Method for preparing copper indium selenium nano tablets

A nanosheet and copper indium selenide technology, applied in the field of nanomaterials, can solve problems such as agglomeration, irregular shape of copper indium selenide, etc., and achieve the effects of low cost, simple method and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] ① Add 2 parts of selenium powder, 10 parts of Vc and 1000 parts of DMF into the polytetrafluoroethylene reactor, then seal the reactor and put it in an oven at 160°C for 6 hours to react The kettle was naturally cooled to room temperature.

[0021] ②Open the reactor and quickly add 1 part of copper acetate, 1 part of indium nitrate and 5 parts of polyvinylpyrrolidone, then seal the reactor, control the temperature at 160°C, and react for 24 hours.

[0022] ③ After the reaction, the reaction kettle was naturally cooled to room temperature, the product was filtered, washed several times with absolute ethanol, and vacuum-dried to obtain copper indium selenide nanomaterials.

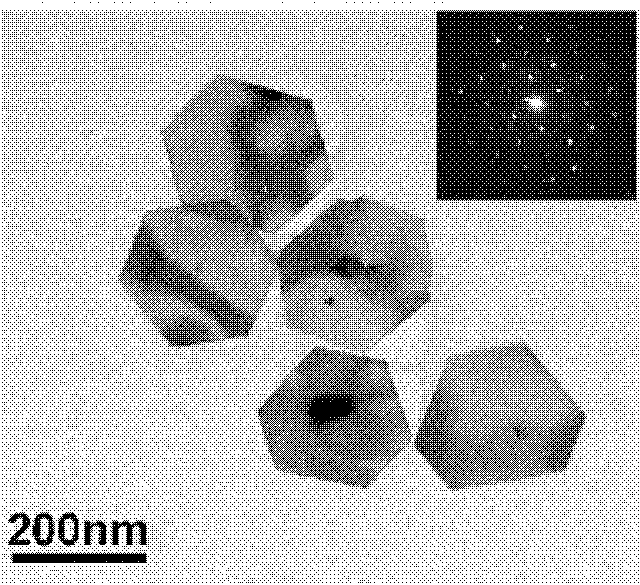

[0023] figure 1 It is the transmission electron micrograph and the electron diffraction pattern of the obtained copper indium selenide nanometer material. It can be seen from the figure that this material is CuInSe with pure phase tetragonal chalcopyrite structure. 2 , a single-crystal two-dimensio...

Embodiment 2

[0025] ① Add 50 parts of selenium powder, 200 parts of Vc and 1000 parts of DMF into the polytetrafluoroethylene reaction kettle according to the amount of the substance, then seal the reaction kettle, put it in an oven at 160°C, and keep it for 6 hours before reacting The kettle was naturally cooled to room temperature.

[0026] ②Open the reactor and quickly add 25 parts of copper nitrate, 25 parts of indium chloride and 100 parts of polyvinylpyrrolidone, then seal the reactor, control the temperature at 180°C, and react for 6 hours.

[0027] ③ After the reaction, the reaction kettle was naturally cooled to room temperature, the product was filtered, washed several times with absolute ethanol, and vacuum-dried to obtain copper indium selenide nanomaterials.

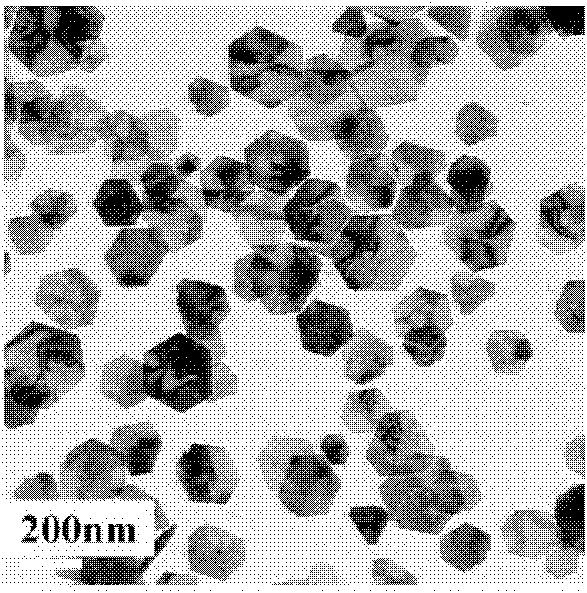

[0028] figure 2 is the transmission electron micrograph of the obtained copper indium selenide nanomaterial. It can be seen from the figure that this material is CuInSe with pure tetragonal chalcopyrite structure. 2 ...

Embodiment 3

[0030] ①According to the quantity of substances, add 10 parts of selenium powder, 50 parts of Vc and 1000 parts of DMF into the polytetrafluoroethylene reaction kettle, then seal the reaction kettle, put it in an oven at 120°C, and keep it for 24 hours before reacting The kettle was naturally cooled to room temperature.

[0031] ②Open the reactor and quickly add 5 parts of copper acetate, 5 parts of indium chloride and 25 parts of polyvinylpyrrolidone, then seal the reactor, control the temperature at 200°C, and react for 12 hours.

[0032] ③ After the reaction, the reaction kettle was naturally cooled to room temperature, the product was filtered, washed several times with absolute ethanol, and vacuum-dried to obtain copper indium selenide nanomaterials.

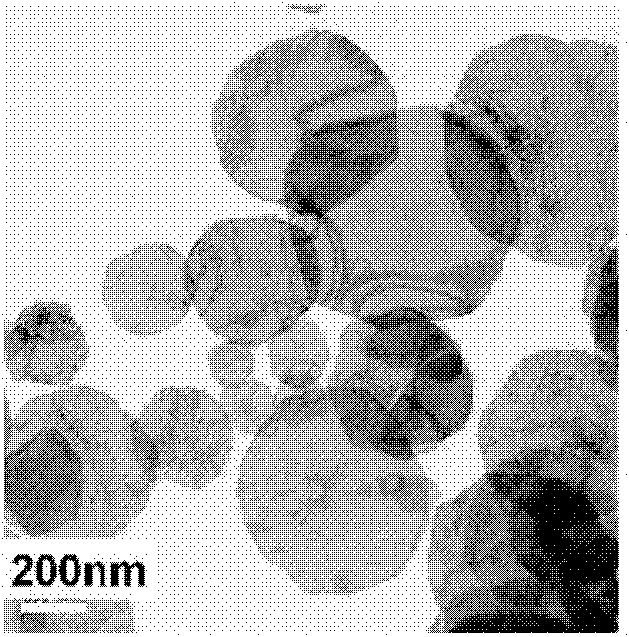

[0033] image 3 is the transmission electron micrograph of the obtained copper indium selenide nanomaterial. It can be seen from the figure that this material is CuInSe with pure phase tetragonal chalcopyrite structure. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com