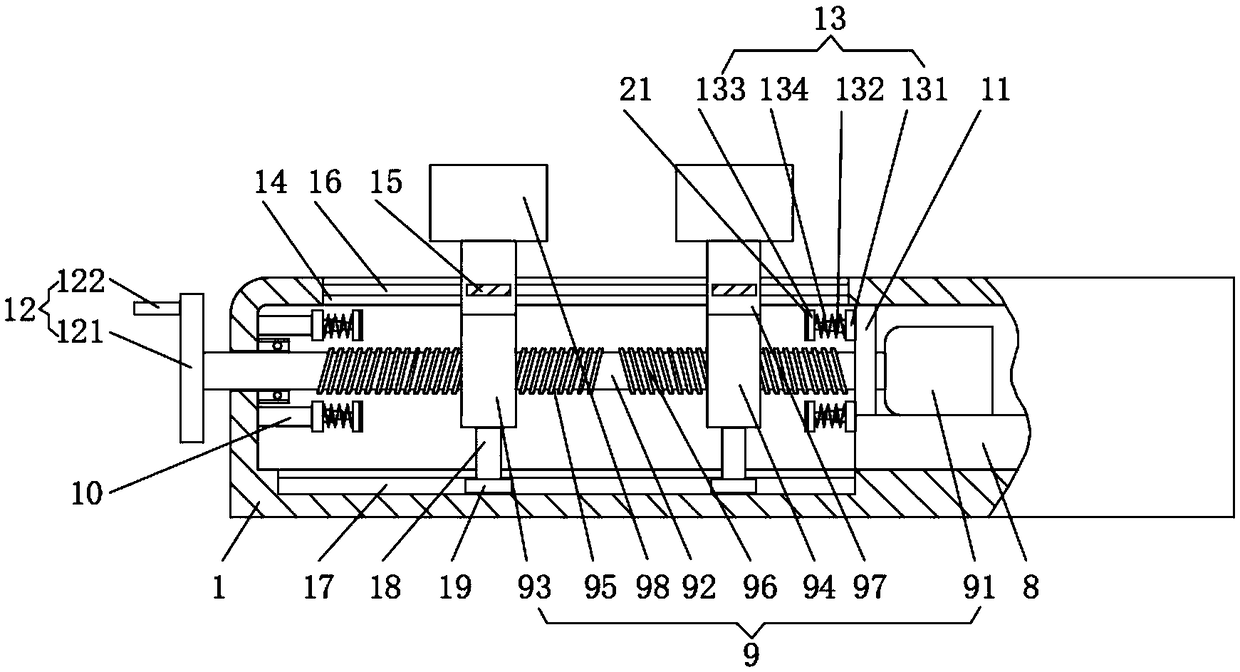

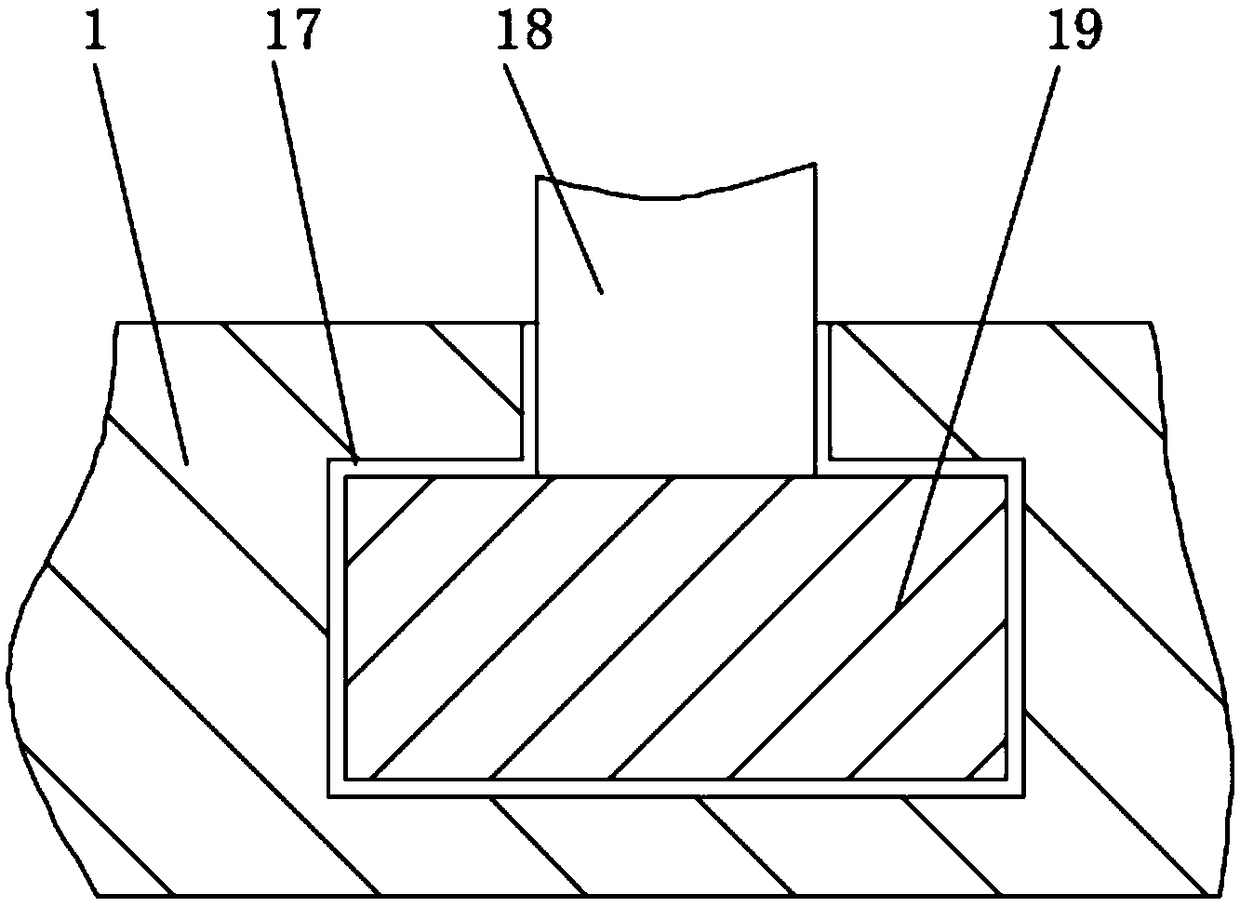

[0031]Embodiment 2: The automatic clamping intelligent production cutting device of the present invention includes a clamping box 1, the right side of the top of the clamping box 1 is fixedly connected with a support seat 2, and the left side of the top of the support seat 2 is fixedly connected with a horizontal Plate 3, the left side of the bottom of the horizontal plate 3 is fixedly connected with a protective cover 4, the left side of the top of the support base 2 is fixedly connected with a drive motor 5, the output shaft of the drive motor 5 is fixedly connected with a drive shaft 6 through a coupling, and the drive shaft 6 The left side of the surface is sleeved with a cutting blade 7, the right side of the bottom of the inner wall of the clamping box 1 is fixedly connected with a fixing seat 8, and the top of the fixing seat 8 is fixedly connected with a clamping mechanism 9, and the left side of the inner wall of the clamping box 1 is fixed. A fixed column 10 is connec...

Embodiment 3

[0032] Embodiment 3: The automatic clamping intelligent production cutting device of the present invention includes a clamping box 1, the right side of the top of the clamping box 1 is fixedly connected with a support seat 2, and the left side of the top of the support seat 2 is fixedly connected with a horizontal Plate 3, the left side of the bottom of the horizontal plate 3 is fixedly connected with a protective cover 4, the left side of the top of the support base 2 is fixedly connected with a drive motor 5, the output shaft of the drive motor 5 is fixedly connected with a drive shaft 6 through a coupling, and the drive shaft 6 The left side of the surface is sleeved with a cutting blade 7, the right side of the bottom of the inner wall of the clamping box 1 is fixedly connected with a fixing seat 8, and the top of the fixing seat 8 is fixedly connected with a clamping mechanism 9, and the left side of the inner wall of the clamping box 1 is fixed. A fixed column 10 is conne...

Embodiment 4

[0033] Embodiment 4: The automatic clamping intelligent production cutting device of the present invention includes a clamping box 1, the right side of the top of the clamping box 1 is fixedly connected with a support seat 2, and the left side of the top of the support seat 2 is fixedly connected with a horizontal Plate 3, the left side of the bottom of the horizontal plate 3 is fixedly connected with a protective cover 4, the left side of the top of the support base 2 is fixedly connected with a drive motor 5, the output shaft of the drive motor 5 is fixedly connected with a drive shaft 6 through a coupling, and the drive shaft 6 The left side of the surface is sleeved with a cutting blade 7, the right side of the bottom of the inner wall of the clamping box 1 is fixedly connected with a fixing seat 8, and the top of the fixing seat 8 is fixedly connected with a clamping mechanism 9, and the left side of the inner wall of the clamping box 1 is fixed. A fixed column 10 is conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com