Patents

Literature

253 results about "Electric strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Electric strength is the maximum voltage that an insulating material can take, after which it loses its insulating properties. The value obtained for the electric strength will depend on the thickness of the insulating material and on the method and conditions of test.

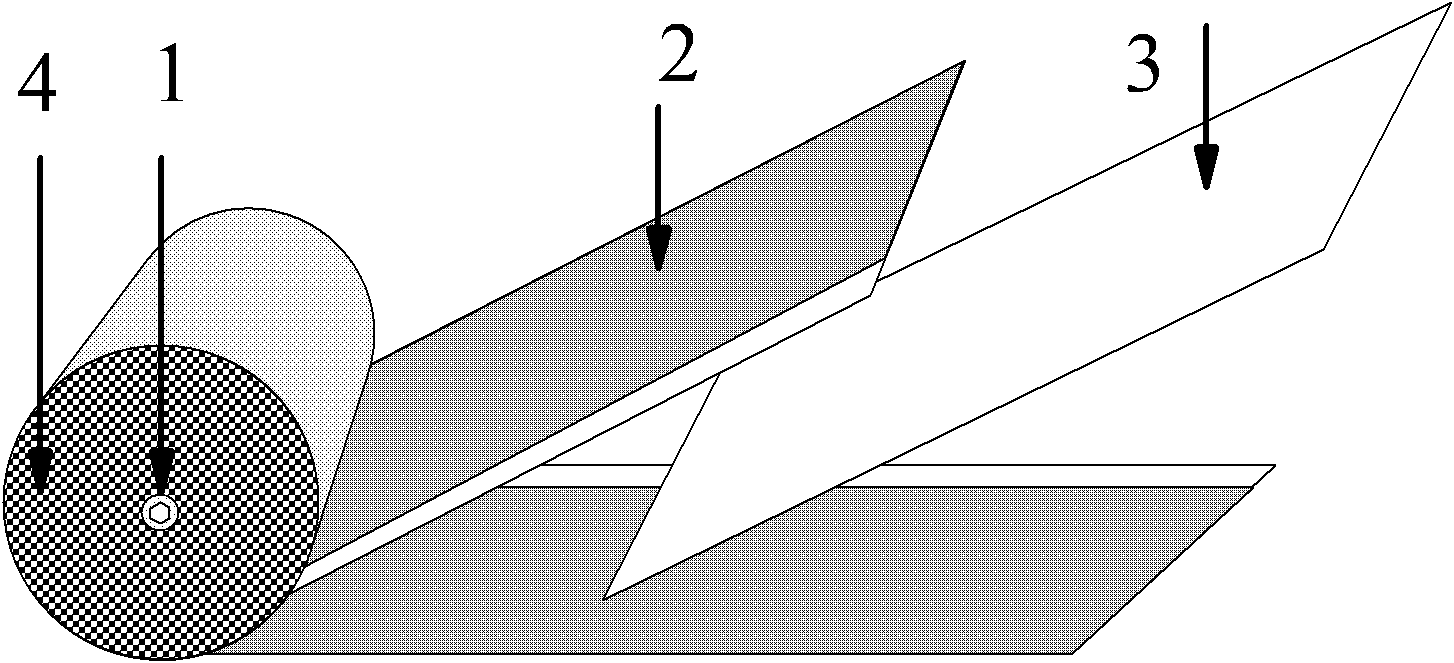

Centrifugal manufacturing method for dielectric functional gradient insulator

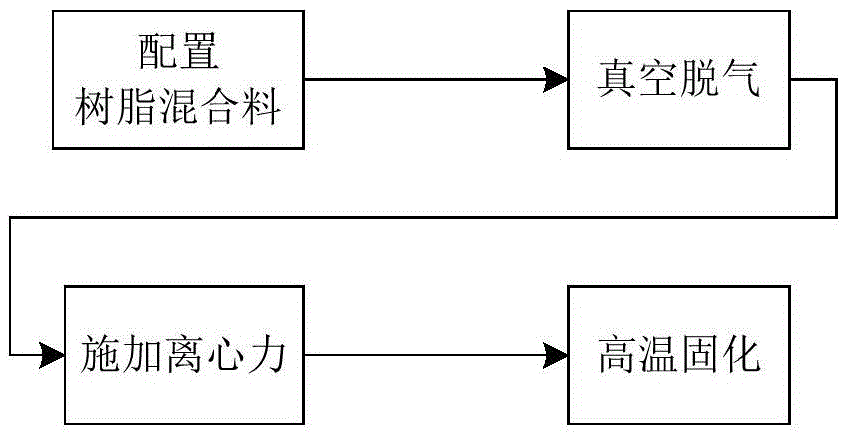

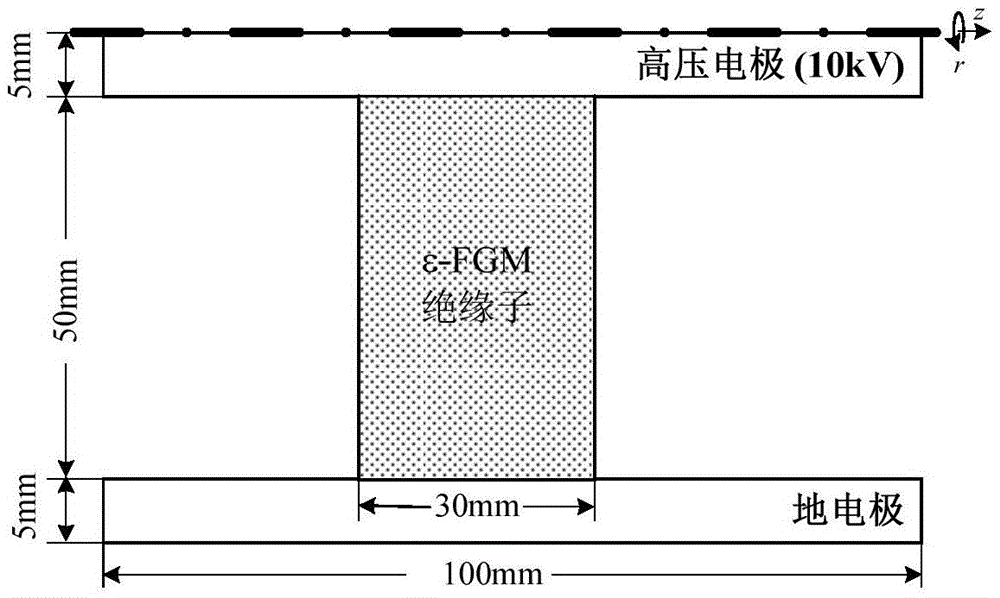

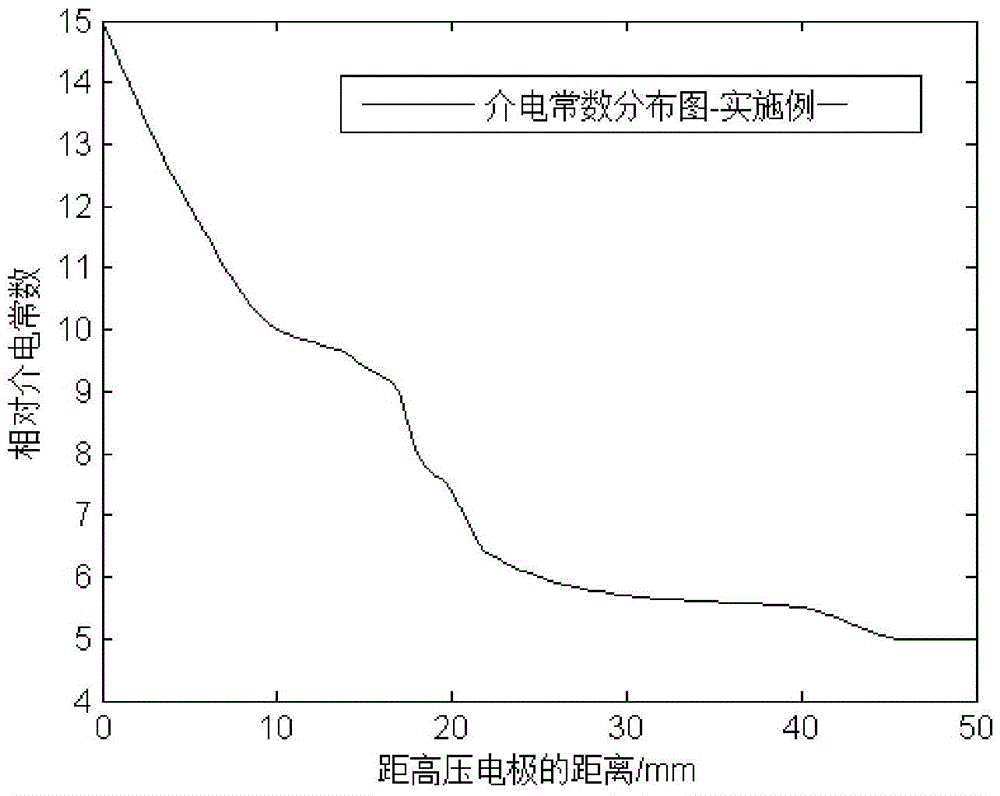

The invention discloses a centrifugal manufacturing method for a dielectric functional gradient insulator. The centrifugal manufacturing method applies a centrifugal force to enable the concentration of a high dielectric filler to realize continuous gradient distribution so as to obtain the insulator, the dielectric parameters of which are in continuous gradient variation. The preparation method comprises the following steps: (1) preparing a resin mixture according to a certain proportion; (2) carrying out vacuum mixing and degassing; (3) placing the mixture into a tailored mold, and mounting the mold on a centrifugal machine; (4) starting up the centrifugal machine to centrifuge the mixture; (5) stopping the centrifugal machine, taking down the mold, solidifying the insulator under the high temperature environment and demolding. The insulator manufacturing method disclosed by the invention can enable the dielectric parameters to achieve continuous gradient variation inside the insulator, so as to effectively improve the whole electric strength of the insulator.

Owner:XI AN JIAOTONG UNIV

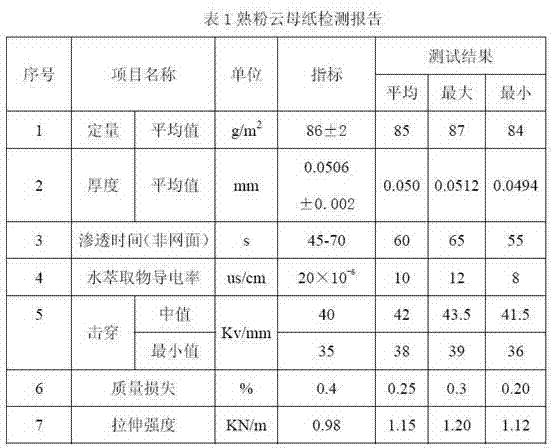

Manufacturing method of ultra-high voltage insulation cooked mica paper

InactiveCN102127882AImprove electrical strengthHigh tensile strengthPlastic/resin/waxes insulatorsUltra high voltagePulp and paper industry

The invention discloses a manufacturing method of ultra-high voltage insulation cooked mica paper, and aims to solve the problem that the mica paper prepared by the existing raw powder technique is not applicable to large-size power equipment. The method disclosed by the invention comprises the following steps: screening the mica raw material, calcining at high temperature, screening, dipping, making cooked mica pulp, manufacturing paper with the pulp, drying and the like. The mica paper produced by the method disclosed by the invention has the characteristics of high electric strength and high tensile strength.

Owner:HANGZHOU KAIER MICA PROD

Nano modified epoxy vacuum pressure impregnation resin and preparation method thereof

ActiveCN102690496AImproved low temperature mechanical propertiesImprove thermal conductivityChemical industryEpoxy resin coatingsDefoaming AgentsMaterials science

The invention relates to a nano modified epoxy vacuum pressure impregnation resin, which comprises the following components in percentage by weight: 36 to 45 percent of bisphenol A epoxy resin, 5 to 20 percent of low-viscosity epoxy active diluent with the viscosity of 3-200mps, 40 to 50 percent of liquid anhydride, 1 to 8 percent of nanopowder with the grain size of 1-100nm, 0.2 to 2 percent of dispersing agent, 0.1 to 2 percent of silane coupling agent, and 0.1 to 1 percent of defoaming agent. Compared with the common epoxy vacuum pressure impregnation resin, the nano modified epoxy vacuum pressure impregnation resin has the advantages that the thermal conductivity and corona resistant performance are obviously improved, the heat resistance and electric strength are improved and the nano modified epoxy vacuum pressure impregnation resin can meet requirements in the fields such as high-power variable frequency motors and low temperature superconducting motors.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

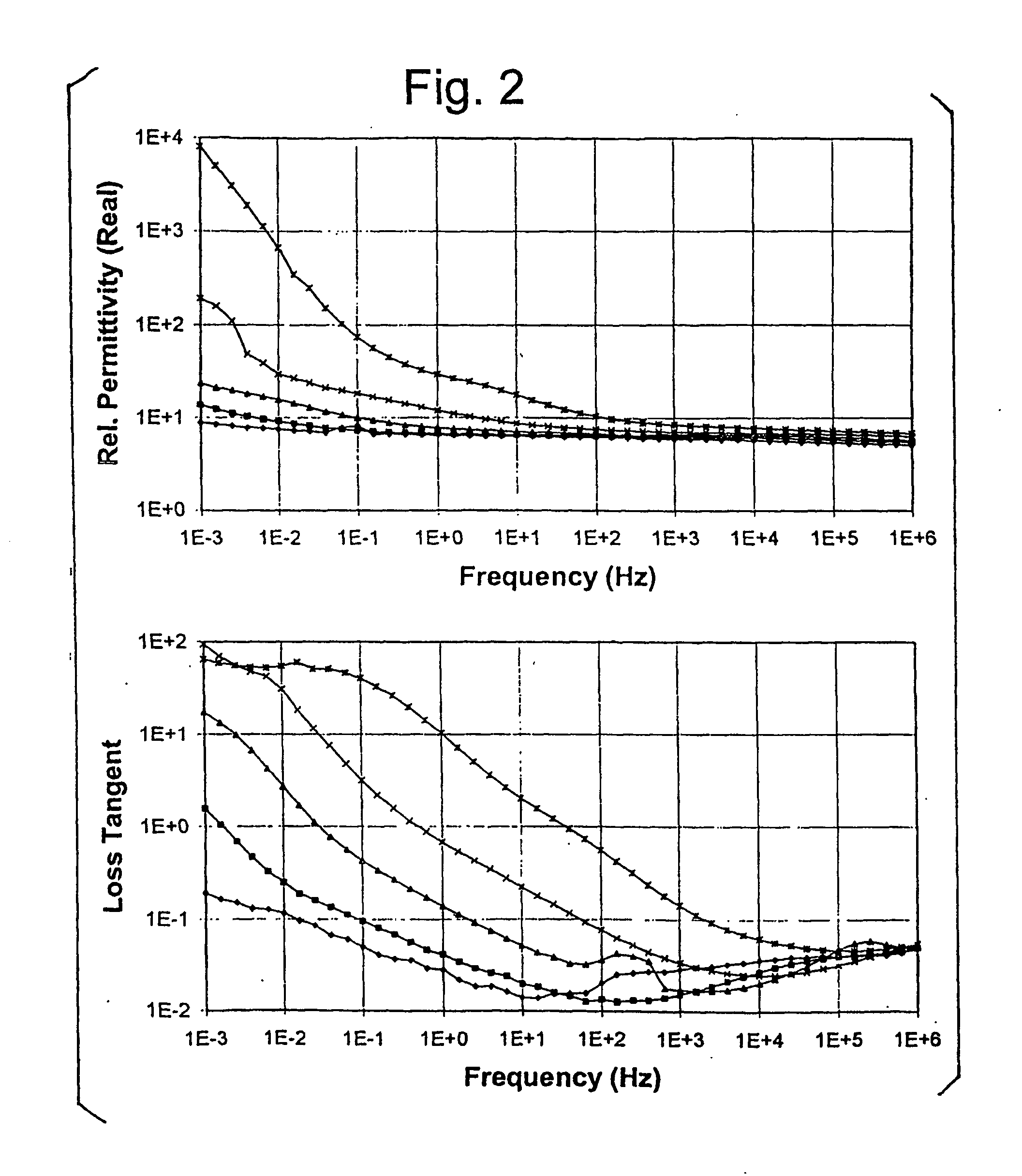

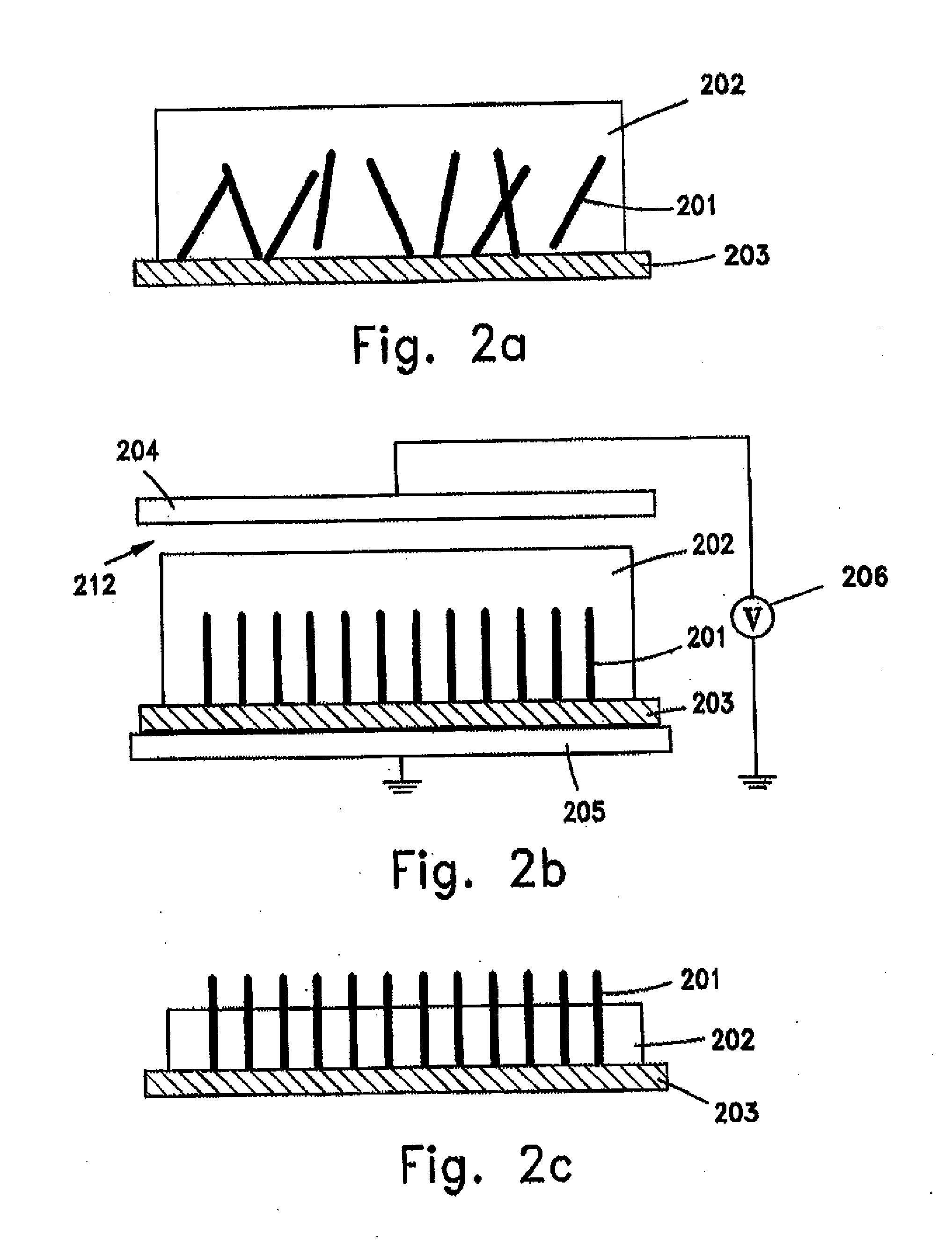

Nanometric composites as improved dielectric structures

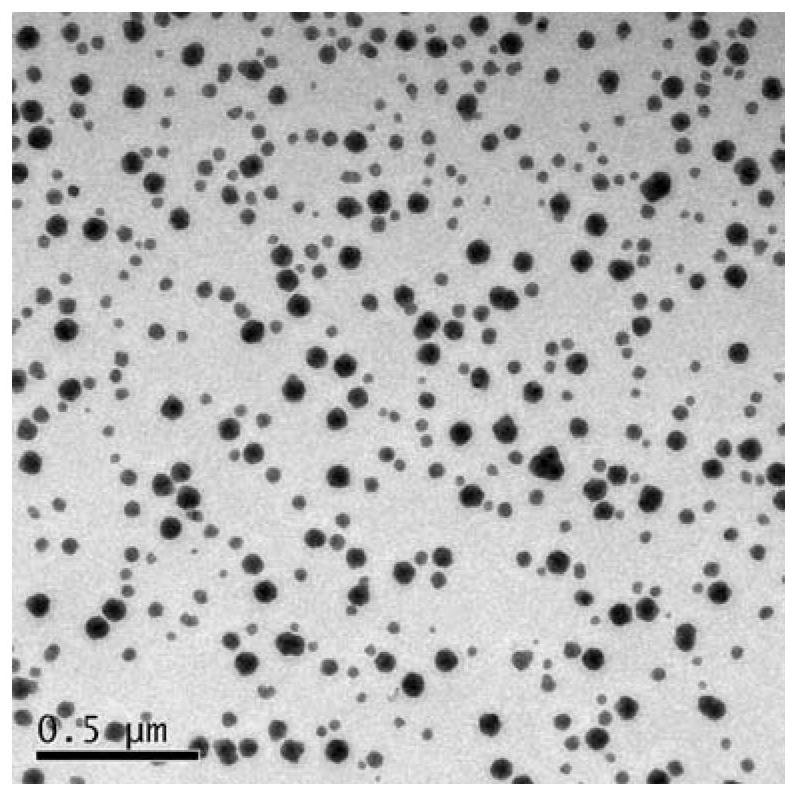

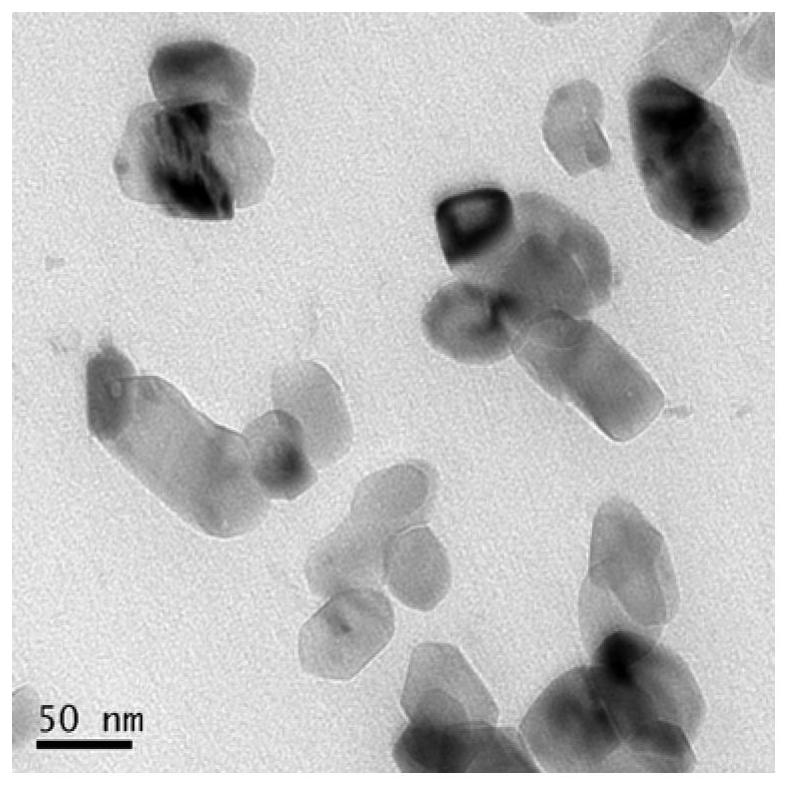

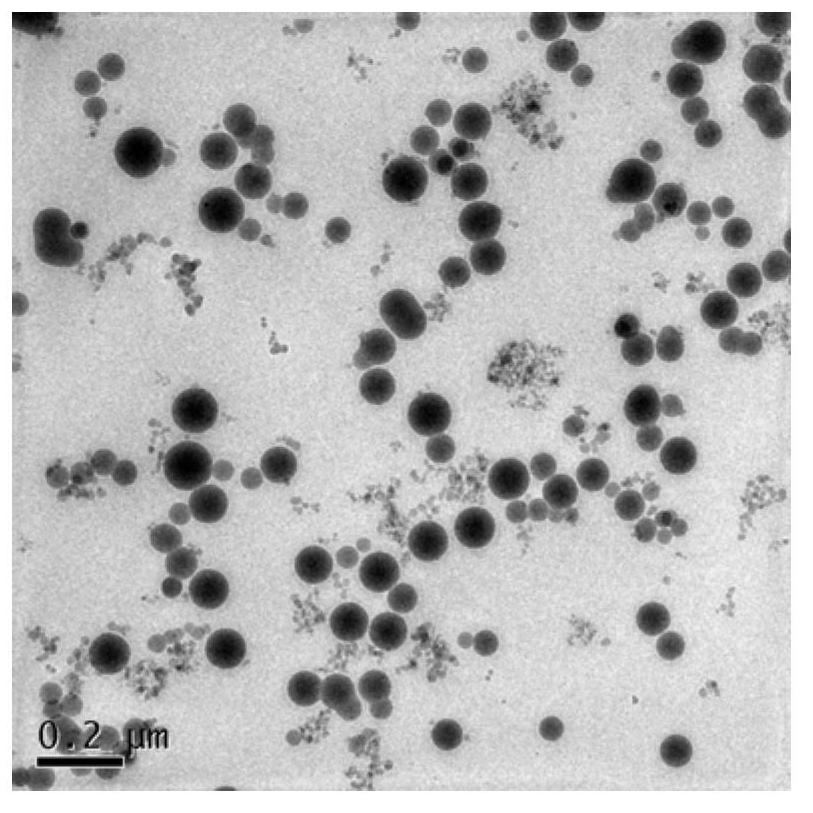

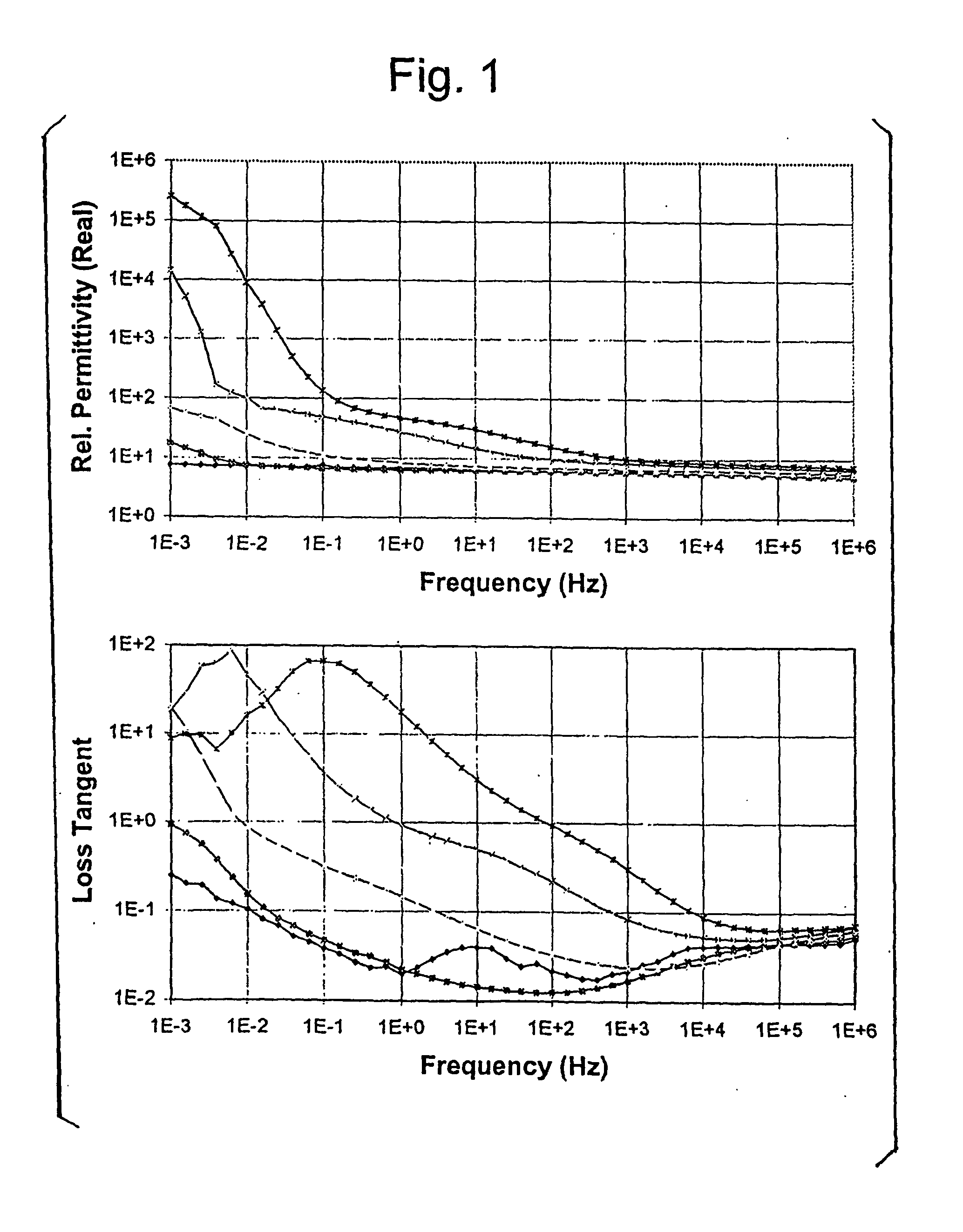

InactiveUS20050256240A1Reduce processReduce polarizationRubber insulatorsMaterial nanotechnologyResin matrixInterfacial polarization

A dielectric is provided which possesses high dielectric constant and high dielectric strength, while having the ca-pabilities of a polymer. The dielectric comprises a nanometric composite, which includes a stoichiometric nano-particulate filler embedded in a polymer or resin matrix. Filler particles are reduced in physical size to dimension to the same order as the polymer chain length of the host material and interact cooperatively thereby mitigating the associated Maxwell-Wagner process and reducing interfacial polarization. The internal fields for the new formulation are nearly a factor of 10 lower then for conventional (micro) material. The large changes in the internal field of the composite permit engineering of nanocomposite materials with enhanced electric strength and improved voltage endurance properties.

Owner:RENESSELAER POLYTECHNIC INST

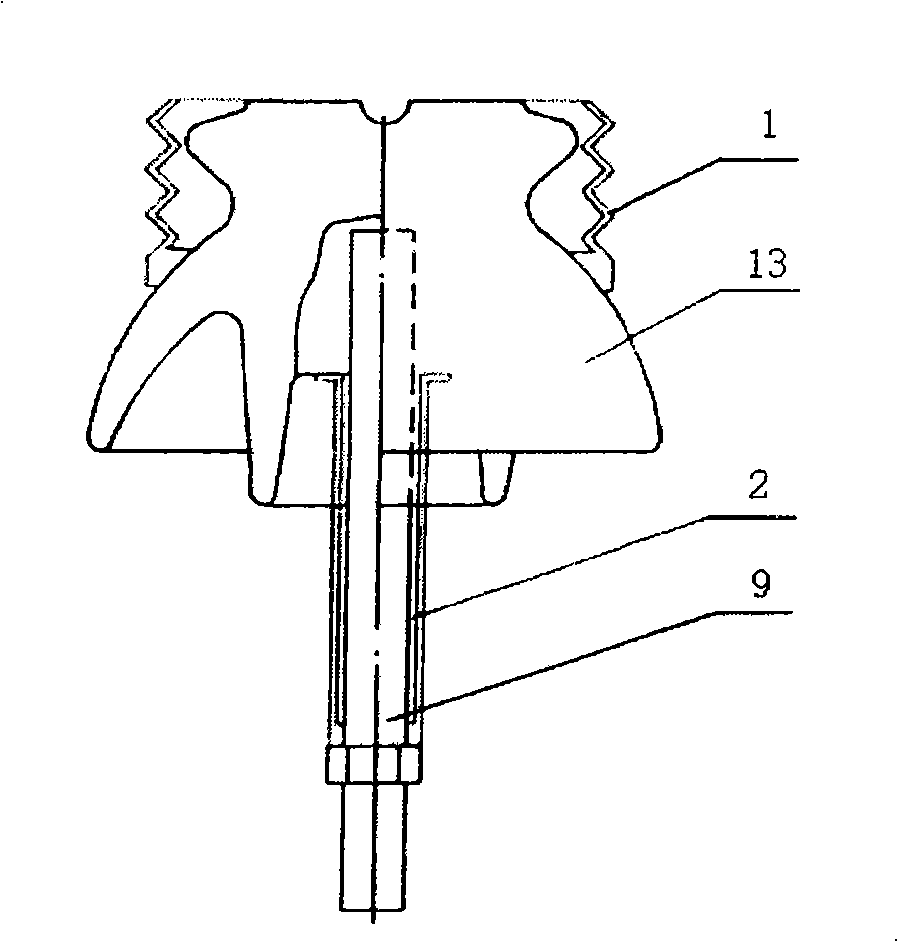

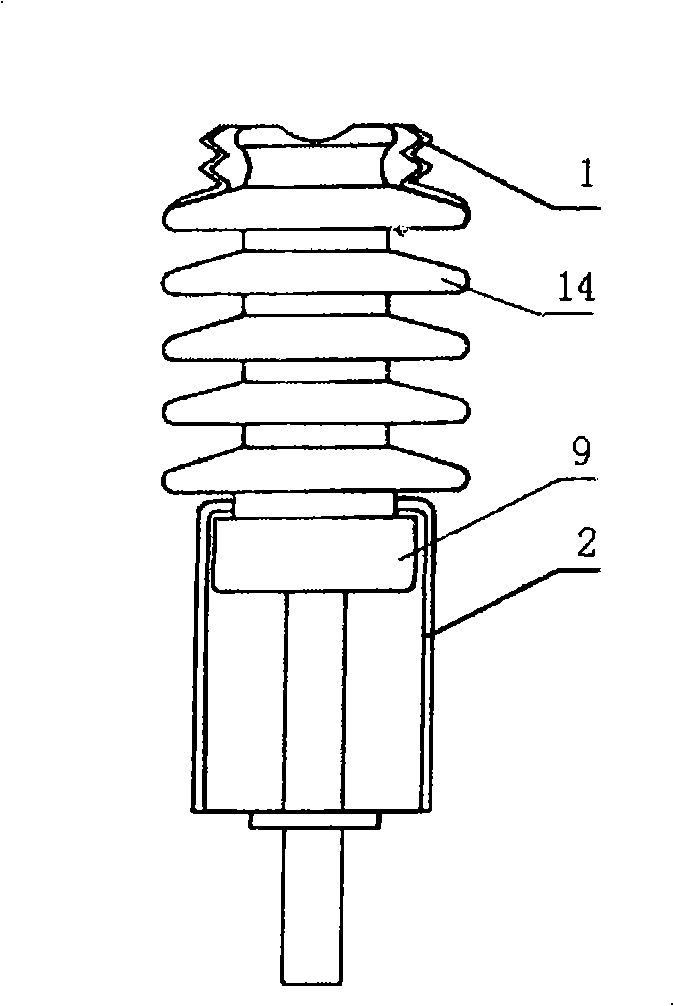

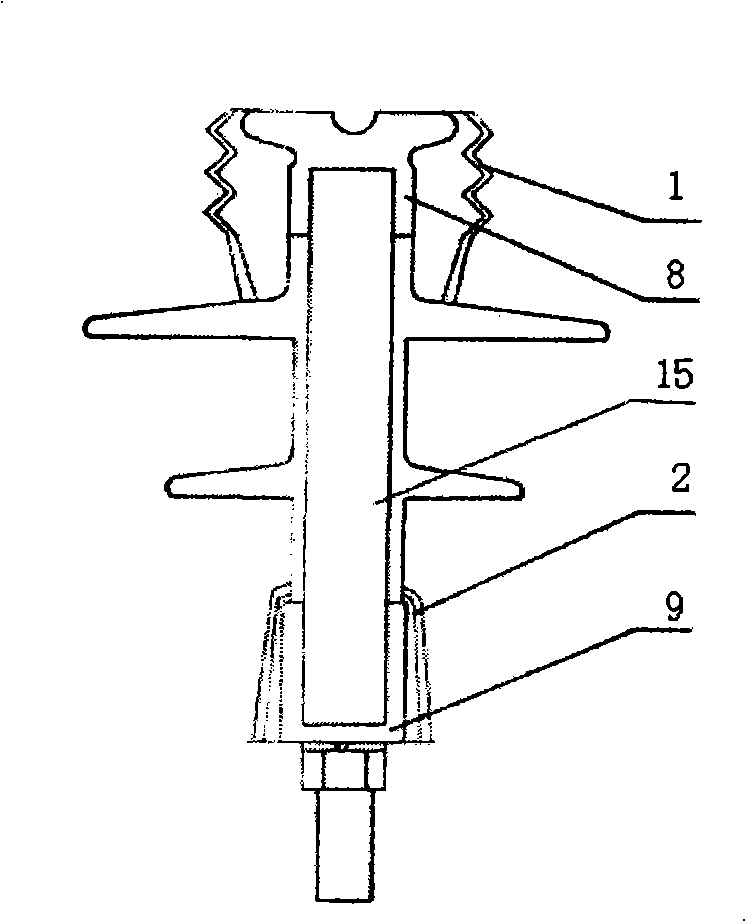

Insulator capable of improving external insulation electric strength

An insulator which can improve the electrical strength of external insulation relates to a line, a pillar and a bushing insulator with high electrical strength. An upper barrier and a lower barrier are arranged on an upper electrode and a lower electrode of the insulator, a middle barrier is arranged at the outside of an cascading electrode of the insulator string, an upper ring barrier and a lower ring barrier are externally arranged on an upper equalizing ring and a lower equalizing ring of the insulator, and an iron tower barrier and a transmission line barrier are arranged nearby an iron tower and a transmission line close to the insulator. The invention arranges one or multiple barriers, which can improve the strength of external insulation of the insulator, between the two electrodes of the insulator, changes the double-element structure of traditional insulators into a three-element structure, namely consisting of three parts of electrodes, insulators and barriers. The barrier stops moving charge entering from an area to another area, thus easing the area with electrical field distribution in a tense state, obviously enhancing the initial corona voltage and flashover voltage of the insulator, reducing radio interference and the power consumption of high-voltage transmission lines and relieving the deterioration of the insulator.

Owner:HUBEI XINDESAI INSULATION TECH

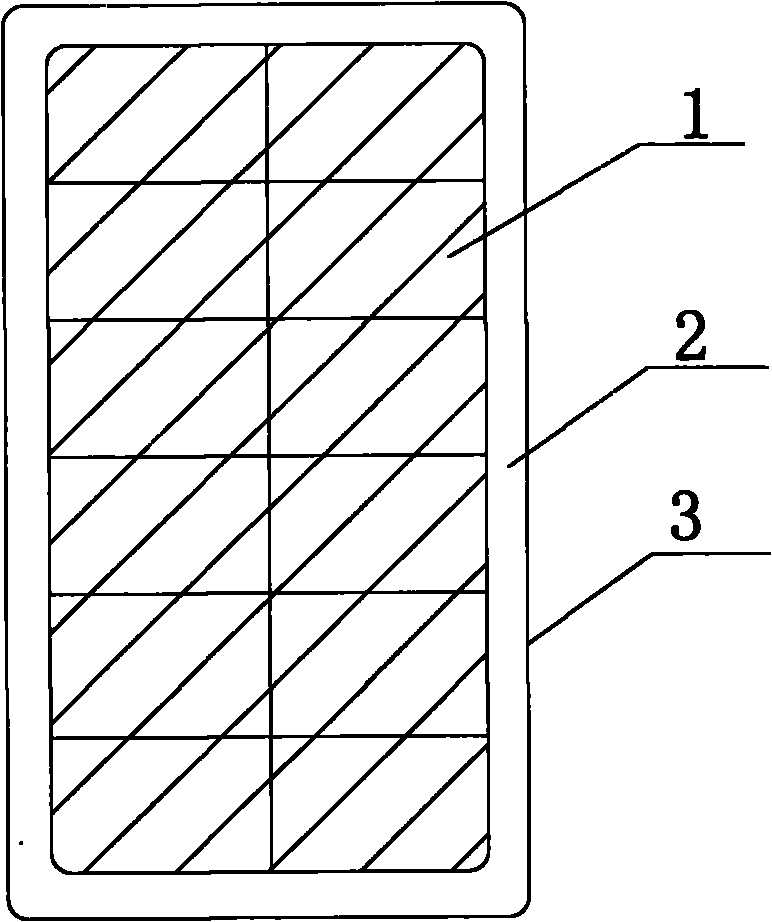

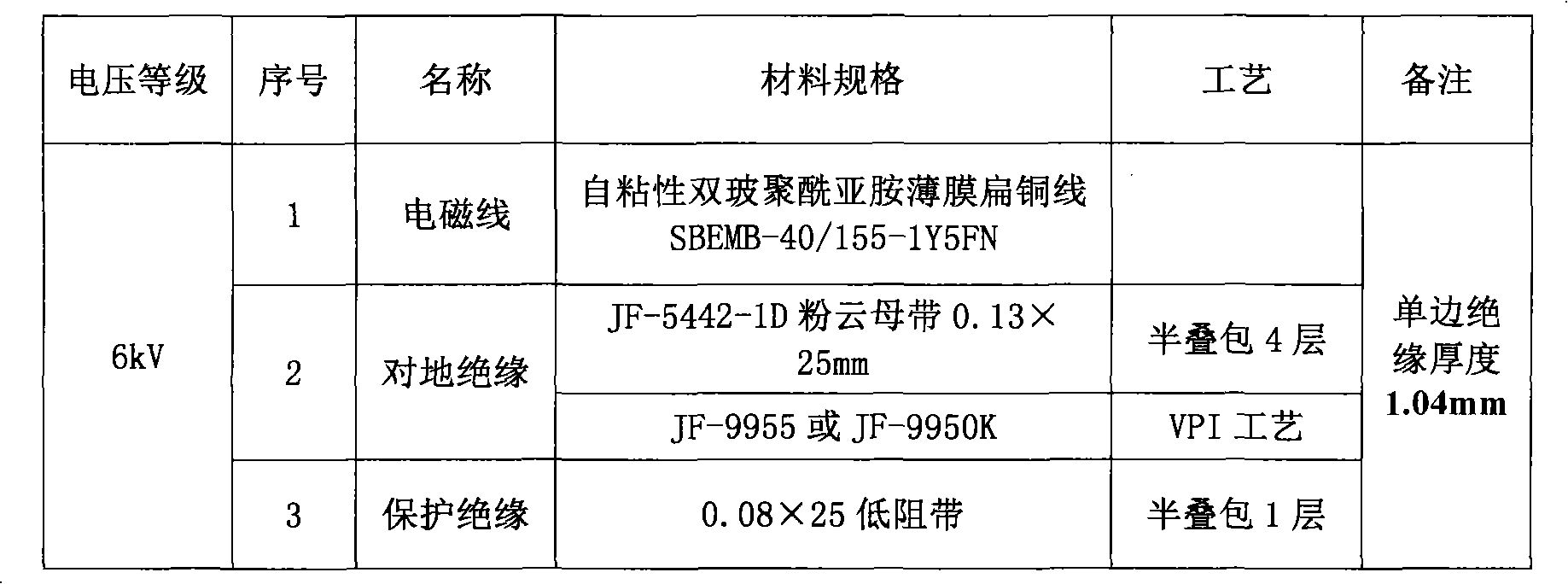

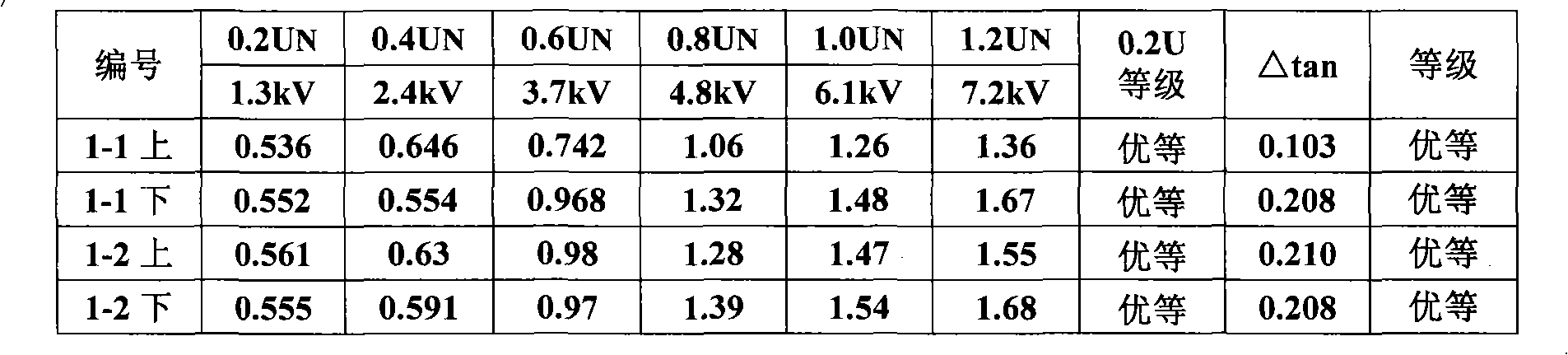

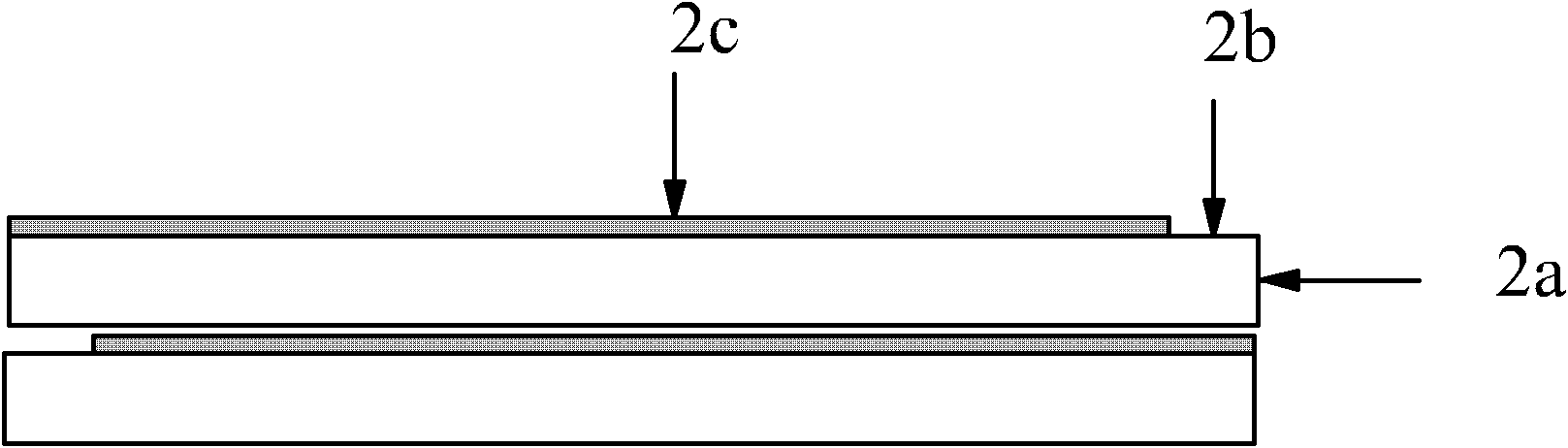

Reduction insulation structure suitable for high-voltage motor and insulation processing method thereof

InactiveCN101854090AImprove electrical strengthNormal dielectric loss is excellentWindings insulation materialWindings insulation shape/form/constructionThermal stateVacuum pressure

The invention discloses a reduction insulation structure suitable for a high-voltage motor and an insulation processing method thereof. The reduction insulation structure comprises a plurality of low resin mica tapes (2) lapped outside an electromagnetic coil (1), and is characterized in that vacuum dipping treatment is carried out by utilizing vacuum pressure dipping resin after the low resin mica tape is lapped, and the insulation structure with reduced insulation thickness is formed after baking and curing. The breakdown voltage of the insulation structure is qualified, the normal dielectric loss, the thermal state dielectric loss, the dielectric loss increment and the electrical strength of the insulation structure reach high grade.

Owner:SUZHOU JUFENG ELECTRICAL INSULATION SYST

Heat-conducting insulated adhesive

InactiveCN103497718AReasonable ratioImprove thermal conductivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesEpoxyAdhesive

The invention discloses a heat-conducting insulated adhesive, comprising the following components in parts by weight: 50-60 parts of epoxy resin, 5-8 parts of curing agent, 6-9 parts of plasticizer, 3-5 parts of diluent, 9-12 parts of aluminium nitride, 5-6 parts of coupling agent, and 2-3 parts of fire retardant. The heat-conducting insulated adhesive is prepared by the following steps: weighing the epoxy resin; adding the diluent; evenly stirring and heating to 160-180 DEG C; cooling at room temperature, adding aluminium nitride and the curing agent, which are processed by the coupling agent; evenly stirring and curing for 4-5 hours at 60-80 DEG C. In the manner, the heat-conducting insulated adhesive disclosed by the invention is reasonable in proportion, has excellent heat-conducting coefficient, electric strength and bonding strength, also has a plurality of functions, and can be used as heat-conducting resin, an adhesive, a coating and a potting compound.

Owner:KUNSHAN FENFA INSULATING MATERIALS

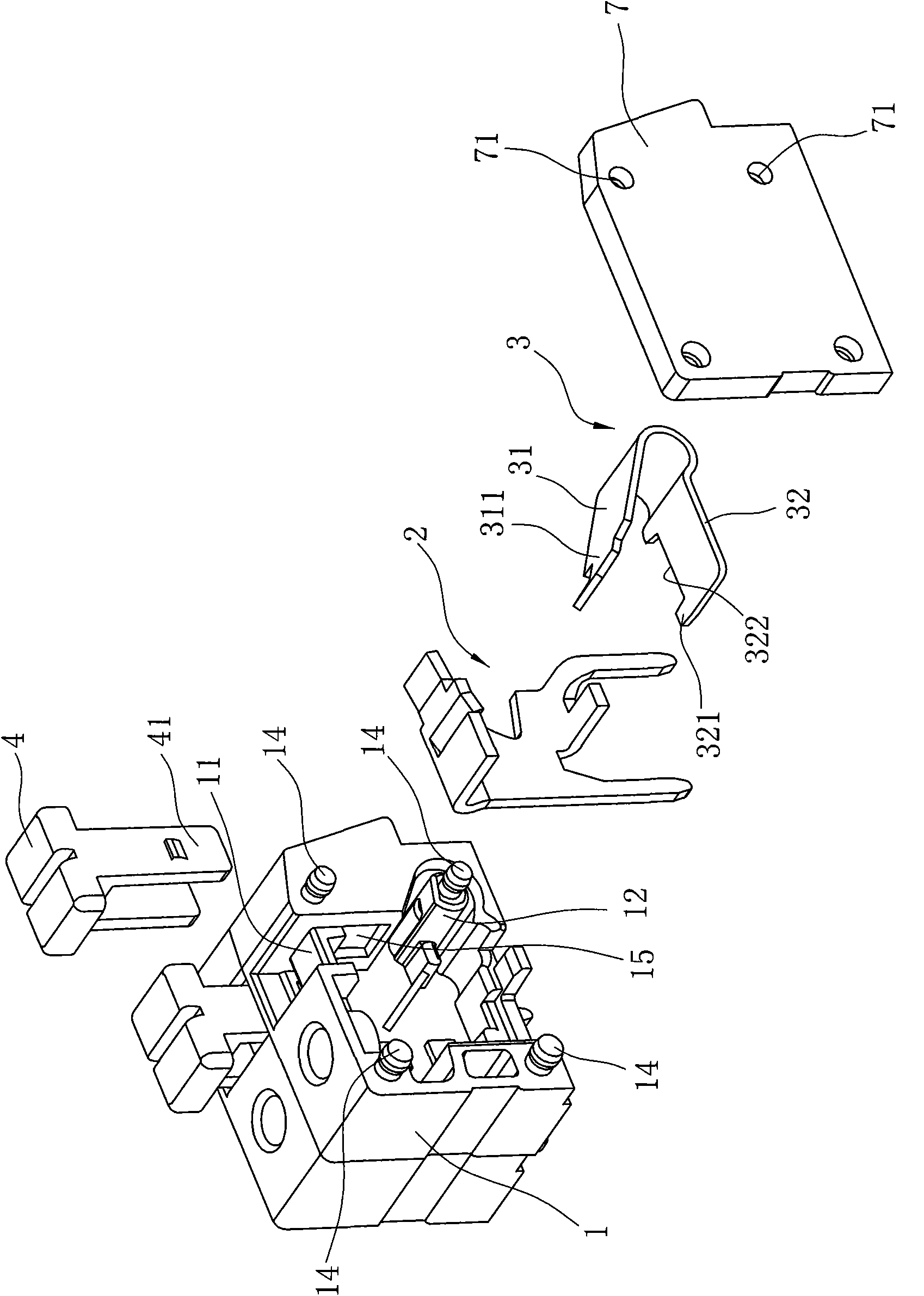

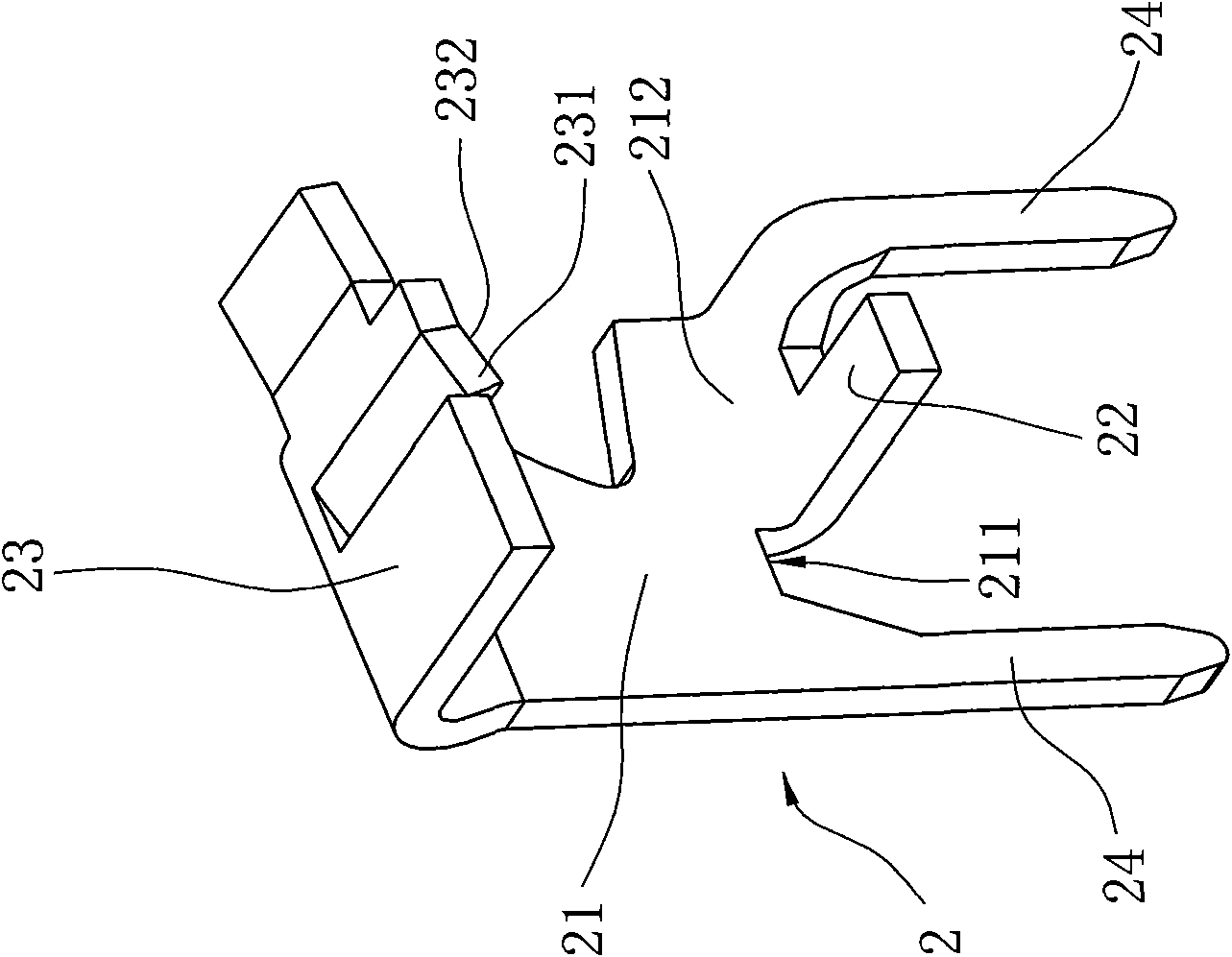

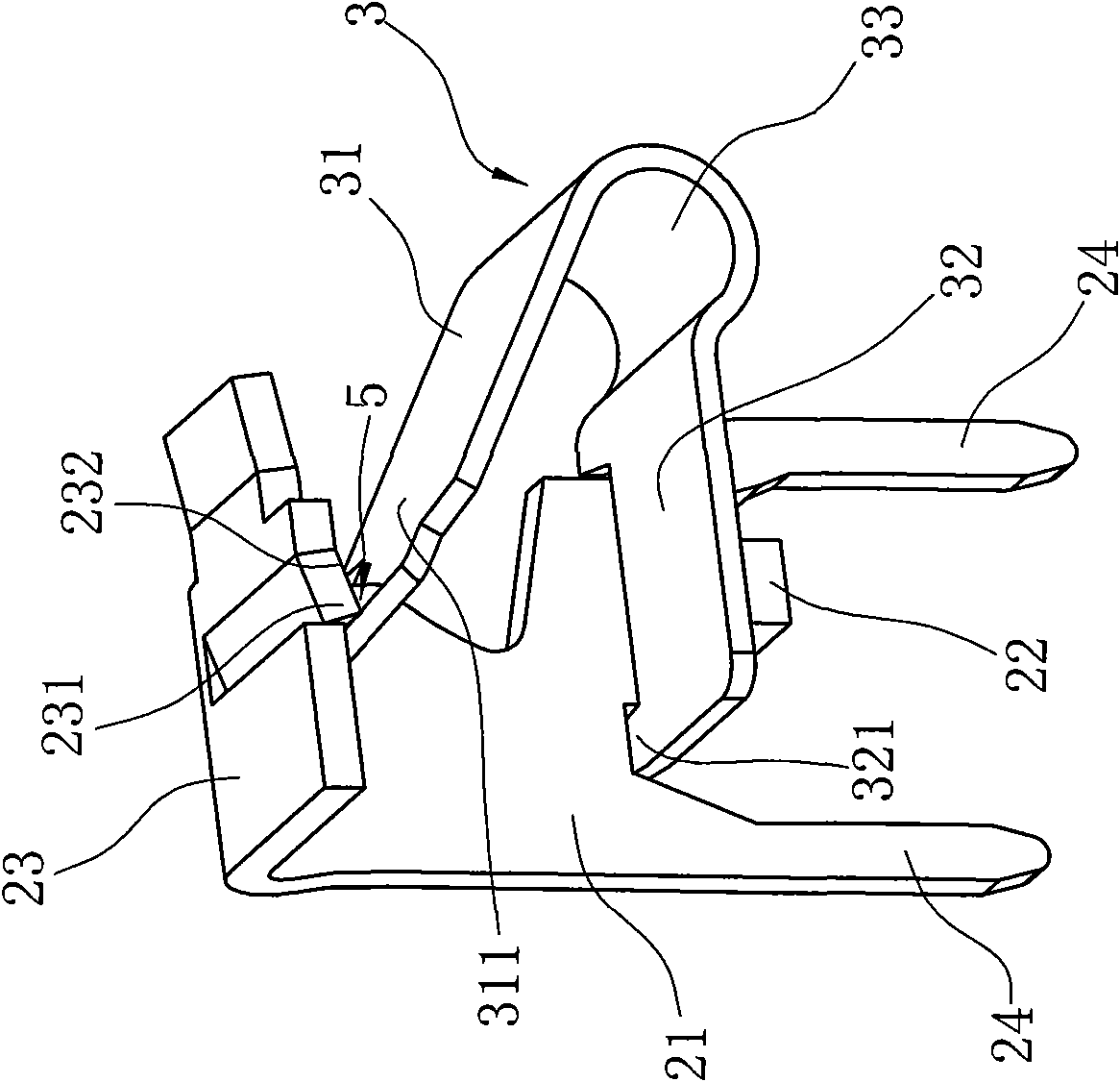

Electric connector

ActiveCN101562282AIncreased current carrying areaImprove conductivityCoupling device connectionsContact member manufacturingElectricityState of art

The invention provides an electric connector. The electric connector comprises an insulating base, a solder terminal fixedly arranged in the insulating base and an elastic plate comprising a free end and a fixed end, wherein the free end always keeps the trend of pressing against the solder terminal; the fixed end is fixedly connected with the solder terminal; and the bottom end of a button connected with the upper part of the base is pressed against the free end of the elastic plate. The electric connector is characterized in that the solder terminal comprises a current carrying main board, and a support plate pressed against the bottom of the fixed end extends out of the lower part of the current carrying main board and the upper edge of the current carrying main board is bended outwards to form a capped edge pressed against the top of the free end; the current carrying main board, the support plate and the capped edge of the solder terminal form a C-shaped cross section; and the bottom of the solder terminal is also provided with two solder legs which are one-piece formed, arranged on both sides of the support plate respectively and staggered front and back. Compared with the prior art, the electric connector has the advantages that the current carrying area of the solder terminal is larger, and the conductivity of the solder terminal is improved; and because the solder legs are staggered front and back, the creepage distance is increased, the withstand voltage value of the electric connector is improved, and the electric strength of the product is further improved.

Owner:NINGBO DEGSON ELECTRONICS CO LTD

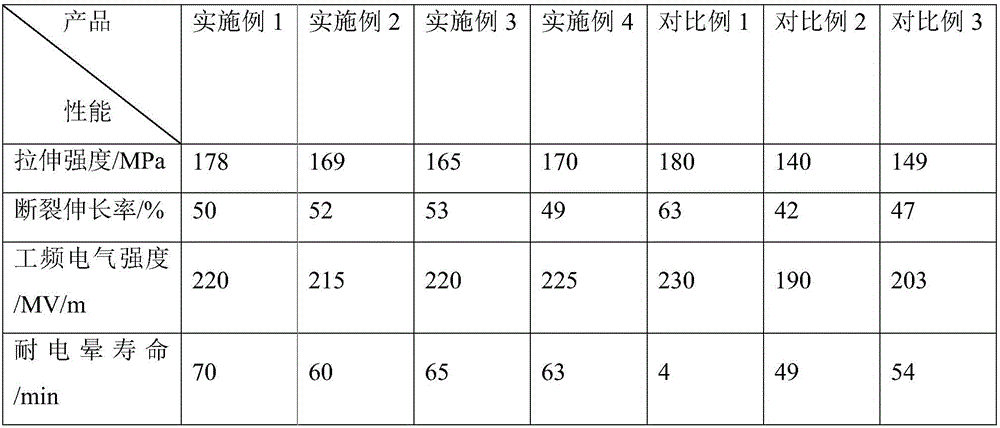

Polyimide thin film and preparation method therefor

ActiveCN106589374AUniform and stable dispersionImprove the interface binding forceEpoxyCoupling reagent

The invention discloses a preparation method for a polyimide thin film. The preparation method comprises the steps of adding an inorganic filler dispersing liquid, the surface of which is modified by coupling agents, and dianhydride and diamine into a polarity organic solvent to be mixed, and performing condensation polymerization on the dianhydride and diamine to obtain polyamide acid resin; and performing de-foaming, curtain coating and imidization on the polyamide acid resin in sequence to obtain the polyimide thin film, wherein the coupling agents comprise a coupling agent A and a coupling agent B; the coupling agent A is selected from a silane coupling agent or a titanate coupling agent with any one reactive group of amino group, formyl group, epoxy group, isocyanato, anhydride group, sulfydryl group and the like; the coupling agent B is selected from the silane coupling agent or the titanate coupling agent comprising long-chain alkyl; and the molar ratio of the coupling agent A to the coupling agent B is 2:8-8:2. The polyimide thin film prepared by the preparation method is 165-180MPa in tensile strength, 48-60% in breaking elongation, 210-230MV / m in power frequency electric strength, and 60-80h in corona resistance service life.

Owner:株洲时代华鑫新材料技术有限公司

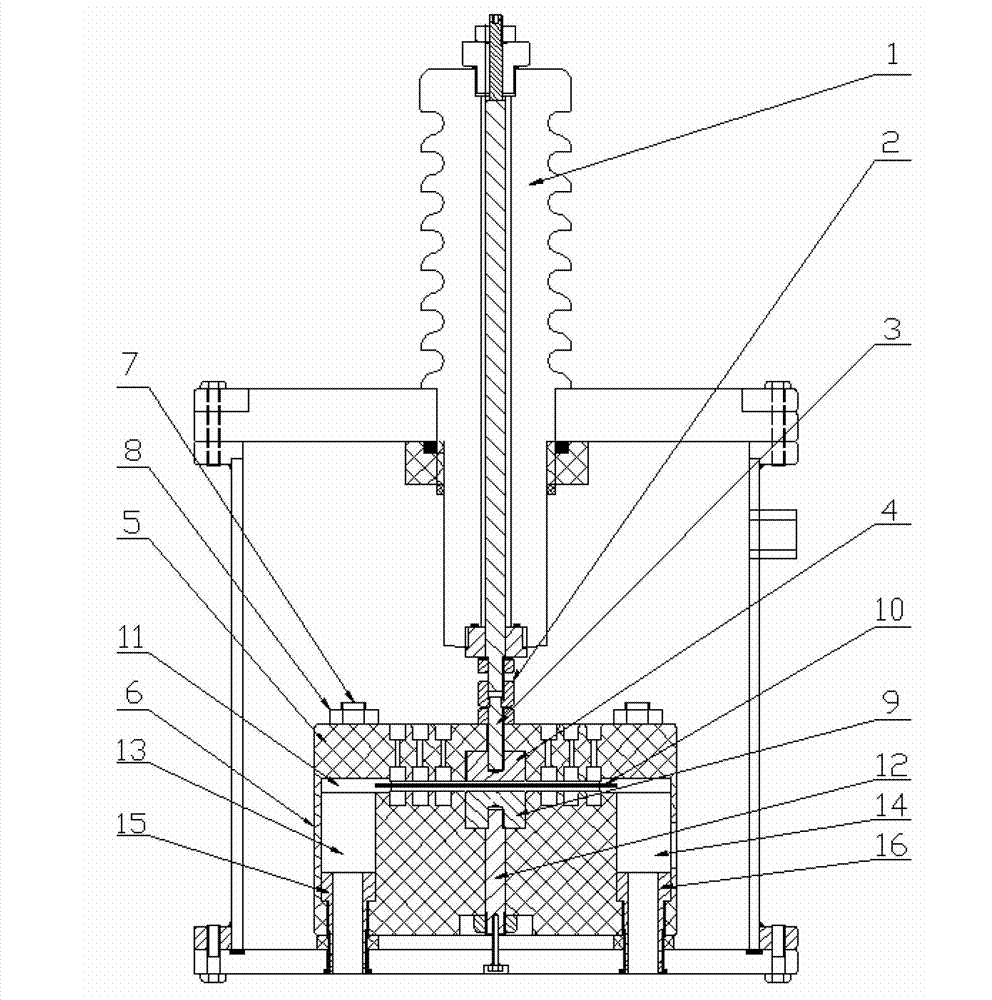

Electric strength inspection device for oil paper compound insulation oil during flowing

InactiveCN102967652ASolve installation difficultiesAvoid flashoverMaterial breakdown voltageTesting dielectric strengthProcess errorEngineering

The invention relates to an electric strength inspection device for oil paper compound insulation oil during flowing, belongs to the technical field of high voltage and insulation, and aims at solving the problems of difficulty in mounting and frequent flashover caused by processing errors of the existing electric strength inspection devices. The electric strength inspection device comprises a high-voltage bushing, a lower connecting piece of the high-voltage bushing, an upper electrode connecting piece, an upper electrode, an upper electrode insulating member, a lower electrode insulating member, an insulating screw rod, an insulating nut, a lower electrode, an insulating paper board, an oil duct, an earthing bolt, an oil inlet, an oil outlet, an oil inlet connecting piece and an oil outlet connecting piece, wherein the low connecting piece of the high-voltage bushing, the upper electrode connecting piece, the upper electrode, the upper electrode insulating member, the lower electrode insulating member, the insulating screw rod, the insulating nut, the lower electrode, the insulating paper board, the oil duct and the earthing bolt are arranged in a high-voltage test box, the upper electrode is arranged right above the lower electrode and is embedded in the upper electrode insulating member, the lower electrode is embedded in the lower electrode insulating member, and the upper electrode insulating member is arranged above the lower electrode insulating member.

Owner:STATE GRID CORP OF CHINA +1

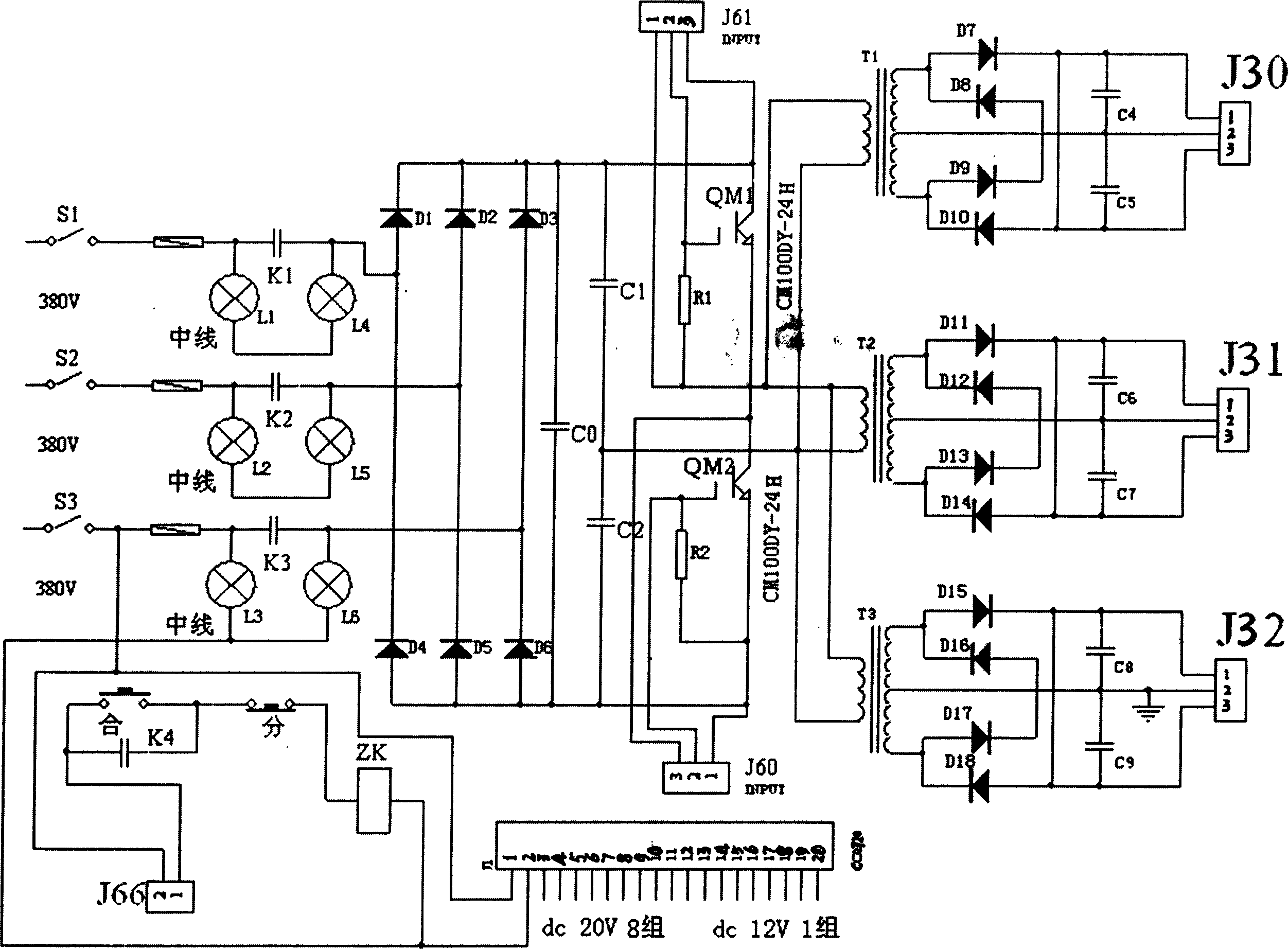

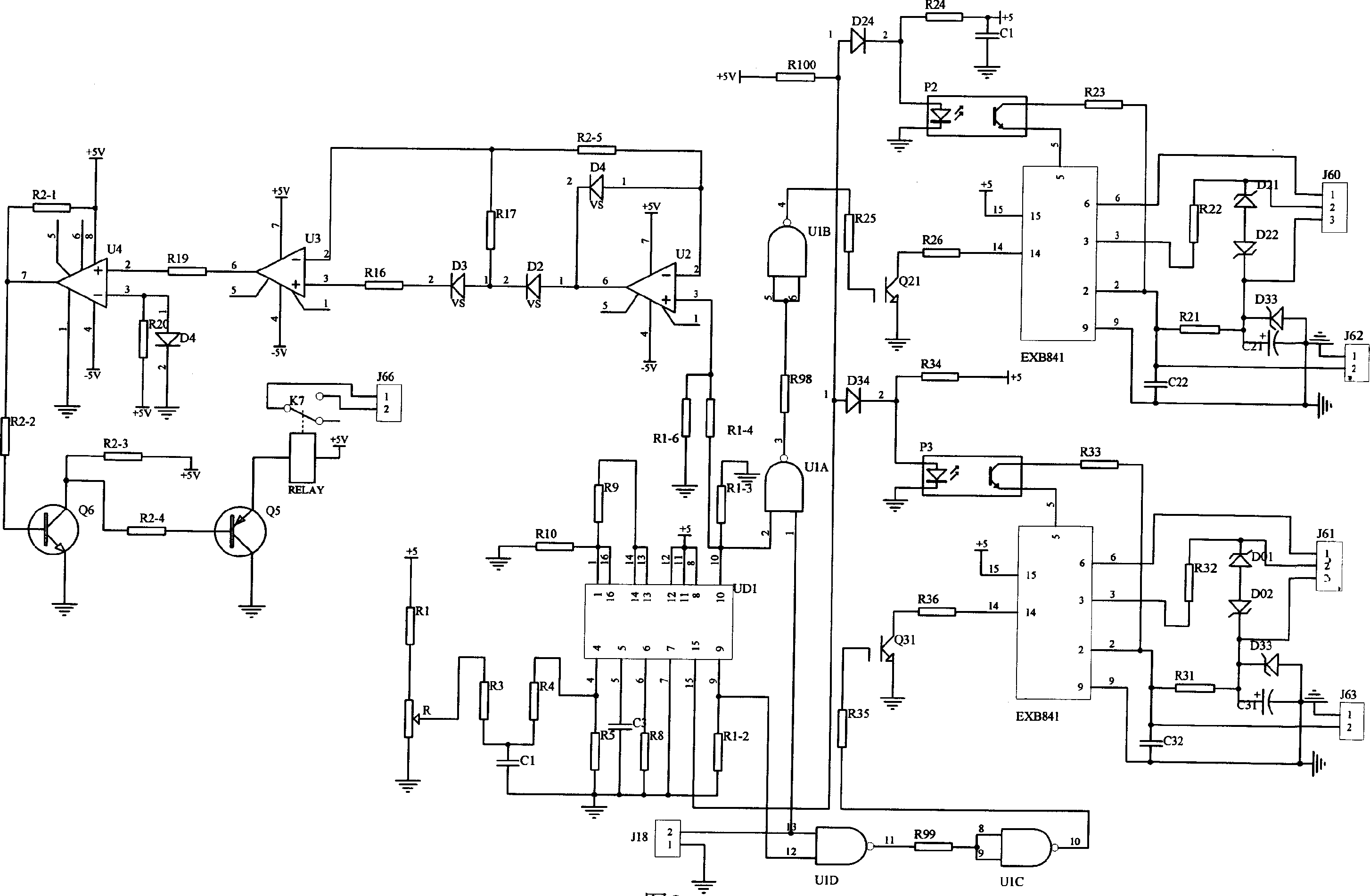

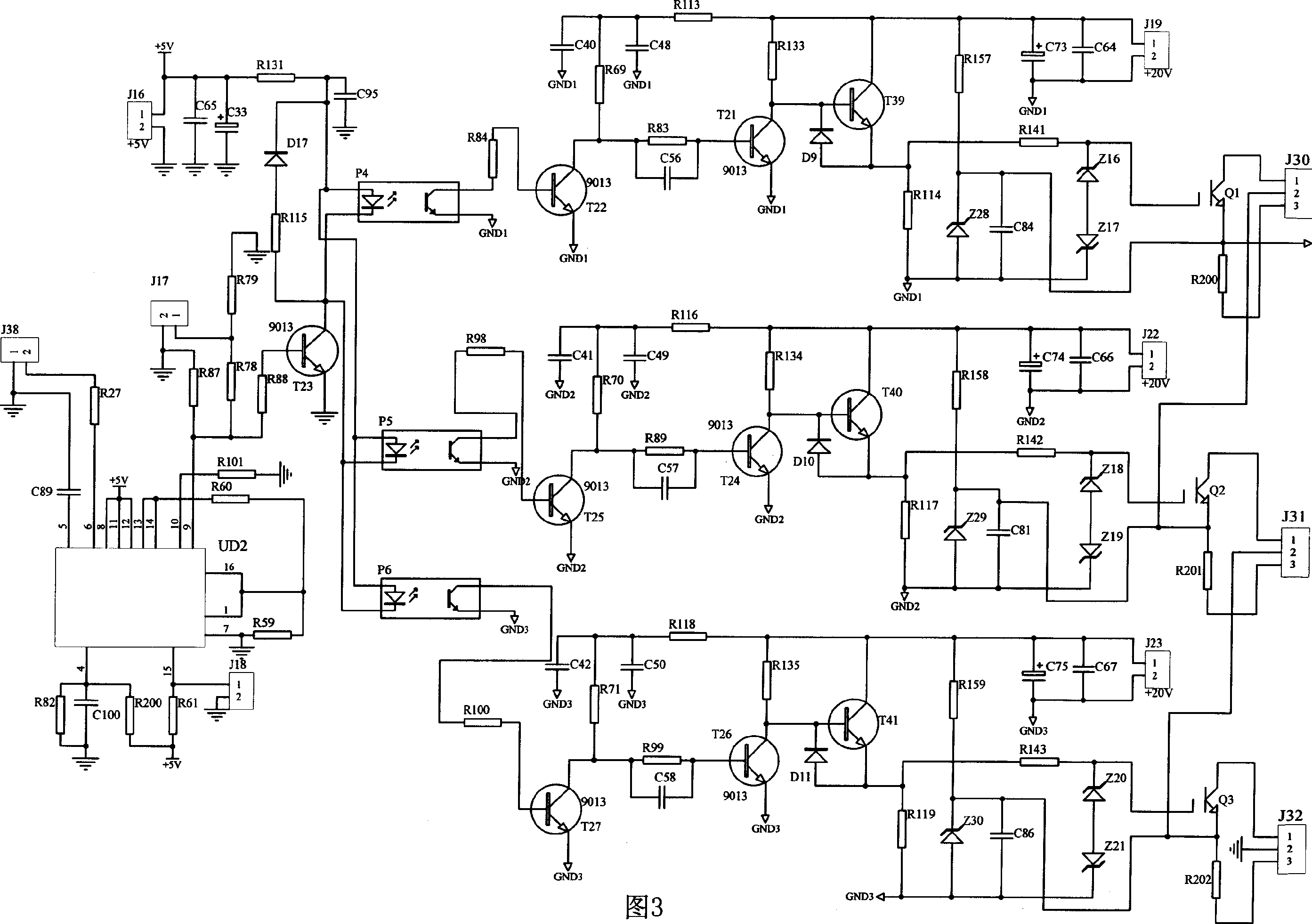

Device for testing electric pulse strength for insulation

The present invention discloses an insulated pulse electric strength testing device. Said device mainly is formed from four portions of adjustable DC power supply, drive circuit, plus or minus 1600V and 25ns pulse generator and sample, protection and timing circuit. Said device can be used for measuring insulated electric strength of enamelled wire or between turns of winding of adjustable frequency motor. Besides, said invention also provides the concrete steps of said testing method.

Owner:XI AN JIAOTONG UNIV

Abrasive steel paperboard and manufacturing process thereof

ActiveCN103147356AImprove water absorptionGood gelling effectSpecial paperPaper/cardboardFiberEmulsion

The invention discloses an abrasive steel paperboard. The abrasive steel paperboard is prepared from the following materials in percentage by weight: 93.8%-96.8% of cotton fiber, 3%-6% of wood fiber and 0.1%-0.2% of styrene-acrylic emulsion. The manufacturing process of the abrasive steel paperboard comprises the following steps of: (1), pulping and rinsing; (2), making paper and gelling; (3), aging and desalinizing; (4), washing and gluing; (5), pre-drying and drying; and (6), carrying out press polishing and packaging. Relative to the pure-cotton fiber abrasive steel paperboard, the volume resistance of the abrasive steel paperboard disclosed by the invention is increased by 30%, the electric strength of the abrasive steel paperboard is increased by 12%, the longitudinal drying shrinkage and the transverse drying shrinkage are reduced by 6% and 15%, respectively; and compared with the water adsorption of the un-glued abrasive steel paperboard, the water adsorption of the abrasive steel paperboard provided by the invention is reduced by 14%.

Owner:杭州特种纸业有限公司

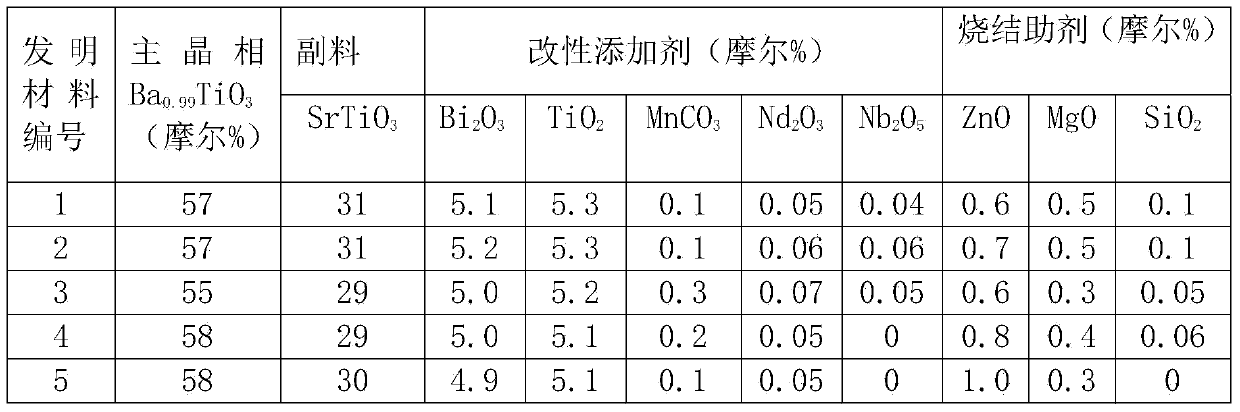

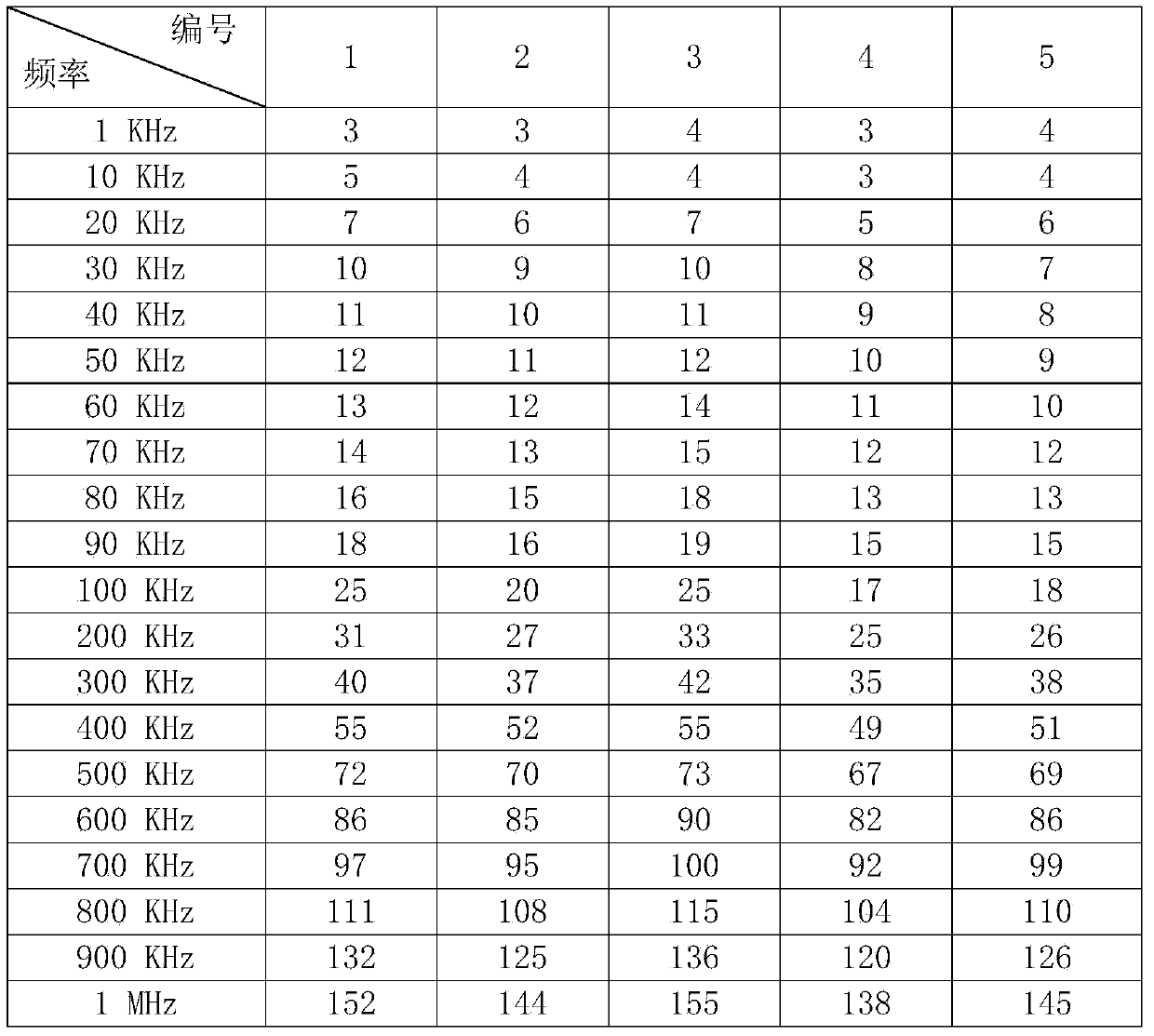

High-power-resistant type lead-free environment-friendly ceramic dielectric material

The invention relates to a high-power-resistant type lead-free environment-friendly ceramic dielectric material which comprises a primary crystalline phase, an indirect material, a modified additive and a sintered fluxing agent, wherein a structural formula of the primary crystalline phase is BaTiO3; the indirect material is SrTiO3; the modified additive refers to one or more of MnCO3, TiO2, CaCO3, ZrO2, Nd2O3 and Nb2O5; the sintered fluxing agent refers to one or more of Bi2O3, ZnO, MgO and SiO2; and the ceramic dielectric material comprises the following components in parts by mole: 50-65mol% of primary crystalline phase, 30-45mol% of indirect material, 2-10mol% of modified additive and 2.5-20mol% of sintered fluxing agent. The ceramic dielectric material accords with the N4700 characteristic, has the advantages of high dielectric constant, good frequency-dielectric loss characteristics, high electric strength, uniform particle size distribution and good forming process and accords with the environment-friendly requirement.

Owner:鞍山信材科技有限公司 +1

Black matte polyimide film and preparation method thereof

The invention discloses a polyacrylonitrile-blended black matte polyimide film and a preparation method thereof. Polyacrylonitrile and polyamide acid are prepared by virtue of an in situ polymerization method to form a blended solution with a molecular interpenetrating network. The preparation method comprises the following steps: mixing polyacrylonitrile powder particles with a high-polarity nonprotic organic solvent, heating, stirring to adequately dissolve, cooling, adding aromatic binary primary amine, after the dissolving is complete, adding aromatic binary anhydride, heating and stirring to obtain a uniform blended solution in which polyacrylonitrile and polyamide acid are in micro-phase separation, wherein different separation phase domains can be obtained by selecting polyacrylonitrile with different weight-average molecular weights; and carrying out salivation, drying, heating and amination on the blended solution, so as to obtain the black matte polyimide film. The black matte polyimide film has relatively high power frequency electric strength, excellent mechanical properties, extremely low light transmittance and a good black matte effect.

Owner:无锡高拓新材料股份有限公司

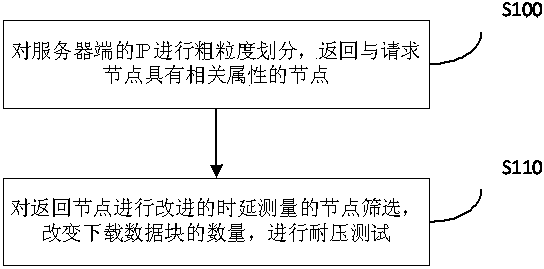

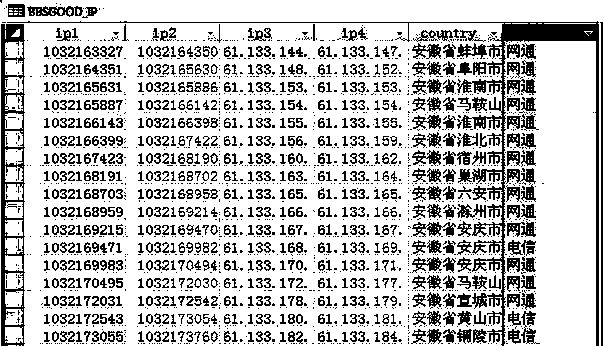

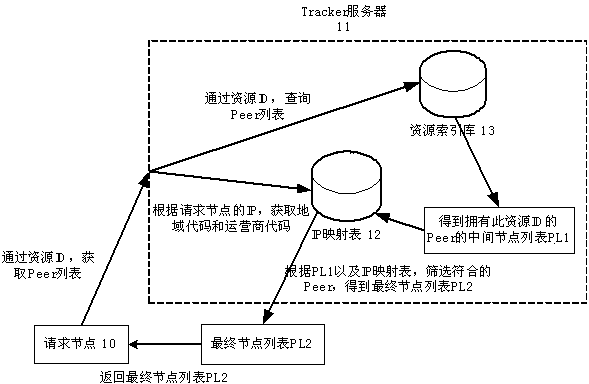

P2P (peer-to-peer) network node selecting method

InactiveCN103973596AEasy to set upReduce buildData switching networksTraffic capacityOperator interface

Disclosed is a P2P (peer-to-peer) network node selecting method. The method includes: through an IP (internet protocol) address mapping library of a Tracker server, performing fast coarse granularity division on existing nodes to enable the divided nodes to have same location information, and selecting a final node list possessing requested media resources according to the location information of a request node; performing improved node selecting for delay measurement on the nodes returned by the final node list, performing electric strength test on the nodes in the node list by the request node, increasing the number of download data blocks so as to fast acquire the nodes preliminarily meeting the requirements, and selecting most suitable nodes as neighbor nodes. The method has the advantages that networking is simplified without participation of operators, establishment and maintenance cost is low, network-to-network flow is reduced, flow among operator interfaces is reduced, data congestion of a backbone network is avoided, the needed neighbor nodes can be selected fast, the selected nodes are fast in response and high in bandwidth.

Owner:ALIBABA (CHINA) CO LTD

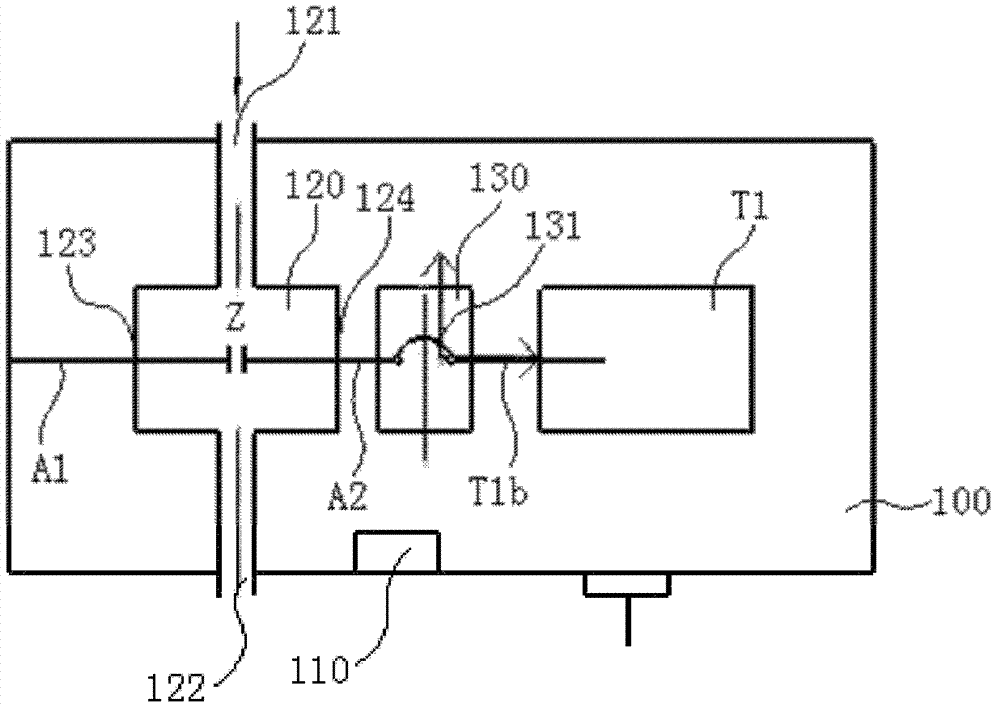

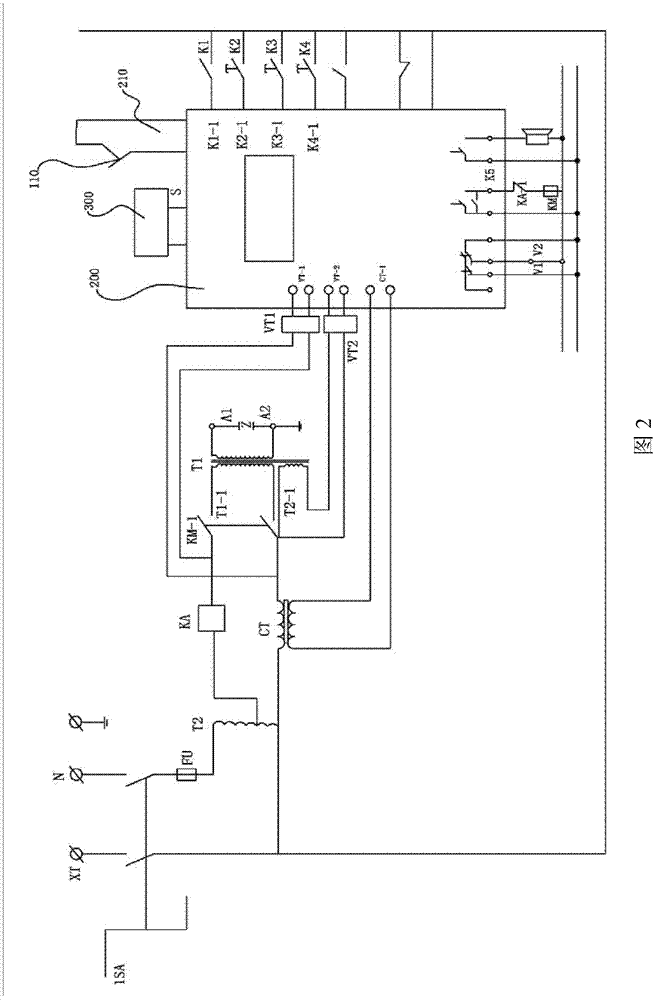

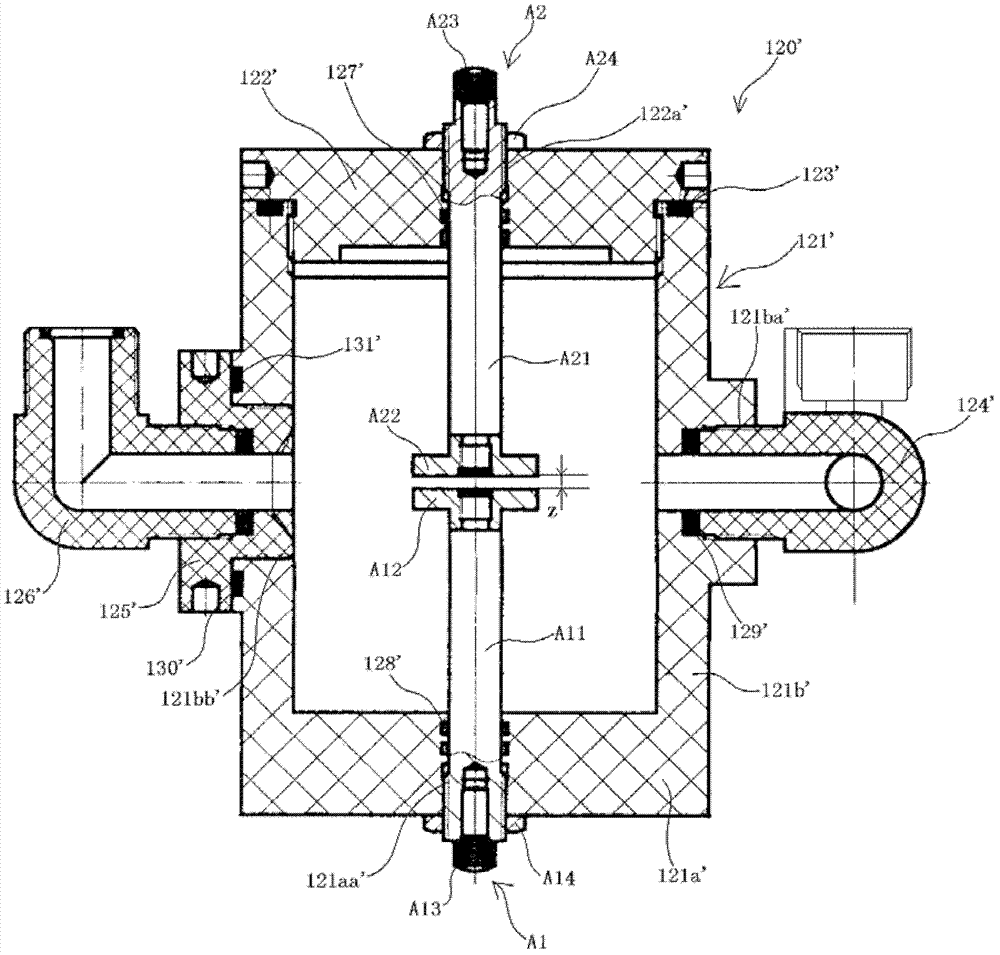

Device for monitoring electric strength of insulating oil medium for on-load tapping switch on line

ActiveCN102788937AReduce particle impuritiesReduce water contentTesting vessel constructionElectricityTransformer

The invention discloses a device for monitoring the electric strength of the insulating oil medium for an on-load tapping switch on line, comprising a high-voltage testing bin and a controller. The high-voltage testing bin is connected in series in a circulating pipe of an on-load switch on-line oil purifying device and provided with a pair of testing electrodes; the output end of a voltage-increasing transformer T1 is electrically connected with the wiring terminals of a pair of testing electrodes so as to apply testing voltage to the pair of testing electrodes; and the controller is used for controlling the voltage increasing and decreasing of the voltage-increasing transformer T1. When the oil breaks down, due to the dual protection of an overcurrent protection device and the controller, the high-voltage power supply is cut off quickly and automatically. When the electric strength of the insulating oil medium for the on-load tapping switch is lower than the predetermined index, the oil is filtered automatically on line by the high-precision high-efficiency particle removing filter and water removing filter, thus the content of particle impurities and trace water in the oil is reduced, the breakdown voltage of the oil is improved, the insulating level of the on-load tapping switch is guaranteed, and the requirements for high-security high-reliability power operation at present are adapted better.

Owner:SHANGHAI HUAMING POWER EQUIP CO LTD

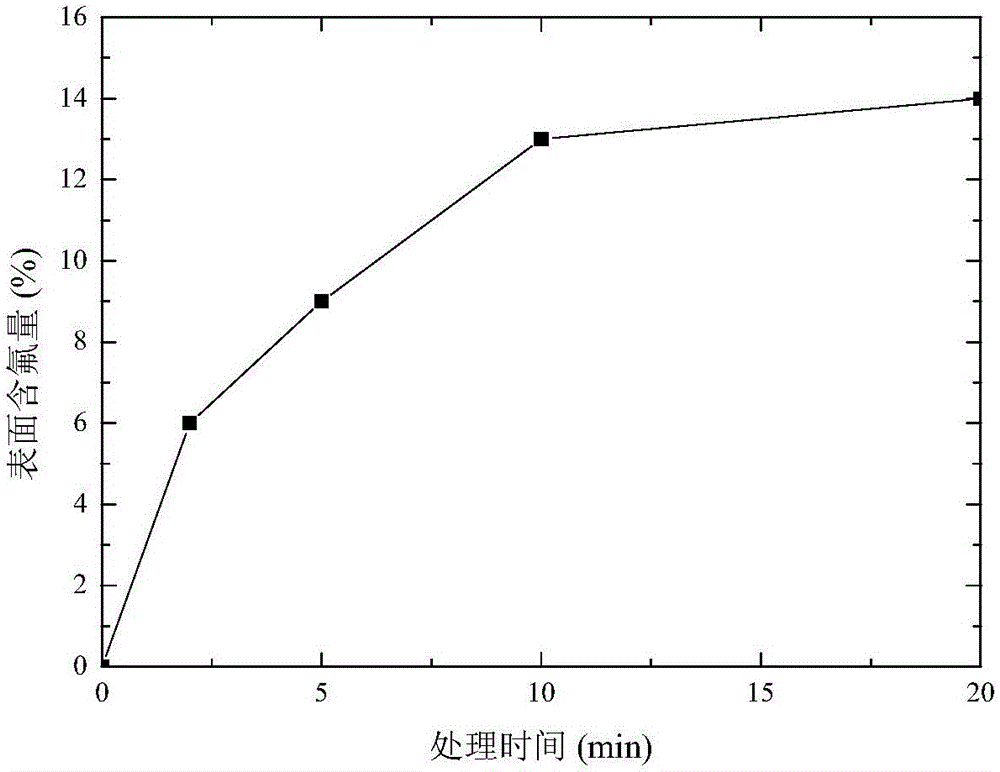

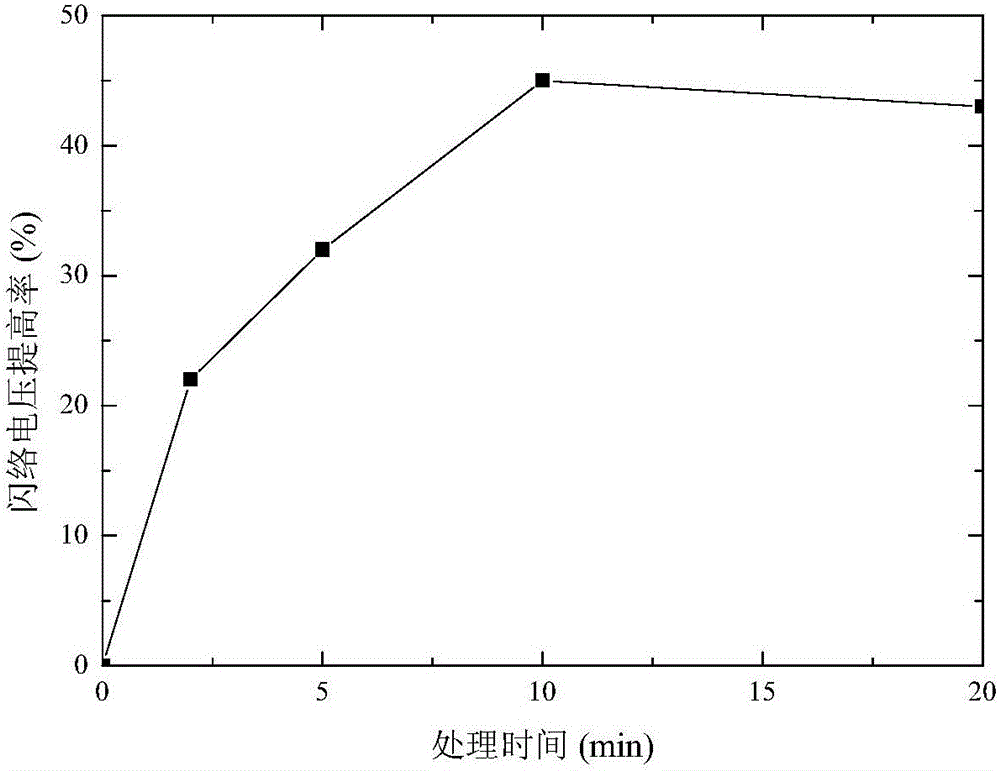

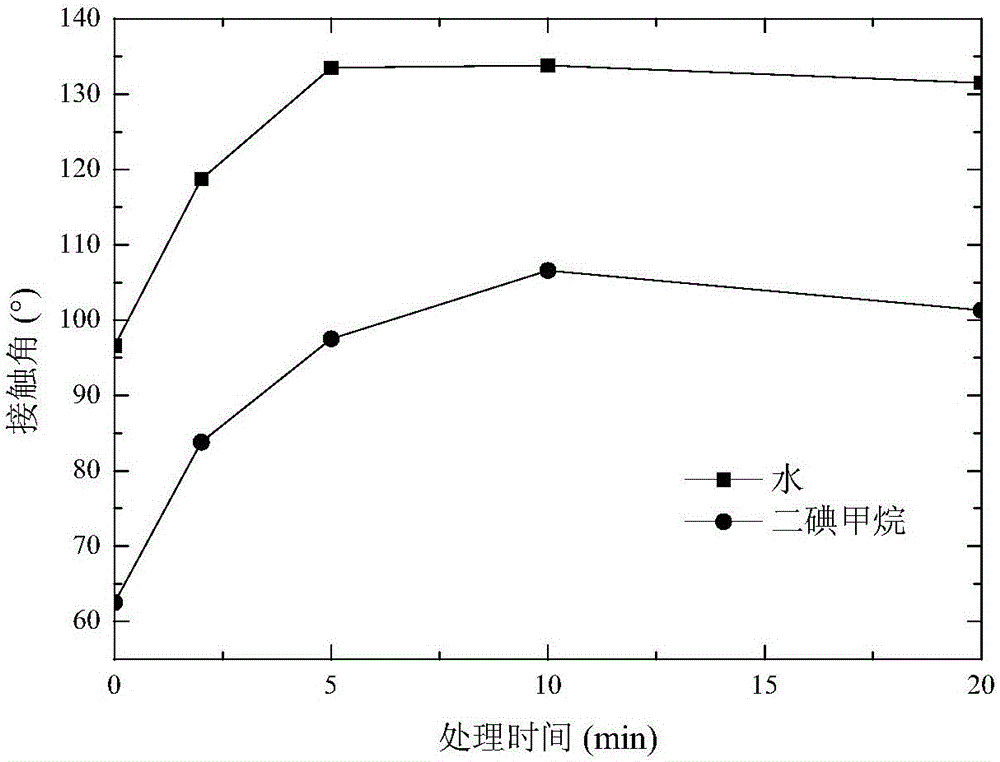

Method for fluorinating insulator through use of CF4 plasma

The invention belongs to the technical field of high voltage and insulation, and specifically relates to a method for fluorinating an insulator through use of a CF4 plasma. According to the method, an insulator is put in a reaction cavity, a mixture of CF4 and an inert gas is fed into the reaction cavity, the insulator is processed by a discharge plasma for 2-30min at room temperature and at low pressure of 0.01-0.1atm, so CF4 and the surface of the insulator are reacted with each other to generate a fluorinated layer. The method has the characteristic that the surface of a insulator is fluorinated through plasma processing in CF4, the surface flashover characteristic of insulators is improved, the electric strength of insulators is improved, the flashover voltage can be improved by about 50% to the maximum, the hydrophobic and oleophobic properties of the surfaces of insulators are improved, and the capability of insulators to prevent wet flashover and pollution flashover is improved.

Owner:XI AN JIAOTONG UNIV

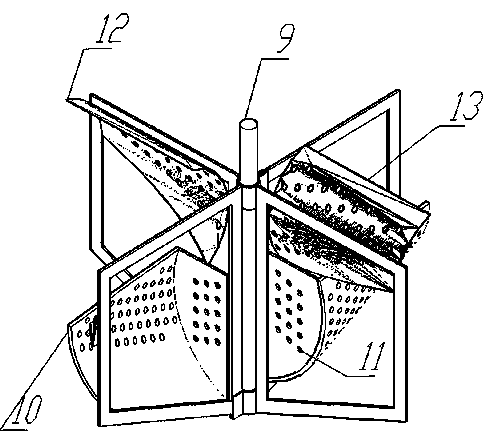

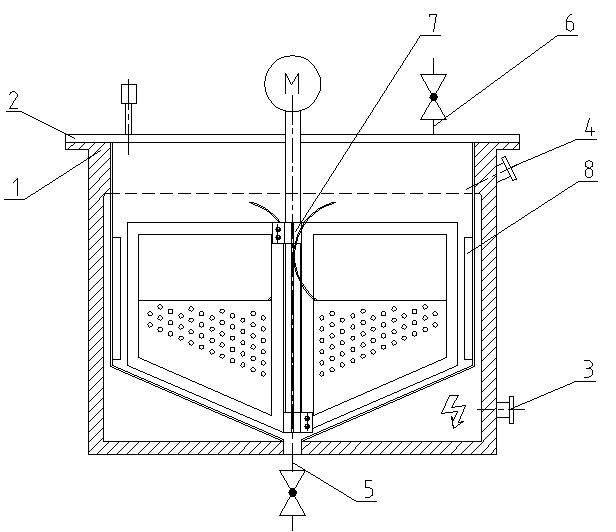

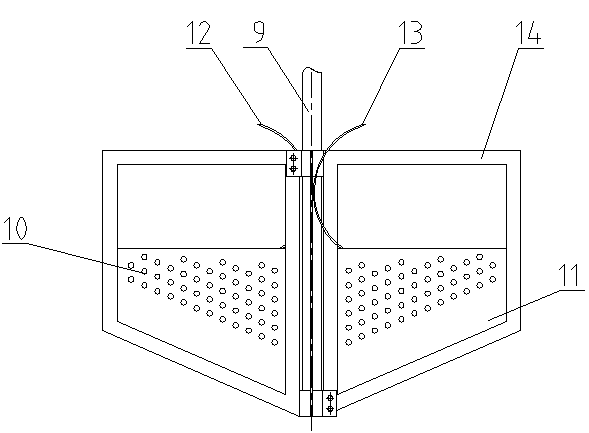

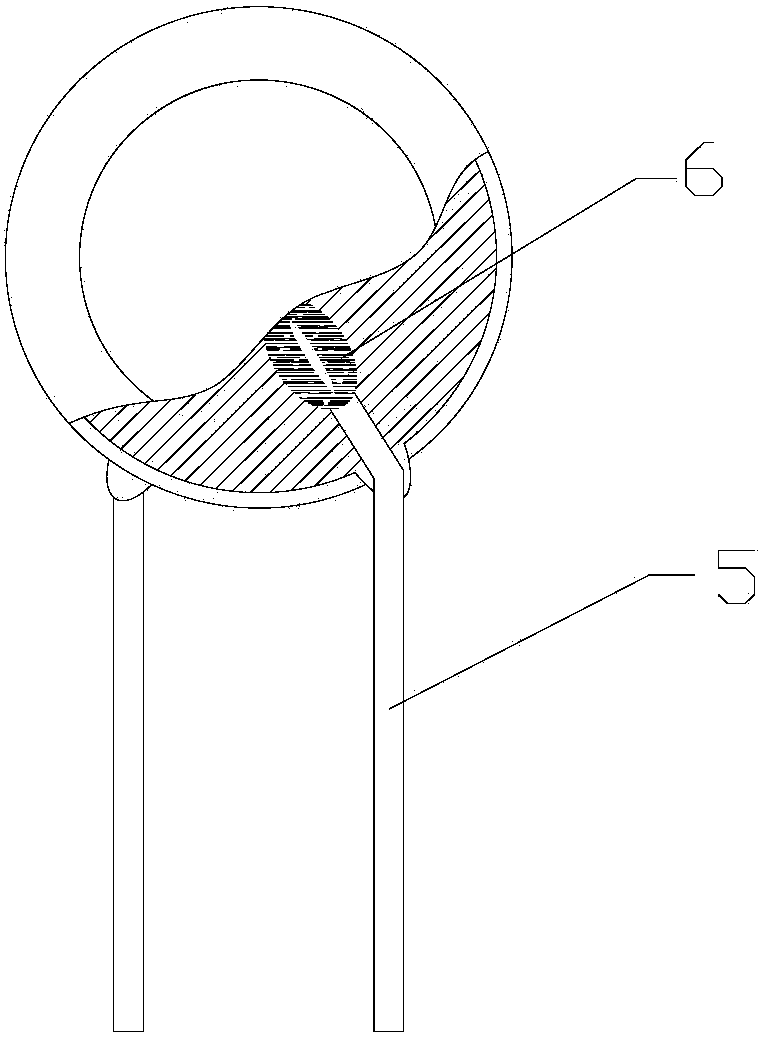

Epoxy resin vacuum degassing mixing tank

ActiveCN103465387AImprove the mixing effectThere is no local frictional overheatingTransportation and packagingRotary stirring mixersEpoxyTransformer

The invention discloses an epoxy resin vacuum degassing mixing tank. The mixing tank comprises a tank body (1), a tank cover (2), an electric heating device (3), a feeding hole (4), a discharge hole (5), a stirring assembly (7) and a motor and is characterized in that the bottom of the tank body (1) is turbinate; spoilers (8) are axially arranged on the cylindrical inner wall sides of the tank body (1); a vacuum valve (6) is arranged on the tank cover (2) and is connected with a vacuum pump; the stirring assembly (7) comprises a rotating shaft (9), lower stirring blades (10, 11), upper stirring blades (12, 13) and a stirring flat steel frame (14). The mixing tank substantially reduces the equipment cost, is simple to manufacture, convenient to maintain and easy to clean, can not only ensure the quality of the mixture but also improve the mixing efficiency, thoroughly eliminates the hidden danger of local friction overheat possibly occurring in the mixing process, especially can achieve good stirring effects when a few mixtures exist and greatly improves the electrical strength and mechanical strength of a transformer.

Owner:JIANGXI GANDIAN ELECTRIC

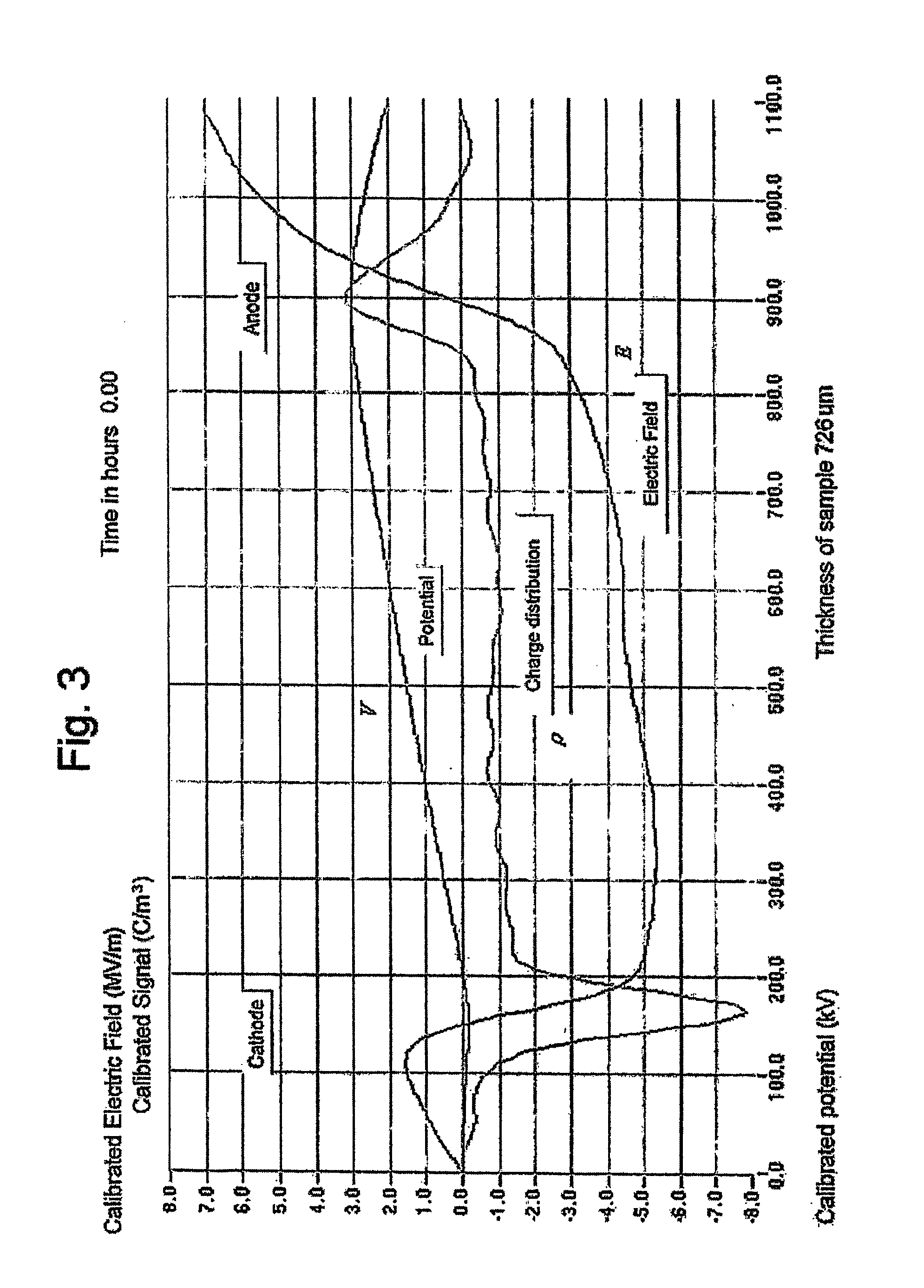

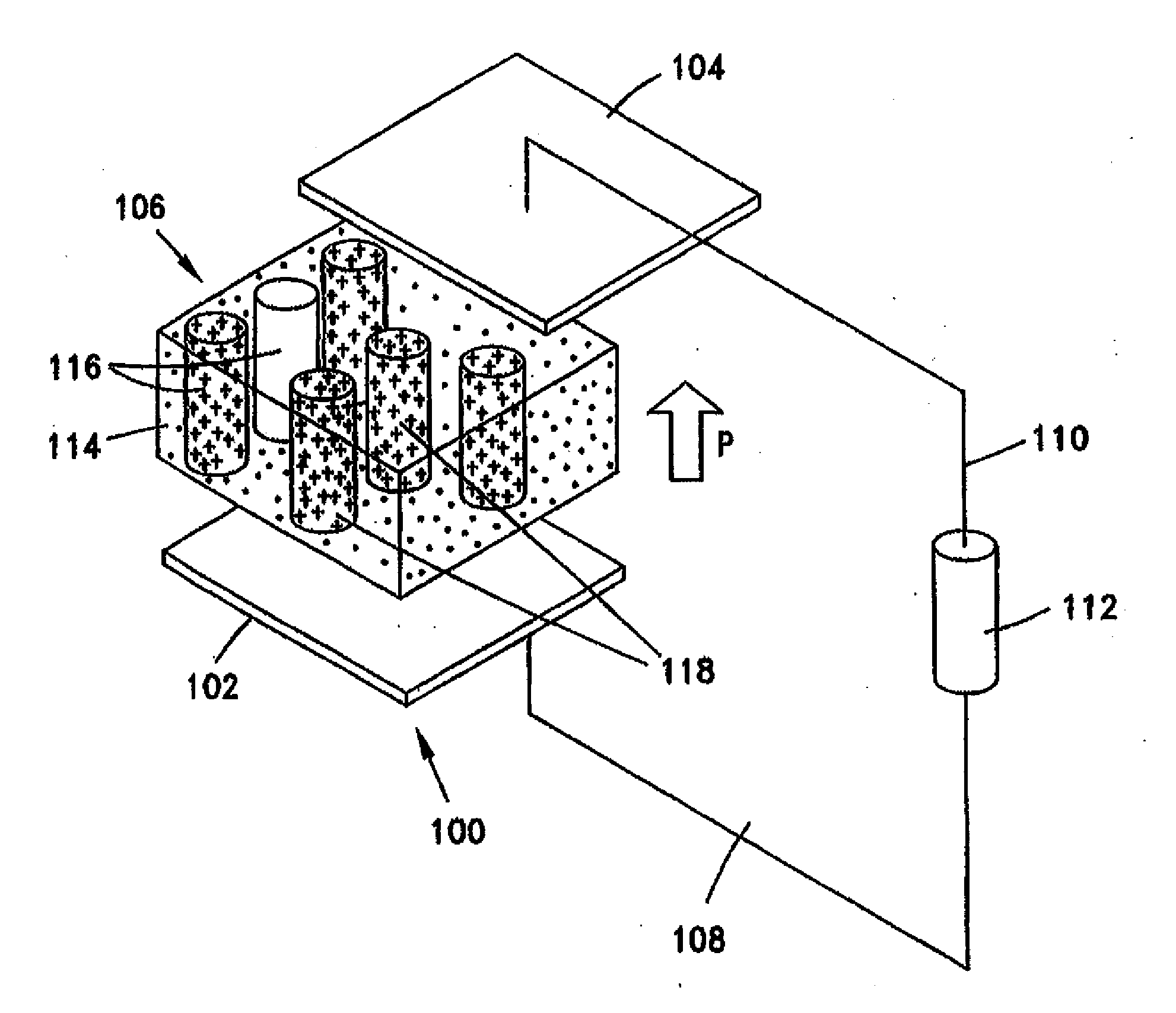

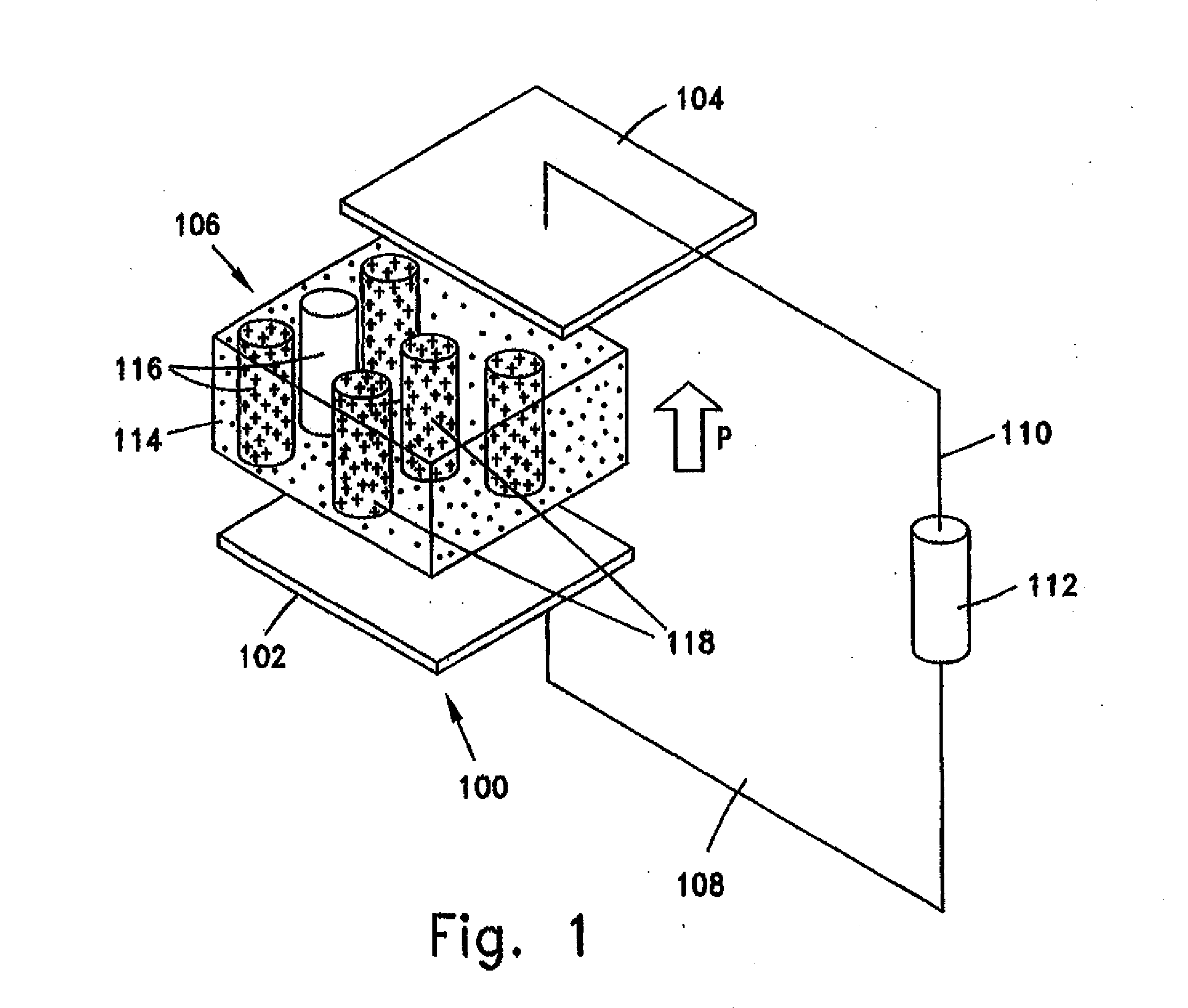

Photovoltaic device on polarizable materials

The invention is a photovoltaic device configured as a sandwiched structure comprising a bulk region between a pair of collecting electrodes. The bulk region comprises an electric-field inducing component and a photoactive component. The photoactive component is in electric contact with the collecting electrodes to provide a continuous conduction path for photo-generated charge carriers between the electrodes. The electric-field inducing component is adapted to provide a permanent electric field having high electric strength in the entire inter-electrode region, thereby inducing an electric field in the photoactive component. The electric-field inducing component does not participate in transport of the photo-generated charge carriers. The field inducing component can be comprised of a material that retains sustained polarization or a material that comprises and sustains a spatial distribution of electrical charges, or it can be comprised of both types of materials.

Owner:THE ISRAEL ELECTRIC CORP LTD

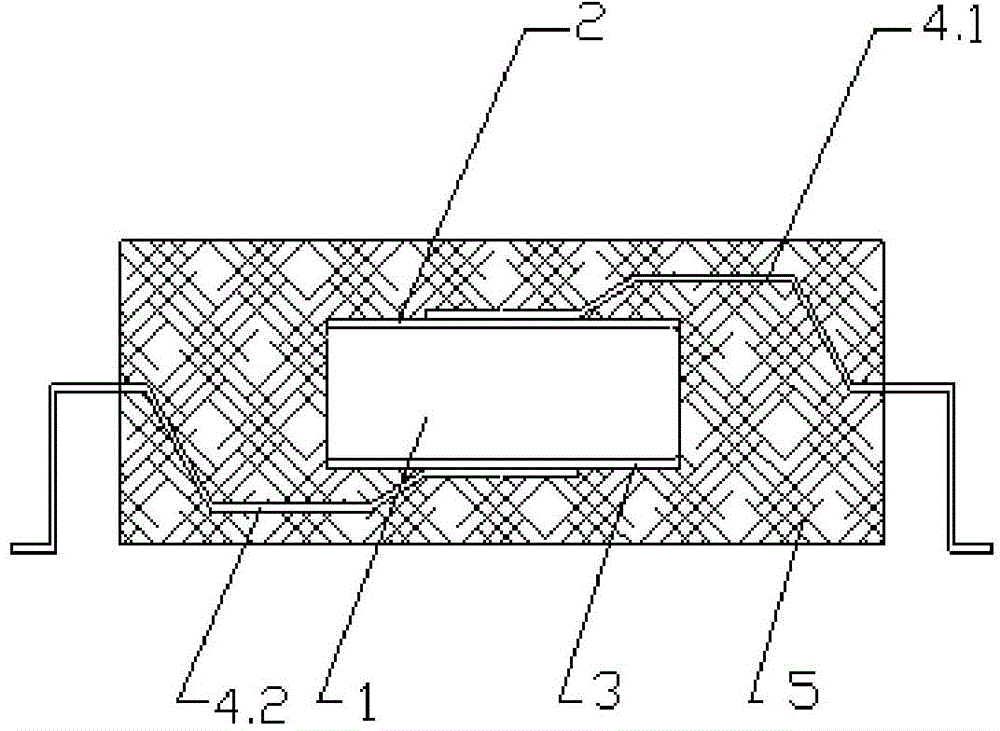

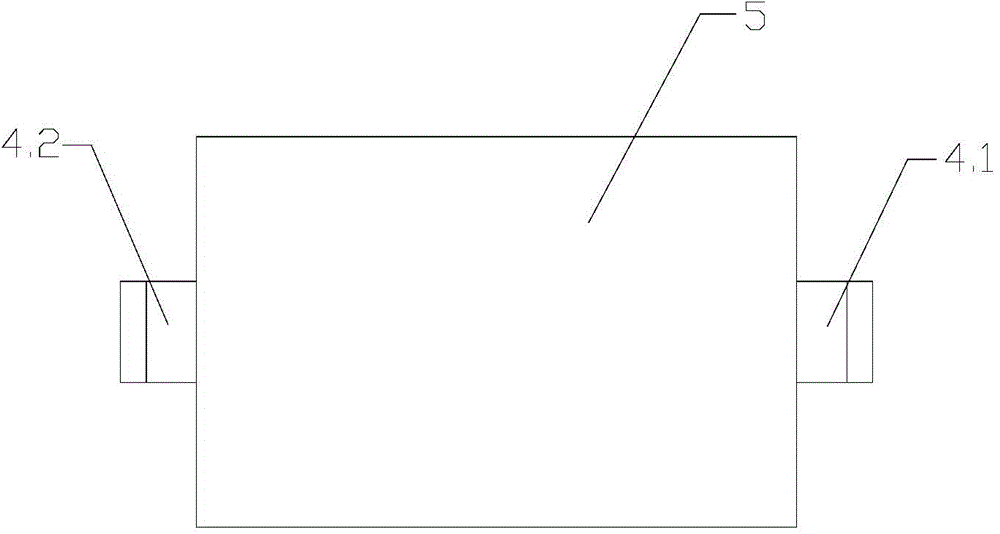

Small-sized chip type surface mounting (SMD) high-voltage and safety standard recognized ceramic capacitor

InactiveCN104701009AMiniaturizationLow costFixed capacitor dielectricFixed capacitor housing/encapsulationEpoxyCopper electrode

Owner:鞍山奇发电子陶瓷科技有限公司

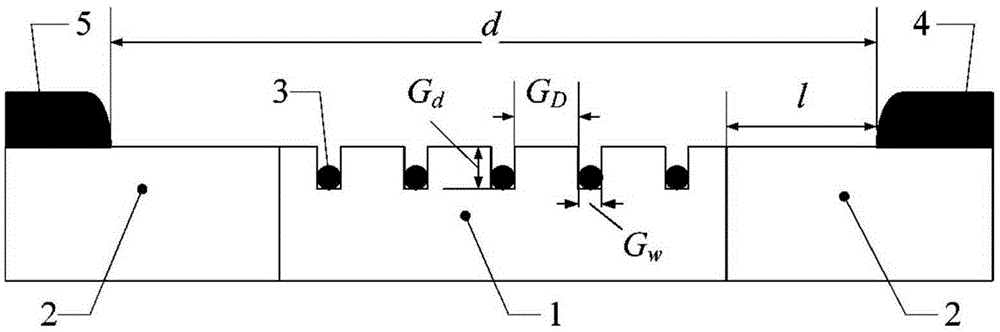

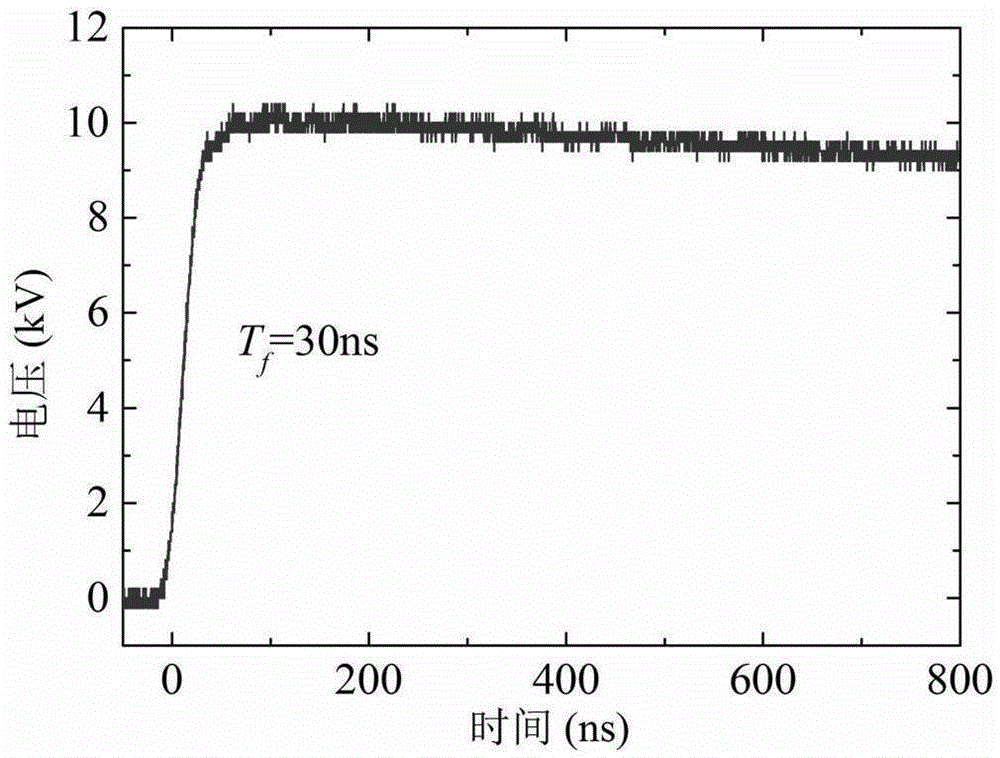

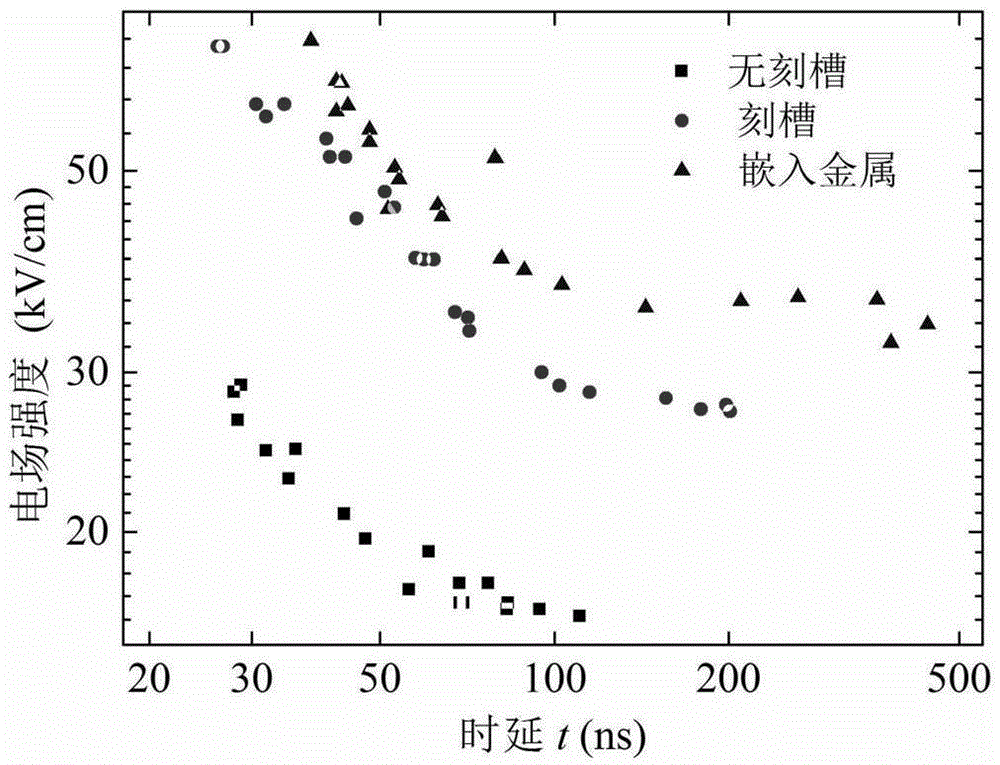

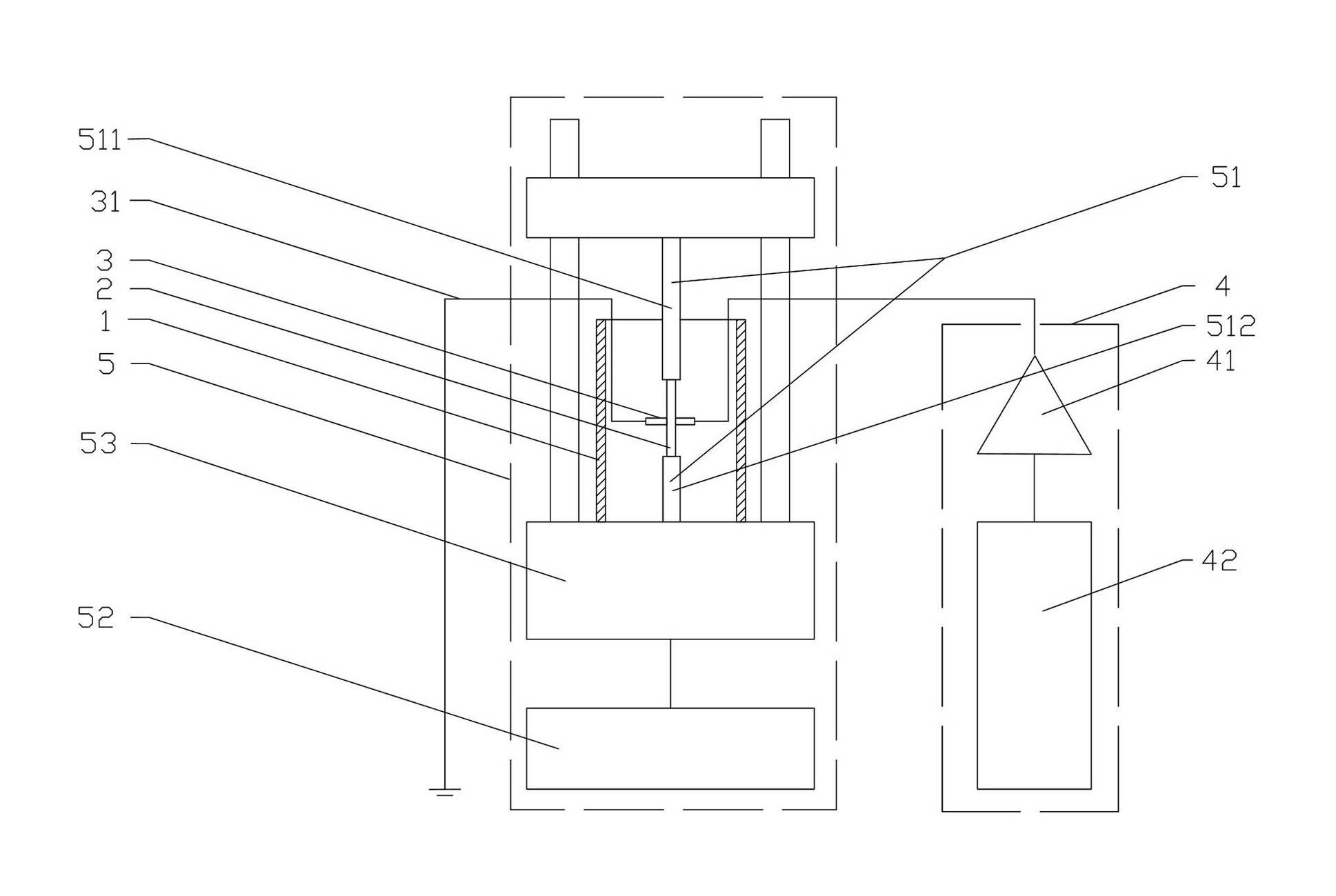

Insulator and method for improving surface electric strength of insulator

ActiveCN105405545AImproved electrical resistance along the surfaceEasy to processInsulatorsManufacturing technologySecondary electrons

The invention discloses an insulator, which comprises two insulator non-groove regions and an insulator groove region, wherein the insulator groove region is located between the two insulator non-groove regions; a plurality of grooves are formed in the insulator groove region; an intercalation electrode is arranged in each groove; cathodes and anodes are arranged in the two insulator non-groove regions respectively; and the grooves, the cathodes and the anodes are located at the same side of the insulator. According to the insulator, adjustment of secondary electron emission and multiplication processes of the surface of the insulator is achieved by simultaneously utilizing the grooves in the surface of the insulator and a periodically changing normal electric field generated by intercalation of the metal electrodes, so that the target of improving the vacuum surface electrical resistance characteristic of the insulator is achieved. The method disclosed by the invention is easy to process, low in manufacturing technology difficulty, and beneficial to conversion toward an actual engineering application layer; and development of a pulse power technology is promoted.

Owner:XI AN JIAOTONG UNIV +1

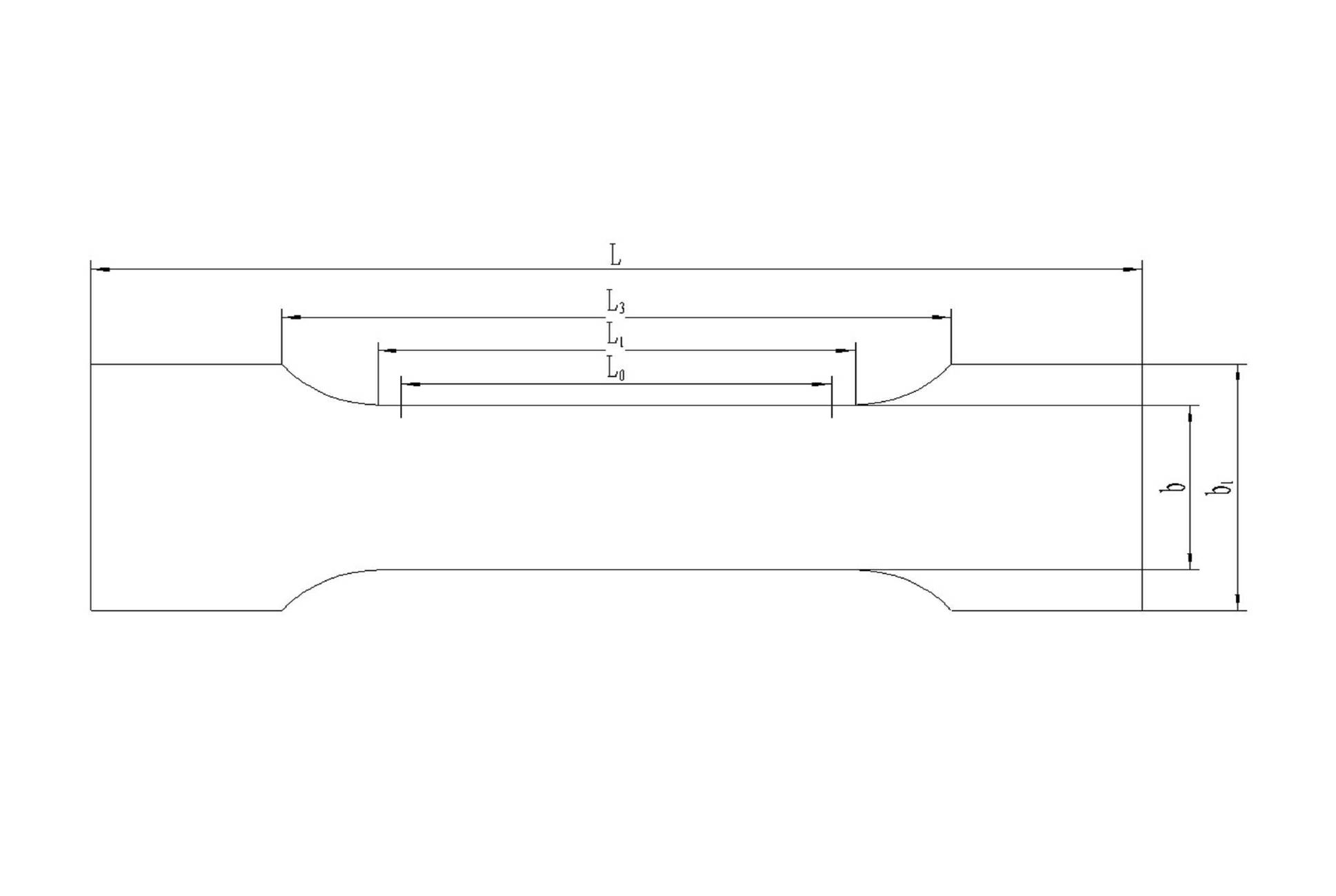

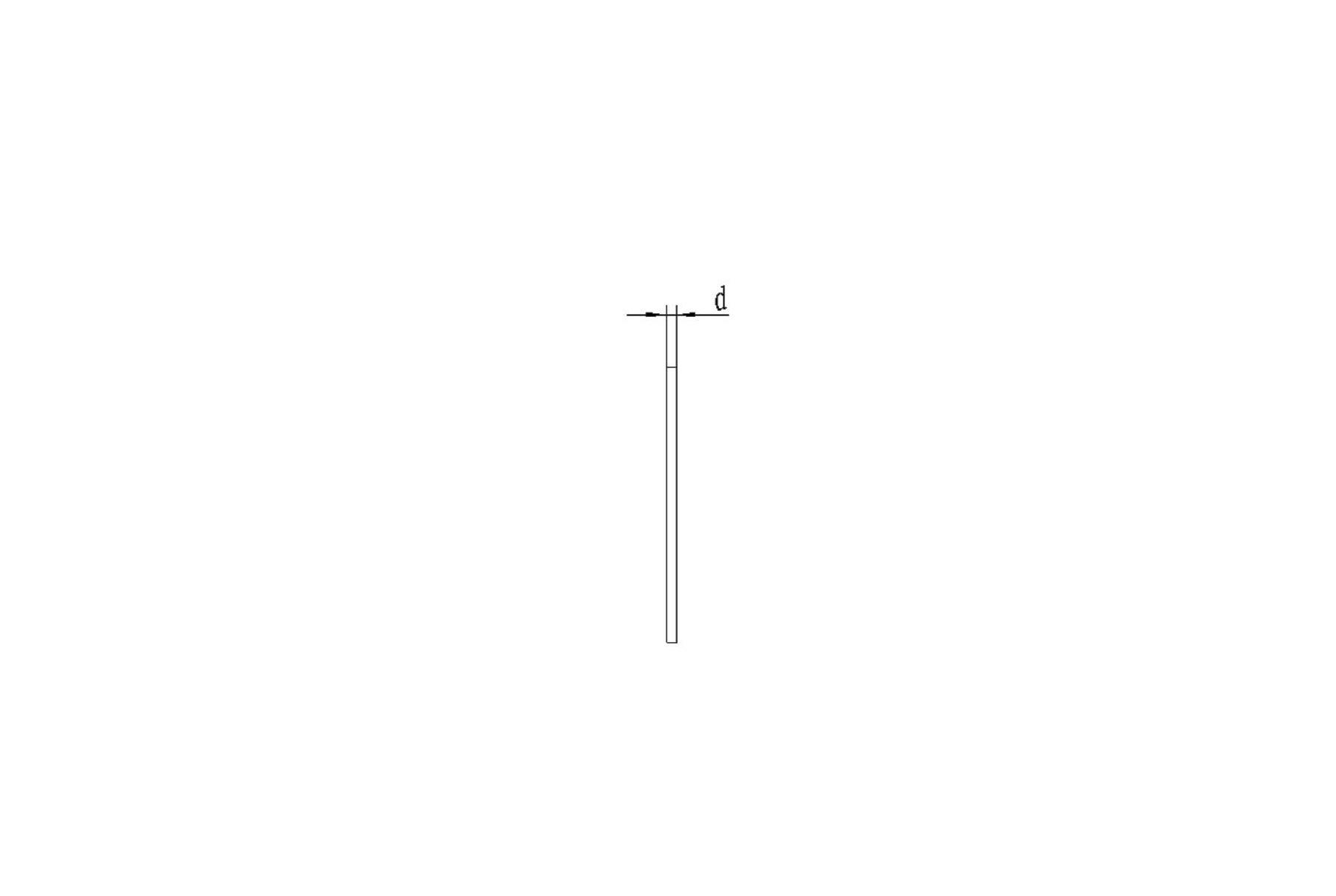

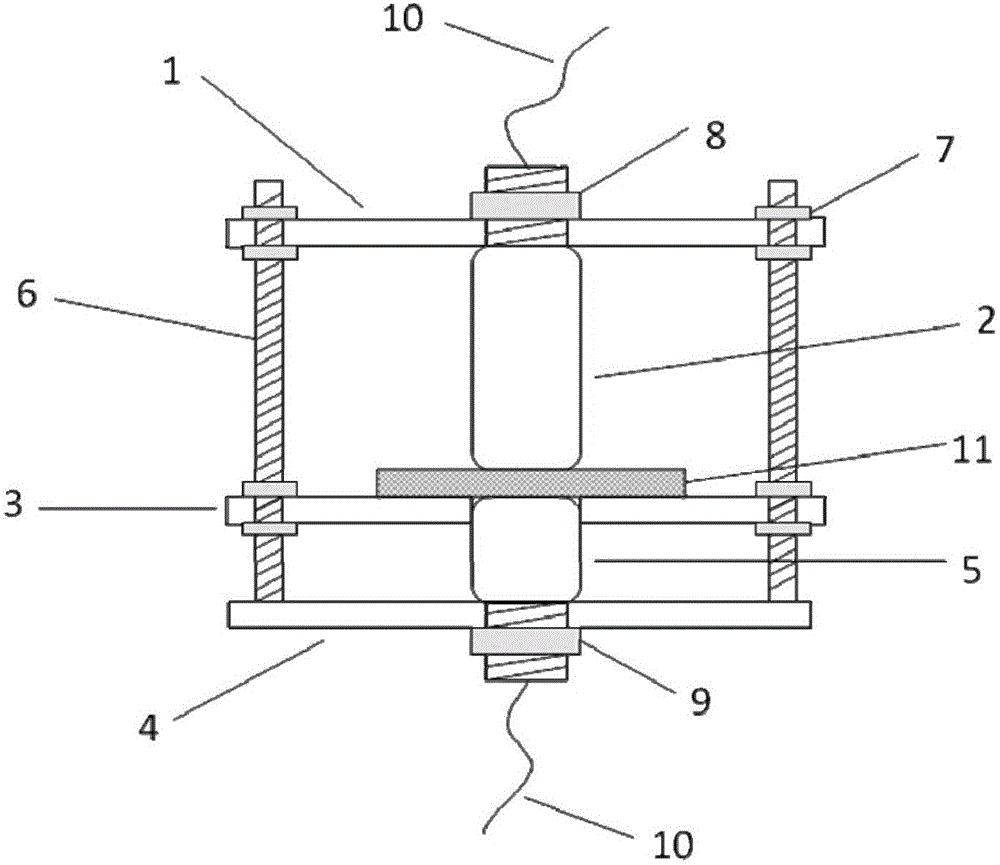

Device and method for measuring electrical strength of material under stress condition

InactiveCN102435925AImprove relative electric strengthReduce negative impactTesting dielectric strengthTest sampleMaterials science

The invention discloses a device and method for measuring the electrical strength of material under the stress condition. The device comprises an insulating oil tank used for encapsulating a sample to be tested, test electrodes, an electrical strength testing device and a stress generation system, wherein the test electrodes are arranged at the two sides of the sample to be tested and are connected with the electrical strength testing device by electrode leads; and the stress generation system comprises a clamping device used for clamping the sample to be tested. The method for measuring the electrical strength of the material under the stress condition comprises the following steps of: firstly encapsulating the sample in the insulating oil tank, and installing the test electrodes; then, leading the sample to be clamped on the stress generation system and connected with the electrical strength testing device, and fully filling insulating oil; starting the stress generation system for providing a load; after that, starting the electrical strength testing device, and recording the voltage values of the tested sample which is broken down along with the rise of output voltage; and finally, obtaining the electrical strength of the sample. The measurement device is simple in structure and convenient in assembly and operation, the test method is simple and convenient, the test cost is lower, and test results is accurate.

Owner:NAT UNIV OF DEFENSE TECH +1

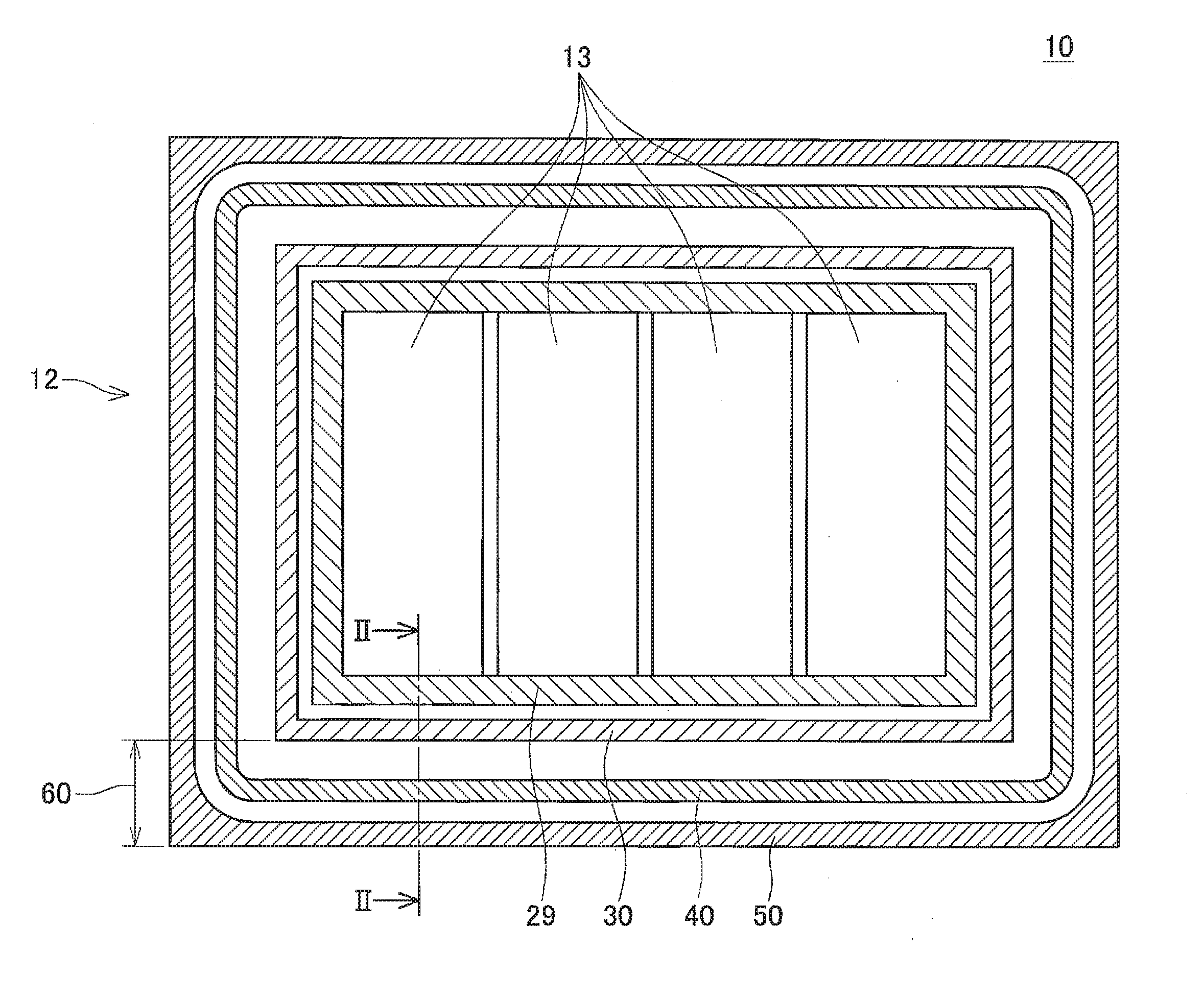

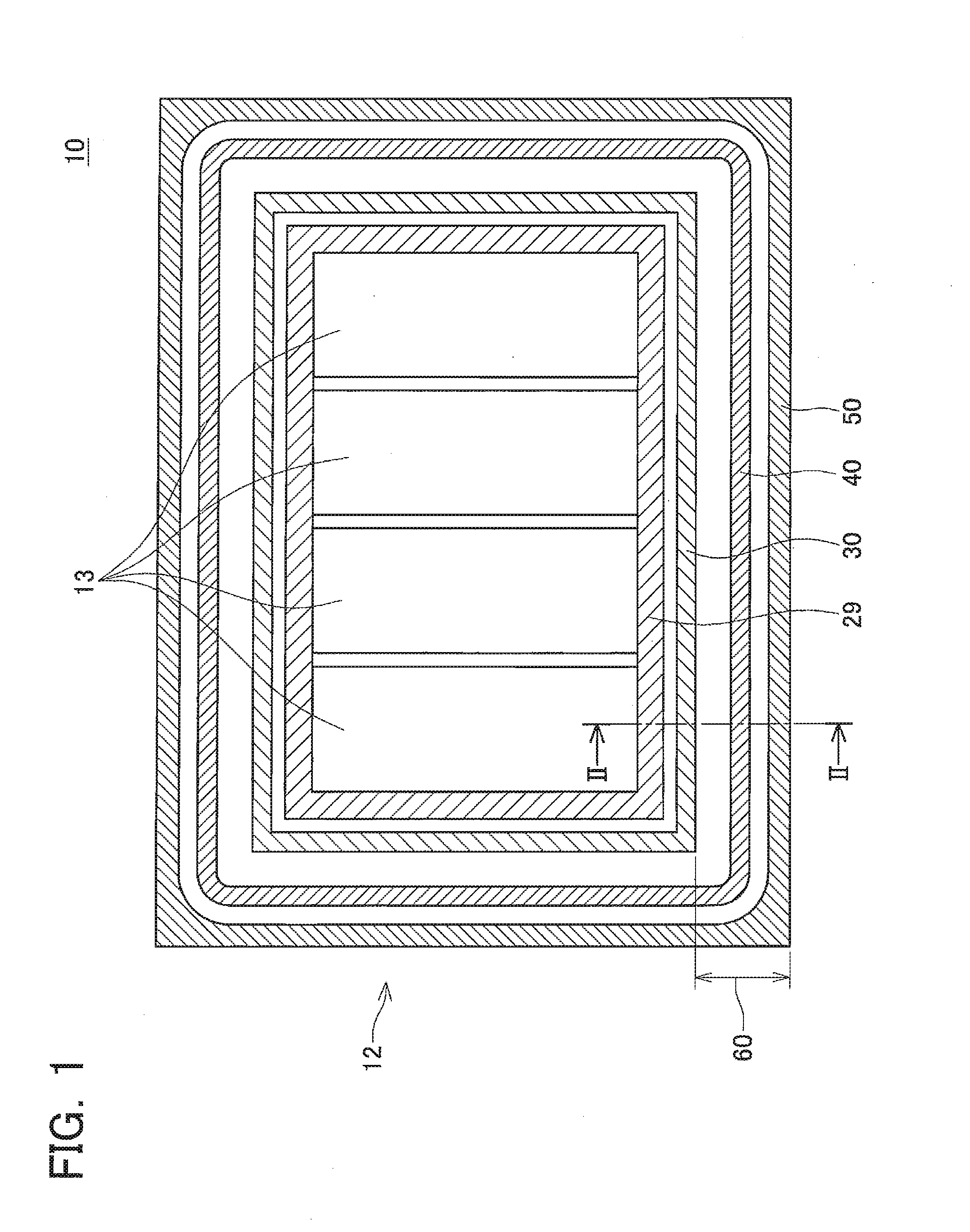

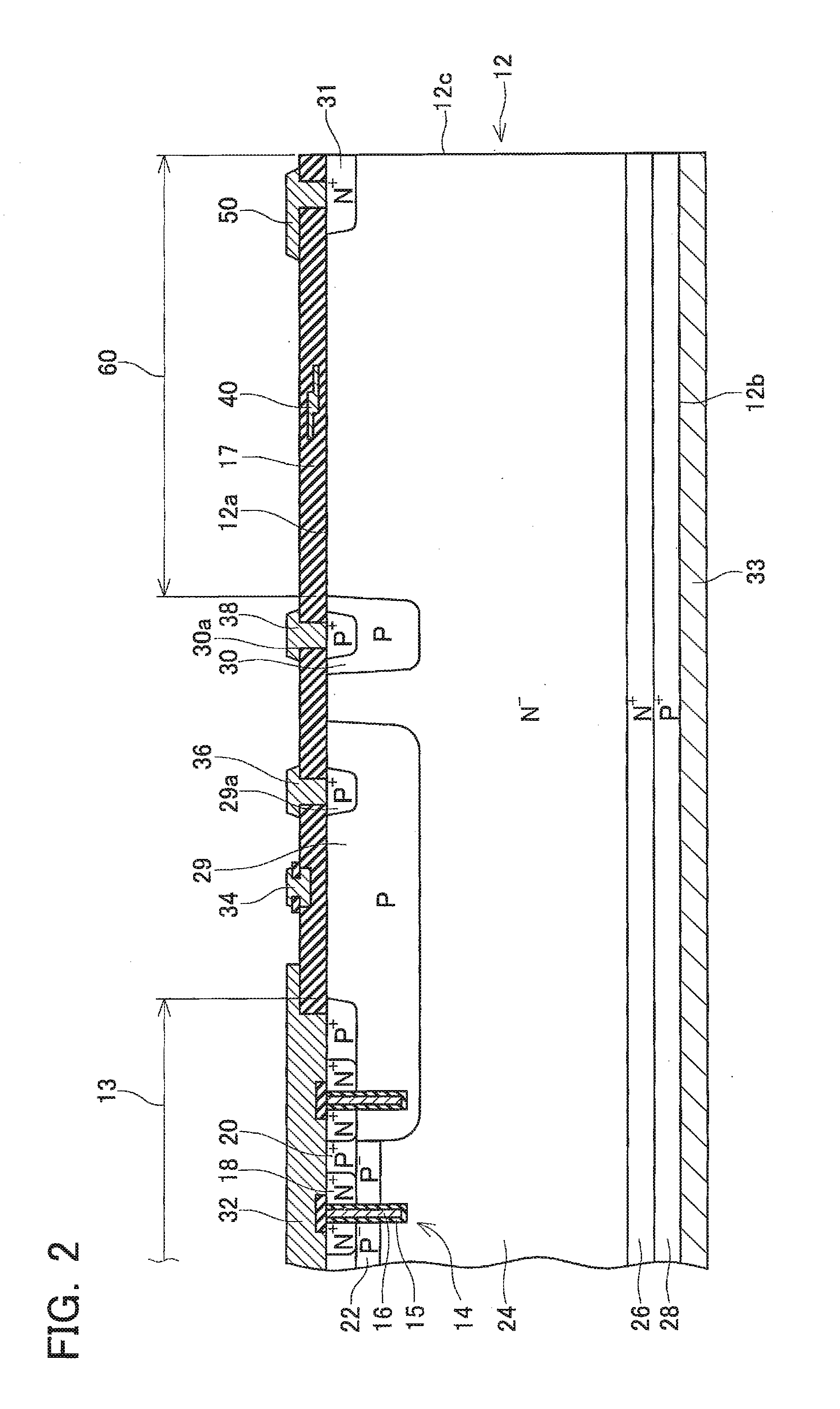

Semiconductor device

ActiveUS20110079870A1Improve electrical strengthSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialSemiconductor device

This specification discloses a semiconductor device having higher electric strength.The semiconductor device disclosed in this specification has a semiconductor element region, a peripheral termination region, a peripheral electrode, an insulating film, and an intermediate electrode. A semiconductor element is formed within the semiconductor element region. The peripheral termination region is formed around the semiconductor element region and formed of a single conductive type semiconductor. The semiconductor element region and the peripheral termination region are exposed at one surface of a semiconductor substrate. The peripheral electrode is formed on a surface of the peripheral termination region and along a circumference of the semiconductor substrate. The insulating film is formed on the surface of the peripheral termination region and between the semiconductor element region and the peripheral electrode. The intermediate electrode is formed on the insulating film. A thickness of the insulating film under the intermediate electrode is larger at a side of the peripheral electrode than at a side of the semiconductor element region.

Owner:TOYOTA JIDOSHA KK

High-arc resistance epoxy insulating material and preparation method thereof and insulator

ActiveCN105504685AGood arc resistanceIncrease the number of pressure operationsPlastic/resin/waxes insulatorsMetallic oxidesPolyethylene glycolGlass transition

The invention discloses a high-arc resistance epoxy insulating material and a preparation method thereof and an insulator. The epoxy insulating material is prepared from the following raw materials in parts by mass: 1 part of composite epoxy resin, 0.51-0.55 part of curing agent methyl tetrahydrophthalic anhydride and 3.25-3.45 parts of aluminum oxide, wherein the composite epoxy resin is a mixture of phenolic aldehyde modified bisphenol A epoxy resin, polyethylene glycol modified bisphenol A epoxy resin and diphenolic acid modified bisphenol A epoxy resin. The epoxy insulating material is equivalent to traditional materials in glass-transition temperature, tensile strength and electric strength, the arc resistance reaches 237s, and after a 252kV circuit breaker is switched on / off under voltage for over 3243 times, flashover appears behind; and the epoxy insulating material has excellent arc resistance, the operation times of a high-voltage circuit breaker under voltage is remarkably increased, the service lives of internal epoxy insulating components are prolonged and reliability of the internal epoxy insulating components is improved, and the maintenance and overhauling cost of a power station is reduced.

Owner:PINGGAO GRP +2

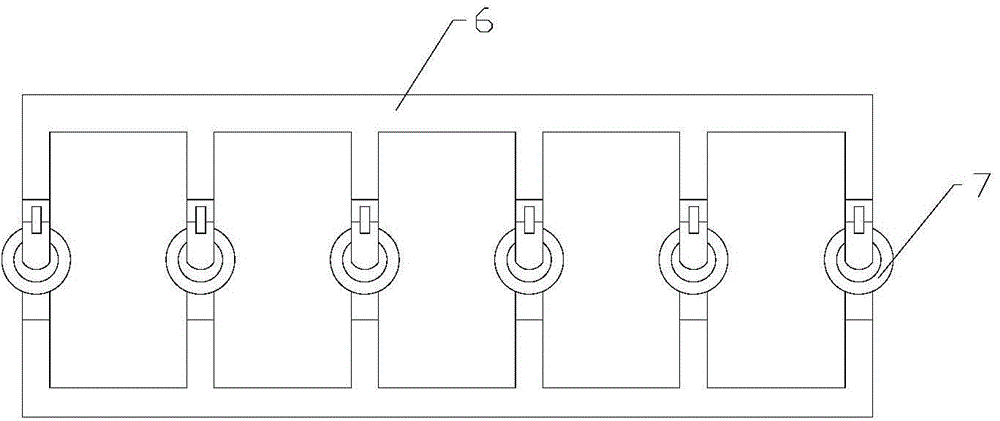

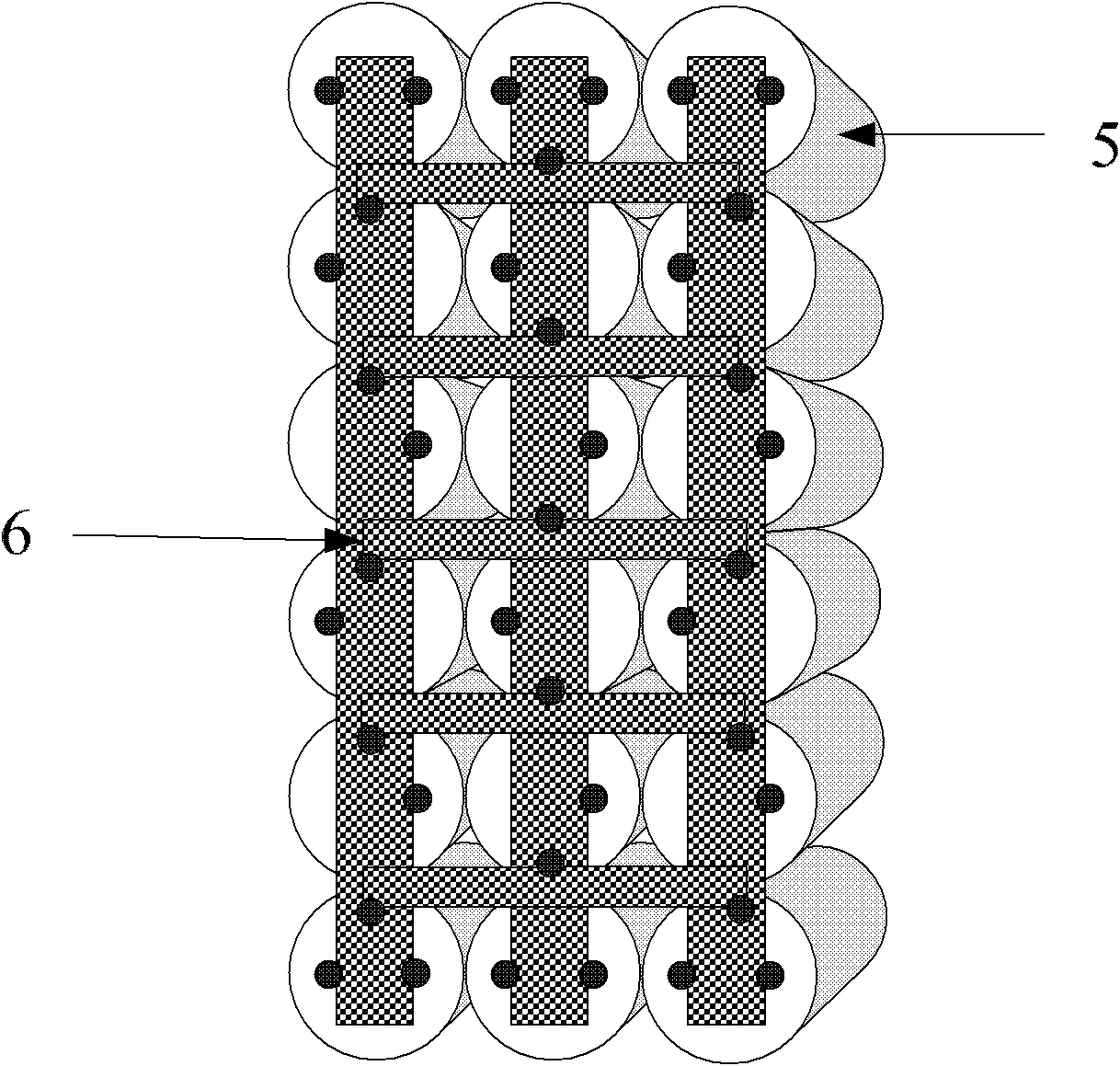

Metallized membrane capacitor assembly

ActiveCN102522198AClosely arrangedReduce self-healing noiseMultiple fixed capacitorsFixed capacitor electrodesCapacitanceLow voltage

The invention discloses a metallized membrane capacitor assembly, which belongs to a capacitor used in the pulse power field and solves the problem that the traditional high-voltage metallized membrane capacitor is readily explosive when used in atmospheric or low pressure environment. The metallized membrane capacitor assembly comprises capacitor cores, DMD (Digital Micromirror Device) insulating papers, a high-voltage extraction electrode and a low-voltage extraction electrode, wherein M capacitor cores achieve the purpose of connecting capacitors in parallel to form capacitor stacks; N capacitor stacks achieve the purpose of connecting capacitors in series to form capacitor assemblies; the DMD insulating papers are arranged among the capacitor stacks; and the capacitor assemblies, the DMD insulation papers, the high-voltage extraction electrode and the low-voltage extraction electrode are integrally encapsulated by polyurethane pouring sealant to form the metallized membrane capacitor assembly. The metallized membrane capacitor assembly has higher energy storage density and electric strength, good insulation reliability in atmospheric or low pressure environment, and better mechanical performance and longer service life under a heavy-current discharging condition.

Owner:HUAZHONG UNIV OF SCI & TECH

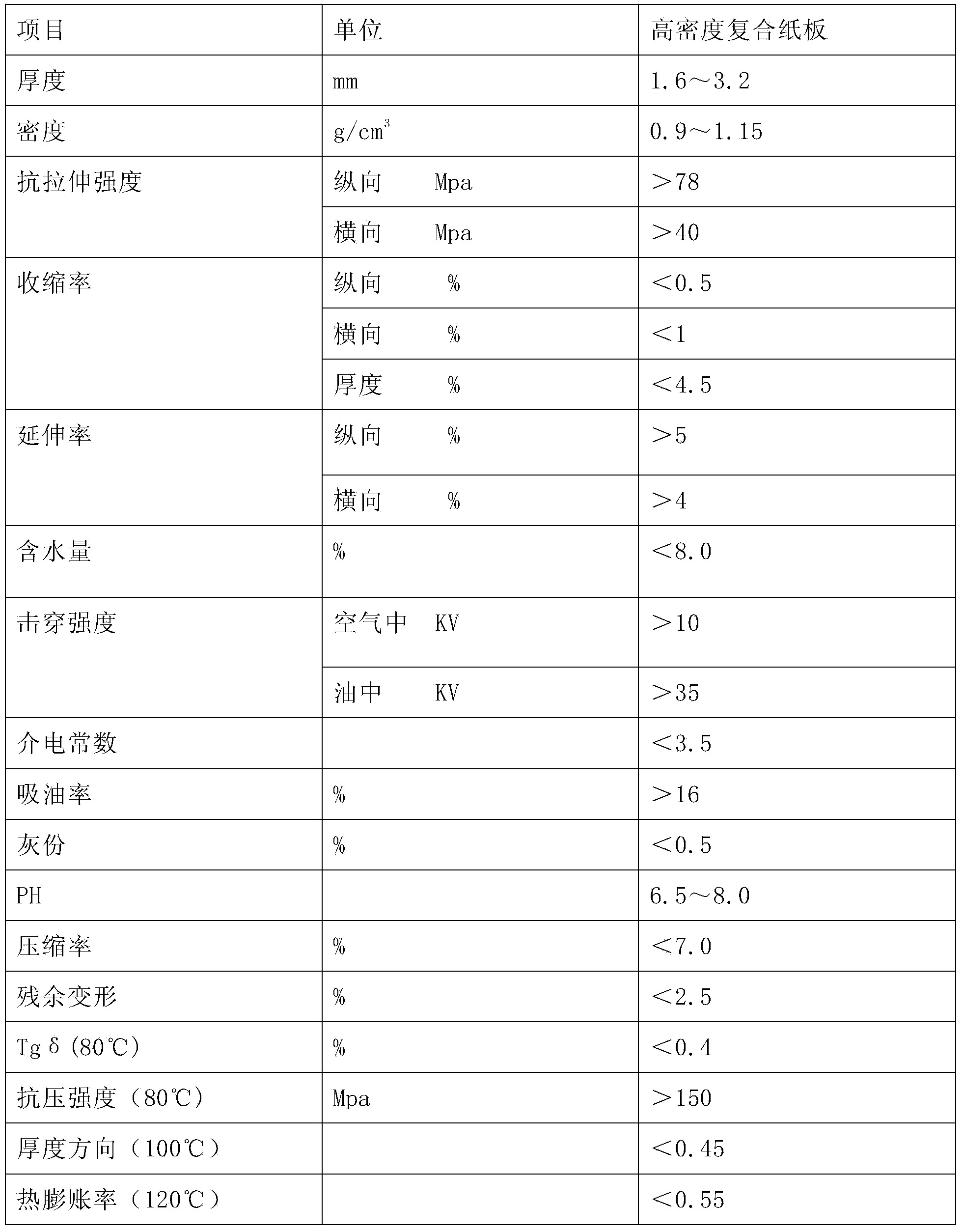

Method for manufacturing extra-high-voltage composite insulation paper board

ActiveCN103489542AHigh temperature resistanceLow dielectric constantInsulating bodiesCardboardElectric intensity

The invention discloses a method for manufacturing an extra-high-voltage composite insulation paper board. The method comprises the following steps that 1) stem grafting modification is conducted on aramid fiber pulp; 2) an aramid paper board is manufactured. The high-temperature (220 DEG C) resistant performance of aramid fiber is utilized, so that the temperature which the insulation paper board is resistant to is increased to 140 DEG C-150 DEG C; the low dielectric constant of the aramid fiber ranges from 1.6 to 3.7 so that the partial discharge of extra-high-voltage transformer oil can be reduced, the electric intensity of the extra-high-voltage transformer oil and paper insulation are completely used, and the dielectric constant of the paper is reduced. The surface modification technology is conducted on the aramid fiber so that the aramid fiber can be completely merged with wood pulp fiber.

Owner:HUNAN HENGYUAN NEW MATERIAL TECH CO LTD

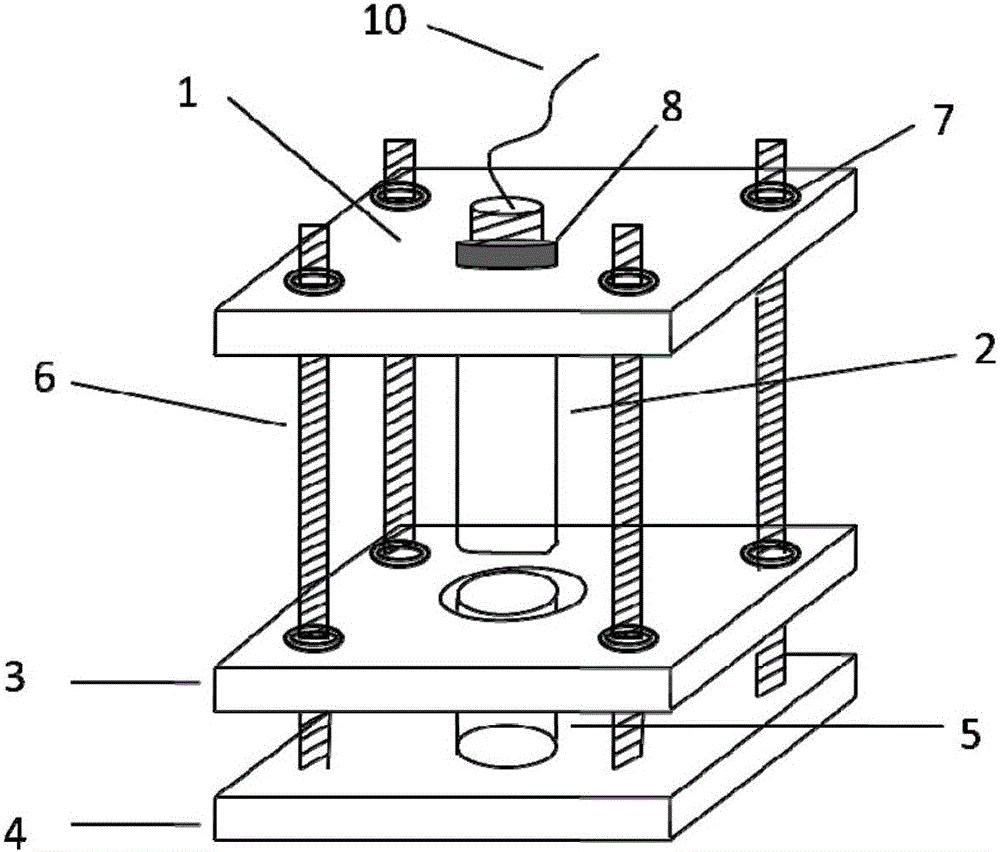

Electrode device for measuring electrical strength of composite insulator silicon rubber umbrella skirt and measuring method

InactiveCN105717434ASimple structureEasy to installTesting vessel constructionComposite insulatorsMeasuring instrument

The invention discloses an electrode device for measuring the electrical strength of a composite insulator silicon rubber umbrella skirt and a measuring method.The electrode device is characterized by comprising an upper plate, an upper electrode fixed with the upper plate through a bolt, a middle support plate, a lower plate and a lower electrode fixed with the lower plate through a bolt, and the vertical height of the middle support plate and the vertical height of the upper plate are adjustable.In the use process, the height of the upper surface of the middle support plate is adjusted to be flush with the upper end of the lower electrode, a silicon rubber sample wafer is put on the middle support plate, and then the position of the upper electrode is adjusted according to the thickness of the silicon rubber sample wafer to enable the electrodes to directly make tight contact with the sample wafer.In the measuring process, the measuring device is immersed in a container filled with transformer oil, a breakdown voltage value of the silicon rubber sample wafer is measured through a voltage measuring instrument, and therefore the electrical strength of the silicon rubber umbrella skirt is obtained.The electrode device is simple in structure, convenient to install, easy to maintain, convenient and rapid in use method and capable of accurately measuring the electrical strength of the composite insulator silicon rubber umbrella skirt.

Owner:STATE GRID CORP OF CHINA +1

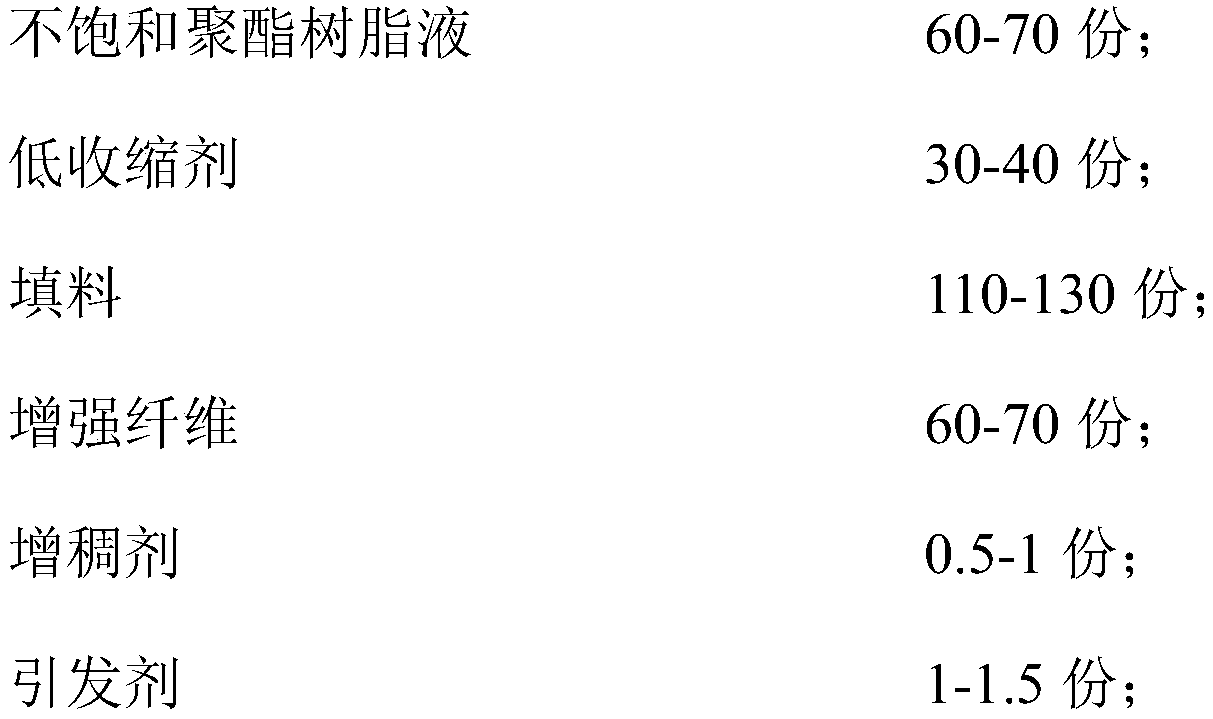

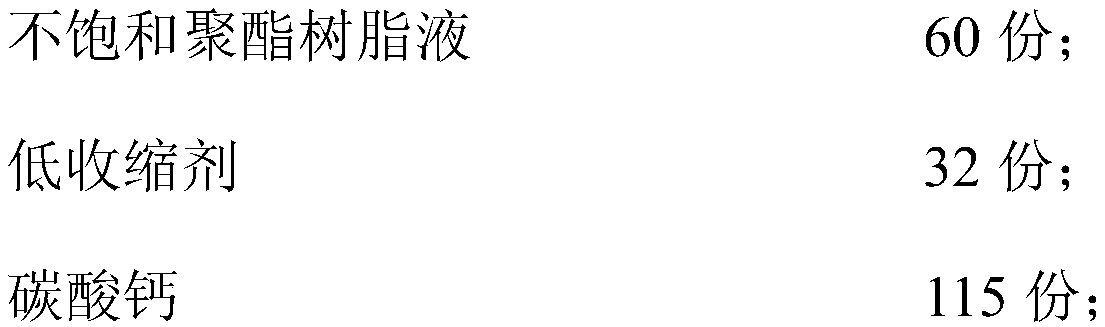

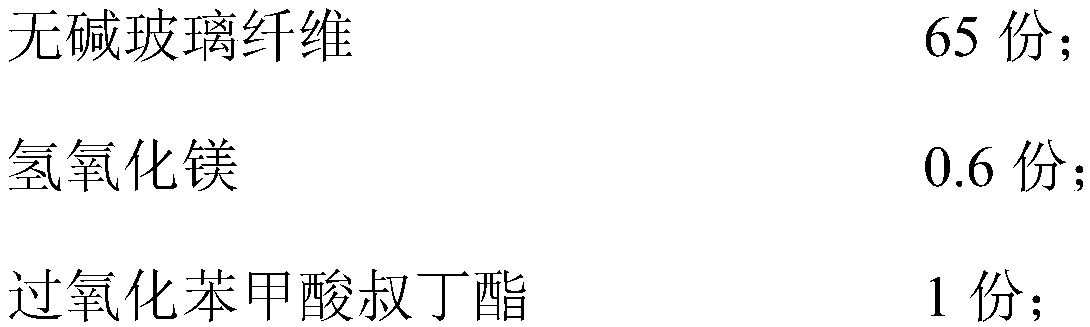

Environment-friendly bulk molding compound and preparation method thereof

The invention provides an environment-friendly bulk molding compound and a preparation method thereof. The bulk molding compound comprises raw material components in parts by weight as follows: 60-70parts of an unsaturated polyester resin solution, 30-40 parts of a low-shrinkage agent, 110-130 parts of packing, 60-70 parts of reinforced fibers, 0.5-1 part of a thickening agent and 1-1.5 parts ofan initiator; the unsaturated polyester resin solution is prepared from unsaturated polyester resin and alicyclic acrylate, and the low-shrinkage agent is prepared from polystyrene and (methyl) acrylate. The bulk molding compound is prepared by steps as follows: the unsaturated polyester resin solution, the low-shrinkage agent and the initiator are firstly mixed, resin paste is formed, then the resin paste, the packing, the thickening agent and the reinforced fibers are added to a kneading machine and kneaded, and the bulk molding compound is obtained. The bulk molding compound is more environmentally friendly without adoption of a styrene raw material, and shrinking percentage, impact strength and electric strength are comparable with those of a bulk molding compound adopting styrene as across-linking monomer.

Owner:WUXI XINHONGTAI ELECTRIC TECH CO LTD

BOPET for ultra-thin weather-proof balanced type capacitor and manufacturing method thereof

ActiveCN102543433AImprove electrical performanceLong charging lifeFixed capacitor dielectricSynthetic resin layered productsDielectricBoPET

The invention discloses a manufacturing method of a BOPET for an ultra-thin weather-proof balanced type capacitor. The BOPET adopts polyester to serve as the major component and comprises an upper surface layer, a sandwich layer and a lower surface layer; the longitudinal and horizontal thermal contraction of the BOPET is 0-2.5 percent; the ratio of the longitudinal thermal contraction rate and the horizontal thermal contraction rate is 0.98-1.12; the dielectric constant is 3.3; and the volume resistance is 1,013-1,017 Omega. The BOPET has the advantages of thin thickness, good heat resistance, high thermal stability, favorable weather ability, long service life, excellent electric insulativity and high electric strength, and is particularly suitable for capacitor dielectric medium.

Owner:ANHUI GUOFENG PLASTIC

Concave dual-electrode integrated chip high-voltage ceramic capacitor and manufacturing process thereof

InactiveCN104167290AReduce volumeReduce thicknessFixed capacitor dielectricCapacitanceCeramic capacitor

The invention relates to a concave dual-electrode integrated chip high-voltage ceramic capacitor and a manufacturing process thereof. The overall shape of the capacitor is a centrosymmetric concave disc, in other words, the center of the capacitor is in the shape of a disc, the outer side of the capacitor is annular, the annular portion of the outer side is thicker than the disc at the center, an outer electrode is arranged on the surface of an annular chip, an inner electrode is arranged on the surface of a disc-shaped chip, the inner electrode and a lead are welded together, and the inner electrode, the outer electrode and a ceramic medium chip are wrapped in a resin-encapsulating layer. The capacitor manufacturing process comprises the steps of manufacturing of a dual-electrode concave copper electrode chip, lead welding, coating, printing and testing. By the adoption of the concave dual-electrode integrated chip high-voltage ceramic capacitor and the manufacturing process thereof, rated capacitance and voltage strength are effectively improved, the contradiction between rated capacitance and voltage strength is effectively resolved, the size of the capacitor is reduced greatly on the premise that high capacity and high electric strength of the capacitor are guaranteed, and the requirement for miniaturization of a complete electronic machine is met.

Owner:鞍山奇发电子陶瓷科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com