Preparation method of semiconductor nano material

A nanomaterial and semiconductor technology, which is applied in the field of semiconductor nanomaterial preparation, can solve the problems of wide size distribution of one-dimensional semiconductor nanocrystals, cumbersome preparation methods, and large particles of impurities, and achieve small size distribution, high electron mobility, and The effect of high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

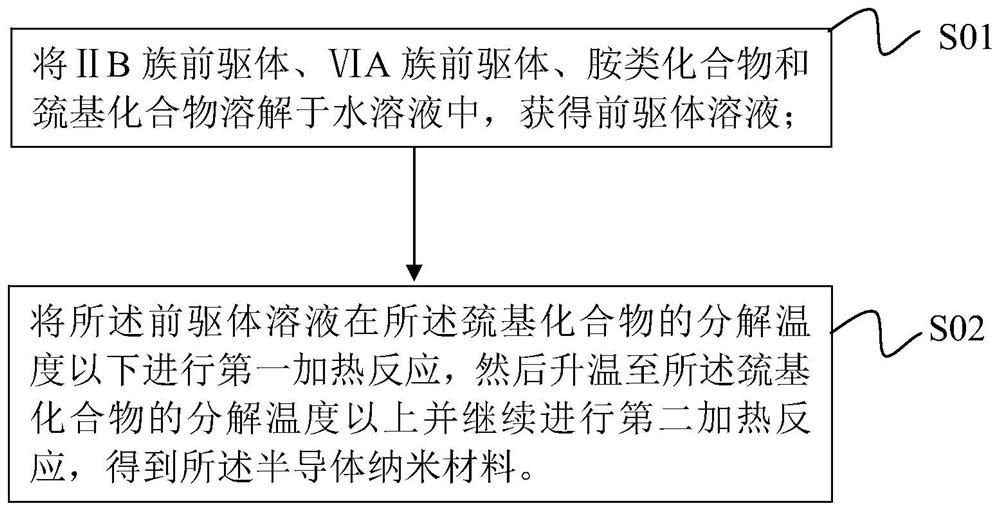

[0019] A method for preparing semiconductor nanomaterials, such as figure 1 shown, including the following steps:

[0020] S01, dissolving the Group IIB precursor, the Group VIA precursor, the amine compound and the mercapto compound in an aqueous solution to obtain a precursor solution;

[0021] S02. Perform a first heating reaction on the precursor solution below the decomposition temperature of the mercapto compound, then raise the temperature to above the decomposition temperature of the mercapto compound and continue the second heating reaction to obtain the semiconductor nanomaterial.

[0022] In the method for preparing semiconductor nanomaterials provided in the embodiments of the present invention, the precursor solution in which group IIB precursors, group VIA precursors, amine compounds, and mercapto compounds are dissolved is sequentially subjected to a first heating reaction and a second heating reaction, and By adjusting and controlling the reaction temperature ...

Embodiment approach

[0027] In the embodiment of the present invention, the amine compound is used as a structure inducer to induce the synthesis of a one-dimensional semiconductor nanomaterial. In the synthesis process of one-dimensional semiconductor nanomaterials, the amine compounds tend to coordinate with the empty orbitals of the IIB group cations located in the peripheral direction of the crystal, which to a certain extent inhibits the combination of the IIB group cations in the crystal peripheral direction and the selenium anion, making The combination rate of group IIB cations in the crystal axial direction and selenium anions is greater than that in the crystal peripheral direction, and then forms semiconductor nanomaterials in the form of nanorods or nanowires. As an embodiment, the amine compound includes at least one of ethylenediamine, ethylenediamine diacetic acid and ethylenediamine diacetate, and this type of amine compound can be linearly coordinated with Cd and Zn atoms, Promote...

Embodiment 1

[0056] This embodiment provides a semiconductor nanomaterial, the preparation of which specifically includes the following steps:

[0057] (1) Add 10mmol of zinc chloride, 3mmol of thioglycolic acid, 20mmol of ethylenediaminetetraacetic acid, and 500mmol of deionized water into a 50mL three-necked flask, and stir at 1000rpm under Ar atmosphere protection until dissolved at room temperature to obtain the first mixed solution.

[0058] 5 mmol of selenium, 10 mmol of sodium borohydride, and 200 mmol of deionized water were sequentially added into a 50 mL three-necked flask, stirred and dissolved under an argon atmosphere at room temperature to obtain a second uniform mixed solution.

[0059] The second mixed solution was injected into the first mixed solution, stirred evenly, and 1M NaOH solution was added to adjust the pH of the solution to 9 to obtain a uniform precursor solution.

[0060] (2) Transfer the above precursor solution mixture to a 50mL autoclave, and transfer the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com