Sizing material for rubber shoe sole and preparation method thereof

A technology for rubber soles and rubber materials, applied in the field of rubber products, can solve the problems affecting the enthusiasm of waste rubber treatment and production, limiting the scale of rubber recycling and utilization, and achieving the effects of smooth appearance, improved performance, and soft brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

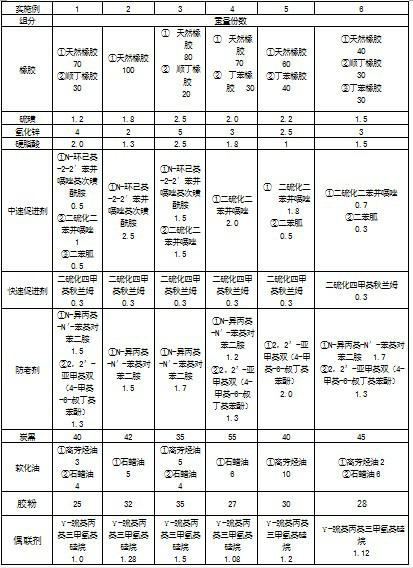

[0037] The raw materials for making its active ingredients include, in parts by weight:

[0038]

[0039] Embodiments 1-3 are respectively a kind of rubber powder modified rubber material for the rubber sole of fashion shoes, and the formula is shown in the table above, and their respective preparation methods are respectively carried out according to the following steps:

[0040] (1) Rubber powder pretreatment: put the rubber powder and coupling agent into the kneader, stir at 50°C at a speed of 20rpm / min for 5min, discharge the material to room temperature, and set aside.

[0041] (2) The natural rubber is masticated, and the William plasticity is controlled to 0.40±0.05; after mastication, the natural rubber is mixed with butadiene rubber evenly according to the formula.

[0042] (3) Mixing process: Use an internal mixer to mix; add zinc oxide, stearic acid, and medium-speed accelerator to the mixed rubber of natural rubber and butadiene rubber mixed uniformly above, and...

Embodiment 6

[0049] Embodiment 6 is a rubber powder modified rubber material for rubber soles of outdoor shoes, the formula is as shown in the table, and its preparation method is carried out according to the following steps:

[0050] (1) Rubber powder pretreatment: put the rubber powder and coupling agent into the kneader, stir at 60°C for 5 minutes at a speed of 35rpm / min, discharge the material and let it cool to room temperature, and set aside.

[0051] (2) The natural rubber is masticated, and the William's plasticity is controlled to 0.40±0.05; after mastication, the natural rubber is mixed with styrene-butadiene rubber and butadiene rubber evenly according to the formula.

[0052] (3) Mixing process: Use an internal mixer to mix; add zinc oxide, stearic acid, and medium-speed accelerator to the above-mentioned mixed rubber of natural rubber, styrene-butadiene rubber and butadiene rubber, and mix for 1.5 minutes; Then add the pretreated rubber powder in step (1), mix for 1.5 minutes,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com