Electric connector

An electric connector and a common technology, applied in the direction of conductive connection, connection, clamping/spring connection, etc., can solve the problems of poor electrical conductivity of the terminal, small current-carrying area of the solder piece, and increase the difficulty of processing, etc., to achieve withstand voltage The effect of higher values, better overall performance, and increased creepage distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

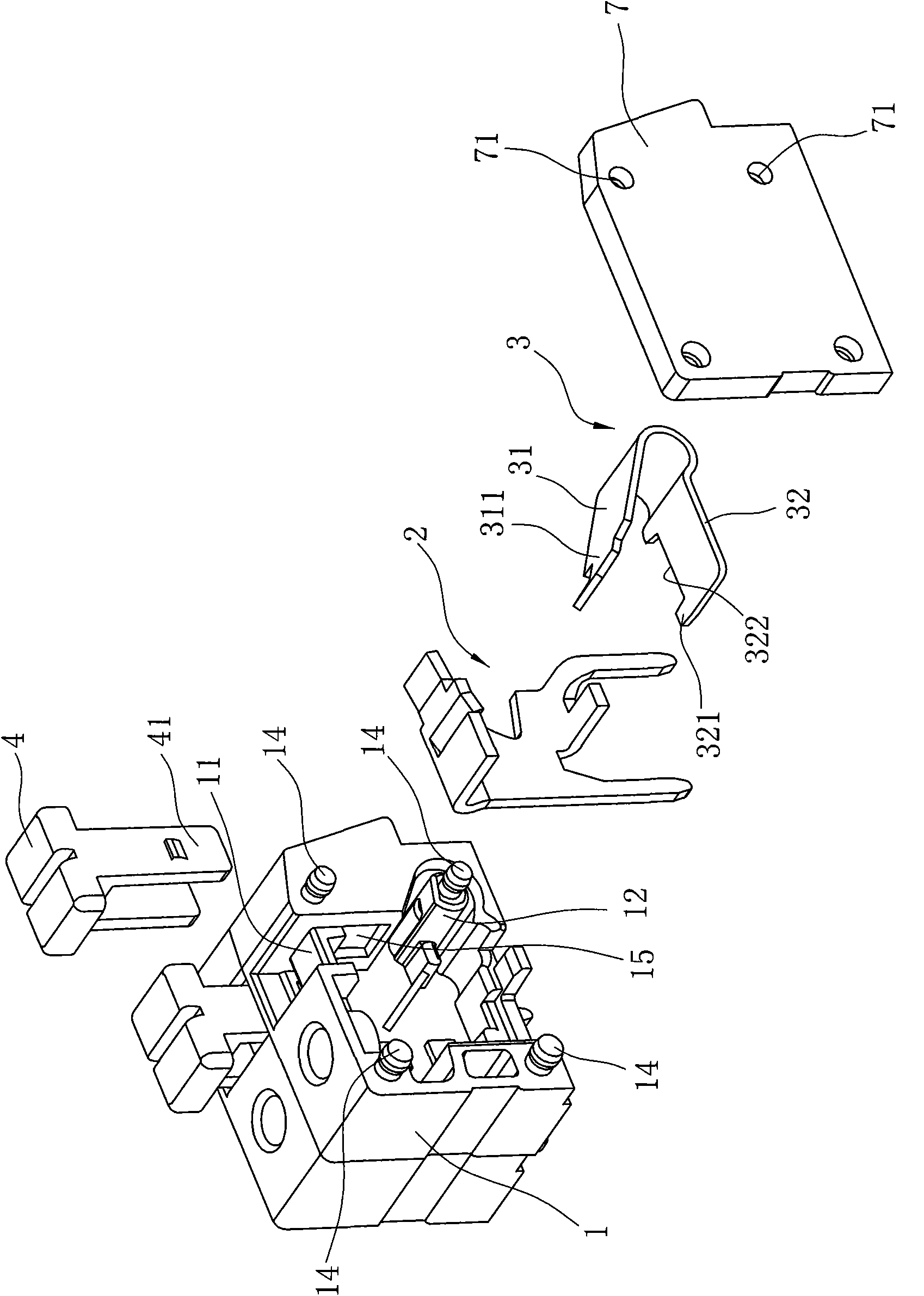

[0026] Embodiment one, refer to Figure 1 ~ Figure 4 Shown:

[0027] The electrical connector of the first embodiment includes two insulating bases 1 that are spliced together, and each base 1 is provided with a wiring hole 15 for insertion of wires in the front;

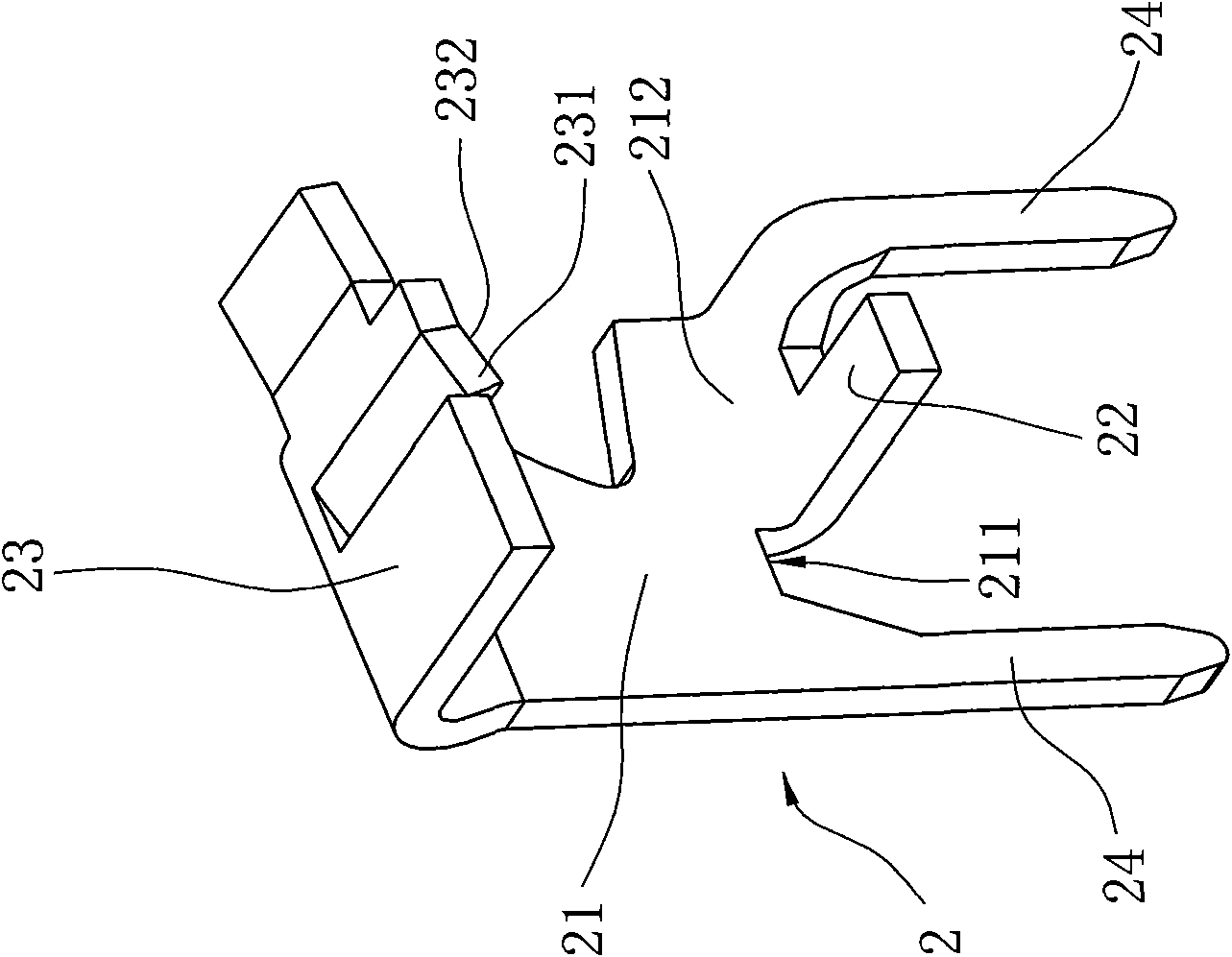

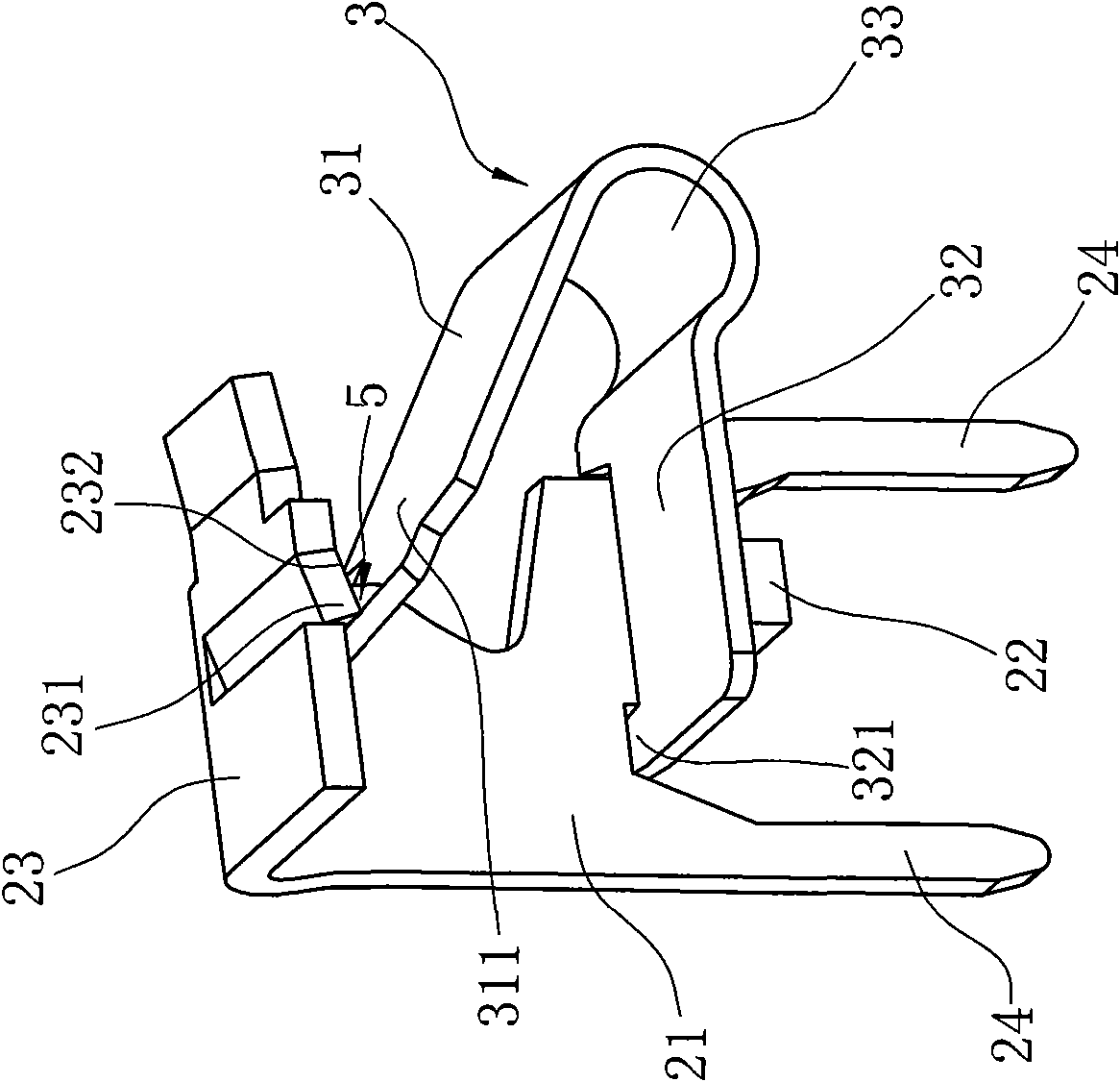

[0028] The soldering piece 2 fixedly arranged in the base 1, the soldering piece 2 acts as a carrier fluid, and is used to realize the electrical connection between the wire and the circuit board;

[0029] The elastic piece 3 connected to the welding piece 2, the elastic piece 3 includes a free end 311 which has a tendency to always abut against the welding piece 2 and a fixed end 321 connected to the welding piece 2;

[0030] The button 4 installed on the top of the base, the cross section of the button is in the shape of "Ji", the base 1 is provided with a beam 11 that can be inserted into the Z-shaped button, the bottom end 41 of the button 4 and the free end of the shrapnel 3 311 offset, pressing down on the...

Embodiment 2

[0037] Embodiment two, refer to Figure 5 ~ Figure 8 Shown:

[0038] The basic structure of the second embodiment is the same as that of the first embodiment. The difference between the two is that the base 1 also has a through hole 13 on the outer wall near the bottom, which can be inserted into the conductive bridging piece 6, wherein the conductive The bridge piece 6 is generally an electric conductor with two pins 61, which can realize rapid conduction of the circuit between adjacent bases. The current-carrying main board 21 of the solder piece 2 is also formed with a current-carrying pin at the position corresponding to the through hole 13. The main board 21 is perpendicular to the side plate 25 , and the side plate 25 defines a hole 251 through which the pin 61 of the conducting bridge 6 can pass and is aligned with the through hole 13 .

[0039] If it is necessary to realize the rapid conduction of the circuit between the two bases, as long as the two pins 61 of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com