Machining device and method for hard alloy valve element of throttle valve

A technology of cemented carbide and processing device, applied in the field of cemented carbide, can solve the problems that the valve core structure cannot be used, the hollow cylinder is difficult to achieve anti-scour, and the small holes cannot be machined, so as to reduce the processing difficulty and avoid clamping The effect of preventing damage and saving processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

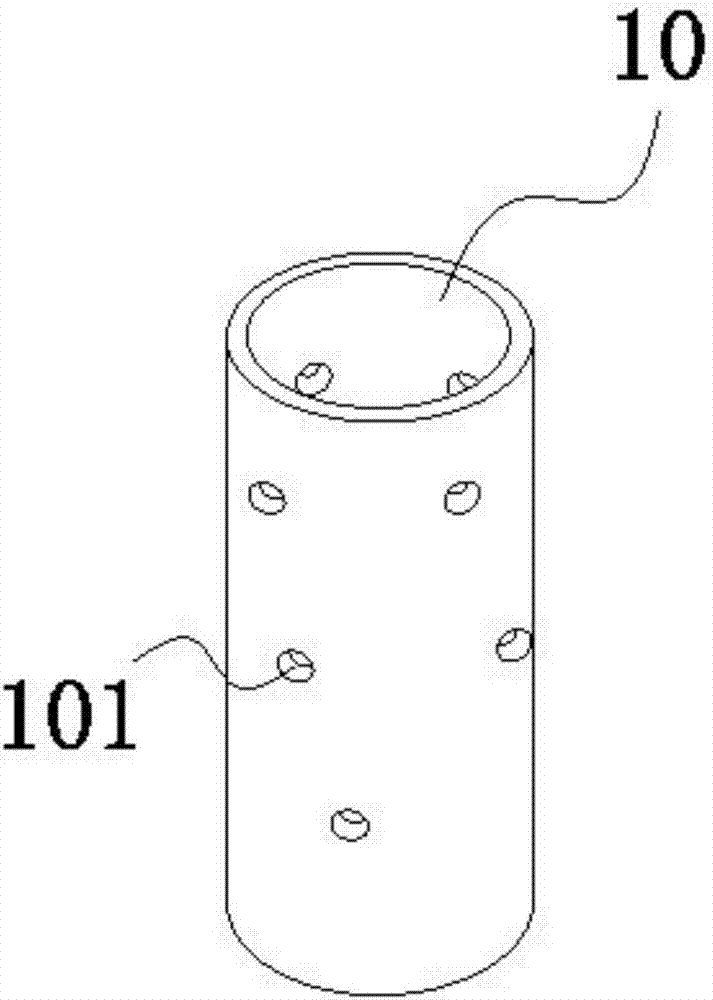

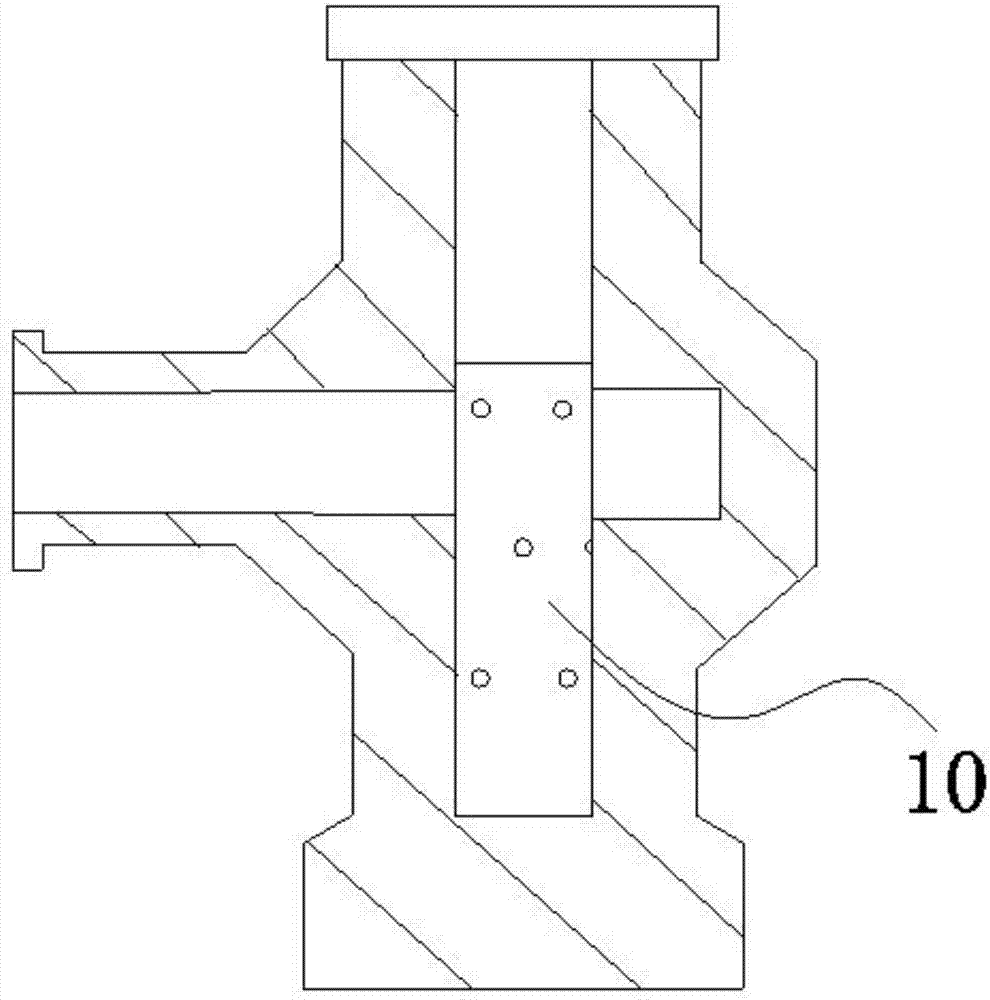

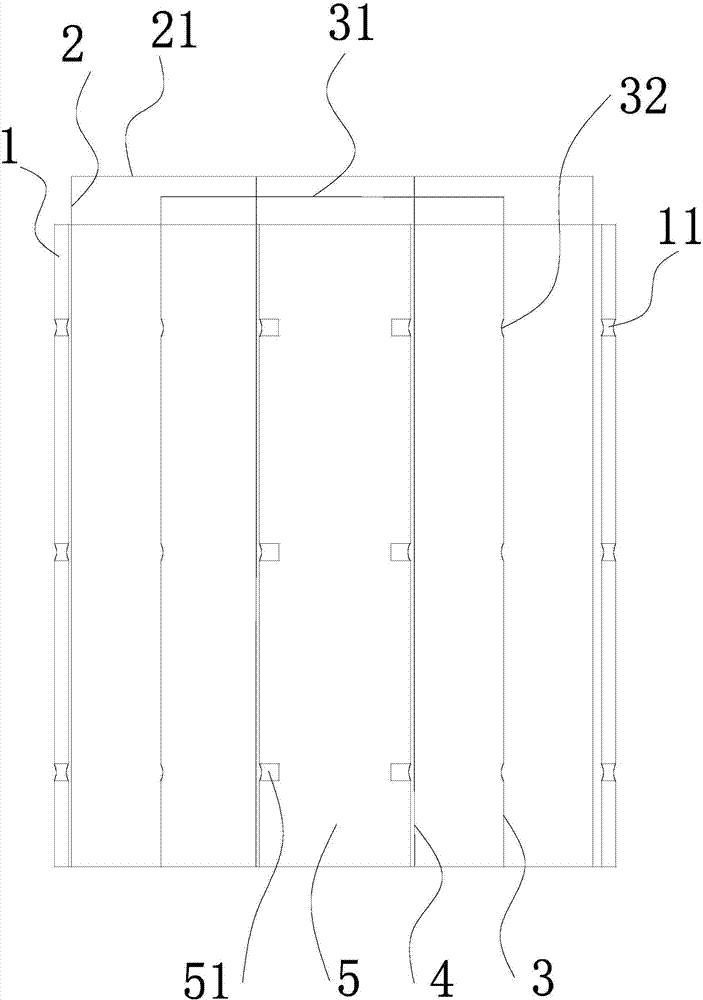

[0049] Such as Figure 1-13 As shown, a processing device for a hard alloy valve core of a throttle valve consists of an outer cover 1, an outer leak-proof plate 2, a partition 3, an inner cover 5, an inner cover leak-proof plate 4, a punching rod 6, The working box 7, the lower extrusion block 9, and the upper extrusion block 8 are composed; on the lower extrusion block 9, the outer casing 1, the outer casing leak-proof plate 2, the partition 3, the inner casing 5, and the inner casing leak-proof plate are placed in sequence from outside to inside 4. The upper extrusion block 8 is aligned with the axis of the inner sleeve 5 and arranged above the inner sleeve 5; the outer sleeve 1 is a hollow cylinder with a height of 150 mm and an inner diameter of 60 mm; the inner sleeve 5 is a solid cylinder with a height of 150 mm , the outer diameter is 45mm; the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com