High-latitude high-temperature permafrost area highway raft plate-pile composite foundation and construction method

A composite foundation, high-latitude technology, used in sheet pile walls, buildings, infrastructure engineering, etc., can solve the problems of the bearing capacity of CFG piles and the reduction of lateral constraints, achieve high fatigue resistance, reduce the thickness of rafts, Lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

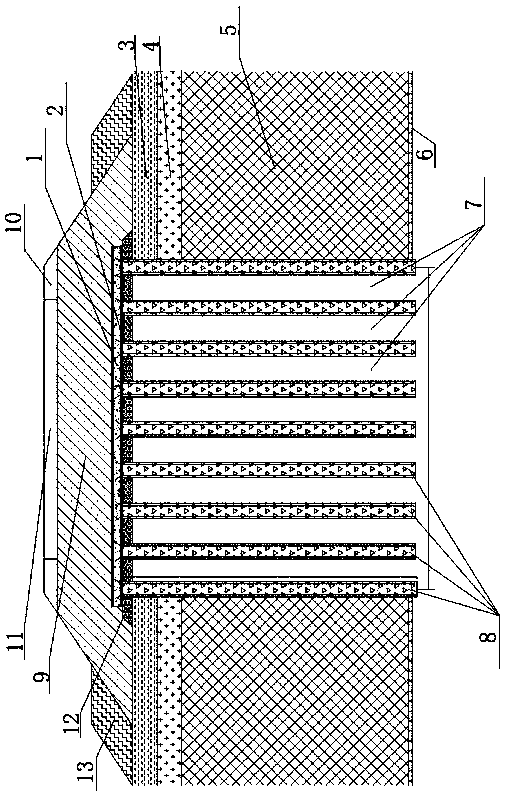

[0037] A raft-pile composite foundation for highway roadbeds in high-latitude and high-temperature frozen soil areas, which consists of a foundation. The foundation has a set of precast piles 8, and there is inter-pile soil 7 between two adjacent precast piles. The lower part of the prefabricated pile passes through the humus soil 3, peat soil 4, and the high-temperature frozen soil layer 5 in turn, and is located on the pile foundation bearing layer 6, and the top of the prefabricated pile goes deep into the raft 1. An XPS insulation board 2 is provided under the board, and a mattress layer 12 is provided under the XPS insulation board.

Embodiment 2

[0039] According to the raft-pile composite foundation of highway subgrade in the high-latitude and high-temperature frozen soil area described in Example 1, the raft has an embankment 9, a soil shoulder 10, a pavement structure layer 11, and a back pressure ramp 13 in sequence.

Embodiment 3

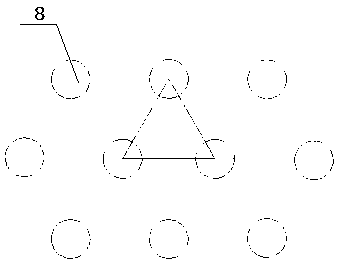

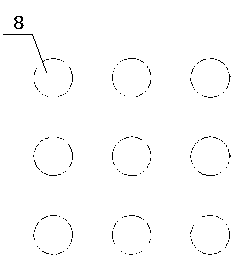

[0041] According to the raft-pile composite foundation of highway subgrade in high-latitude and high-temperature frozen soil area according to embodiment 1 or 2, the prefabricated piles are prestressed hollow pipe piles or prestressed solid square piles, and two adjacent prefabricated piles The pile spacing is determined by design verification.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com