High-power-resistant type lead-free environment-friendly ceramic dielectric material

A ceramic dielectric and power type technology, applied in the field of ceramic dielectric materials, can solve problems such as thermal breakdown failure, and achieve the effects of small dielectric loss, high dielectric constant, and high dielectric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The preparation method of above-mentioned ceramic dielectric material:

[0018] Main ingredient BaTiO 3 Preparation: The raw material BaCO with a purity of more than 99.0% 3 and TiO 2 According to the molar ratio of 1: (1-1.05), the ball mill is mixed evenly, and calcined at 1200-1300°C for 2-4 hours.

[0019] Sub-material SrTiO 3 Preparation: The raw material SrCO with a purity of more than 99.0% 3 and TiO 2 After mixing uniformly by ball milling at a molar ratio of 1:1, calcining at 1150-1250°C for 2-4 hours.

[0020] Ceramic dielectric material preparation: mix the main material, auxiliary material, modified additive and sintering flux in molar ratios, mix and grind with a sand mill to make the overall particle size below 5 μm, add 3% polyvinyl alcohol solution to it and mix Evenly, granulate to form a dry pressing molding powder with uniform particle size and good distribution.

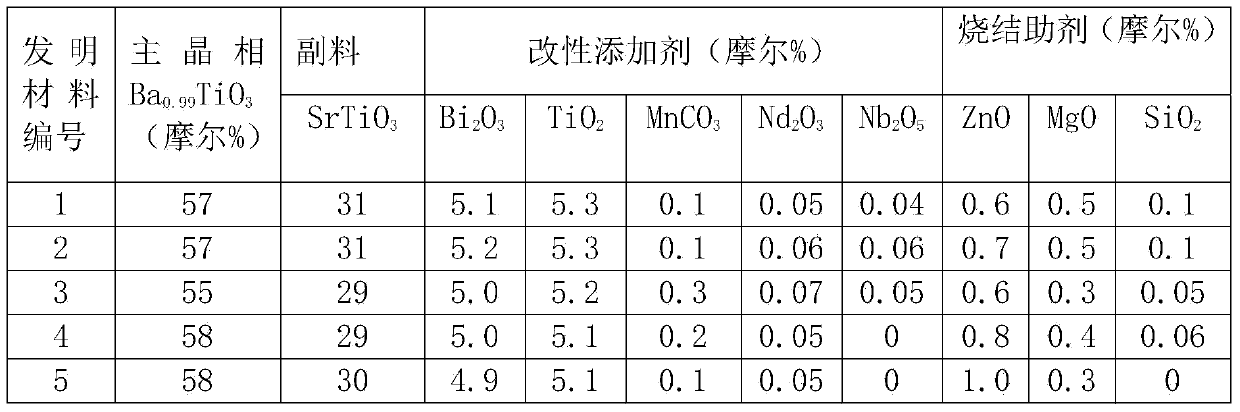

[0021] Embodiment 1~No. 5 material formula is shown in Table 1

[0022] Table 1...

Embodiment 1

[0025] Main ingredient BaTiO 3 Preparation: The raw material BaCO with a purity of more than 99.0% 3 , with 0.99 mol BaCO 3 and 1.0 mol TiO 2 Proportion, ball milling and mixing evenly, pre-calcine the mixture at 1220°C for 3 hours, and then make the average particle size below 100μm through ultra-fine grinding, that is, the main crystal phase is Ba 0.99 TiO 3 Material.

[0026] Sub-material SrTiO 3 Preparation: The raw materials with a purity of more than 99.0% were mixed with 1.0 mole of SrCO 3 and 1.0 mol TiO 2 Proportion, ball milling and mixing evenly, pre-calcine the mixture at 1180°C for 3.5 hours, and then make the average particle size below 100 μm through ultra-fine pulverization, that is, the main crystal phase is SrTiO 3 Material.

[0027] Ceramic dielectric material preparation: 0.57 moles of the main material BaTiO 3 , 0.31 mol of sub-material SrTiO 3 , 0.05 mol 1Bi 2 o 3 , 0.053 mol TiO 2 , 0.001 mol MnCO 3 , 0.0005 mol Nd 2 o 3 , 0.0004 mol Nb ...

Embodiment 2

[0029] Main ingredient BaTiO 3 Preparation: The raw material BaCO with a purity of more than 99.0% 3 , with 0.99 mol BaCO 3 and 1.0 mol TiO 2 Proportion, ball milling and mixing evenly, pre-calcine the mixture at 1250°C for 2.5 hours, and then make the average particle size below 100μm through ultra-fine grinding, that is, the main crystal phase is Ba 0.99 TiO 3 Material.

[0030] Sub-material SrTiO 3Preparation: The raw materials with a purity of more than 99.0% were mixed with 1.0 mole of SrCO 3 and 1.0 mol TiO 2 Proportion, ball milling and mixing evenly, pre-calcine the mixture at 1220°C for 3 hours, and then make the average particle size below 100 μm through ultra-fine grinding, that is, the main crystal phase is SrTiO 3 Material.

[0031] Ceramic dielectric material preparation: 0.57 moles of the main material BaTiO 3 , 0.31 mol of sub-material SrTiO 3 , 0.05 mol 2Bi 2 o 3 , 0.053 mol TiO 2 , 0.001 mol MnCO 3 , 0.0006 mol Nd 2 o 3 , 0.0006 mol Nb 2 o 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com