Paper cut tail cutter heating apparatus

A technology of heating device and water needle, which is applied in the direction of papermaking, paper machine, textile and papermaking, etc., can solve the problems such as fouling and loosening of water needle nozzles on trimming edges, shortening the service life of forming nets, and abrasion of forming net edges, etc., to achieve Reduce poor cutting, reduce cutting spatter, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

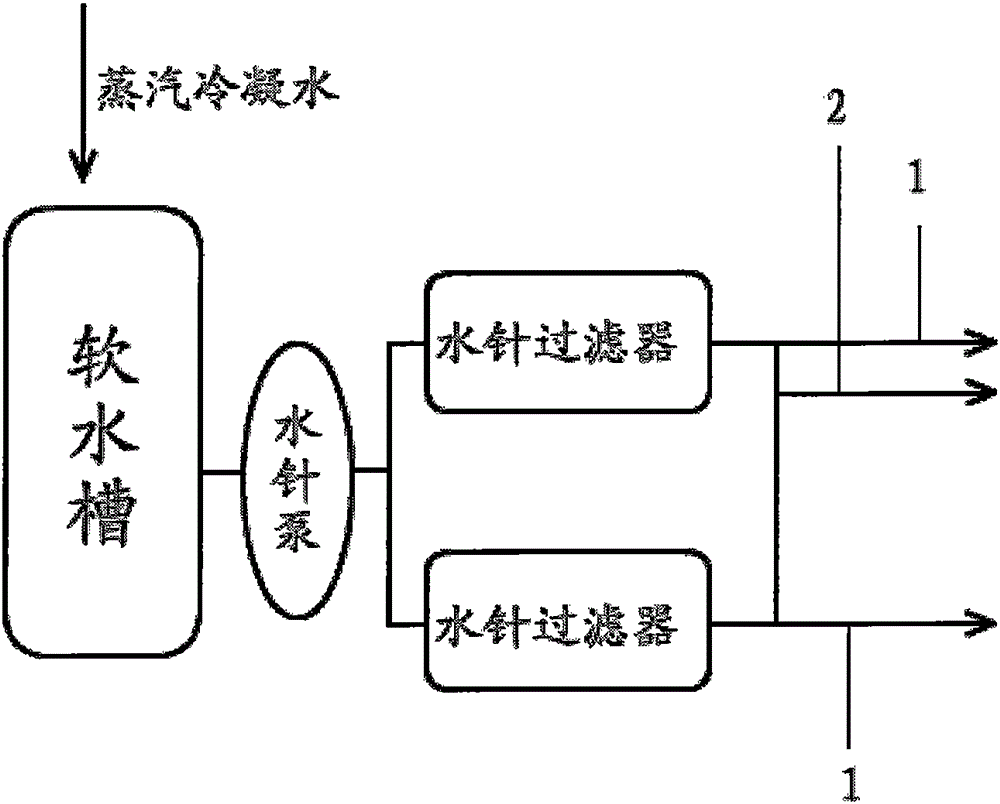

[0013] The present invention is specifically described below in conjunction with accompanying drawing, as shown in the figure,

[0014] A water needle heating device for paper cutting, which consists of a soft water tank, a water needle pump, a water needle filter and a cutting edge water needle,

[0015] The soft water tank collects steam condensed water from the drying cylinder to obtain hot soft water;

[0016] The needle pump transmits hot soft water to the needle filter.

[0017] The water needle filter passes the hot soft water to the trimming water needle after filtering;

[0018] The trimming water needles include two fixed water needles 1 and one mobile standby water needle 2 .

[0019] The invention utilizes steam condensed hot soft water of the drying cylinder as high-pressure water for trimming water needles, and the hardness of steam condensed hot soft water is low, which will not cause fouling of trimming water needles and cause water needles to scatter, and at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com