Device and method for measuring electrical strength of material under stress condition

A technology of electrical strength and testing device, applied in the direction of testing dielectric strength, etc., can solve the problems of reduced bearing capacity of insulating materials, component fracture, stress concentration, etc., to achieve the effect of improving relative electrical strength and reducing negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

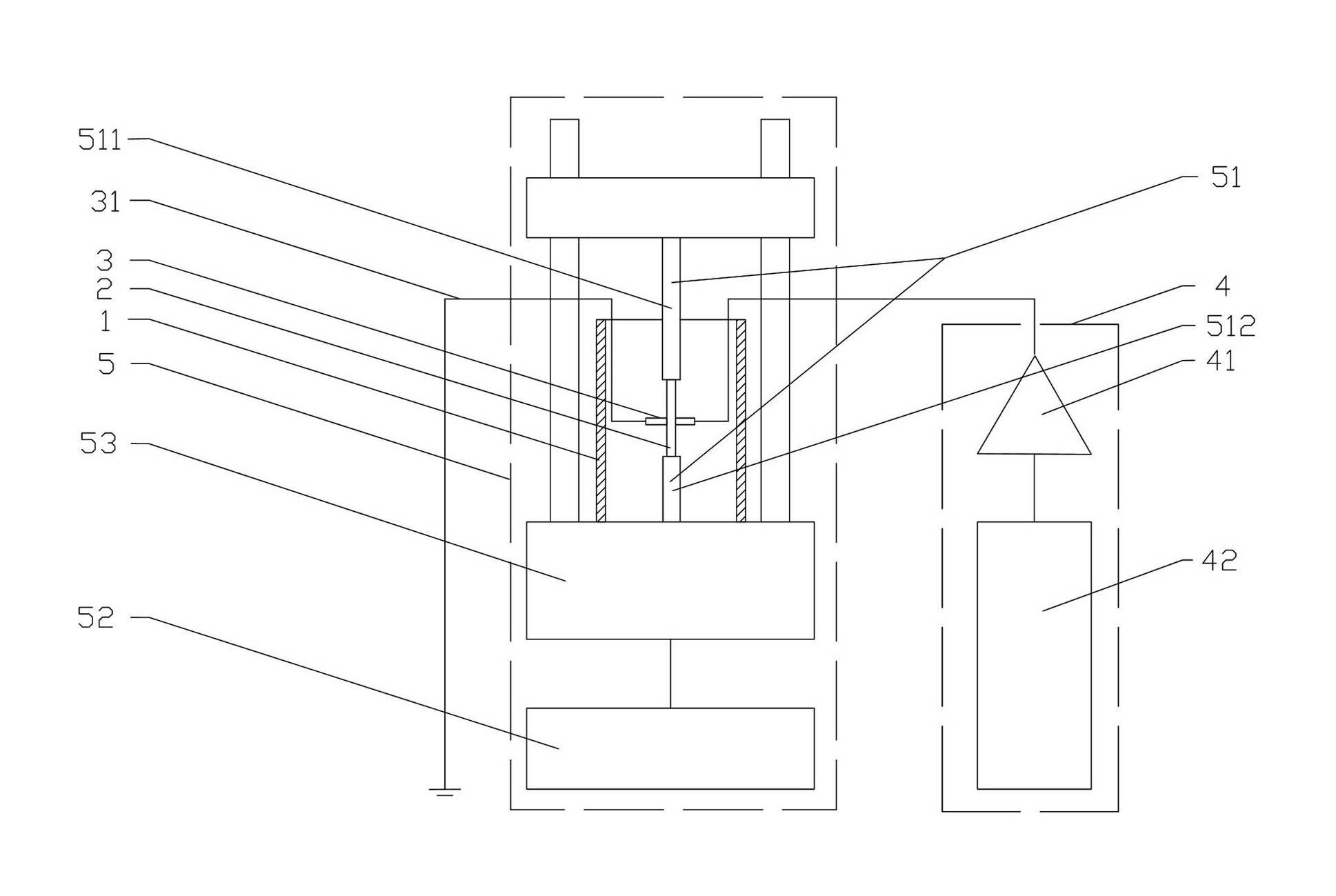

[0038] a kind of like figure 1 The device for determining the electric strength of materials under stress conditions is shown, which can be used to test the electric strength of materials under tensile conditions. The test device 4 and the stress generation system 5, the test electrodes 3 are installed on both sides of the test sample 2 and connected to the electric strength test device 4 through the electrode leads 31, the stress generation system 5 includes a clamp for clamping the test sample 2 Device 51.

[0039] In this embodiment, the upper end of the insulating oil barrel 1 is open, and the lower end is covered with a flexible insulating material. rubber film). The flexible insulating material is cut to a suitable size, and its outer edge is sealed and connected to the bottom of the side wall of the insulating oil barrel 1 through a sealing material. There is a small opening in the center, and the sample to be tested can be sealed and connected to the opening through ...

Embodiment 2

[0044] A method of material electric strength under the device test stress condition of embodiment 1, comprises the following steps:

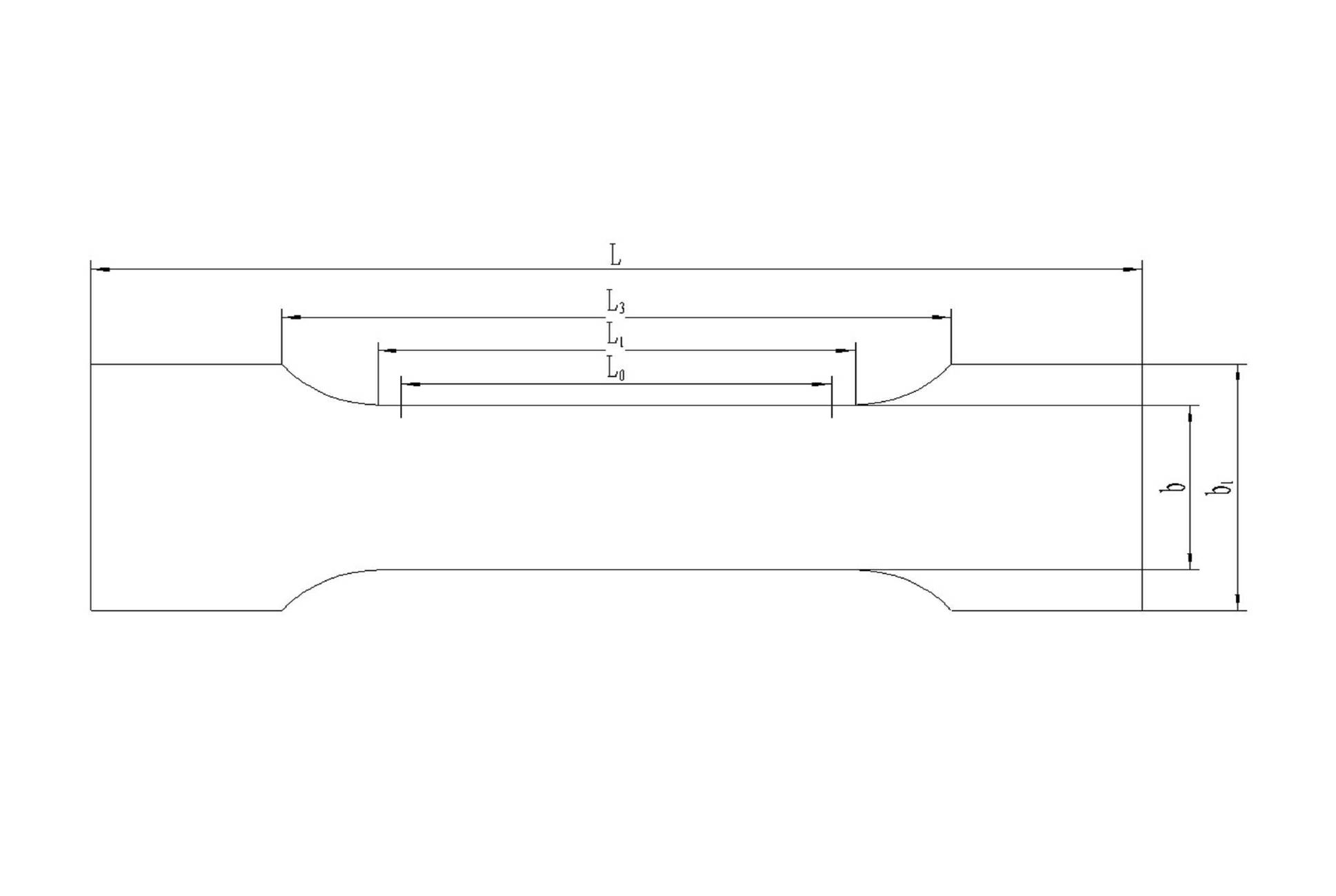

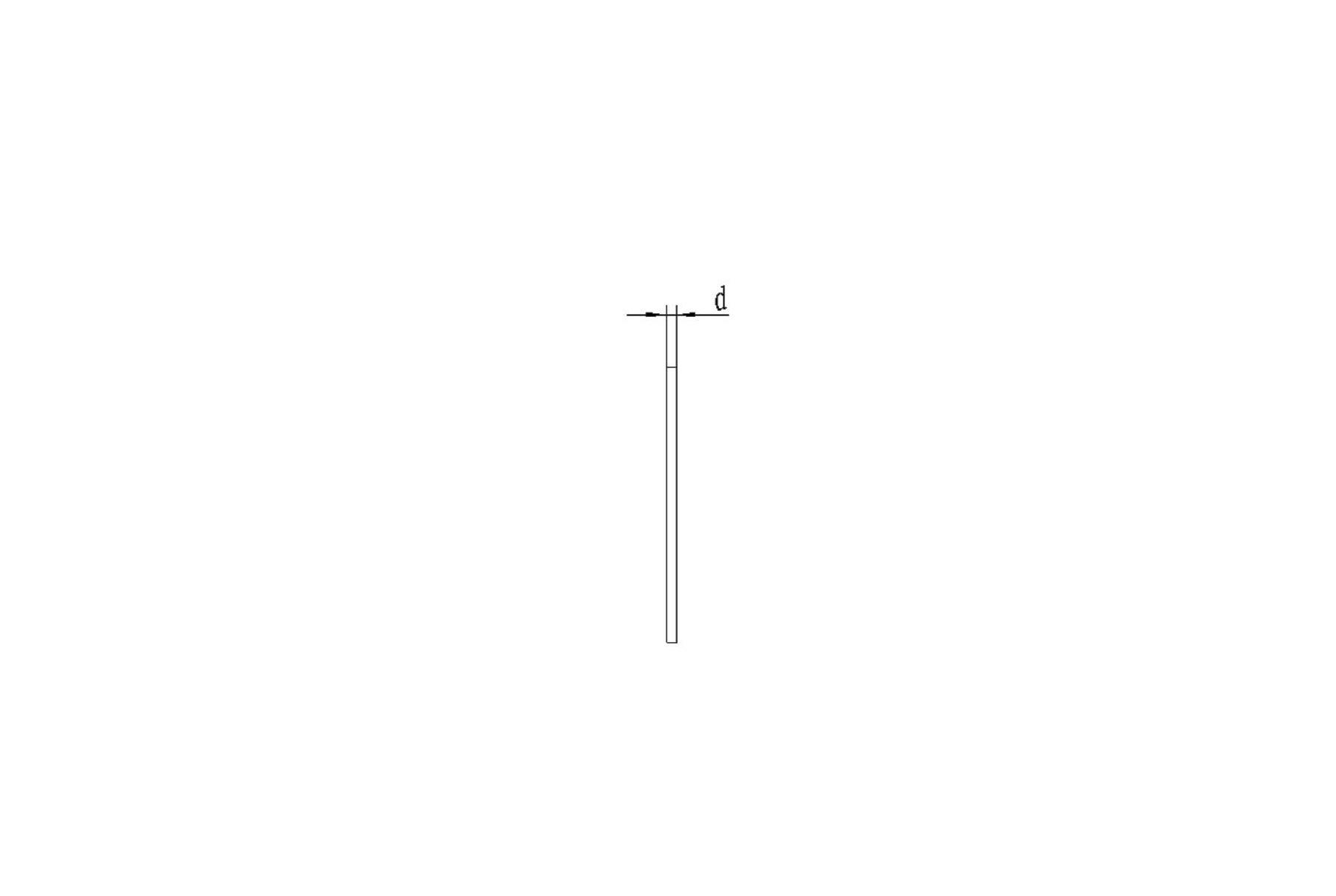

[0045] (1) Sample installation: Prepare the shape as figure 2 , image 3 Several tensile test specimens of the acrylic unsaturated polyester resin 9001 cast body shown (the specimen size must meet the requirements of both the tensile or compression test and the insulation withstand voltage test, and its size is: L=220mm; L 0 =90;L 1 =100; L 3 =140mm; b=40; b 1 =60; thickness d is 2mm); the test sample 2 is packaged in the insulating oil barrel 1 of the above device, and the test electrodes 3 are symmetrically installed on both sides of the test sample 2; the insulating oil barrel 1 is clamped at the place where the stress occurs On the clamping device 51 of the system 5;

[0046] (2) System connection: clamp the test sample 2 on the clamping device 51, use sealant to connect the lower clamp 512 of the clamping device 51 with the bottom o...

Embodiment 3

[0051] A method of material electric strength under the device test stress condition of embodiment 1, comprises the following steps:

[0052] (1) Sample installation: Prepare the shape as Figure 5 , Figure 6 Several longitudinal tensile test specimens of the unidirectional glass fiber reinforced acrylic unsaturated polyester resin 9001 composite material (the size of which is as follows Figure 5 , Figure 6 Shown: L=400mm; L 0 =240mm; L 2 =280mm; b=40mm; d=3mm); the test sample 2 is packaged in the insulating oil barrel 1 of the above device, and the test electrode 3 is symmetrically installed on both sides of the test sample 2; the insulating oil barrel 1 is clamped on the clamping device 51 of the stress generating system 5;

[0053] (2) System connection: clamp the test sample 2 on the clamping device 51, use sealant to connect the lower clamp 512 of the clamping device 51 with the bottom of the insulating oil drum 1 reliably and seal, and the upper clamping device ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com