Manufacturing method of ultra-high voltage insulation cooked mica paper

A manufacturing method and technology of mica paper, applied in the direction of insulators, organic insulators, plastic/resin/wax insulators, etc., can solve the problems of unsatisfactory electrical strength and tensile strength of mica paper, and achieve simple manufacturing process, low production cost, Good electrical strength and tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

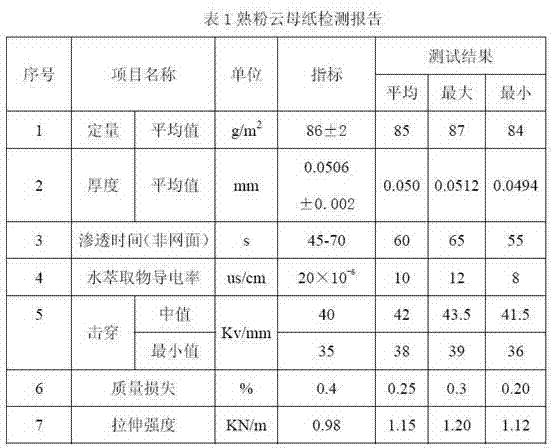

Embodiment 1

[0023] Using natural muscovite fragments as raw materials, the raw materials are first manually sorted to remove biotite, green mica, etc. that are not suitable for making cooked powder mica paper. After manual sorting, they are further passed through an 8-mesh sieve to initially remove crystal stones and mud. Sand and other impurities to ensure the purity of mica fragments. Put pure mica fragments into an electric furnace, heat to 600°C and calcined for 80 minutes. The calcined mica fragments are called mica clinker. Pass the mica clinker through a 4-mesh sieve, and then sieve the mica clinker at a mass concentration of Immerse in 60% ammonium carbonate solution for 30 minutes, add the impregnated mica clinker: water = 1:6 weight ratio into the reaction kettle, and heat the reaction kettle to 100°C with steam at the bottom of the reaction kettle for 90 minutes , the steam pressure of the feed is 0.3 MPa, and the cooked mica pulp is obtained, and the cooked mica pulp is dilute...

Embodiment 2

[0025] Using natural muscovite fragments as raw materials, the raw materials are first manually sorted to remove biotite and green mica that are not suitable for making cooked powder mica paper. After manual sorting, they are further passed through a 4-mesh sieve to initially remove crystal stones and mud. Sand and other impurities to ensure the purity of mica fragments. Put pure mica fragments into an electric furnace, heat to 800°C and calcined for 50 minutes. The calcined mica fragments are called mica clinker. Pass the mica clinker through a 10-mesh sieve, and then pass the sieved mica clinker at a mass concentration of Immerse in 90% ammonium carbonate solution for 5 minutes, add the impregnated mica clinker: water = 1:14 weight ratio into the reaction kettle, and heat the reaction kettle to 200°C with steam at the bottom of the reaction kettle for 10 minutes , the steam pressure introduced is 0.1 MPa to obtain cooked mica pulp, which is diluted with water to 3 times, and...

Embodiment 3

[0027]Using natural muscovite fragments as raw materials, the raw materials are first manually sorted to remove biotite, green mica, etc. that are not suitable for making cooked powder mica paper. After manual sorting, they are further passed through a 6-mesh sieve to initially remove crystal stones and mud. Sand and other impurities to ensure the purity of mica fragments. Put pure mica fragments into an electric furnace, heat to 700°C and calcined for 60 minutes. The calcined mica fragments are called mica clinker. Pass the mica clinker through an 8-mesh sieve, and then pass the sieved mica clinker at a mass concentration of Immerse in 70% ammonium carbonate solution for 20 minutes, add impregnated mica clinker: water = 1:10 weight ratio into the reaction kettle, and heat the reaction kettle to 120°C with steam at the bottom of the reaction kettle for 60 minutes , the steam pressure of the feed is 0.2 MPa, and the cooked mica pulp is obtained, and the cooked mica pulp is dilu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com