Method for fluorinating insulator through use of CF4 plasma

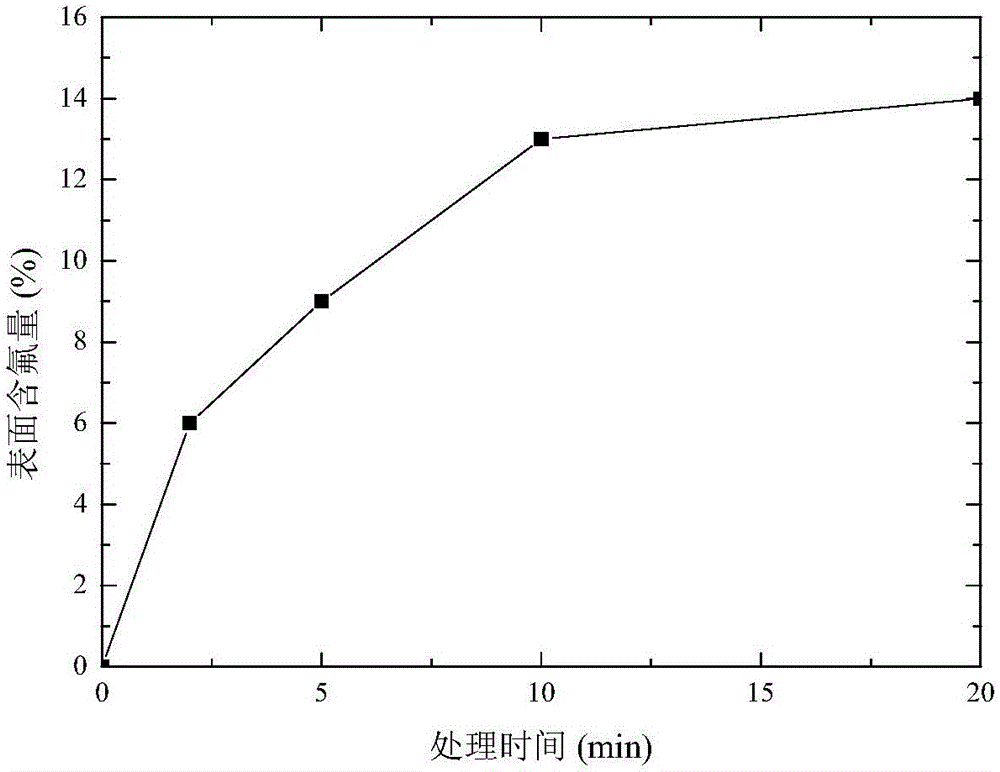

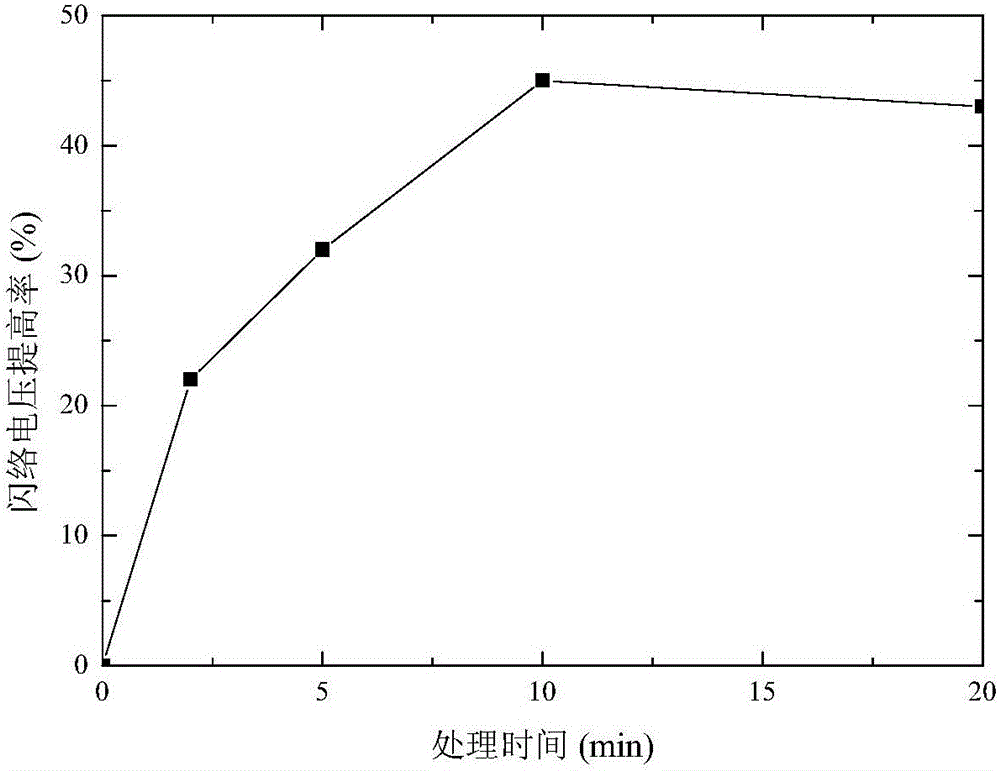

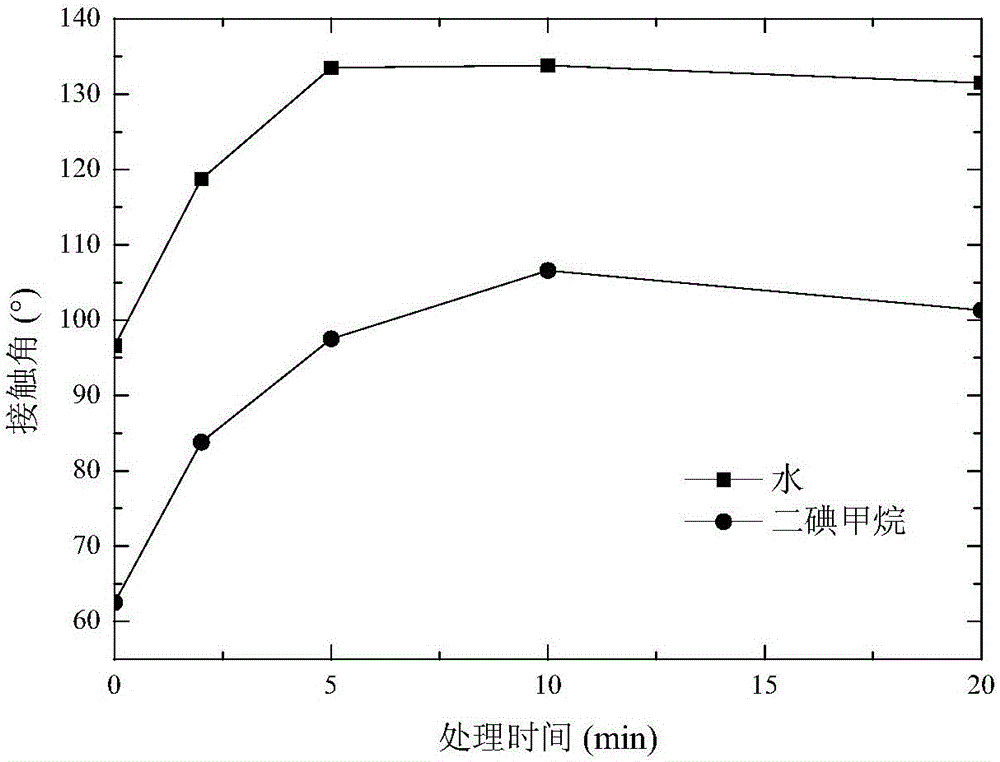

A plasma and insulator technology, which is applied in the field of plasma fluorinated insulators, achieves the effects of simple and fast processing, improved contact angle and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) At room temperature, put the pot insulator sample (the main component is epoxy resin) into a closed reaction chamber, and then vacuumize the reactor to a pressure of less than 10 -2 Pa;

[0031] 2) Fill CF into the reaction chamber 4 Mixed gas with argon until the pressure in the cavity reaches 0.1atm, and the concentration of CF4 is 10%;

[0032] 3) Apply high voltage to the electrodes in the reaction chamber to generate plasma and process the insulator sample for 5 minutes;

[0033] 4) After the reaction, the gas in the reaction chamber was fully replaced with nitrogen, and the insulator samples were taken out to test the flashover voltage and surface contact angle.

Embodiment 2

[0035] 1) At room temperature, put the silicone rubber insulator into a closed reaction chamber, and then vacuumize the reactor to a pressure of less than 10 -2 Pa;

[0036] 2) Fill CF into the reaction chamber 4 Mixed gas with argon until the pressure in the cavity reaches 0.1atm, and the concentration of CF4 is 10%;

[0037] 3) Apply high voltage to the electrodes in the reaction chamber to generate plasma and process the insulator sample for 10 minutes;

[0038] 4) After the reaction, the gas in the reaction chamber was fully replaced with nitrogen, and the insulator samples were taken out to test the flashover voltage and surface contact angle.

Embodiment 3

[0040] 1) At room temperature, put the alumina ceramic insulator into a closed reaction chamber, and then vacuumize the reactor to a pressure of less than 10 -2 Pa;

[0041] 2) Fill CF into the reaction chamber 4 Mixed gas with argon until the pressure in the cavity reaches 0.1atm, and the concentration of CF4 is 10%;

[0042] 3) Apply high voltage to the electrodes in the reaction chamber to generate plasma and process the insulator sample for 8 minutes;

[0043] 4) After the reaction, the gas in the reaction chamber was fully replaced with nitrogen, and the insulator samples were taken out to test the flashover voltage and surface contact angle.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com