Polyimide thin film and preparation method therefor

A technology of polyimide film and polyamic acid resin, applied in the field of insulating materials, can solve problems such as being unsuitable for large-scale production and complex process flow, and achieve good mechanical properties, improve interface bonding force, and excellent corona resistance performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

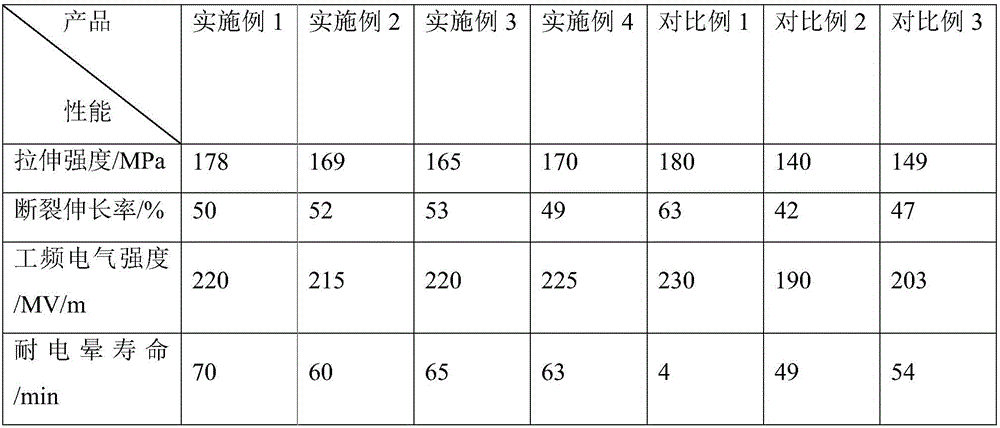

Examples

Embodiment 1

[0042] The polyimide film described in this embodiment is prepared by the following method:

[0043] After mixing 0.5kg of γ-aminopropyltriethoxysilane, 0.5kg of n-octyltriethoxysilane, 1kg of alumina nanoparticles with a particle size of 15nm, and 8kg of N-methylpyrrolidone, at a temperature of 70°C The reaction was carried out for 5h under the conditions, and cooled to room temperature to obtain a dispersion of alumina; the dispersion of 10kg of alumina and 40kg of N-methylpyrrolidone were mixed, and then 7.8kg of pyromellitic dianhydride and 4,4'-dicarbonate were added. Amino diphenyl ether 7.2kg, the temperature of the reaction system was raised to 30°C, after the dianhydride and diamine were fully dissolved, the reaction was continued for 2 hours, and the reaction system was cooled to room temperature to obtain the polyamic acid resin; Transfer to the defoaming kettle and vacuumize the defoaming under the condition that the vacuum degree is -0.09MPa. The defoaming is comp...

Embodiment 2

[0046] The polyimide film described in this embodiment is prepared by the following method:

[0047] After mixing 0.4 kg of γ-mercaptopropyl triethoxysilane, 0.7 kg of octadecyl trimethoxysilane, 2 kg of silica nanoparticles with a particle size of 100 nm, and 10 kg of N-methylpyrrolidone, the mixture was heated at 60°C. Under temperature conditions, react for 6h, cool to room temperature, and obtain a dispersion of silica; mix 10kg of silica dispersion and 50kg of N-methylpyrrolidone, and then add 7.8kg of pyromellitic dianhydride and 4,4 '-diaminodiphenyl ether 7.2kg, the temperature of the reaction system was raised to 30 ℃, after the dianhydride and diamine were fully dissolved, the reaction was continued for 4h, and the reaction system was cooled to room temperature to obtain the polyamic acid resin; The amic acid resin is transferred to the defoaming kettle and vacuumized and defoamed under the condition of vacuum degree of -0.09MPa. The defoaming is completed when no bu...

Embodiment 3

[0050] The polyimide film described in this embodiment is prepared by the following method:

[0051] 0.8kg of γ-(2,3-glycidoxy)propyltrimethoxysilane, 0.5kg of octadecyltriethoxysilane, 2kg of titanium dioxide nanoparticles with a particle size of 200nm, N,N-dimethyl After mixing 12Kg of dimethylformamide, react at 80°C for 4h, and cool to room temperature to obtain a dispersion of titanium dioxide; mix 10kg of the dispersion of titanium dioxide and 60kg of N,N-dimethylformamide, and then add 3 , 15.5kg of 3',4,4'-benzophenone tetracarboxylic dianhydride and 9.5kg of 4,4'-diaminodiphenylmethane, the temperature of the reaction system was raised to 40°C, and the dianhydride and diamine were treated After fully dissolving, continue the reaction for 4 hours, and cool the reaction system to room temperature to obtain the polyamic acid resin; transfer the polyamic acid resin to the defoaming kettle and vacuumize and defoam under the condition that the vacuum degree is -0.09MPa, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com