Reduction insulation structure suitable for high-voltage motor and insulation processing method thereof

A high-voltage motor and insulation structure technology, applied in the shape/style/structure of winding insulation, winding insulation materials, laying solid insulation, etc., can solve problems such as gaps, and achieve the effect of excellent electric strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

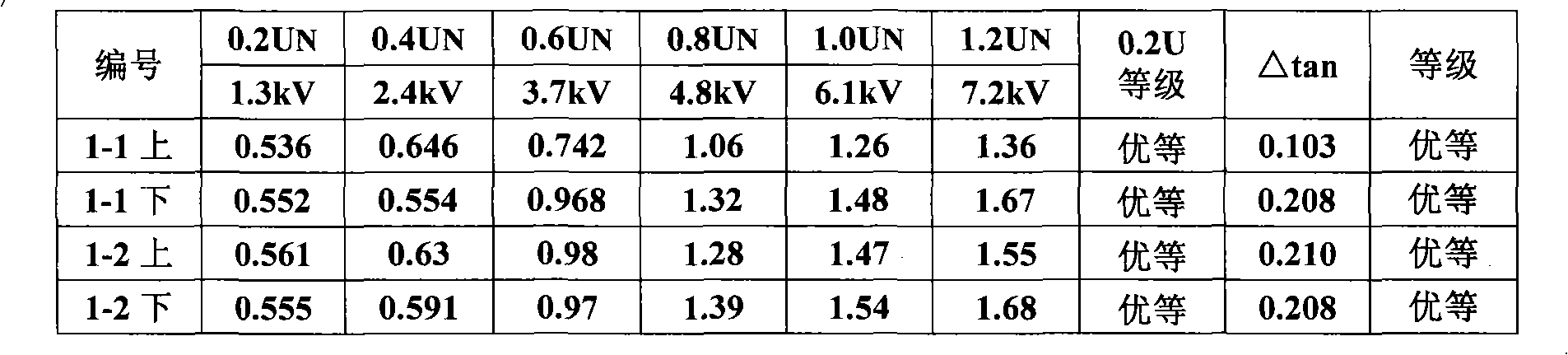

[0028] Example 1: Thinned insulation structure of 6kV high-voltage motor and its electrical performance measurement

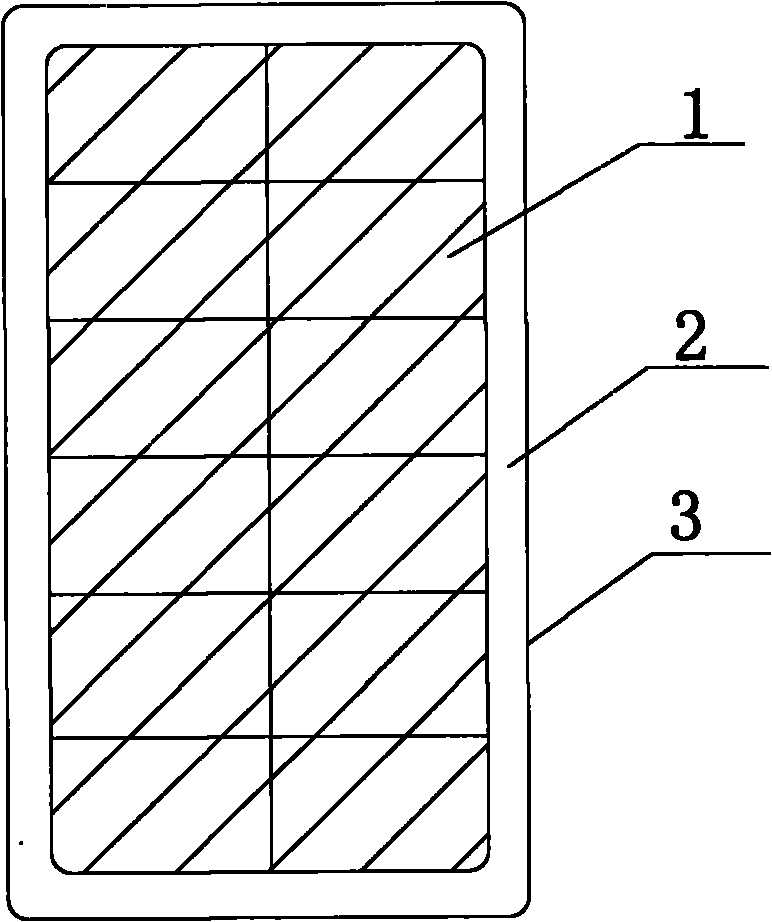

[0029] The thinned insulation structure of the high-voltage motor coil of this embodiment is shown in Figure 1, including an electromagnetic coil 1, a ground insulation 2, and a protective insulation 3; the ground insulation 2 includes less rubber powder mica tape and VPI impregnated resin; The electromagnetic coil 1 is wrapped flat copper wire; the ground insulation is a polyester film reinforced mica tape with little powder and vacuum pressure impregnated resin; the protective insulation is a low-resistance anti-corona tape.

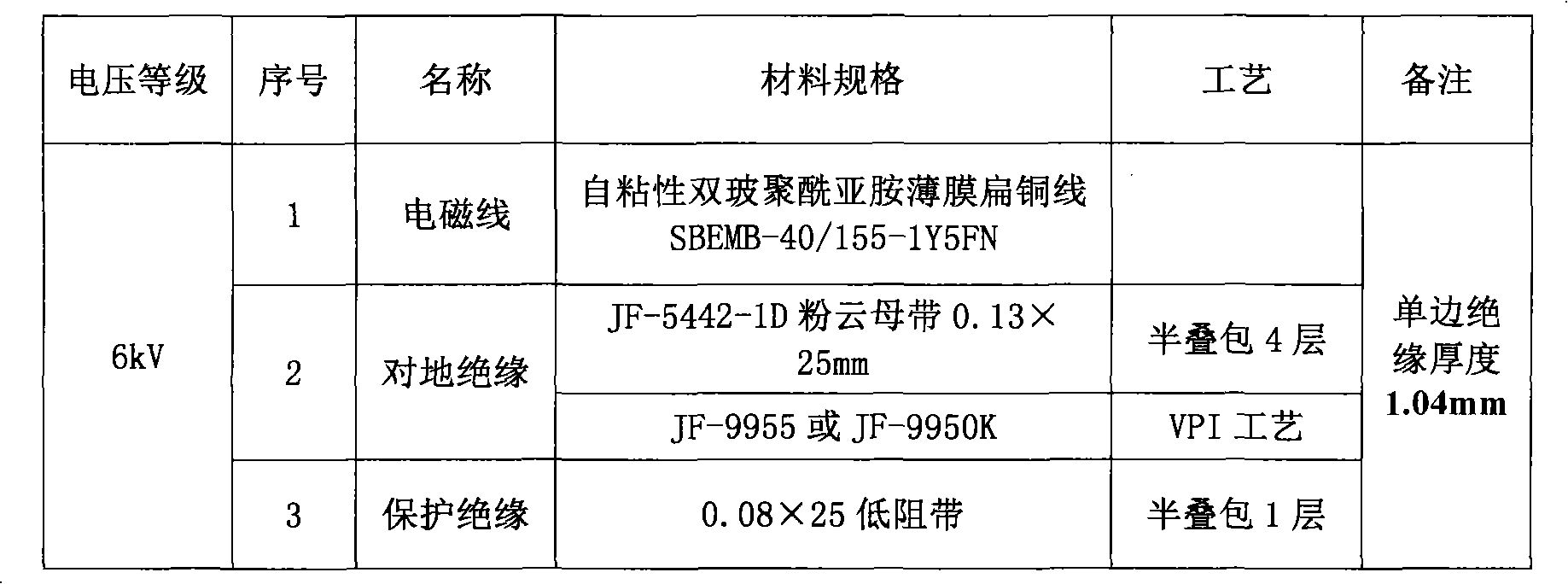

[0030] The thinned insulating structure is formed by winding electromagnetic wire, expanding, and gelling to form an electromagnetic coil, and then wrapping various structures of less glue mica tape and anti-corona tape, and is formed by vacuum pressure impregnation, baking, and curing. The specific materials and processes used are show...

Embodiment 2

[0038] Example 2: Thinned insulation structure of 6kV high-voltage motor and its electrical performance measurement

[0039]The thinned insulation structure of the high-voltage motor coil of this embodiment is shown in Figure 1, including an electromagnetic coil 1, a ground insulation 2, and a protective insulation 3; the ground insulation 2 includes less rubber powder mica tape and VPI impregnated resin; The electromagnetic coil 1 is a wrapped flat copper wire; the ground insulation is made of single-sided glass cloth reinforced less rubber powder mica tape and single-sided polyester film reinforced less rubber powder mica tape mixed package and vacuum pressure Composed of impregnated resin; the protective insulation is a low-resistance anti-corona tape.

[0040] The thinned insulating structure is formed by winding electromagnetic wire, expanding, and gelling to form an electromagnetic coil, and then wrapping various structures of less glue mica tape and anti-corona tape, an...

Embodiment 3

[0048] Example 3: 10kV high-voltage motor thinning insulation structure

[0049] The high-voltage motor coil thinning insulation structure of the present embodiment is similar to that of Figure 1, including an electromagnetic coil 1, ground insulation 2, and protective insulation 3; the ground insulation 2 includes less rubber powder mica tape and VPI impregnated resin; the The electromagnetic coil 1 described above is wrapped flat copper wire; the ground insulation is a single-sided glass cloth reinforced mica tape with less rubber powder and a single-sided polyester film reinforced mica tape with less rubber powder and vacuum pressure impregnated resin; The protective insulation described above is a low-resistance anti-corona tape.

[0050] The high-voltage motor is formed by winding, expanding, and gelling the electromagnetic wire to form an electromagnetic coil, and then wrapping various structures of less-glue mica tape and anti-corona tape, and then vacuum pressure impre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com