Preparation method of color toner with core-shell structure

A technology of color toner and core-shell structure, which is used in instruments, developers, optics, etc., can solve the problems of uneven coating of shell resin self-aggregation into granules and shell layer, and the production process of core-shell structure toner is not specifically described. , to avoid carbon black agglomerates, controllable thickness, and uniform coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

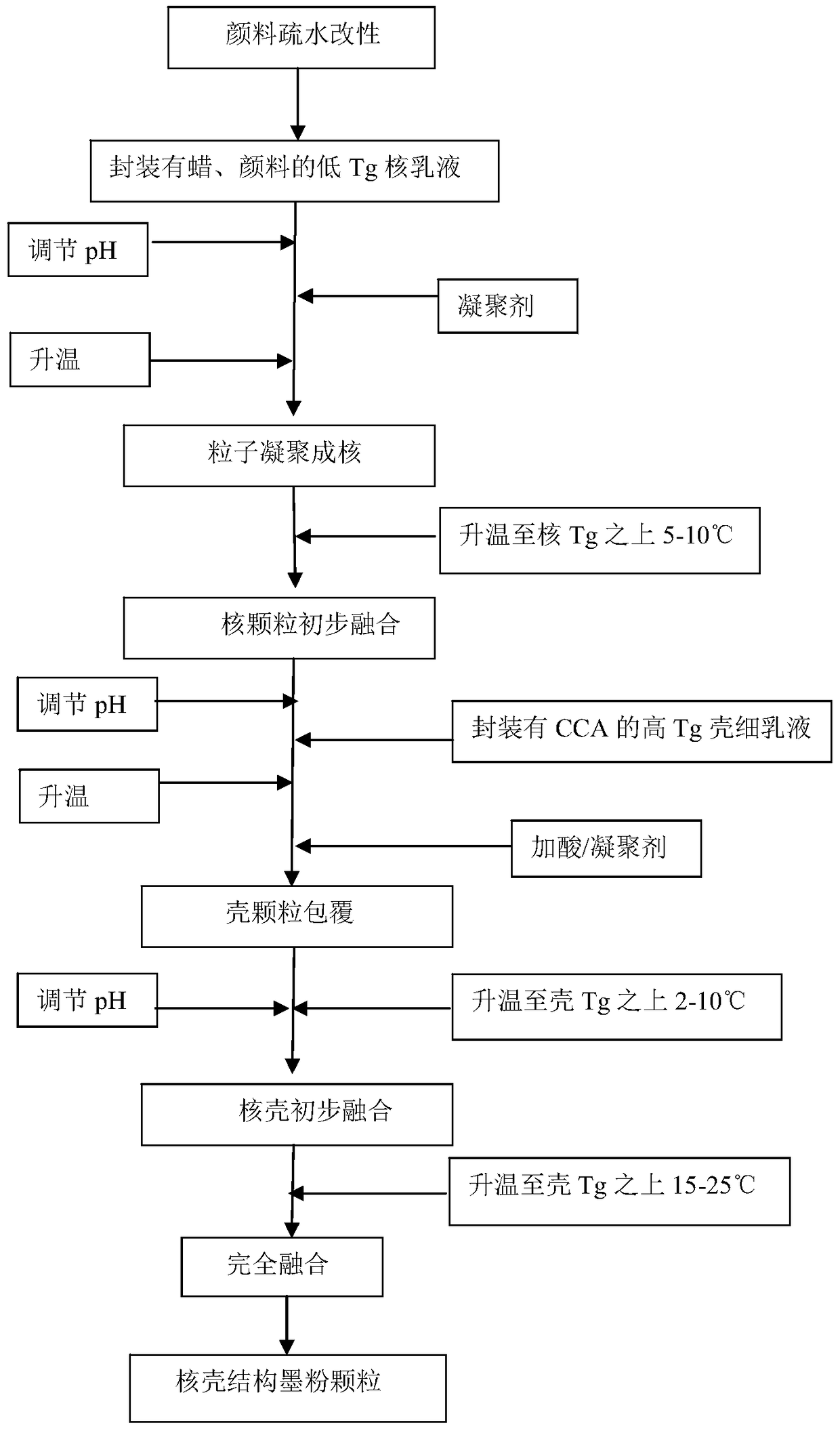

Method used

Image

Examples

Embodiment 1

[0074] 1) Preparation of modified carbon black

[0075] Add 1.0 g of silane coupling agent KH-570 into 100 mL of isopropanol / water mixed solvent (volume ratio 1:1), and ultrasonically disperse at 300 rpm for 0.5 h. Add 10g of carbon black NP60 to the system, and wet it at 200rpm for 1h. Raise the temperature to 80°C while dispersing at a high speed of 2000rpm for 2h. The hydrophobically modified carbon black B can be obtained by drying and grinding the dispersion liquid.

[0076] 2) Preparation of nuclear emulsion A with low Tg of modified carbon black and wax encapsulated

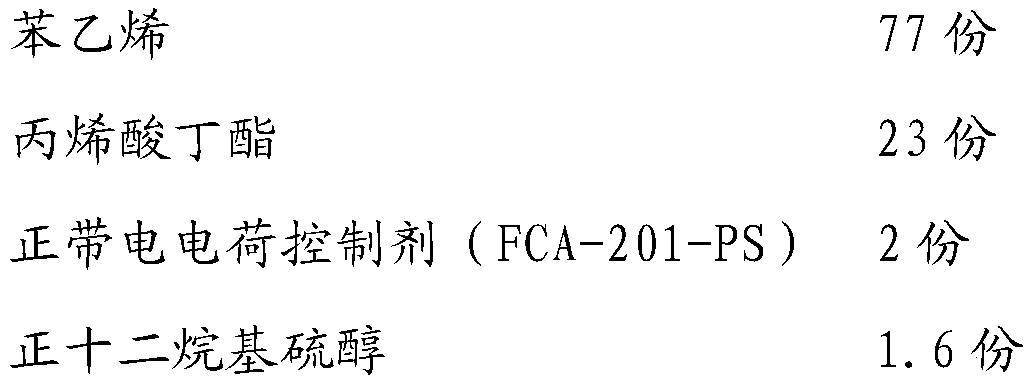

[0077]

[0078]

[0079] The above-mentioned raw materials were added into a 1L four-necked flask, and dispersed at 42° C. and 300 rpm for 0.5 h. Add 8 parts of modified carbon black to the system, ultrasonically disperse for 0.5 h, then add 8 parts of ester wax to fully dissolve, add 7 parts of tert-butyl peroxypivalate to the system to obtain a monomer mixture. Take another 1L beaker, add 2 par...

Embodiment 2

[0087] In embodiment 1, the carbon black NP60 pigment used is replaced by yellow pigment 180 (manufactured by Clariant), and the positively charged charge control agent FCA-201-PS is replaced by the negatively charged charge control agent FCA-1001-NS (Japan Teng Cang Chemical Industry Co., Ltd. Co., Ltd.), 80 parts of 25%wt shell emulsion A was changed to 140 parts, and the remaining operations were consistent with Example 1. The toner (2) with core-shell structure (particle size: 6.5 μm, mass ratio of shell resin to core resin: 35%) can be obtained. Table 1 shows the obtained toner characteristic evaluation results.

Embodiment 3

[0089] The carbon black NP60 pigment used in Example 1 is replaced by cyan pigment 15:3 (manufactured by Clariant), the styrene used to prepare the shell resin emulsion B is changed to 92 parts, and butyl acrylate is changed to 8 parts, that is, the shell resin Tg is by 70°C was changed to 80°C, and the core-shell melting temperature was changed from 75°C to 85°C. 80 parts of 25%wt shell emulsion B was changed to 60 parts, and the rest of the operations were the same as in Example 1. The toner (2) with core-shell structure (particle size: 5.8 μm, mass ratio of shell resin to core resin: 15%) can be obtained. Table 1 shows the obtained toner characteristic evaluation results.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com