Centrifugal compressor used for generating two different pressure ratios

A centrifugal compressor and compressor technology, which is applied to the components, mechanical equipment, machines/engines, etc. of the pumping device for elastic fluid, can solve the problems of increasing wear, reducing mechanical efficiency, and the rotor system being too long, etc. Achieve the effect of improving rotor balance, simplifying overall structure, reducing bending resistance and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

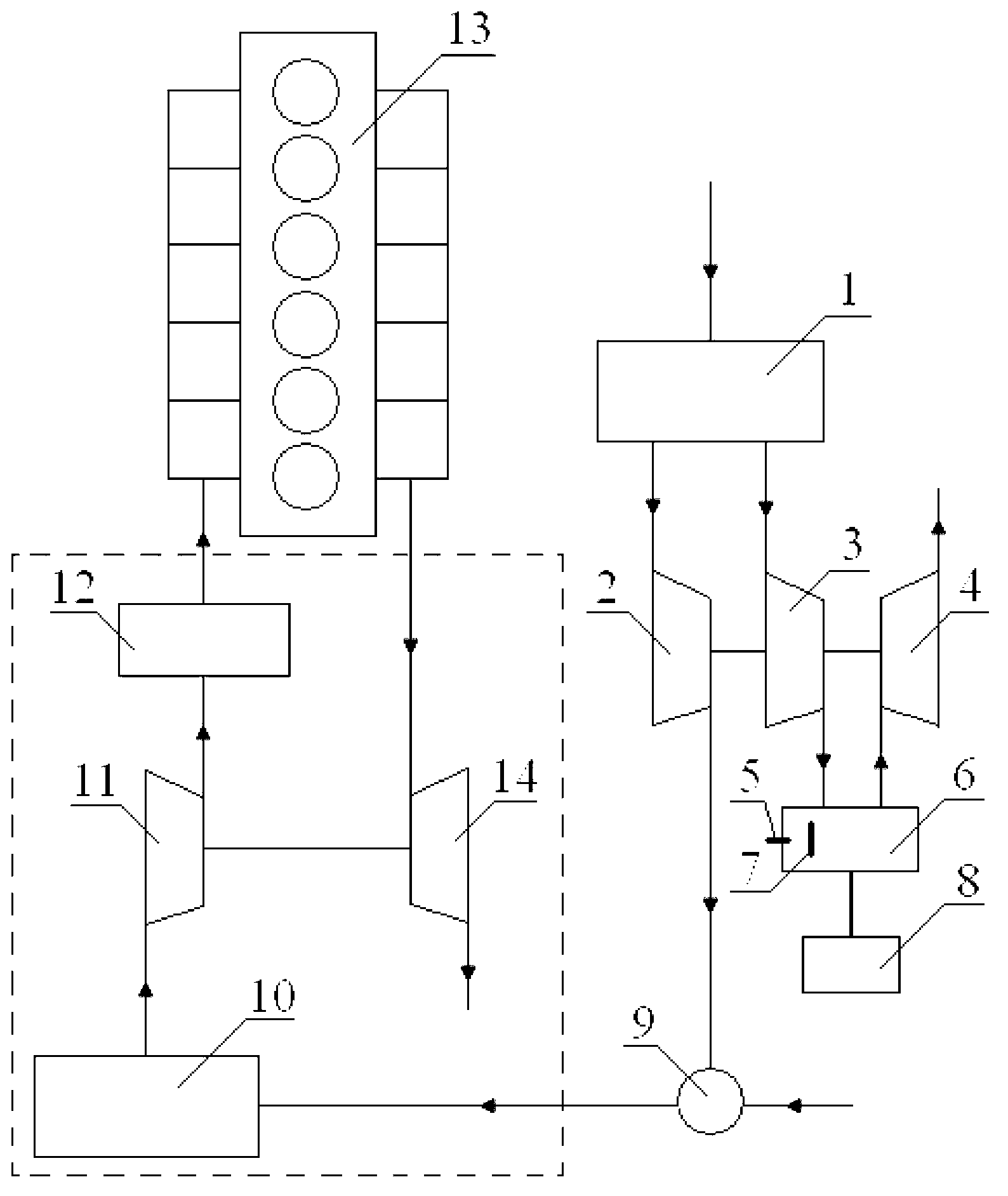

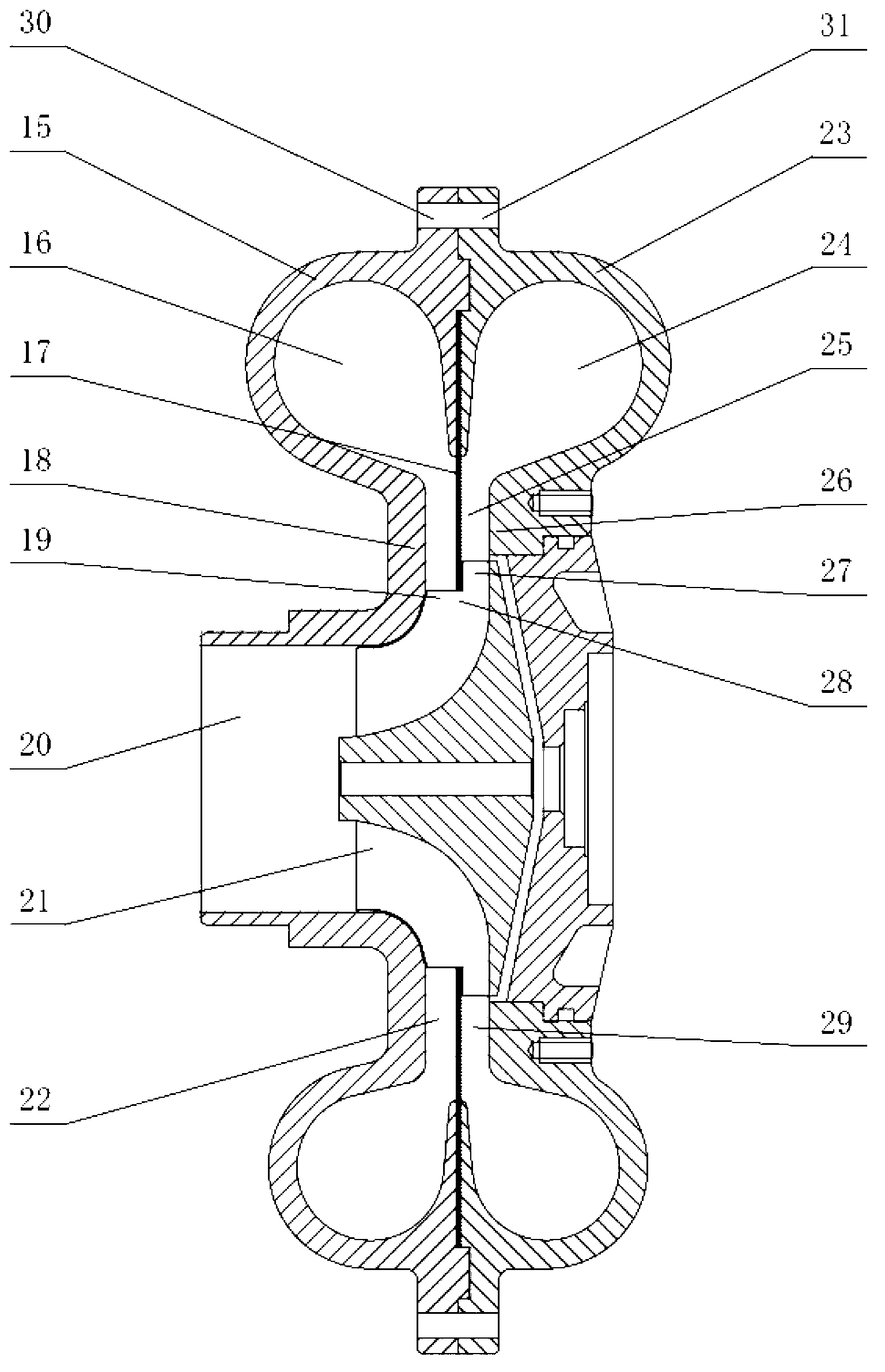

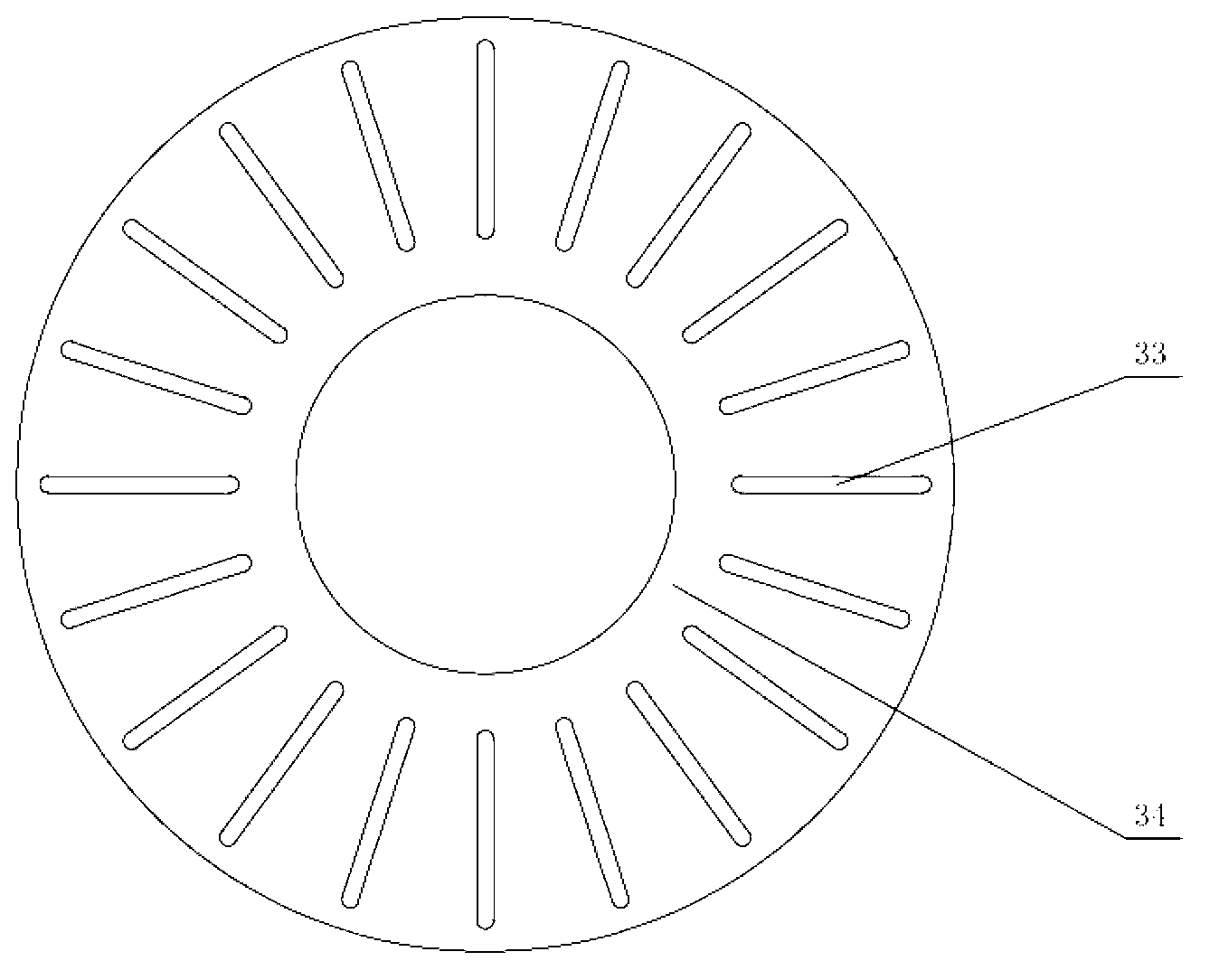

[0025] Embodiment 1: as figure 2 As shown, a centrifugal compressor device for generating two different pressure ratios includes a compressor front shell 15 , a compressor rear shell 23 , an annular plate 17 and a stepped centrifugal compressor impeller 21 . The compressor front shell 15 is provided with a compressor air inlet 20 and a compressor front collector runner volute 16; The rear casing 23 of the machine is connected by bolts, and an annular plate 17 is clamped therebetween. The part other than the clamping surface of the annular plate 17 is an annular splitter plate 34; The diffuser channel formed by the diffuser wall 26 is divided into two, forming a double-channel vaneless diffuser 25; a stepped centrifugal compressor impeller 21 is installed inside the compressor front shell 15 and the compressor rear shell 23, and the impeller outlet 28 is that big and small two kinds of diameters make the impeller outlet form step shape.

[0026] The compressor front shell 15...

Embodiment 2

[0033] Embodiment 2: as Figure 5 , Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that the stepped centrifugal compressor impeller 21 is different from the impeller shape in Embodiment 1. This embodiment is opposite to Embodiment 1, and the impeller outlet is designed to have a large diameter near the end of the compressor front casing 15, and is designed to have a small diameter near the end of the compressor rear casing 23. All the other parts are identical to Example 1.

[0034] The flow of the air-flow in this embodiment is basically the same as that in Embodiment 1. The air-flow flows to the impeller outlet 28 after passing through the compressor inlet 20 and the impeller 21. The air-flow is divided into two strands, and one enters near the compressor through the front end 35 of the large-diameter impeller outlet. The front vaneless diffuser 22 at the front shell 15 end, the air flow is a high-pressure air flow; the other stream enters t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com