Device for monitoring electric strength of insulating oil medium for on-load tapping switch on line

A technology of on-load tap changer and monitoring device, which is applied in the direction of testing dielectric strength and test ship construction, can solve the problem of low precision and difficulty in ensuring the oil dielectric strength of the tap changer, and cannot accurately and comprehensively respond to the on-load switch. Oil quality and other issues, to achieve the effect of ensuring insulation level, light weight, and intuitive man-machine interface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

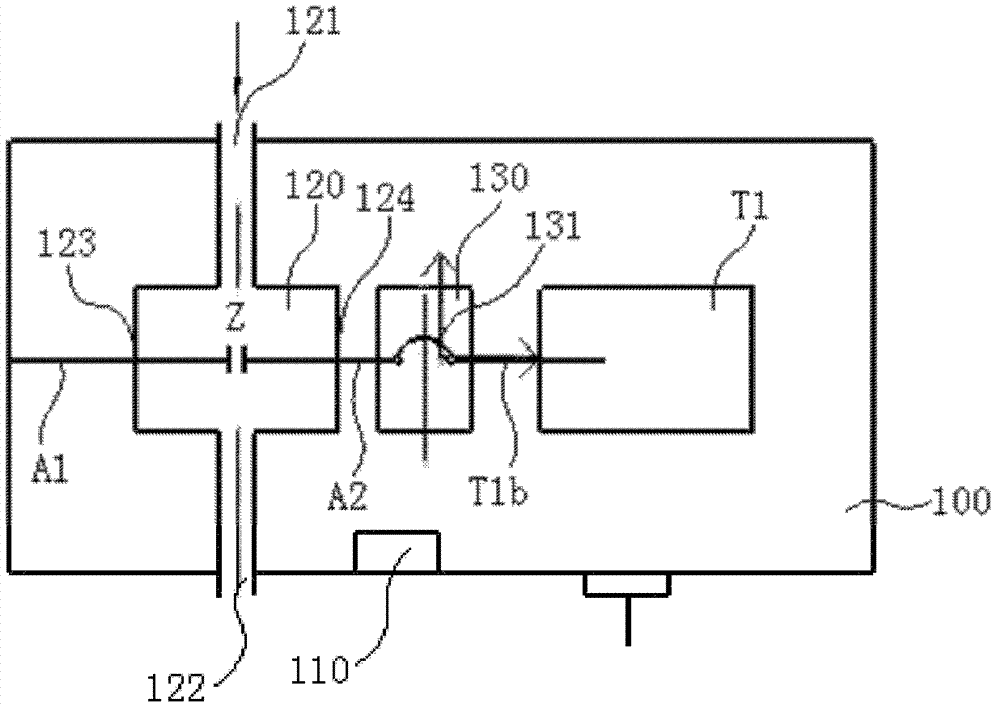

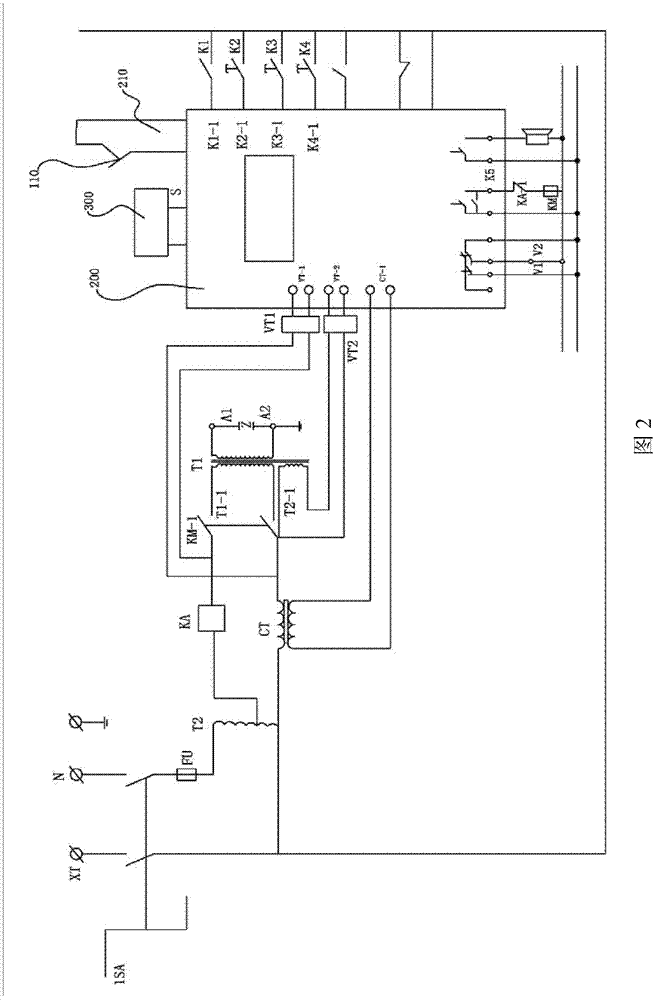

[0028] see figure 1 , the on-line monitoring device for the electric strength of the insulating oil medium of the on-load tap changer and the on-line oil cleaning device for the on-load switch (not shown in the figure) of the present invention are installed in a box body 100 . The box body 100 is composed of a box bottom plate made of metal and four side box panels connected around the box bottom plate. A box door is hinged on one side box panel of the box body 100. There is an opening and locking switch assembly 110 between them, the opening and locking switch assembly 110 is equivalent to a door switch, and its signal is connected to the controller 200 through the opening signal input terminal 210 provided on the controller 200 (see figure 2 ), once the box door is opened, the cover opening and locking switch assembly 110 sends a signal to the controller 200, and the controller 200 cuts off the power supply of the step-up transformer T1 to ensure safety.

[0029] A high-vo...

Embodiment 2

[0036] This embodiment is the same as Embodiment 1 except for the structure of the high-voltage test chamber and the absence of a high-pressure channel chamber.

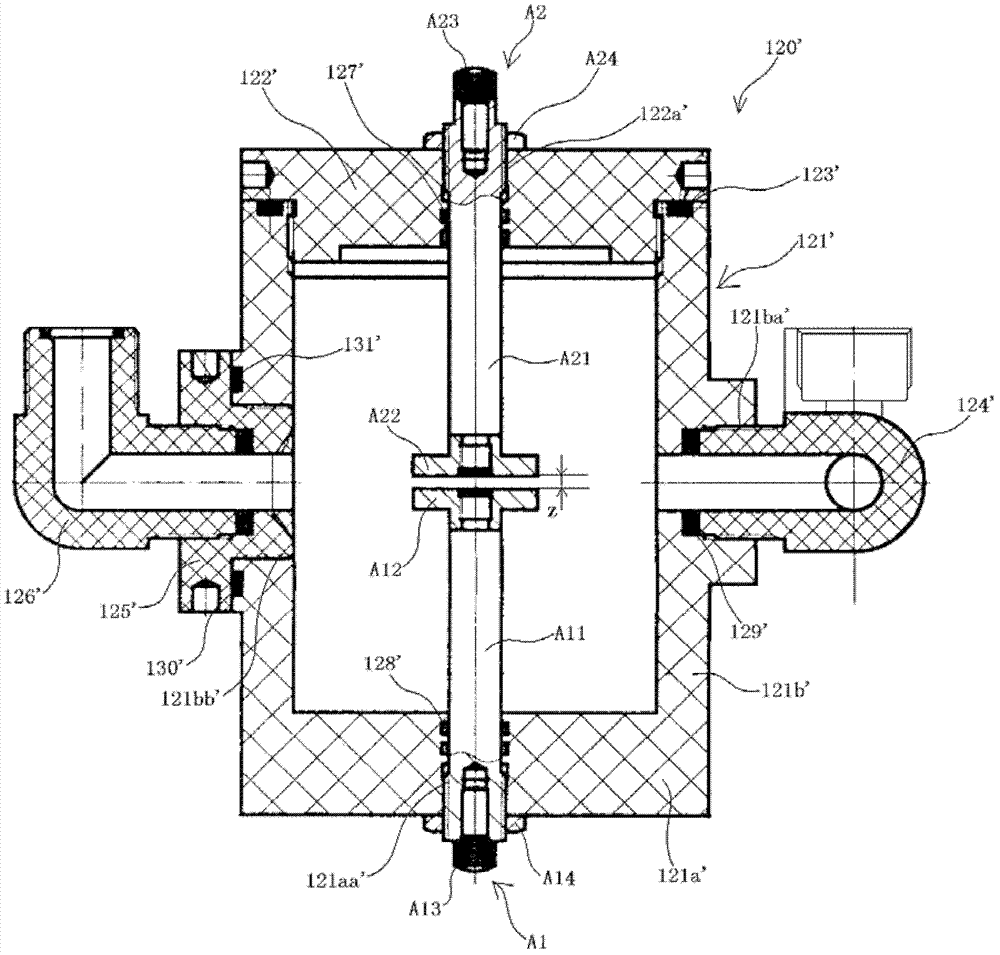

[0037] In this embodiment, the step-up transformer T1 and the high-voltage test chamber 120' are installed on the bottom plate of the box body 100, wherein the output low-voltage end of the step-up transformer T1 is located at the end of the step-up transformer T1 close to the bottom plate of the box and is connected to the bottom plate of the box To form a ground, the output high voltage terminal T1b of the step-up transformer T1 is located at the end of the step-up transformer T1 close to the box door.

[0038] The coaxial lines of a pair of test electrodes A1 and A2 arranged on the high-voltage test chamber 120' are perpendicular to the bottom of the box, and the terminal of the test electrode A1 near the bottom of the box is connected to the bottom of the box to form a ground, and the side near the door of the box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com