Powder metallurgy synchronizer gear hub

A technology of powder metallurgy and synchronizer, which is applied to clutches, components with teeth, mechanically driven clutches, etc., can solve the problems of debris generation, easy to be crushed and damaged, and easy to produce deflection, etc., to achieve the elimination of debris, The effect of avoiding crushing damage and smoothly transmitting power and torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

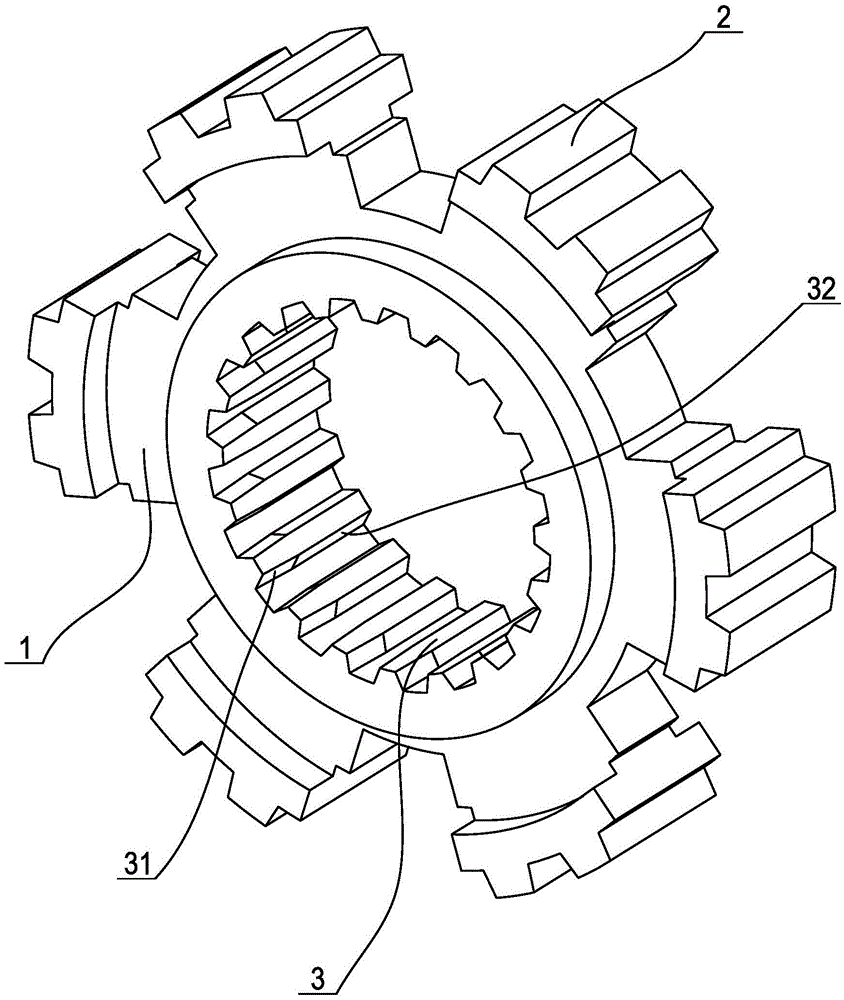

[0025] Embodiment 1: as figure 1 As shown, a powder metallurgy synchronizer hub includes a hub body 1, on the outside of the hub body 1 there is an outer spline 2 of the hub that meshes with the connecting sleeve in the synchronizer, and on the inside of the hub body there is a transmission The external splines of the shaft engage the internal splines of the gear hub 3. When assembling the synchronizer, the synchronizer gear hub is coaxially sleeved on the transmission shaft in a fixed direction and pressed into the external spline of the transmission shaft. When the synchronizer gear hub is assembled, it is first close to the drive shaft One end of the external spline becomes the press-in end. At this time, the internal spline 3 of the synchronizer hub forms a tight fit with the external spline on the transmission shaft, that is to say, the internal spline 3 of the gear hub and the external spline on the transmission shaft The external splines of the external splines cannot ...

Embodiment 2

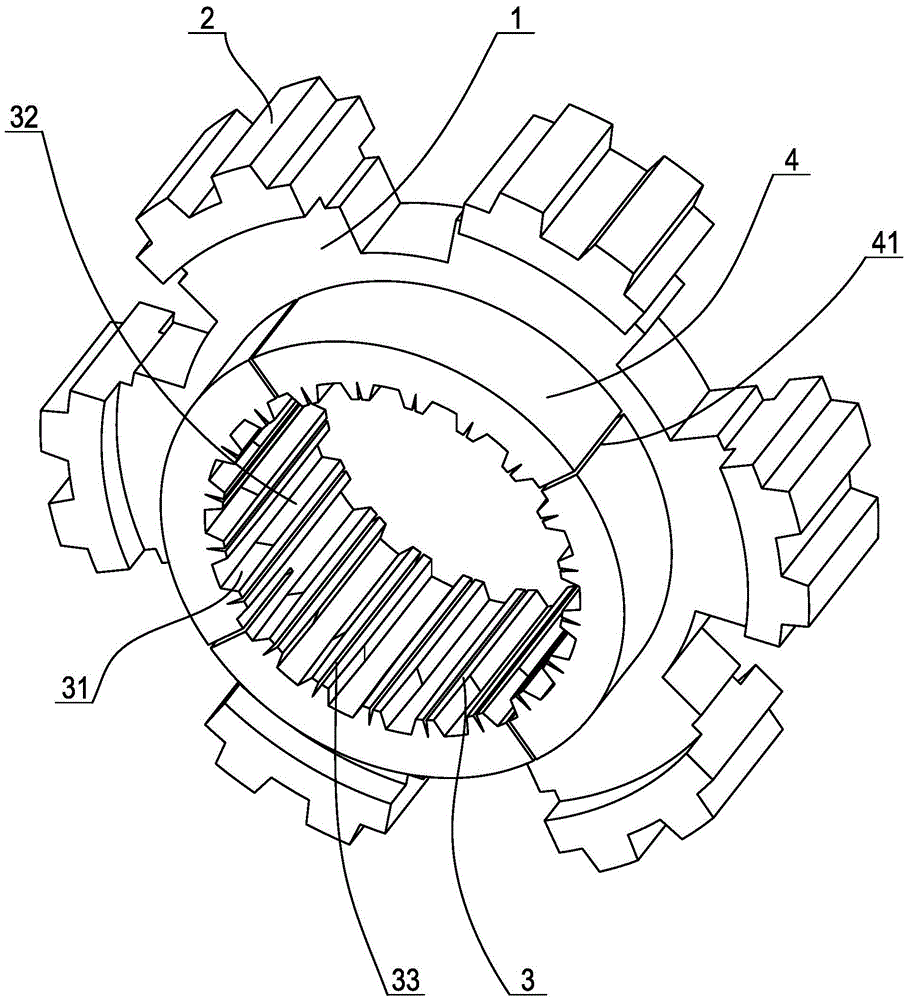

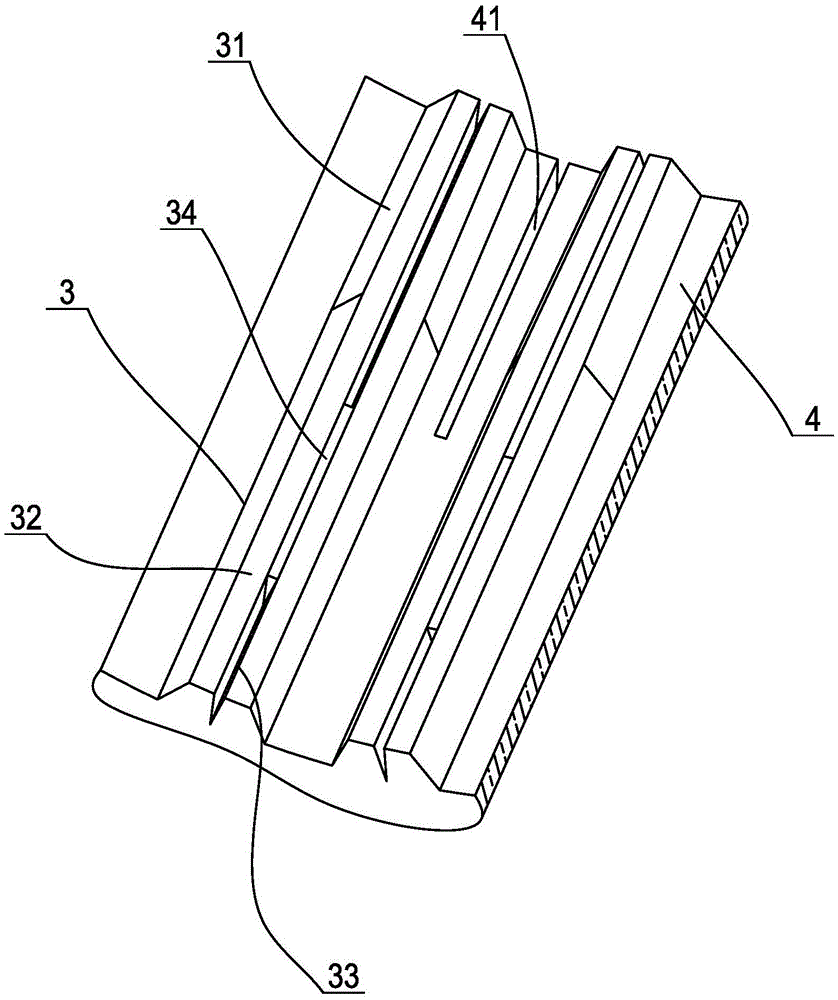

[0031] Embodiment 2: as Figure 4 As shown, a powder metallurgy synchronizer hub includes a hub body 1, on the outside of the hub body 1 there is an outer spline 2 of the hub that meshes with the connecting sleeve in the synchronizer, and on the inside of the hub body there is a transmission The external splines of the shaft engage the internal splines of the gear hub 3. In order to enable the synchronizer hub to transmit power and torque to the transmission shaft stably and reliably, the inner spline 3 of the gear hub includes a guide section 31 close to the press-in end of the synchronizer hub and a positioning section 32 away from the press-in end of the synchronizer hub. The teeth of the spline 3 in the gear hub are composed of transmission teeth 35 and 2-4 positioning teeth 36 equidistantly arranged between the transmission teeth 35 . The indexing round tooth thickness of each positioning spline 36 in the positioning section 32 is less than the indexing round tooth groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com