Manual reinforcing steel bar bending tool and operation method thereof

A steel bar bending and tool technology, which is applied in the field of manual steel bar bending tools, can solve the problems of heavy workload, large space occupation, and high cost, and achieve the effects of convenient operation, simple structure, and improved bending efficiency and bending accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0102] The present invention is described in detail below with reference to accompanying drawing and embodiment:

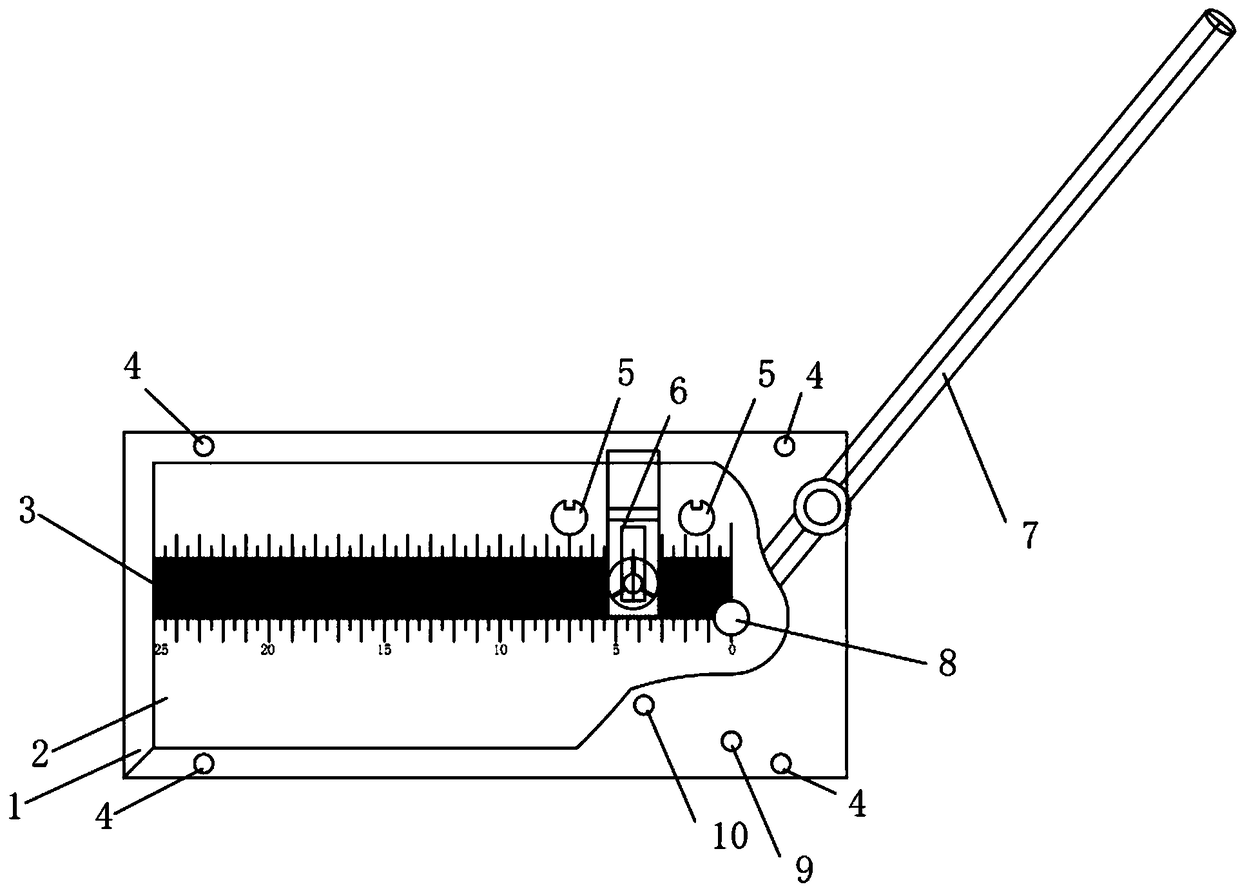

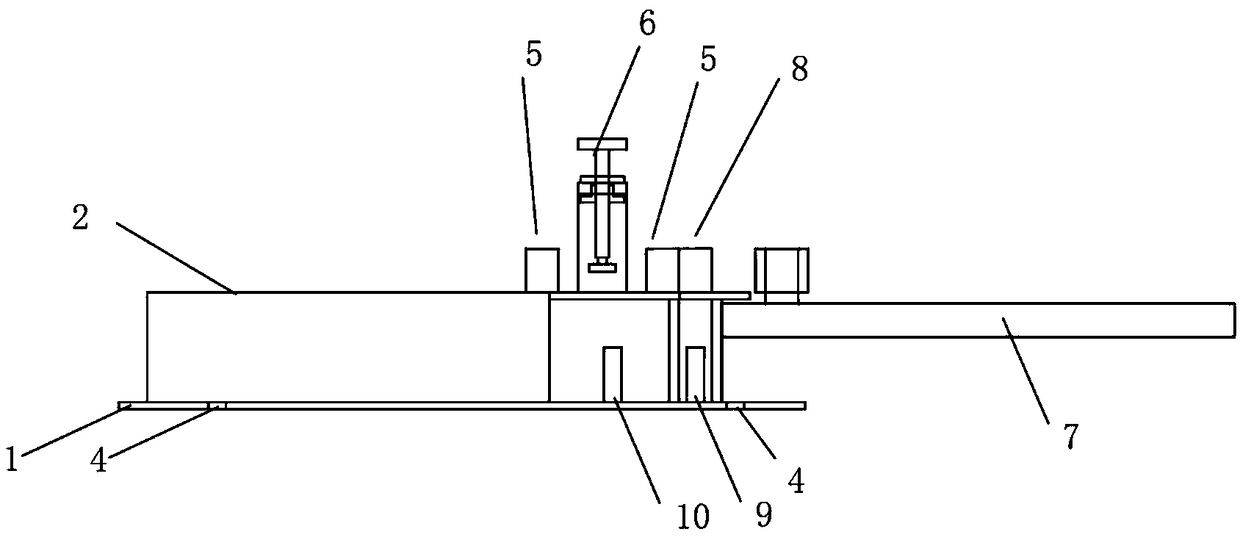

[0103] attached Figure 1-12 It can be seen that a manual steel bar bending tool,

[0104] Including: including console base 1 and console top 2;

[0105] The operating table 2 is arranged above the operating table base 1;

[0106] The operating table 2 is connected to the operating table base 1 through a connecting plate arranged in the vertical direction, and is characterized in that:

[0107] The operating table 2 is provided with a positioning column 5, a compactor 6 and a bending center positioning column 8;

[0108] A wrench 7 is arranged between the console base 1 and the console surface 2 .

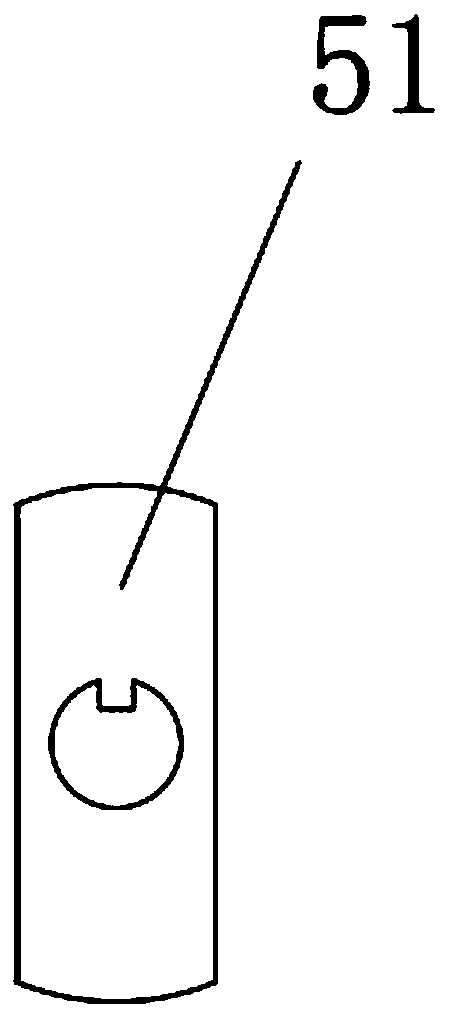

[0109] The positioning column 5 is provided with a groove;

[0110] A positioning sleeve 51 is set on the outside of the positioning column 5;

[0111] The positioning sleeve 51 is provided with a connecting hole;

[0112] A protrusion is arranged in the connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com