Patents

Literature

90results about How to "Increase the number of pieces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

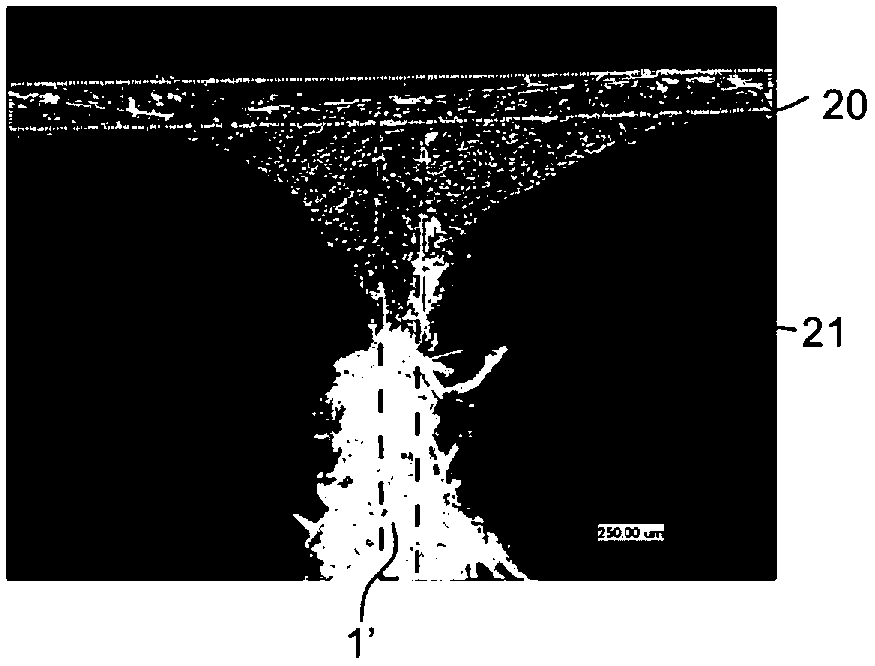

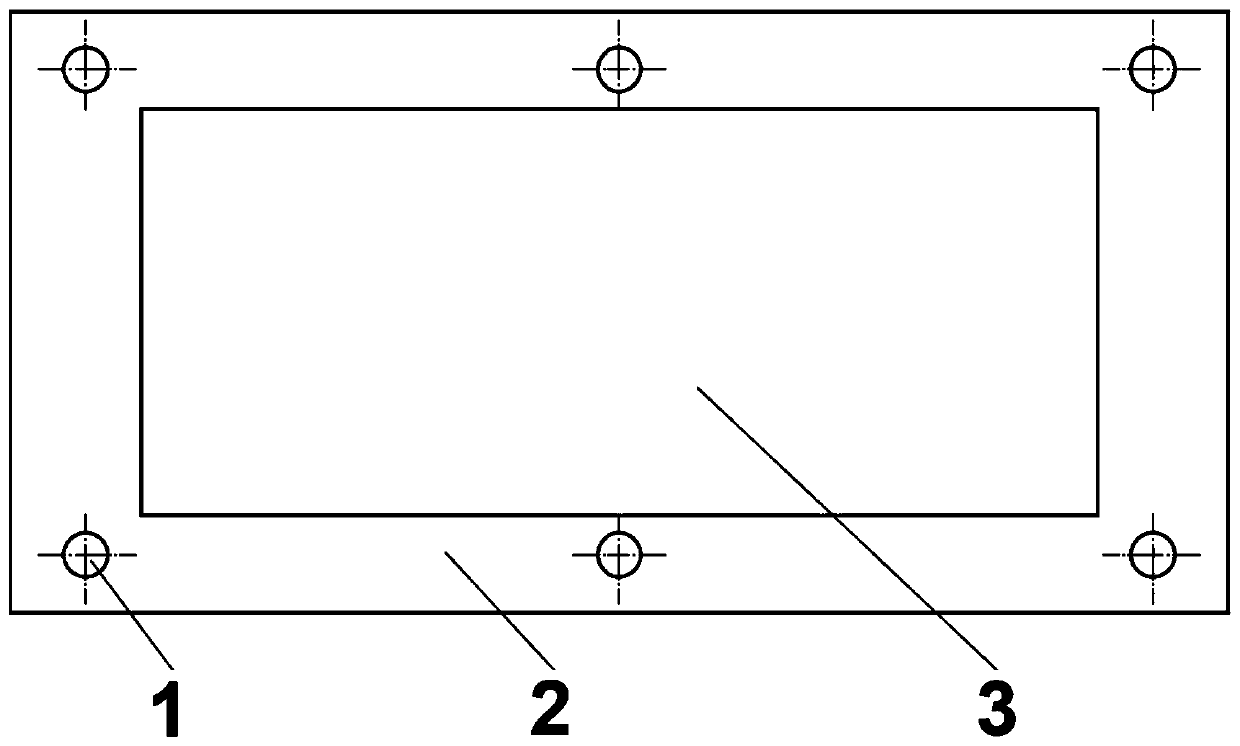

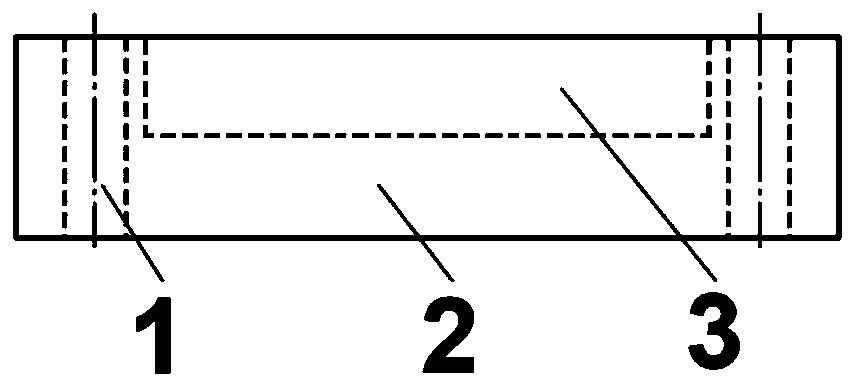

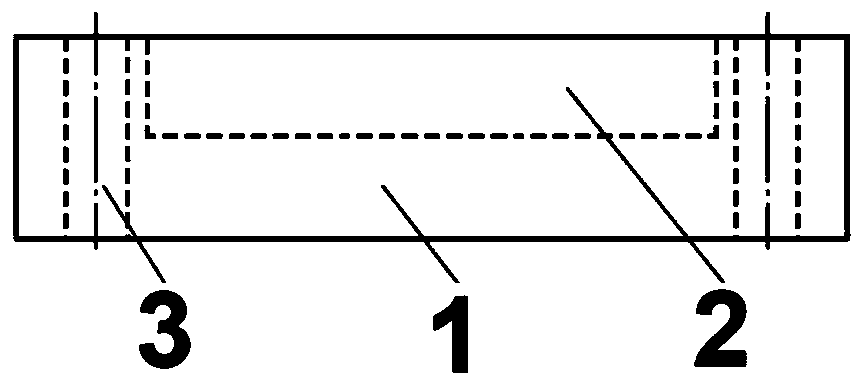

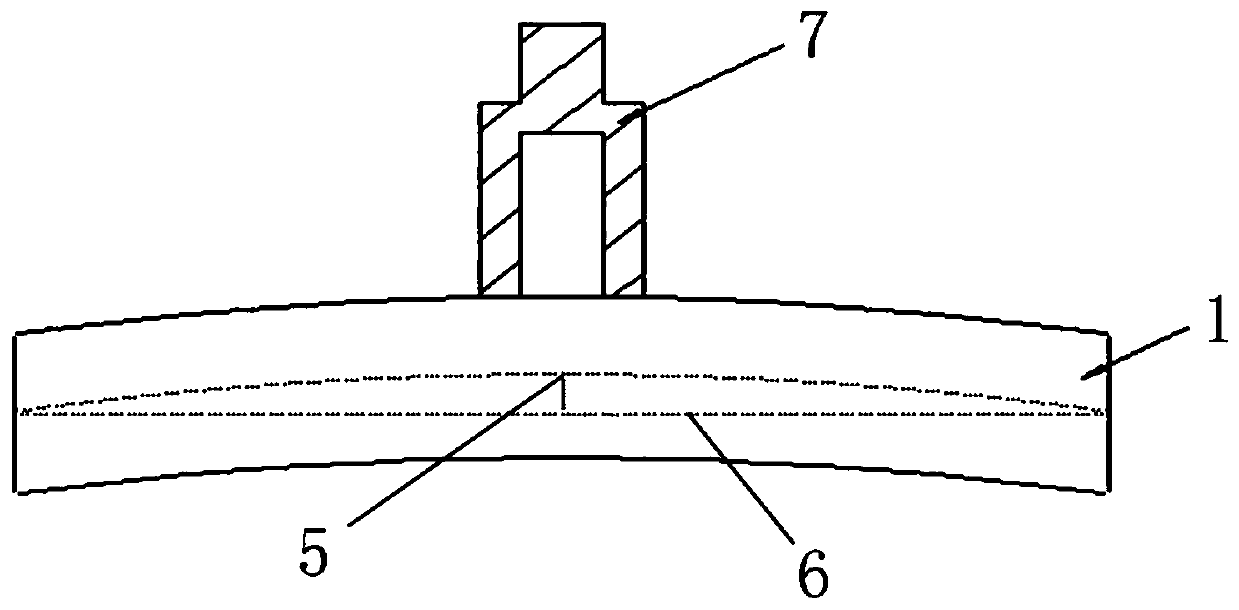

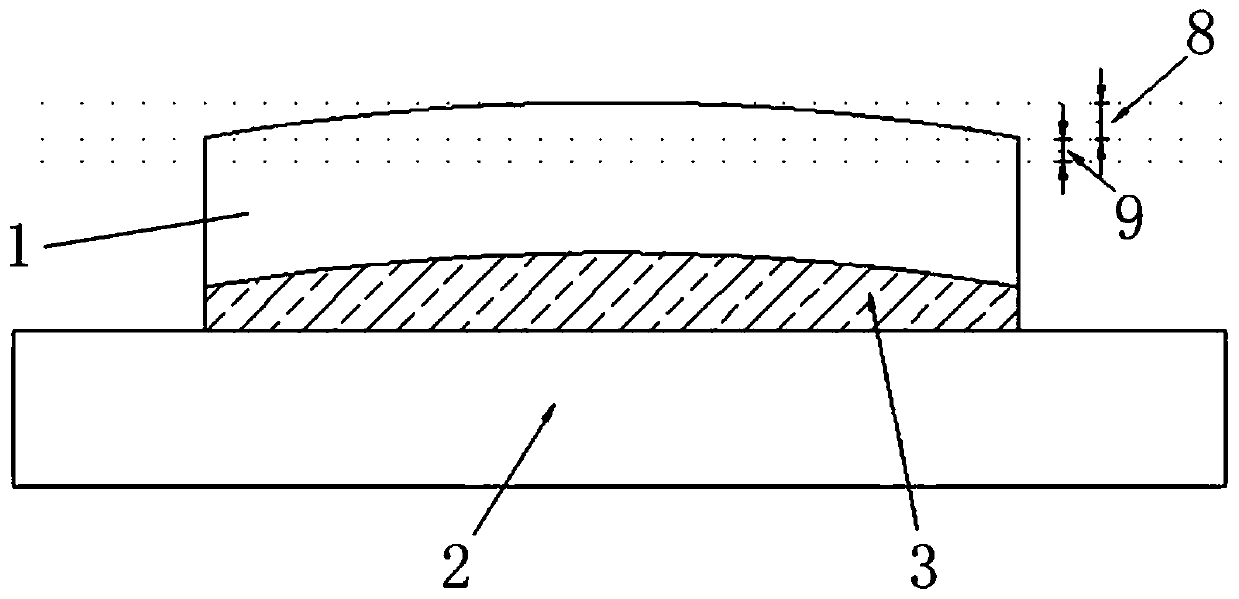

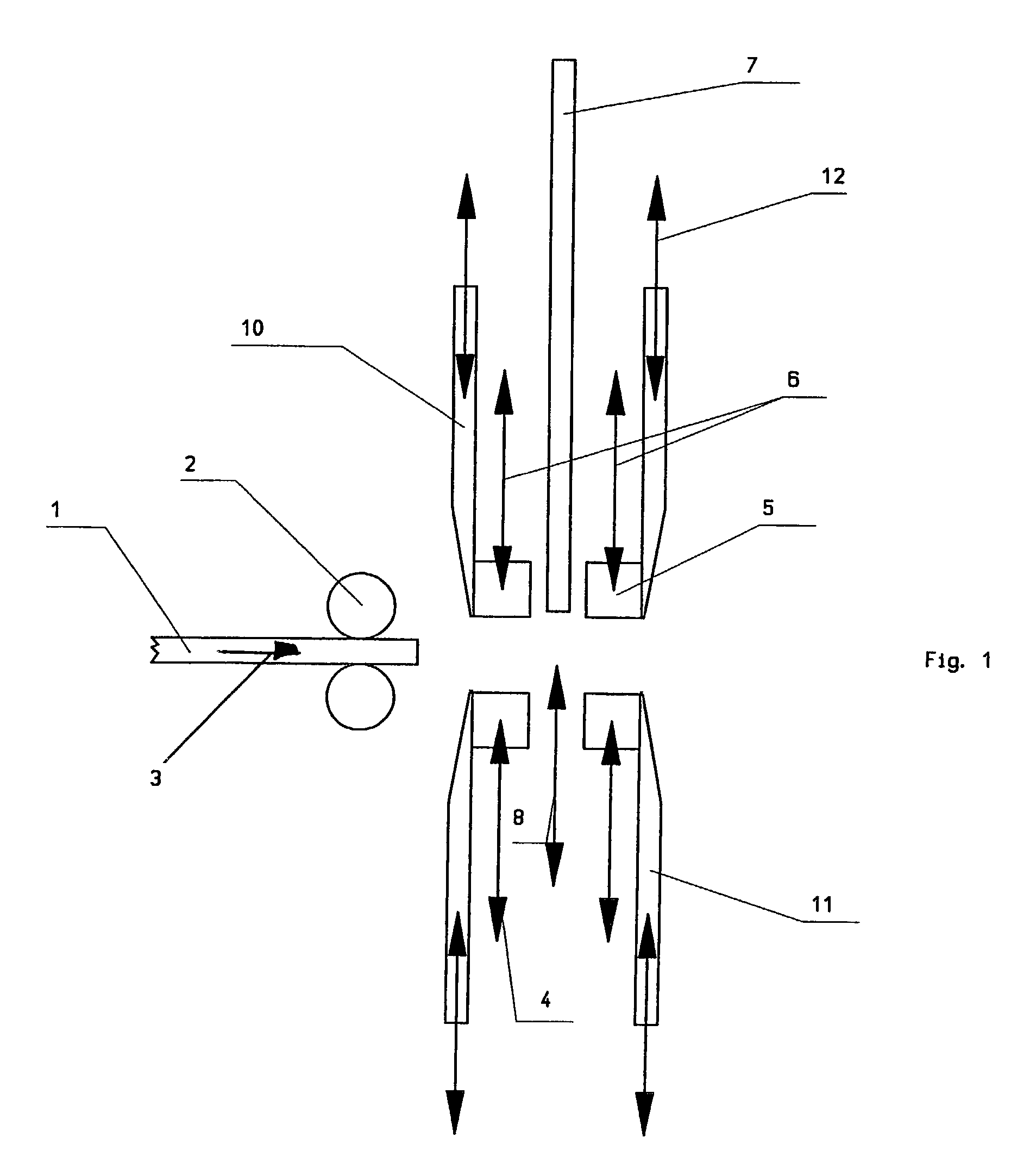

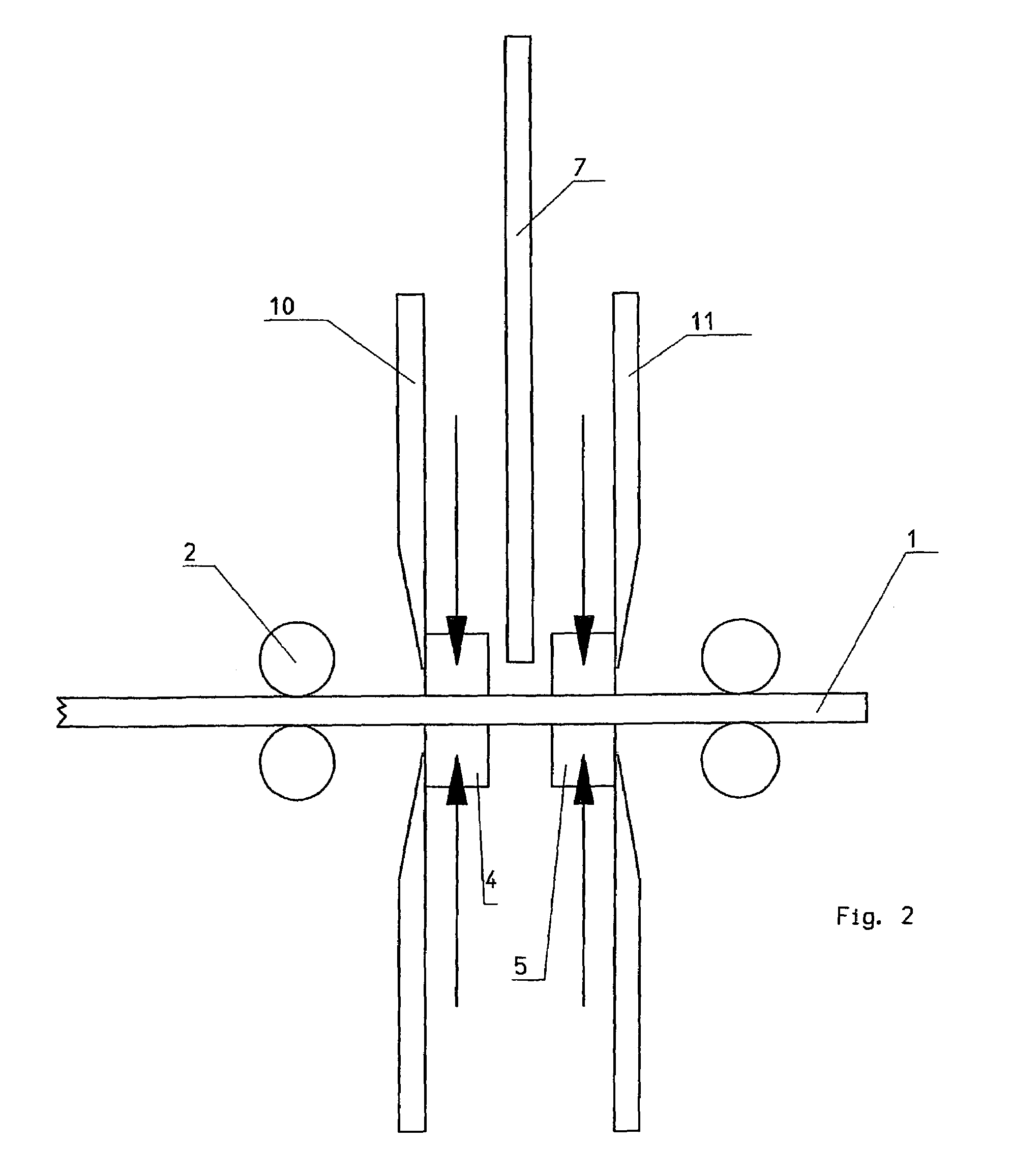

Sandwich component and method for the production thereof

InactiveCN102712141AMechanical connection changeIncrease the number of piecesLamination ancillary operationsLayered product treatmentCelluloseHoneycomb

The present invention relates to a sandwich component, which comprises a honeycomb core (1) having a plurality of webs (1') and at least one cover layer (2, 3), wherein the honeycomb core (1) is made of a cellulose-based material, in particular paper. The cover layer (2, 3) is formed from a fiber-reinforced semifinished product having a thermoplastic material matrix, wherein the webs (1') of the honeycomb core (1) are partially received into the thermoplastic material matrix of the cover layer (2, 3) at connection points (A) to the cover layer (2, 3) so that the sandwich component is bonded. The invention further relates to production methods for the sandwich component.

Owner:DAIMLER AG

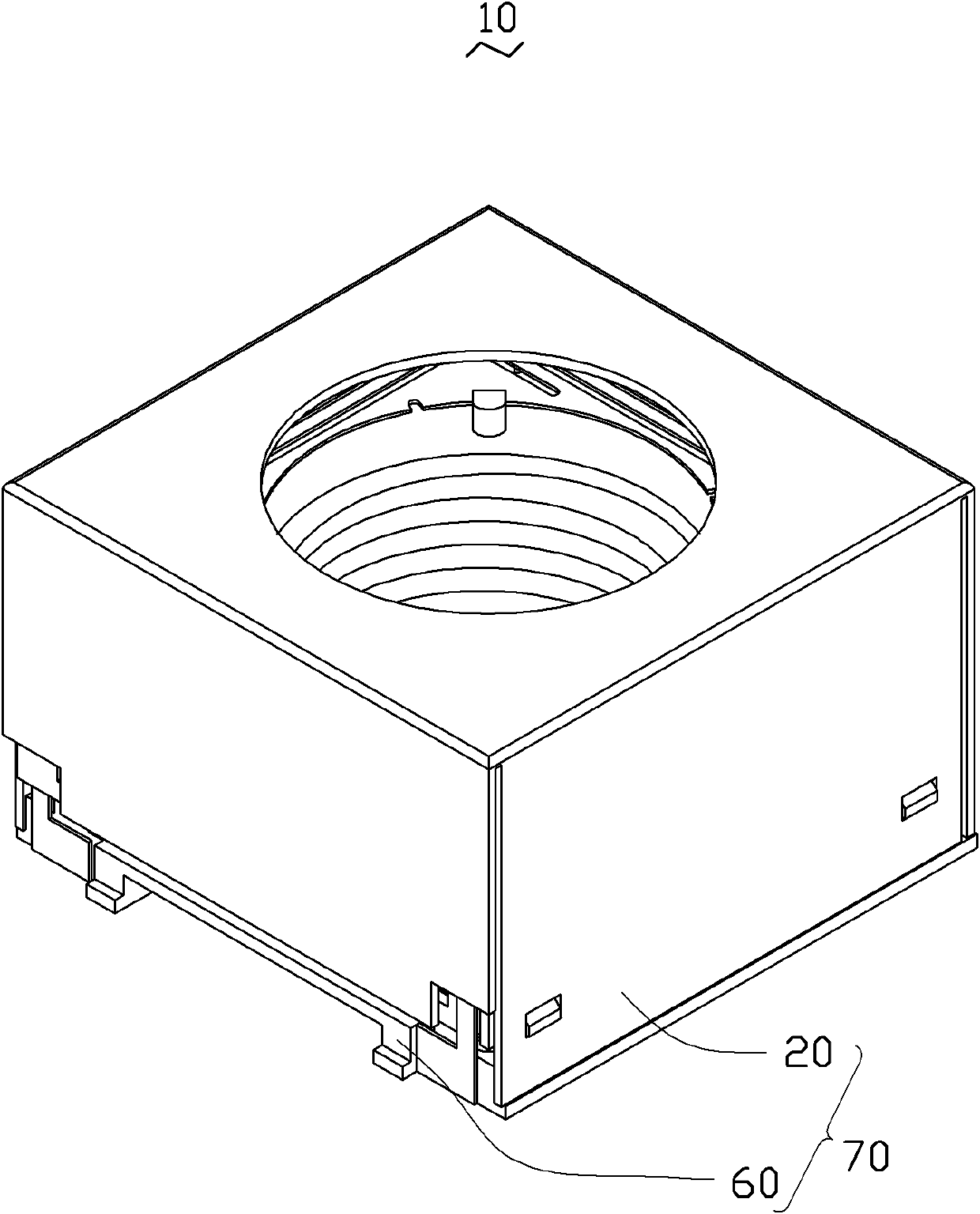

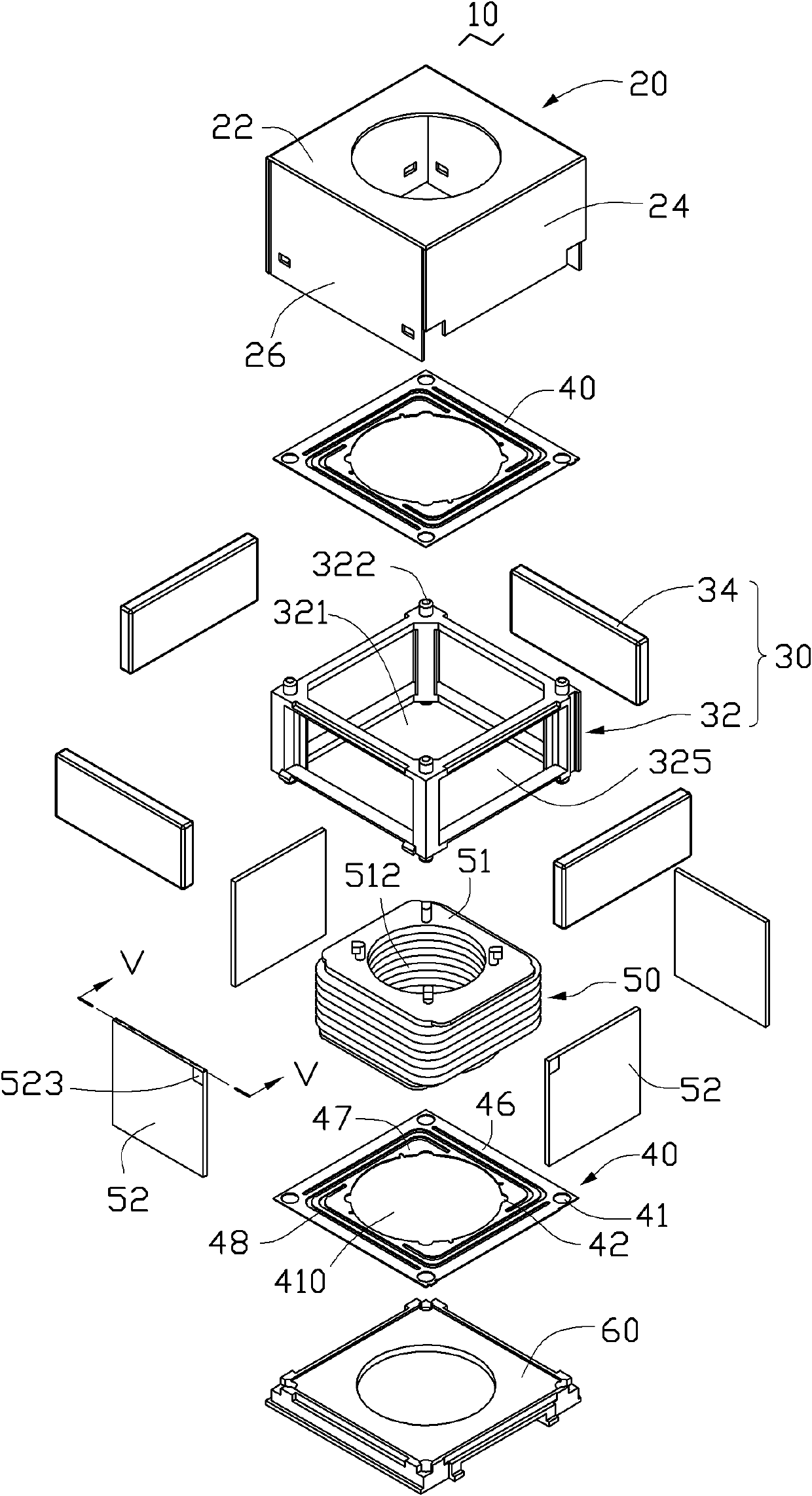

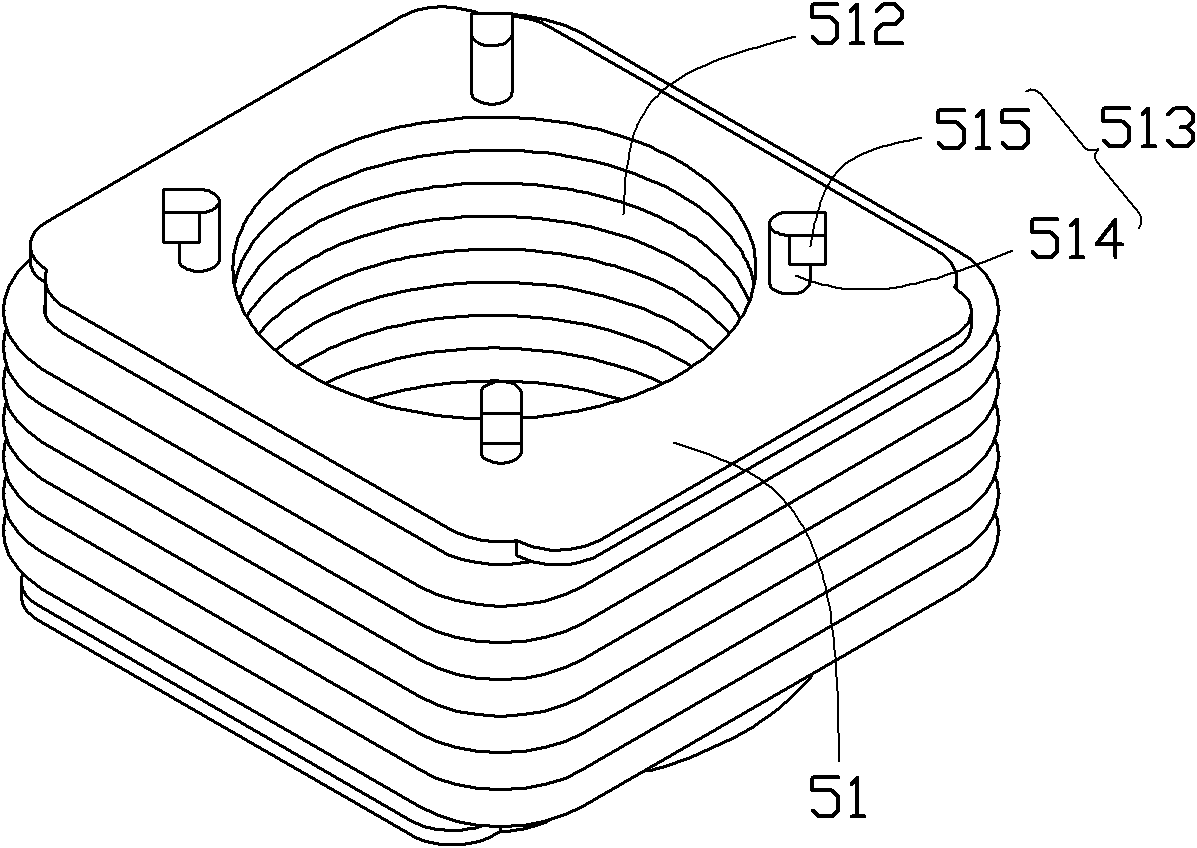

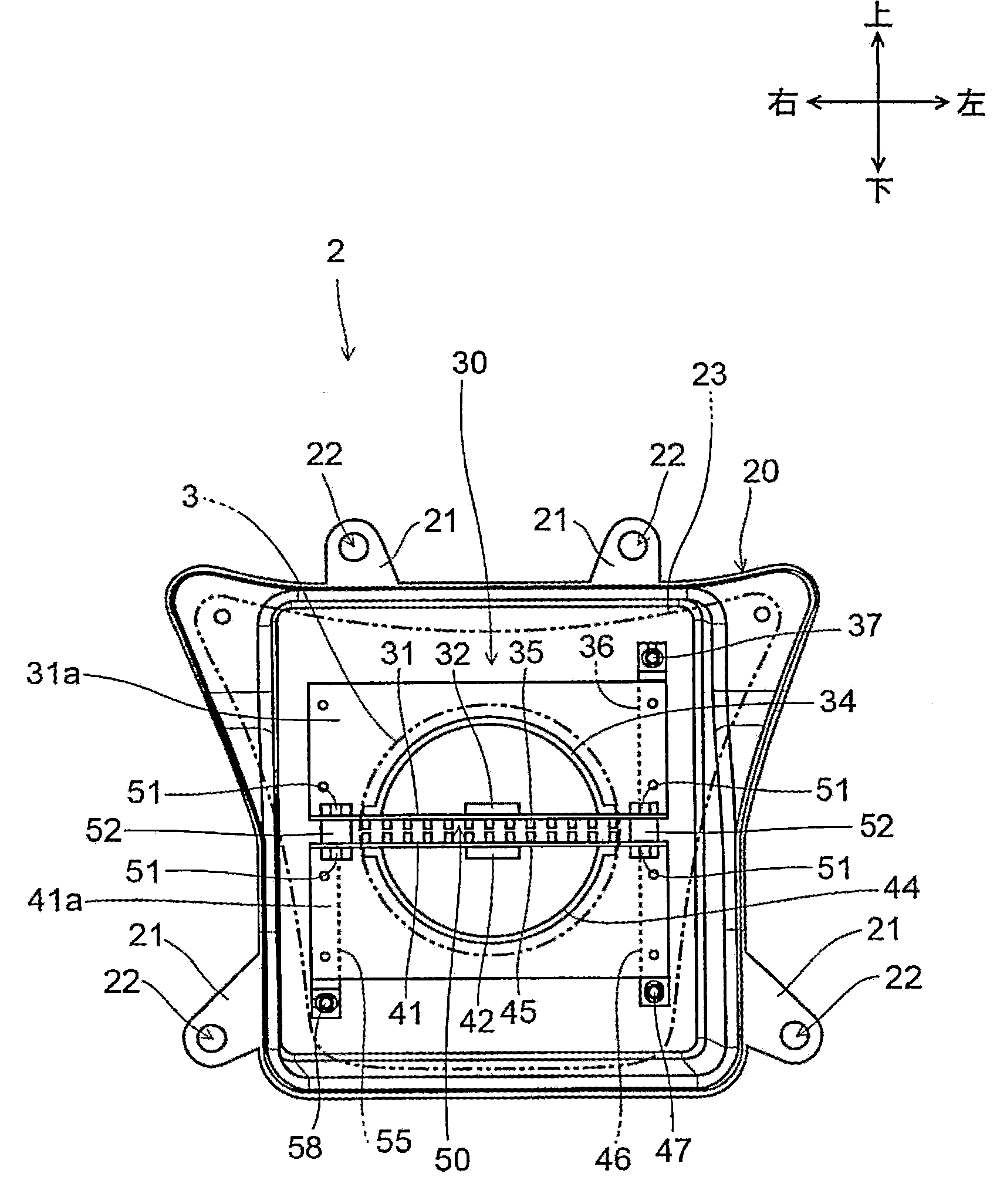

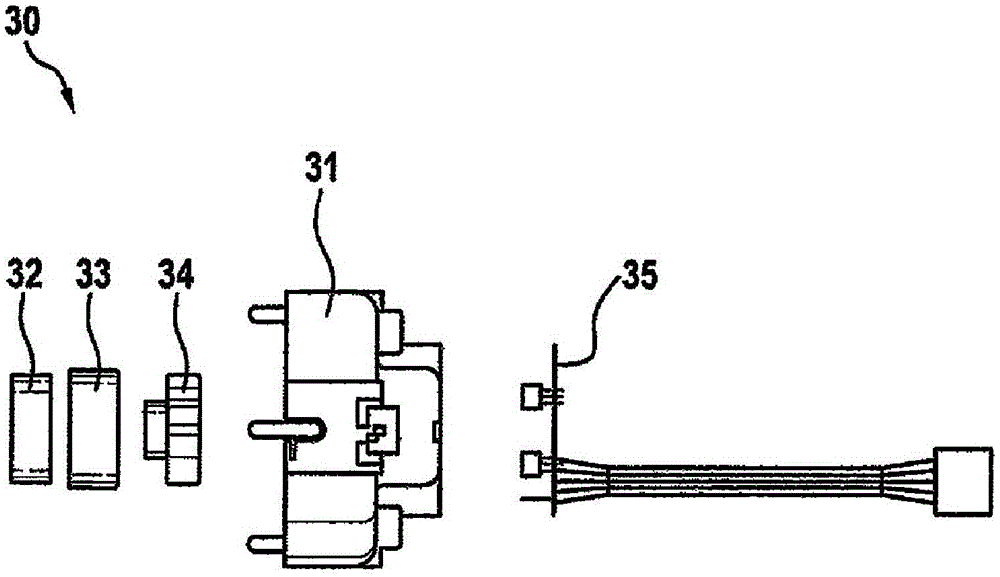

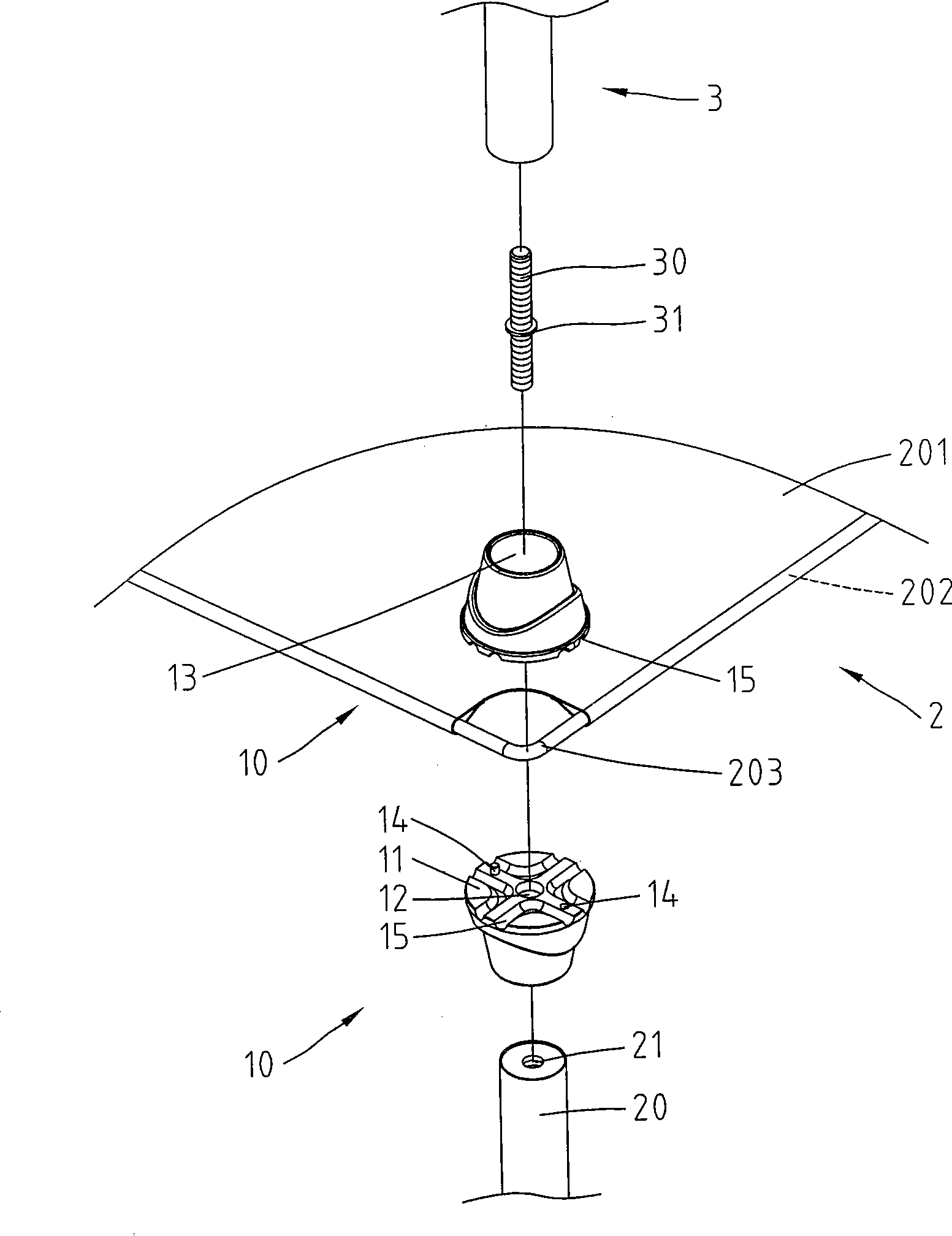

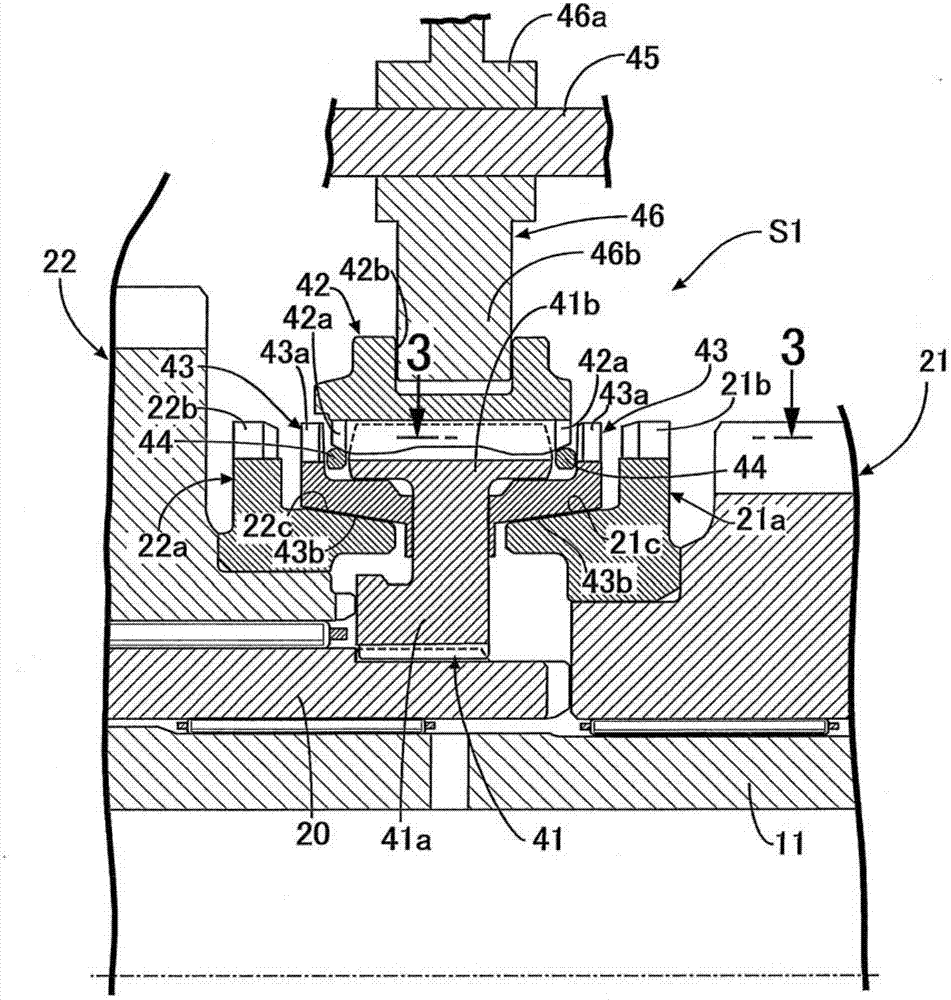

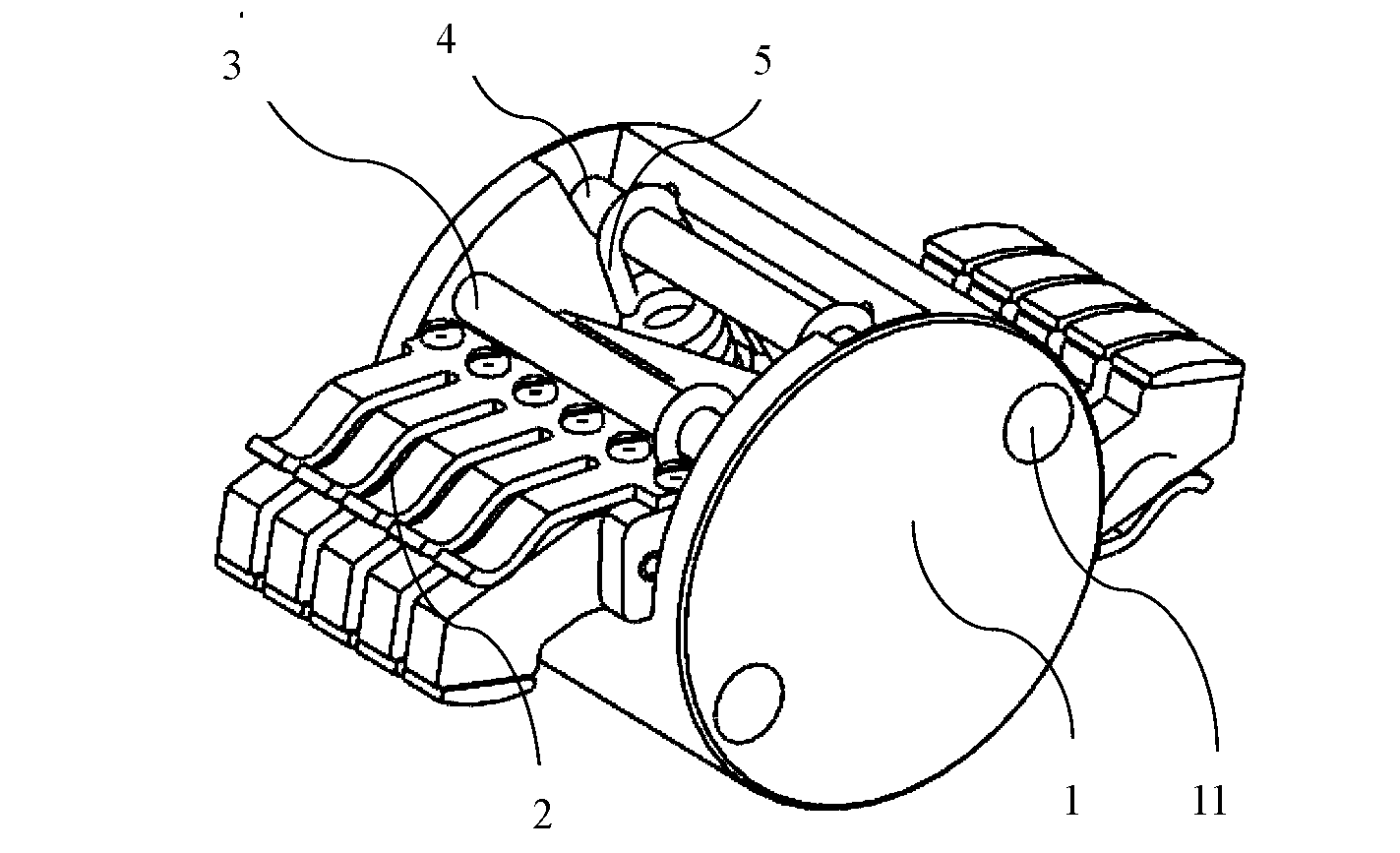

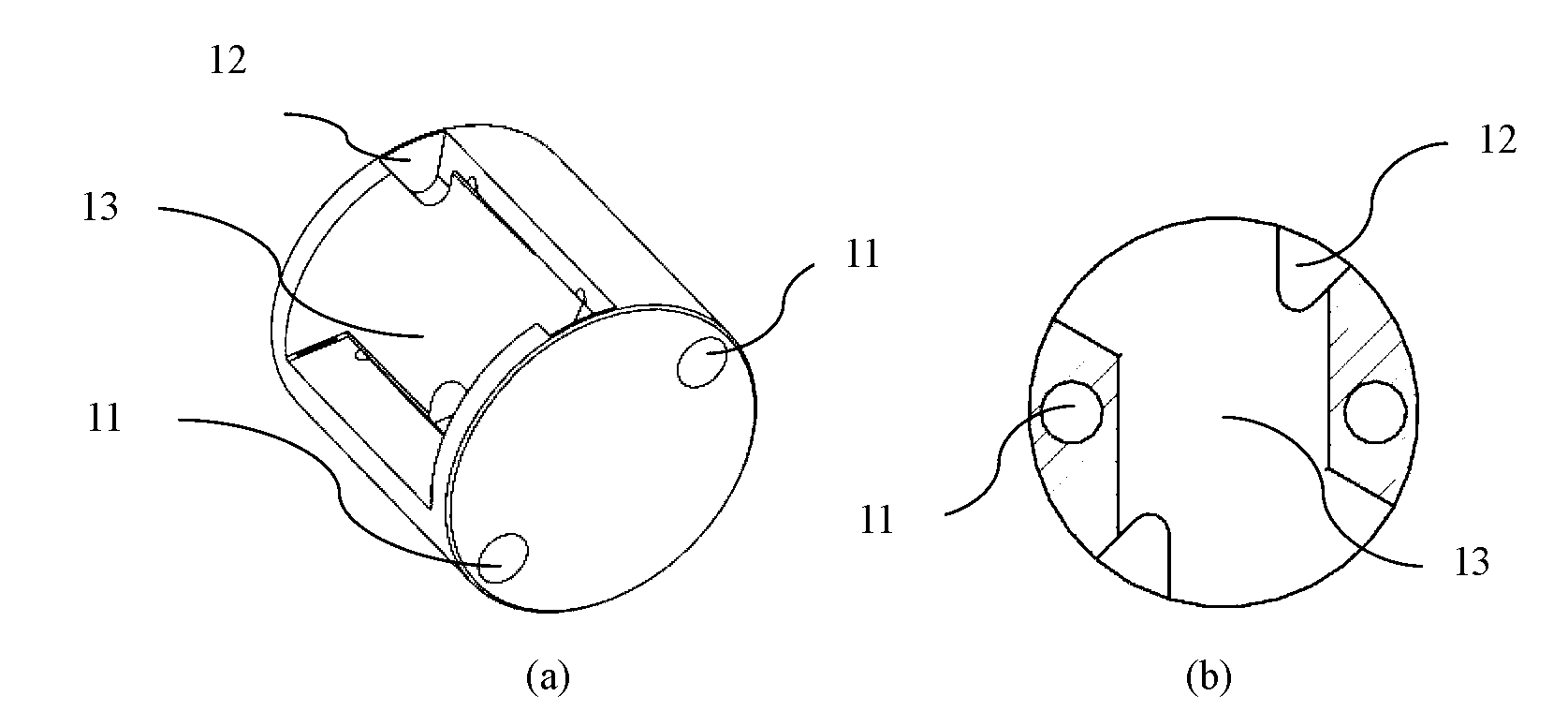

Voice coil motor

InactiveCN102570762AFlexibility to increase the number of slicesIncrease the number of piecesDynamo-electric machinesMountingsPrinted circuit boardVoice coil

The invention relates to a voice coil motor, which comprises a lens cylinder, a magnet, at least one spring plate and a printed circuit board process coil, wherein the lens cylinder is provided with a lateral wall and a first accommodating cavity for accommodating a lens; the magnet surrounds the lateral wall and is separated from the lateral wall; the at least one spring plate is connected with the lens cylinder; and the printed circuit board process coil is fixed on the lateral wall and is opposite to the magnet. The printed circuit board process coil generates a magnetic field force with the magnet after being electrified, to drive the lens cylinder to move along the axis. The at least one spring plate generates deformation when the lens cylinder moves, and applies a restoring force to the lens cylinder, so that the lens cylinder moves to a preset position from an initial position under the actions of the magnetic field force and the restoring force, is then still and restores to the initial position after the current of the printed circuit board process coil is powered off. The voice coil motor is convenient to assemble.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

LED lighting unit for a vehicle

InactiveCN103528005ADoes not damage appearanceIncrease cooling areaVehicle headlampsPoint-like light sourceEffect lightEngineering

Owner:HONDA MOTOR CO LTD

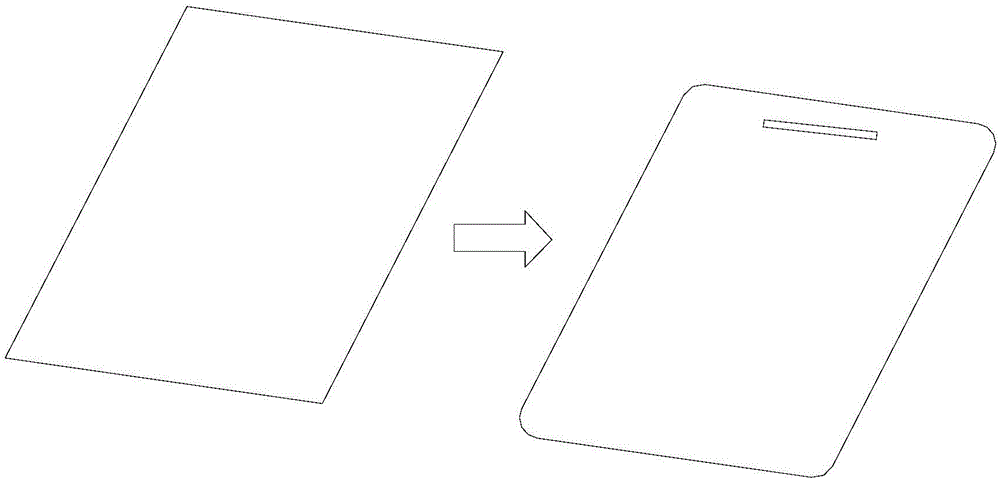

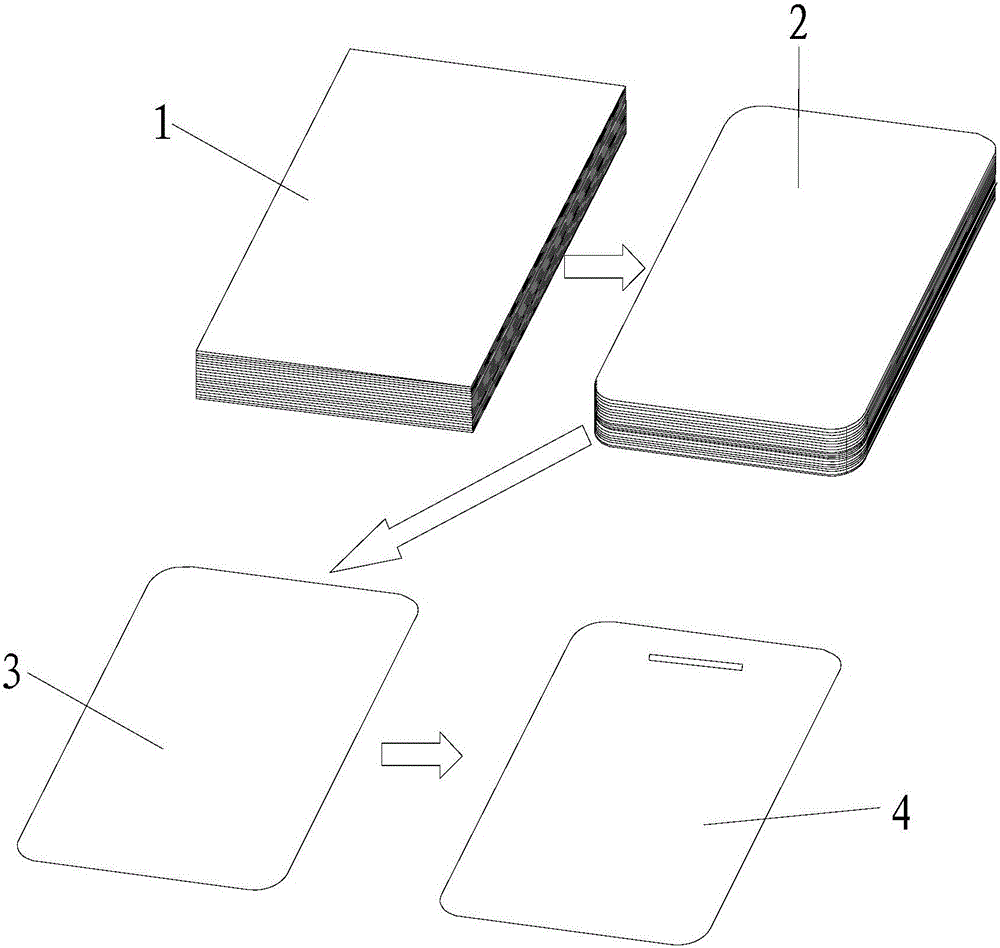

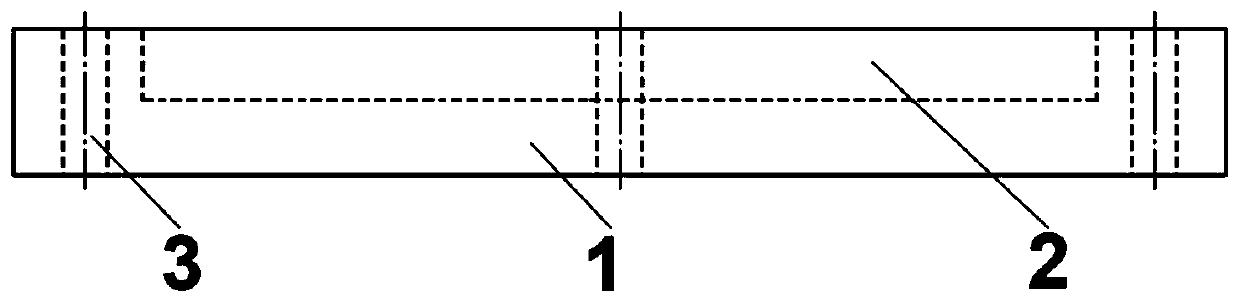

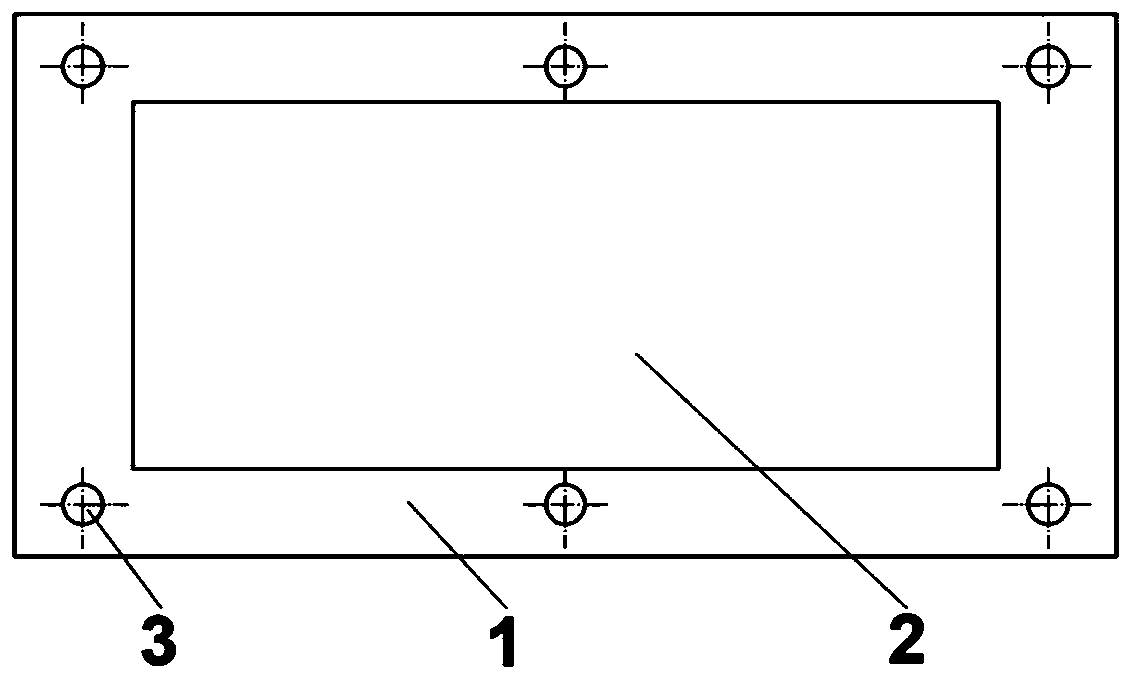

CNC multi-plate production technology for capacitive touch screen glass cover plates

InactiveCN105817967AIncrease the number of piecesImprove efficiencyEdge grinding machinesGlass coverSingle plate

The invention relates to the technical field of capacitive touch screens and especially relates to a CNC multi-plate production technology for capacitive touch screen glass cover plates. The technology comprises the production technologic manners that regular CNC single-plate production is replaced; colophony adhesion is carried out at first; 20-30 plates are pre-processed simultaneously; 85% of scrap materials are removed; and CNC is then used for single-plate fine trimming and processing of the rest 15% of scrap materials, so that shapes and sizes of finished products can satisfy standards. The technology has the advantages that production efficiency of CNC can be increased greatly; output with a higher yield can be obtained through the same production equipment; and production cost of the products can be reduced.

Owner:DONGGUAN YUANHONG ELECTRONICS TECH CO LTD

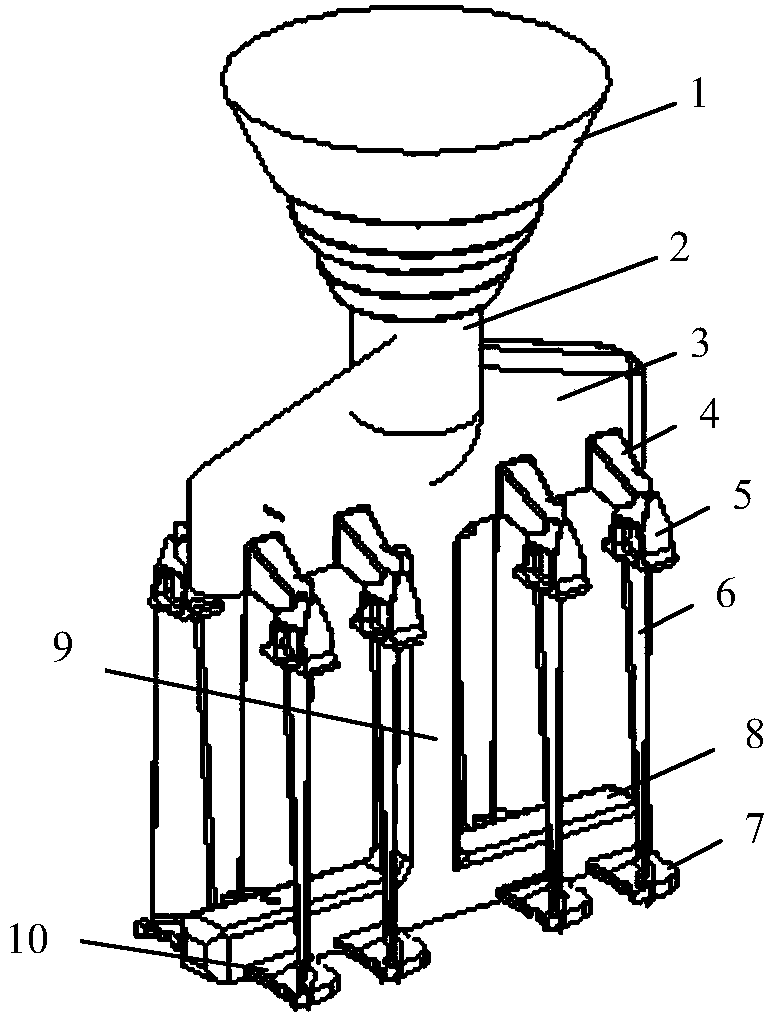

Planar metal micro-needle array and preparation method thereof

The invention discloses a planar metal micro-needle array and a preparation method thereof, and belongs to the technical field of medical instruments and the field of machining. A large-size metal sheet is cut into small-sized metal sheets, a clamping tool composed of an upper metal cover plate and a lower metal cover plate is machined, a groove matched with the size of the small-sized metal sheets is formed in the inner side of the upper cover plate of the tool, and through holes are formed in the edges of the periphery of the cover plate; the metal sheet is placed in the groove, and fastenedthrough bolts; the geometrical shape and the size of the sheet-shaped micro-needle array are designed, and a plane micro-needle CAD model is constructed; according to a cutting wire feeding path of the CAD model, the sharp degree of needle tips is ensured by adopting an 8-shaped path during machining of the micro-needle tips, and a few materials are left on the two sides of a micro-needle array substrate to be not cut; and after the processing is finished, a tool is disassembled to clean the substrate, and unprocessed parts of the two sides of the micro-needle substrate are cut to obtain theplanar metal micro-needle array with a plurality of micro-needle bodies. The micro-needle array can be manufactured in a large scale through simple assembly, the cost is low, the efficiency is high, and the machining precision of the micro-needle tips can be guaranteed.

Owner:DALIAN UNIV OF TECH

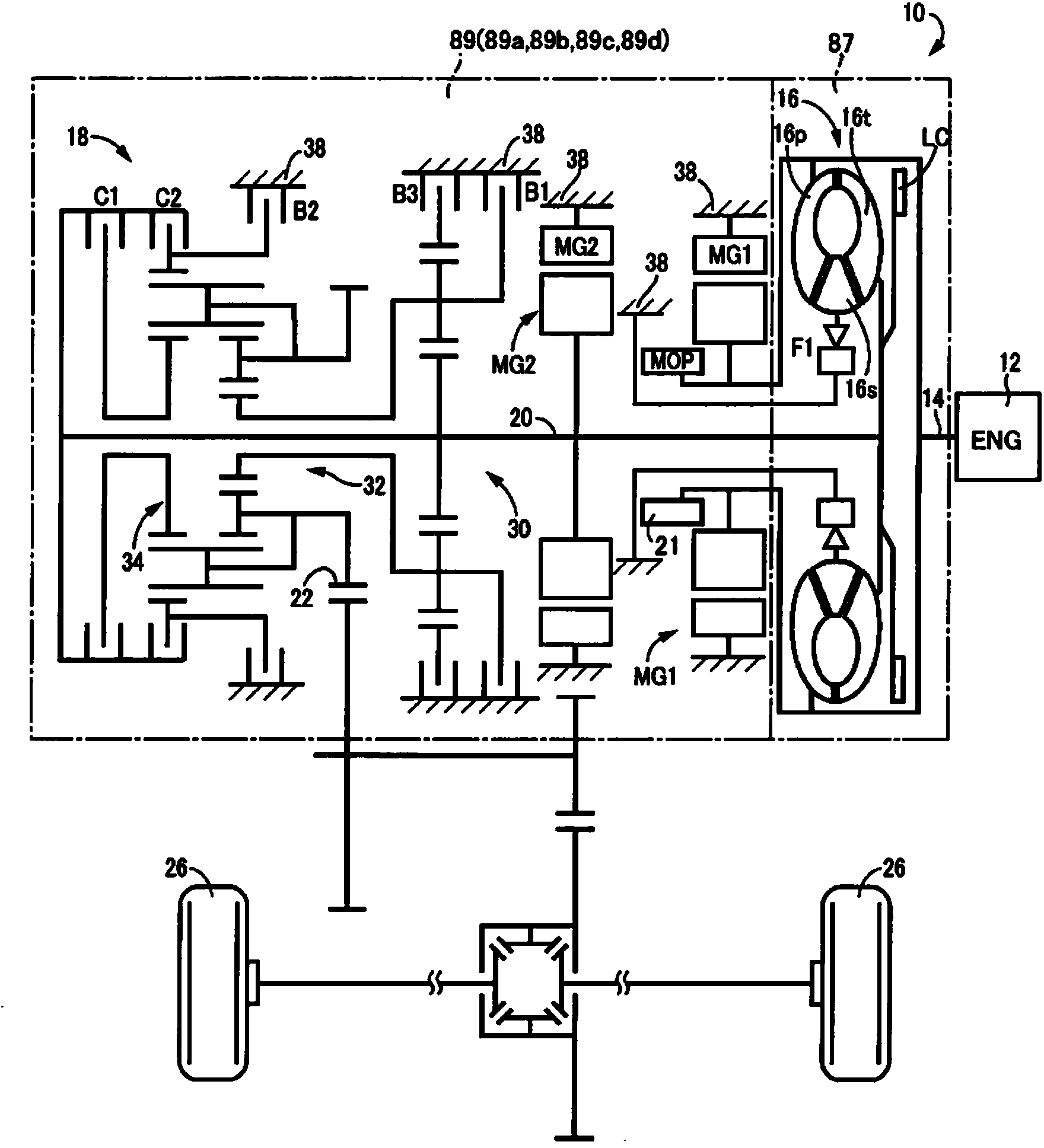

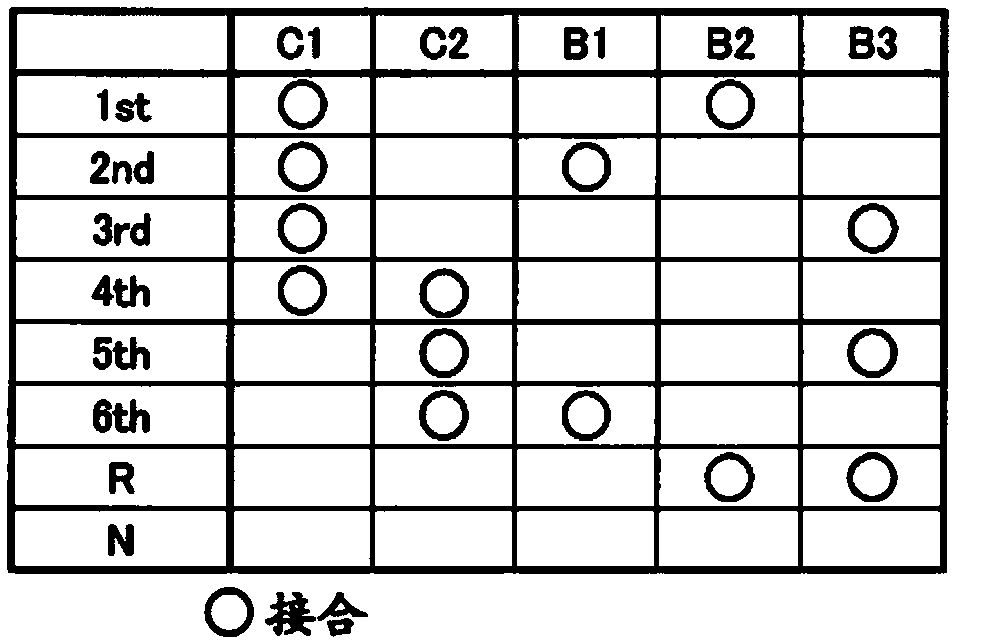

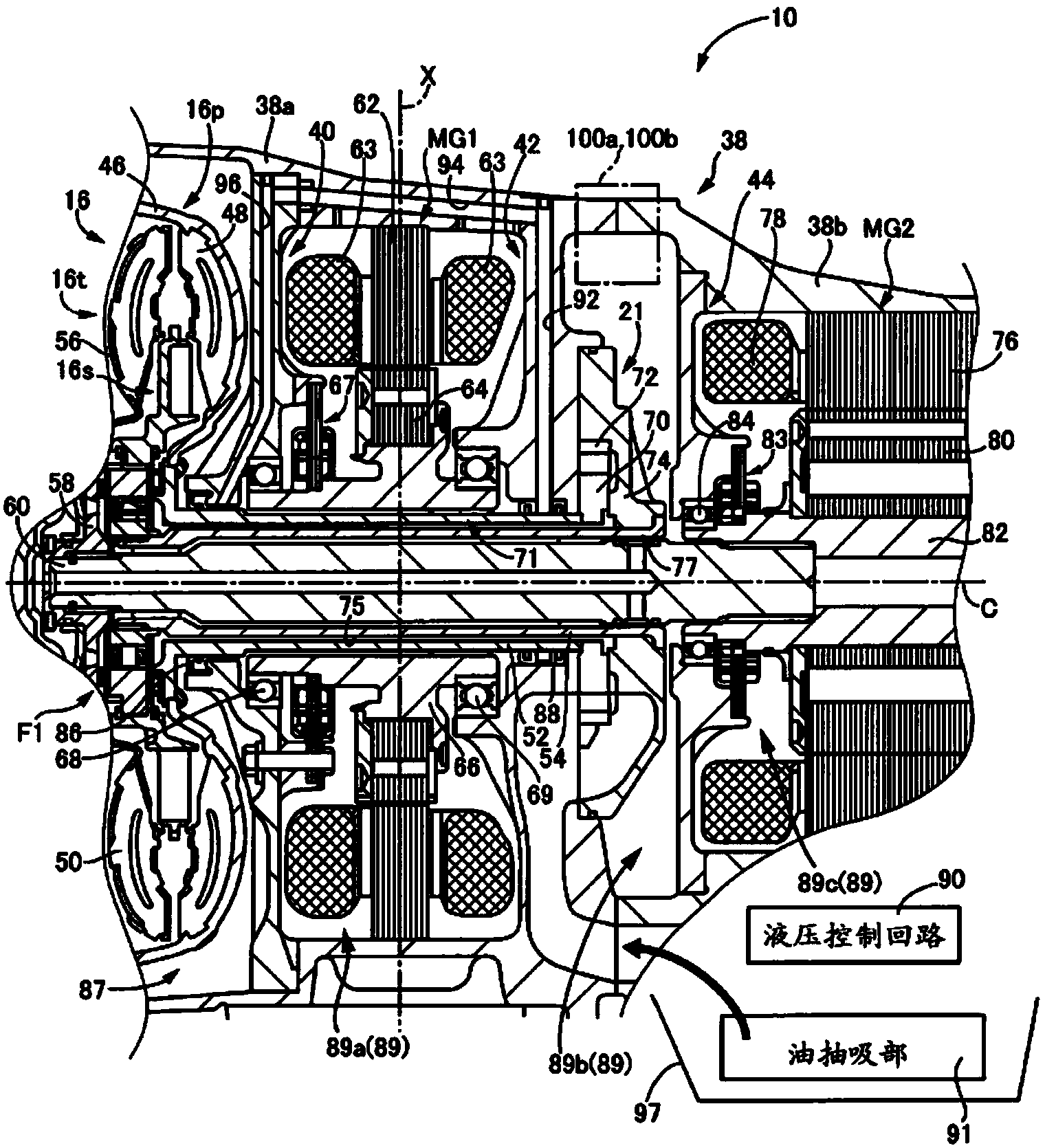

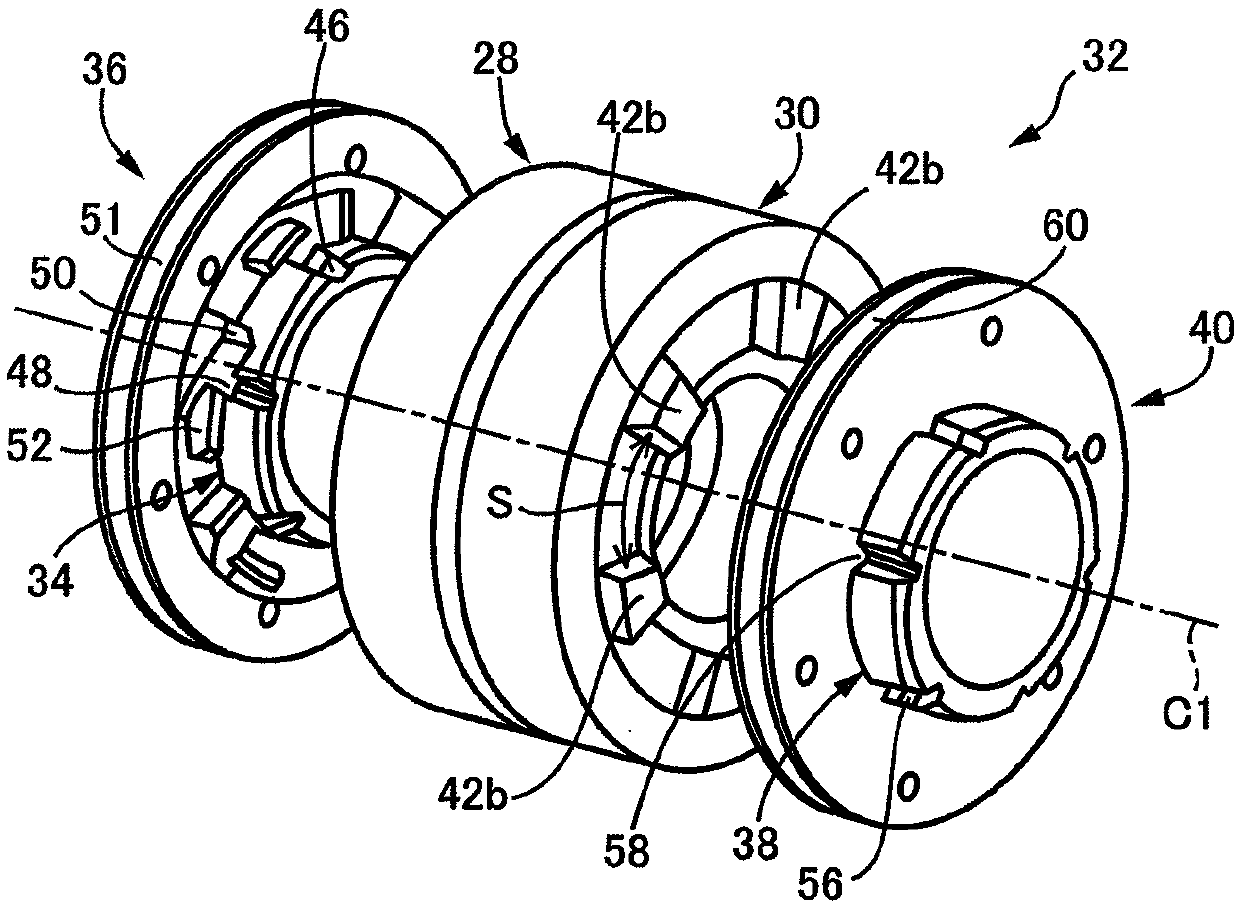

Vehicle drive device

ActiveCN104066608AImprove cooling effectAchieve oil coolingElectric propulsion mountingGas pressure propulsion mountingImpellerAutomatic transmission

Provided is the structure of a vehicle drive device provided with a fluid transmission device, an electric motor and a transmission, said vehicle drive device being capable of improving the cooling performance of the electric motor. Even in a configuration in which an engine (12) and a first electric motor (MG1) are linked to a pump impeller (16p) of a torque converter (16), the engine (12) and the first electric motor (MG1) are positioned in a location where the torque converter (16) is sandwiched in the axial direction, thus enabling the first electric motor (MG1) to be positioned in a space (89) (inside an oil chamber) in which an automatic transmission (18) is housed. Moreover, housing the first electric motor (MG1) inside said space (89) allows the first electric motor (MG1) to be cooled by oil, thus enabling the cooling performance of the first electric motor (MG1) to be improved.

Owner:TOYOTA JIDOSHA KK

Loose control method for fine and long thin-wall crowned isometric crystal cast turbine blade

ActiveCN108176817AIncrease the number of piecesIncrease productivityFoundry mouldsFoundry coresWaxThin walled

The invention relates to the technical field of investment pattern precision casting, in particular to a loose control method for a fine and long thin-wall crowned isometric crystal cast turbine blade. According to the provided loose control method for the fine and long thin-wall crowned isometric crystal cast turbine blade, a blade body inner pouring gate does not need to be additionally arrangedduring wax pattern combination, the opening design is made on a prepared shell when the 1 / 3 section of the middle portion of a blade body is wrapped by heat preservation cotton, the temperature at the blade body cotton wrapping opening position of the shell is low, solidification is fast, and the 1 / 3 section of the middle portion of the blade body can be promoted to be preferably solidified; goodfeeding can be provided for the preferably-solidified 1 / 3 section of the middle portion of the blade body through the non-solidified or slowly-solidified tenon end blade body 1 / 3 section and the blade crown end blade body 1 / 3 section, good feeding can be provided for the tenon end blade body 1 / 3 section and the blade crown end blade body 1 / 3 section through a blade crown inner pouring gate, a tenon inner pouring gate and a transverse sprue, accordingly, the sequential solidification mode that the 1 / 3 section of the middle portion of the blade body is preferably solidified can be achieved, andthe loose degree of the fine and long thin-wall crowned isometric crystal cast turbine blade can be effectively reduced.

Owner:GUIYANG AVIC POWER PRECISION CASTING

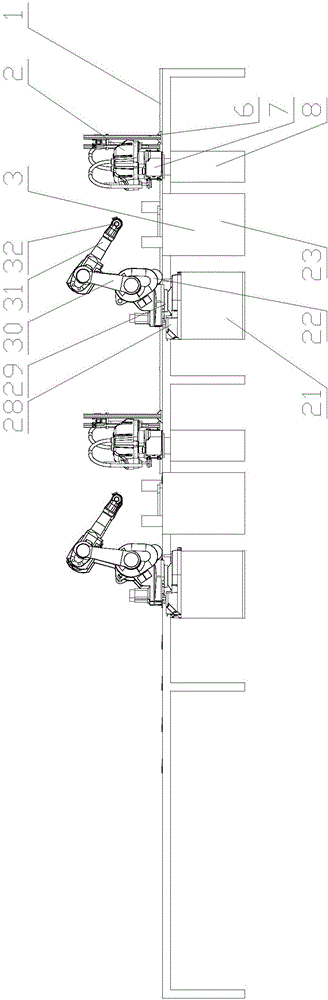

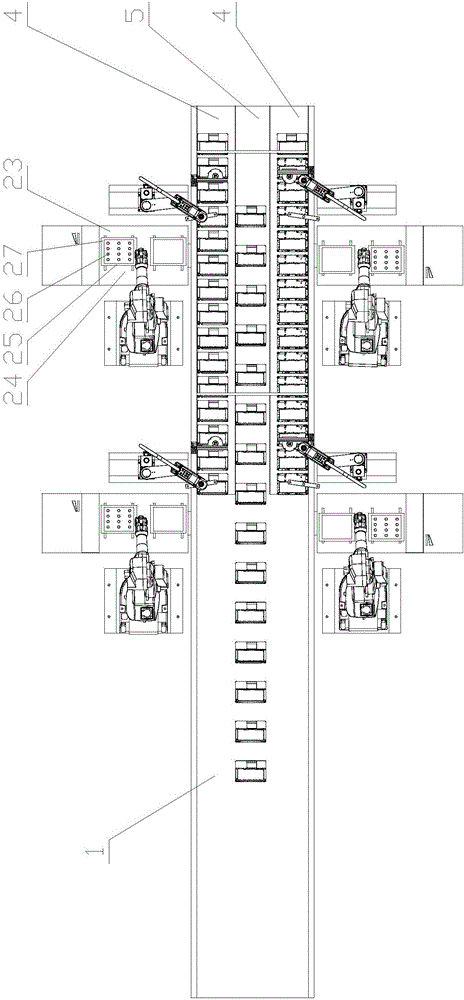

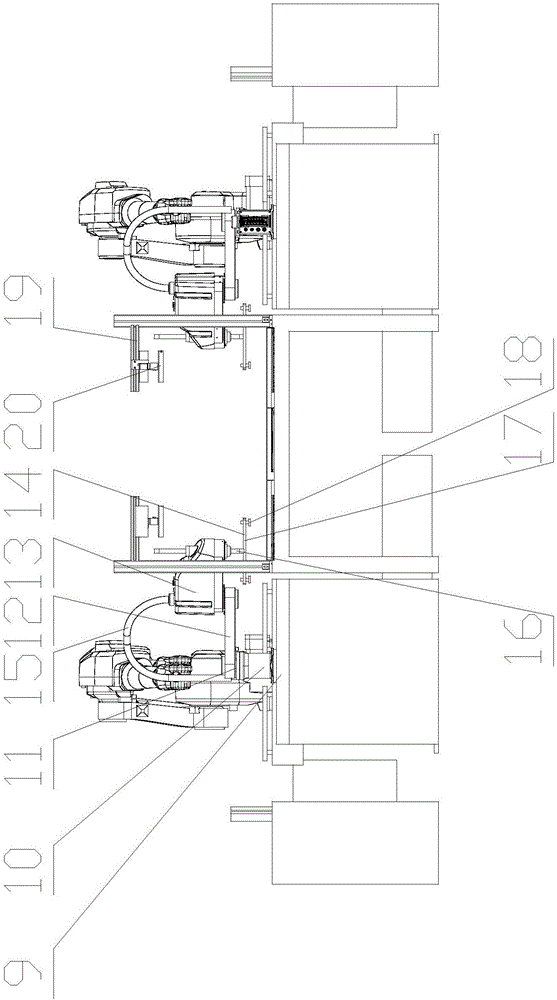

Automatic platform for plane polishing

InactiveCN107175565AIncrease the number of piecesImprove processing efficiencyGrinding machinesGrinding feedersEngineeringMachining

The invention provides an automatic platform for plane grinding, which includes a grabbing unit, a grinding unit and a conveyor belt; each of the grabbing unit and the polishing unit is provided with no less than one, and one of the grabbing units corresponds to one of the The grinding units are all arranged on one side of the conveyor belt and fixed in the factory building; the conveyor belt is provided with a conveying flow channel, which is an upper material flow channel and a lower material flow channel in turn; the upper material flow channel Not less than one, located on one side of the discharge channel, adjacent to the grasping unit; no less than one discharge channel, adjacent to the upper channel . The automatic plane grinding platform provided by the invention can automatically pick up and position the processed products, and simultaneously process them alternately at multiple stations. In addition, increasing the number of grinding units and grabbing units can directly increase the number of processed products at the same time, effectively The processing efficiency is improved and the labor cost is saved.

Owner:安徽信陆电子科技有限公司

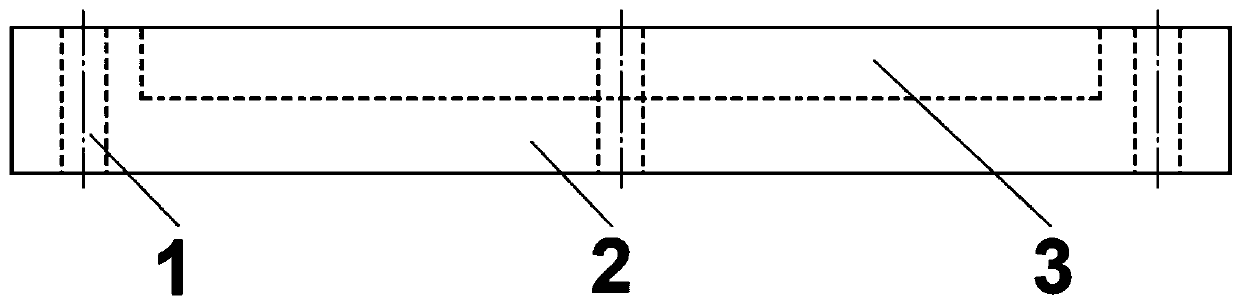

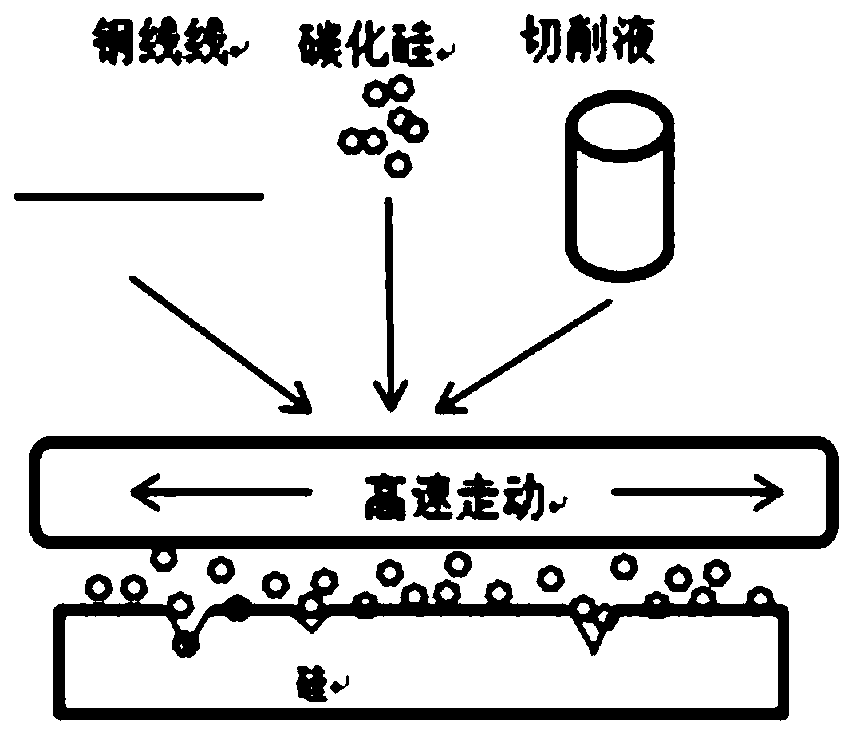

Process for carrying out multiline cutting on silicon slices

InactiveCN102152419AIncrease the number of piecesReduce dosageFine working devicesSiliconUtilization rate

The invention relates to a process for carrying out multiline cutting on silicon slices. The process comprises the following steps that firstly a steel wire is arranged on a multiline cutting machine; then the steel wire cuts the silicon slices by a bidirectional routing method at certain routing speed; when the steel wire completes routing and retracts on a take-up reel, a pay-off wheel and the take-up reel are interchanged, the diameter of the steel wire is measured, and a main roll which meets the thickness requirement of the steel wire and has a corresponding slot pitch is arranged on the multiline cutting machine again; and then the steel wire cuts the silicon slices by a unidirectional routing method at the routing speed which is 1.5 to 2.5 times of the original bidirectional routing speed. Due to the adoption of the method, in the process of carrying out multiline cutting on the silicon slices, the using amount of the used steel wire is reduced by one third and the utilization rate of the steel wire is improved. Moreover, after the bidirectional routing method is changed into the unidirectional routing method, cutting is carried out continuously. The steel wire is thinner. The slot pitch is smaller. The slice outlet number of the silicon slices can also be increased.

Owner:ZHEJIANG RONGMA ELECTRONICS TECH

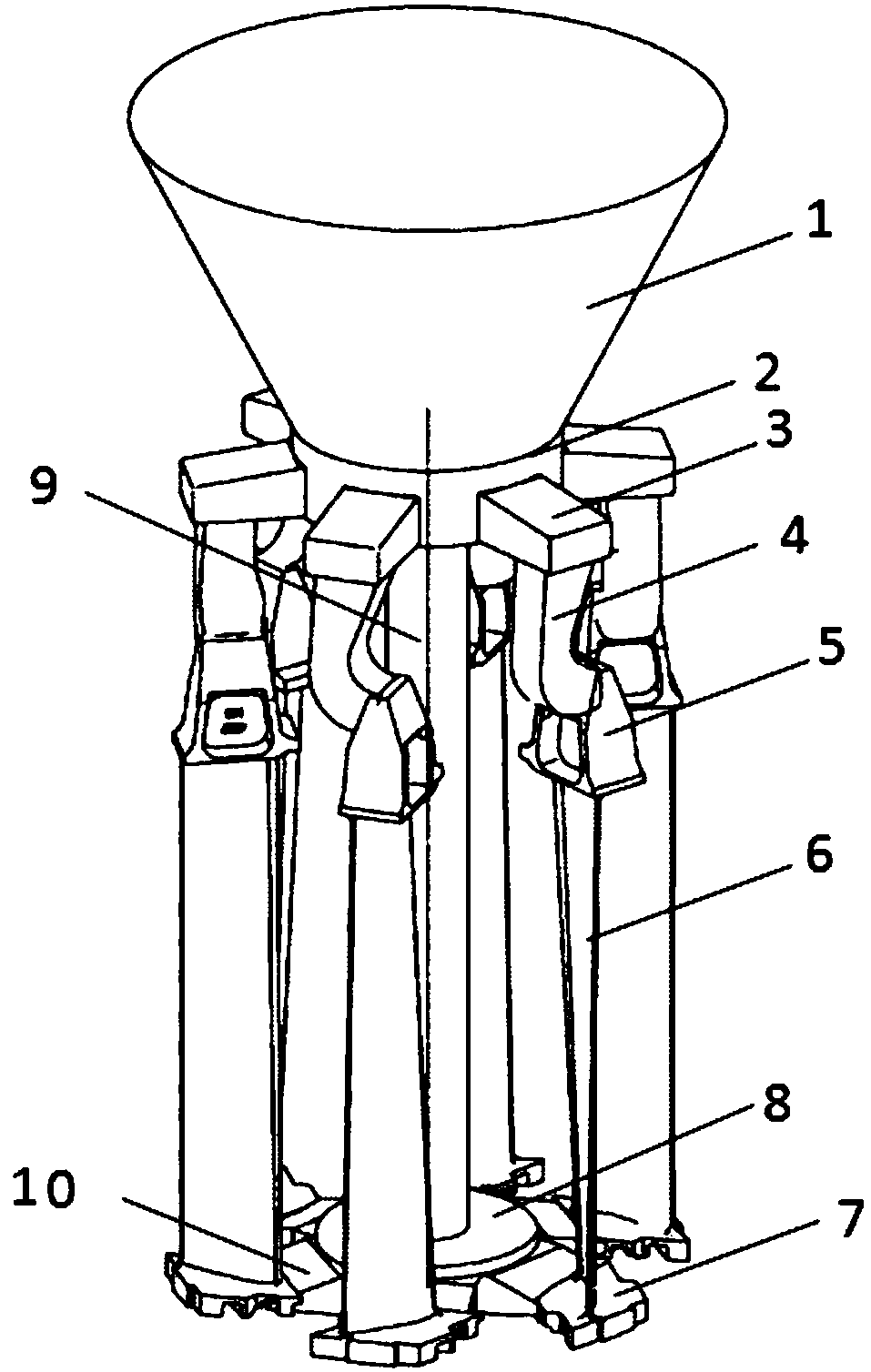

Large length-diameter ratio plane metal microneedle array, preparation method and clamping and penetration auxiliary devices of large length-diameter ratio plane metal microneedle array

The invention discloses a large length-diameter ratio plane metal microneedle array, a preparation method and clamping and penetration auxiliary devices of the large length-diameter ratio plane metalmicroneedle array, and belongs to the technical field of medical instruments. A large-sized metal sheet is cut into small-sized metal sheets; a clamping tool consisting of an upper metal cover plate and a lower metal cover plate is machined, wherein the inner sides of the upper metal cover plate and the lower metal cover plate of the clamping tool are provided with grooves, and the metal sheets are placed in the grooves and fastened through bolts; and the geometric shape and the size of the microneedle array are designed, and linear cutting is performed on the tool and the metal sheets as a whole to obtain the plane metal microneedle array with a plurality of microneedle bodies. In addition, the invention also provides the assembly clamping device and the penetration auxiliary device of the large-aspect-ratio plane metal microneedle array. The assembled penetration auxiliary device is placed on the skin, and the microneedle array penetrates into the skin through the auxiliary device. The microneedle array can be manufactured in large batches through simple assembly, the cost is low, the efficiency is high, and the processing precision of microneedle tips can be guaranteed; and moreover, the use reliability of large length-diameter ratio microneedles can be comprehensively improved.

Owner:DALIAN UNIV OF TECH

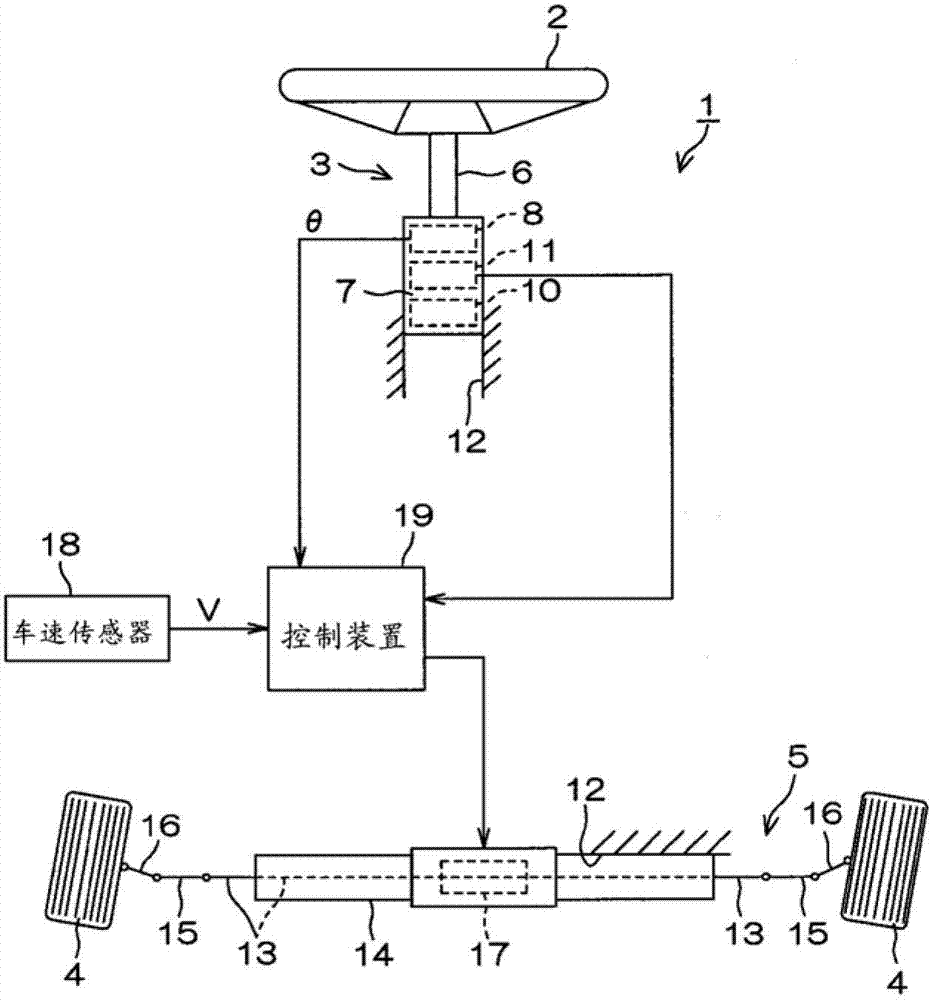

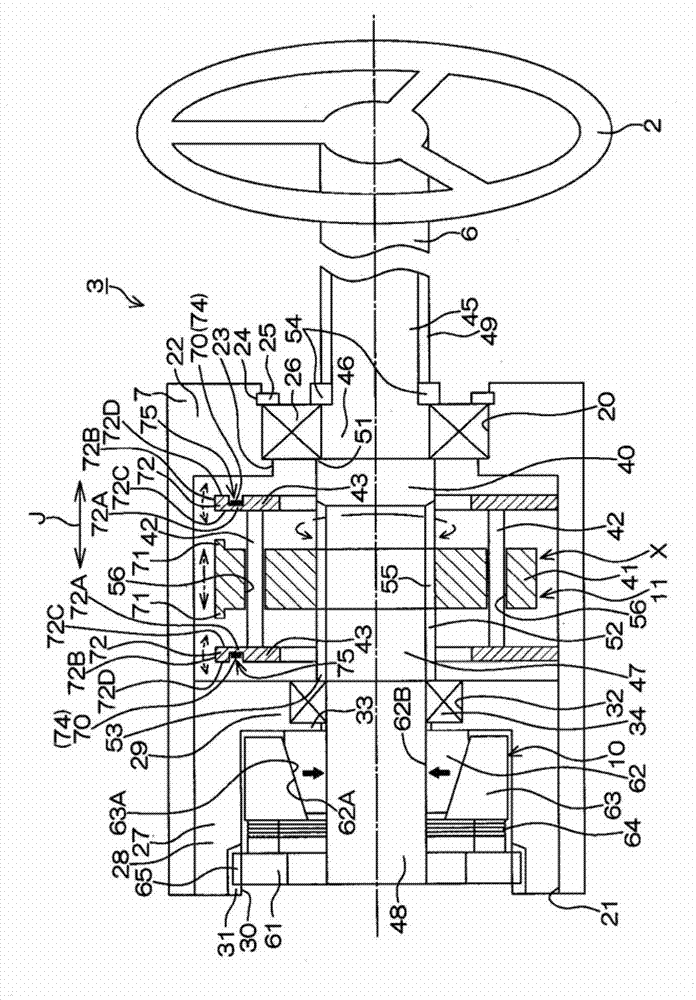

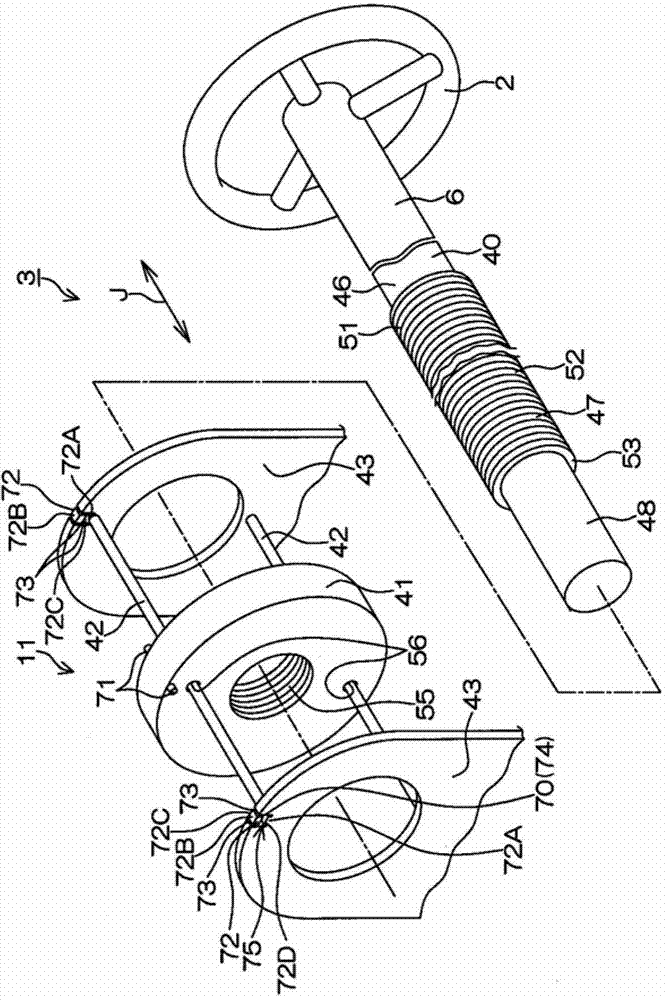

Steering system

InactiveCN103171618AIncrease the number of piecesAvoid rising costsMechanical steeringElectrical steeringSteering angleDirection detection

The invention provides a steering system which includes: an operation mechanism that includes an operation member used to perform a steering operation; and a steered mechanism that is not mechanically coupled to the operation mechanism, and that steers a wheel based on the steering operation of the operation member. The operation mechanism includes a steering angle sensor that detects a steering angle of the operation member, and steering direction detection unit that detects only a steering direction of the operation member.

Owner:JTEKT CORP

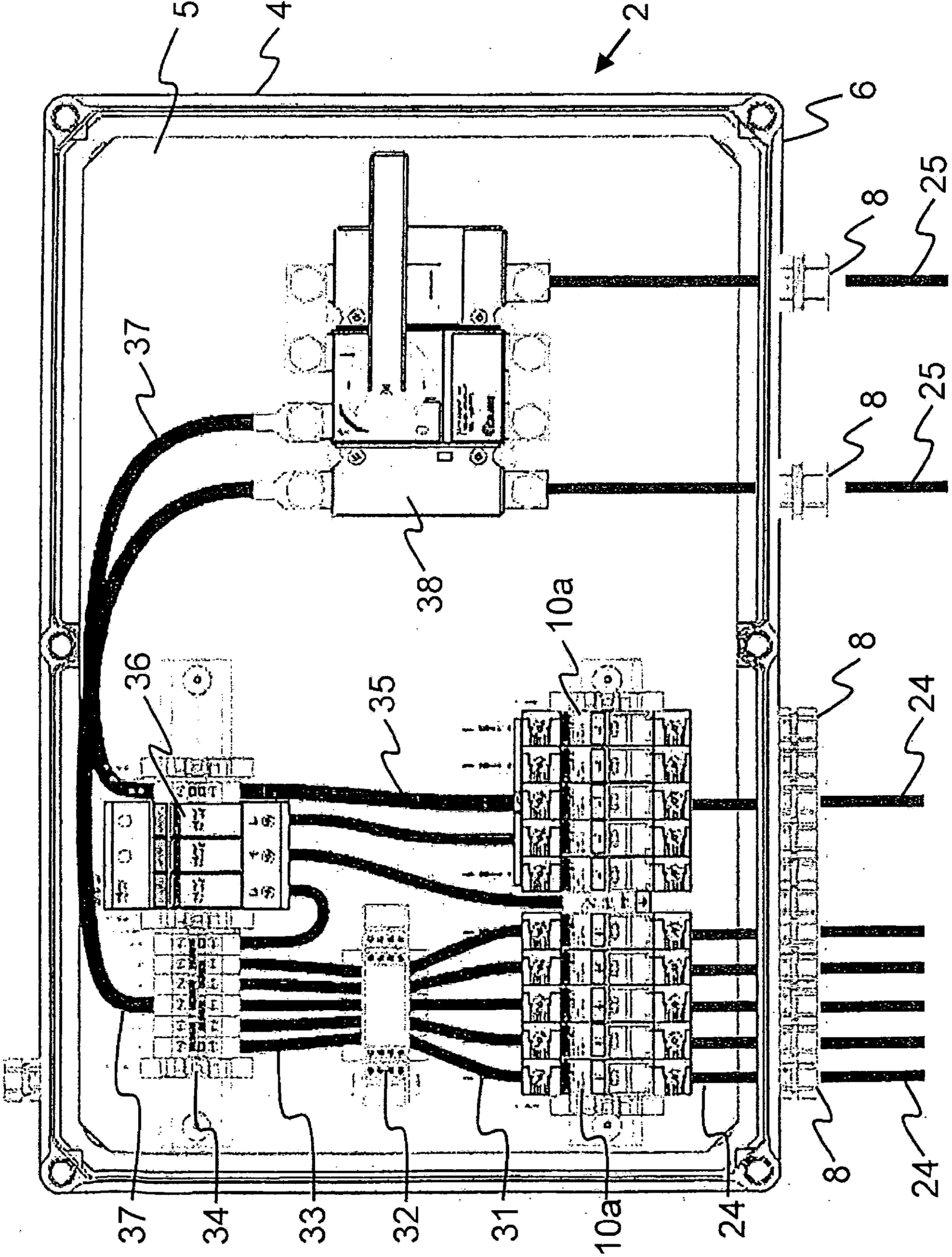

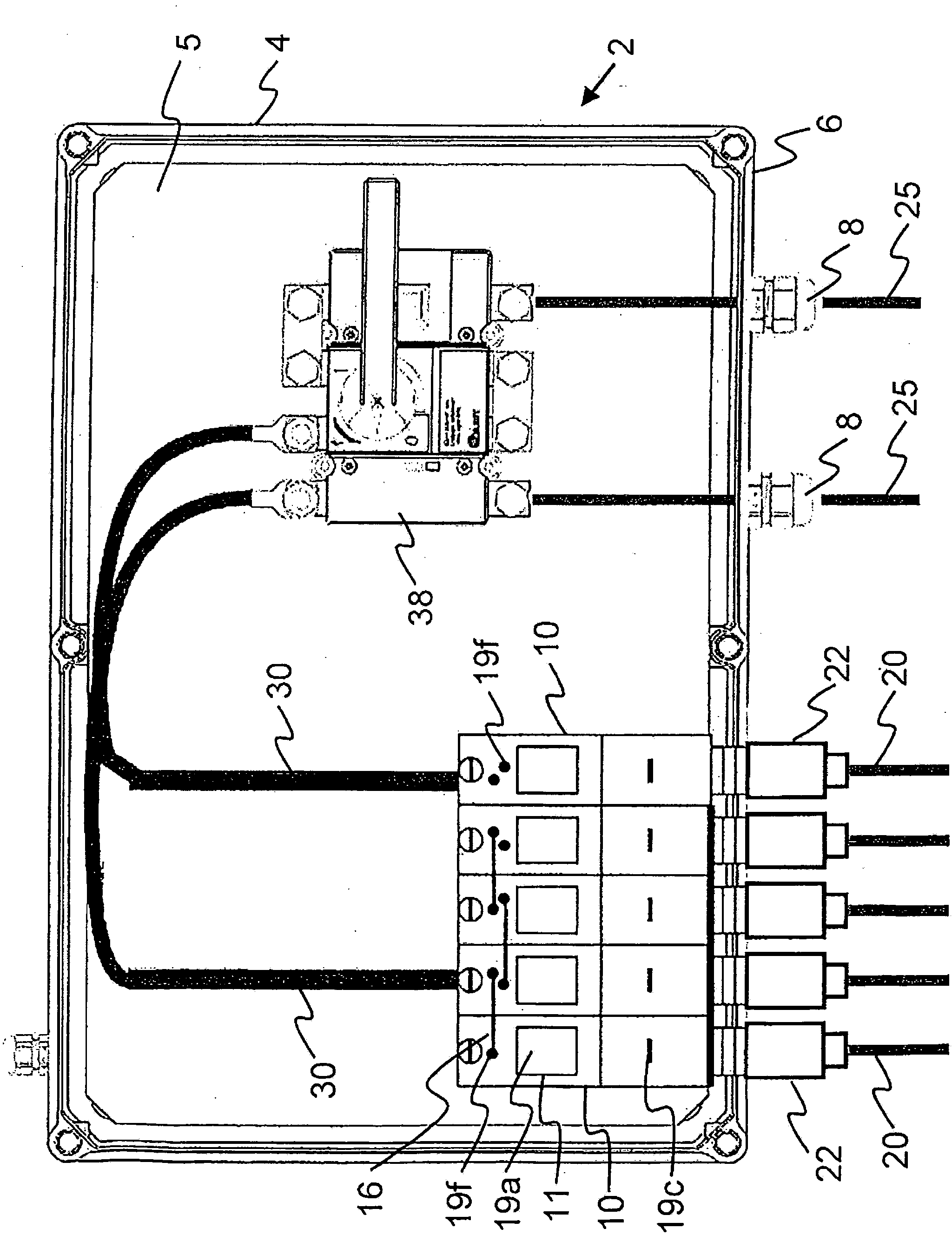

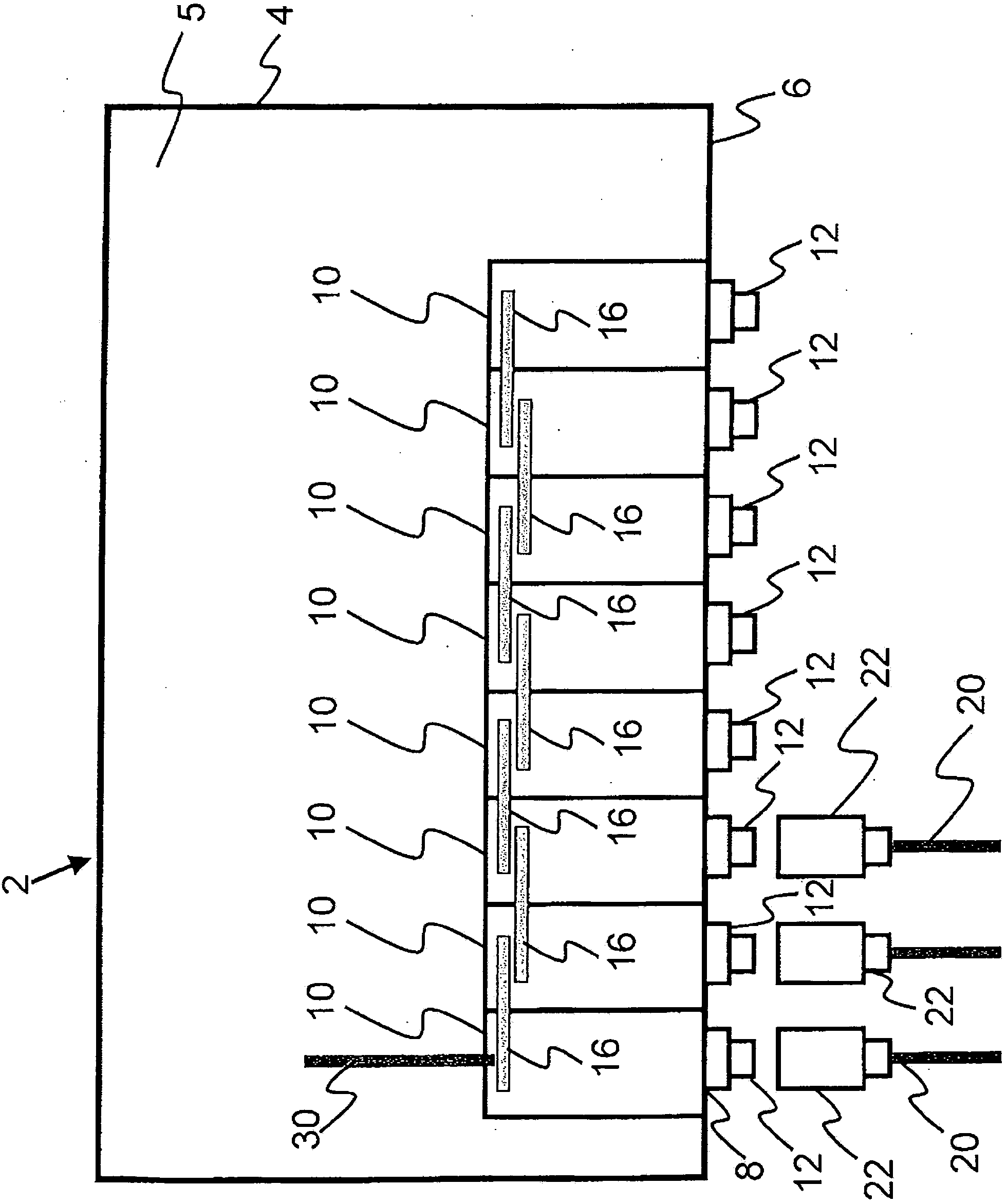

Generator connection box for photovoltaic installations

InactiveCN103999356AIncrease the number of piecesLow costSubstation/switching arrangement detailsPhotovoltaicsPhotovoltaic generatorElectric generator

A generator connection box for a photovoltaic generator is presented, which comprises a connection box housing having a rear wall and a circumferential side wall and input modules each having an integrated quick connector for connecting a generator string line to the associated input module, wherein the input modules are arranged directly on the circumferential side wall of the connection box housing in such a way that the string lines can be connected to the quick connector of the associated input module directly from outside.

Owner:PHOENIX CONTACT GMBH & CO KG

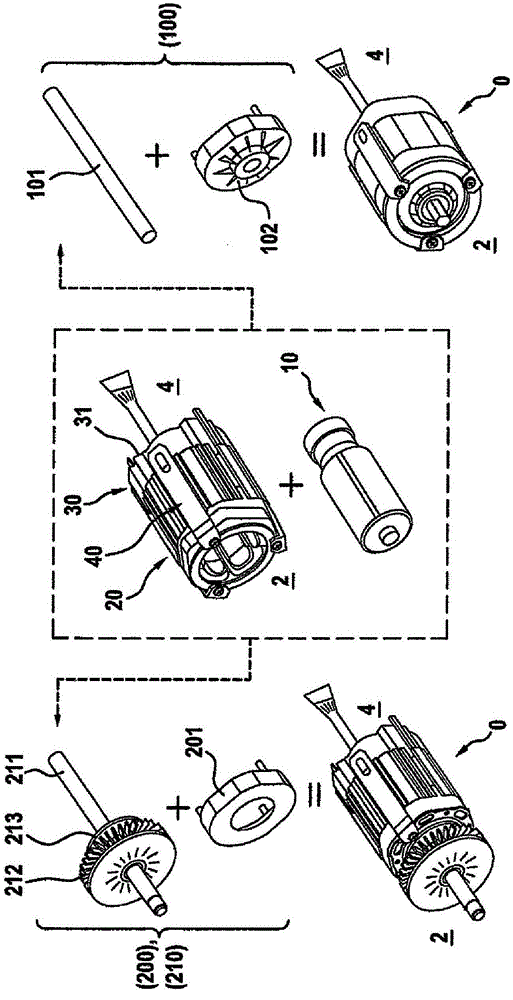

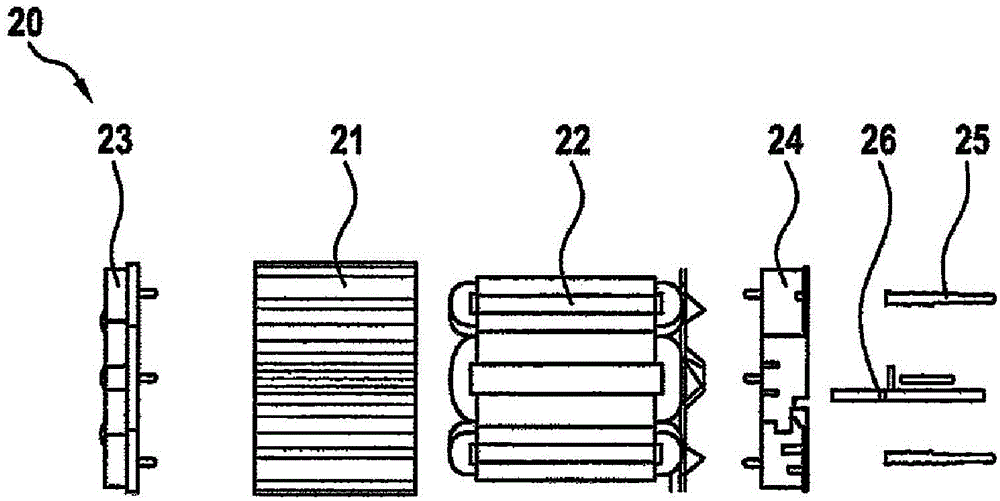

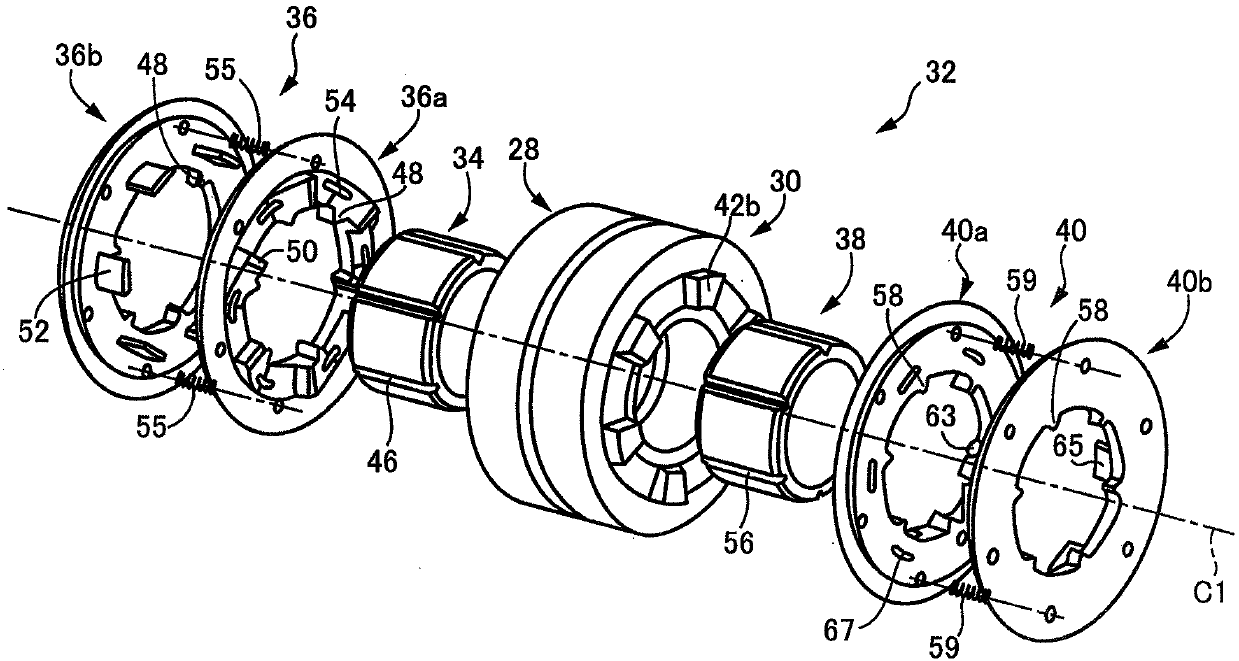

Electric motor construction kit and electric motor

ActiveCN105281485AR & D costs are lowReduce R&D costsMagnetic circuit rotating partsEducational modelsComputer moduleElectric motor

The invention relates to an electric motor construction kit for assembling a plurality of electric motors, in particular for mounting at least two configurations or types of preferred electronically commutated electric motors. The electric motor construction kit for assembling a plurality of electric motors includes at least one module and a plurality of assemblies for constructing the plurality of electric motors. At least one assembly of the plurality of assemblies includes one or more modules of the at least one module. Apart from a cooling system of an electric motor of the plurality of electric motors, each module of the electric motor assembly is constructed from general parts. In addition, the invention further relates to an electric motor or diffent types of electric motors, in particular electronically rectified electric motor or electronically rectified different types of electric motors, preferably full-bearing motor and / or semi-bearing motor (0), has / have a support module or a support module in the electric motor assembly, the support module of the motor is suitable for a second motor in different type, or different motors have substantially the same support module.

Owner:ROBERT BOSCH GMBH

Capsules of multienzyme combination

InactiveCN1562359AOvercoming Formulation DisadvantagesSimple manufacturing processPeptide/protein ingredientsAntipyreticMedical prescriptionBiomedical engineering

Owner:北京奥路特生物医药研发有限公司

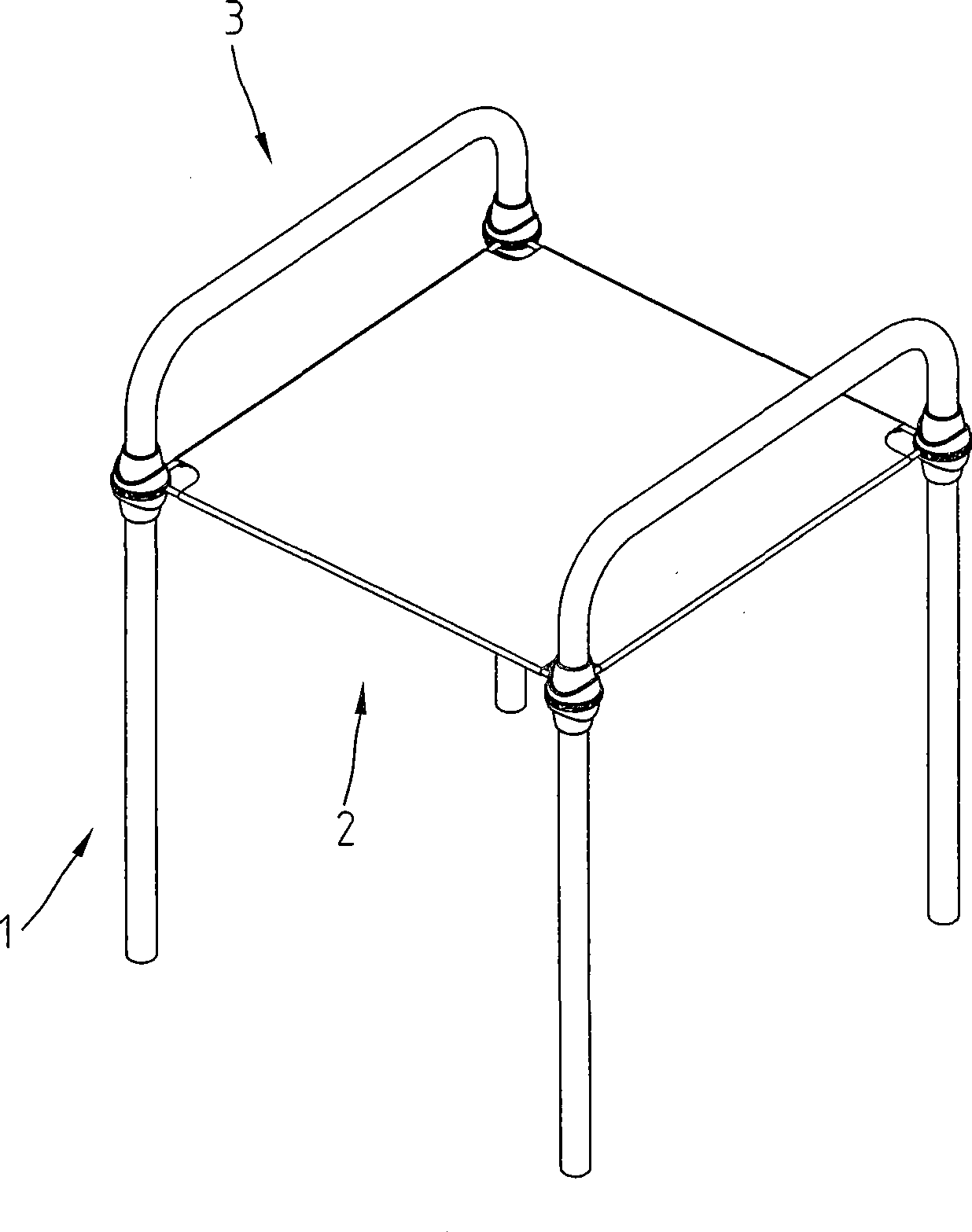

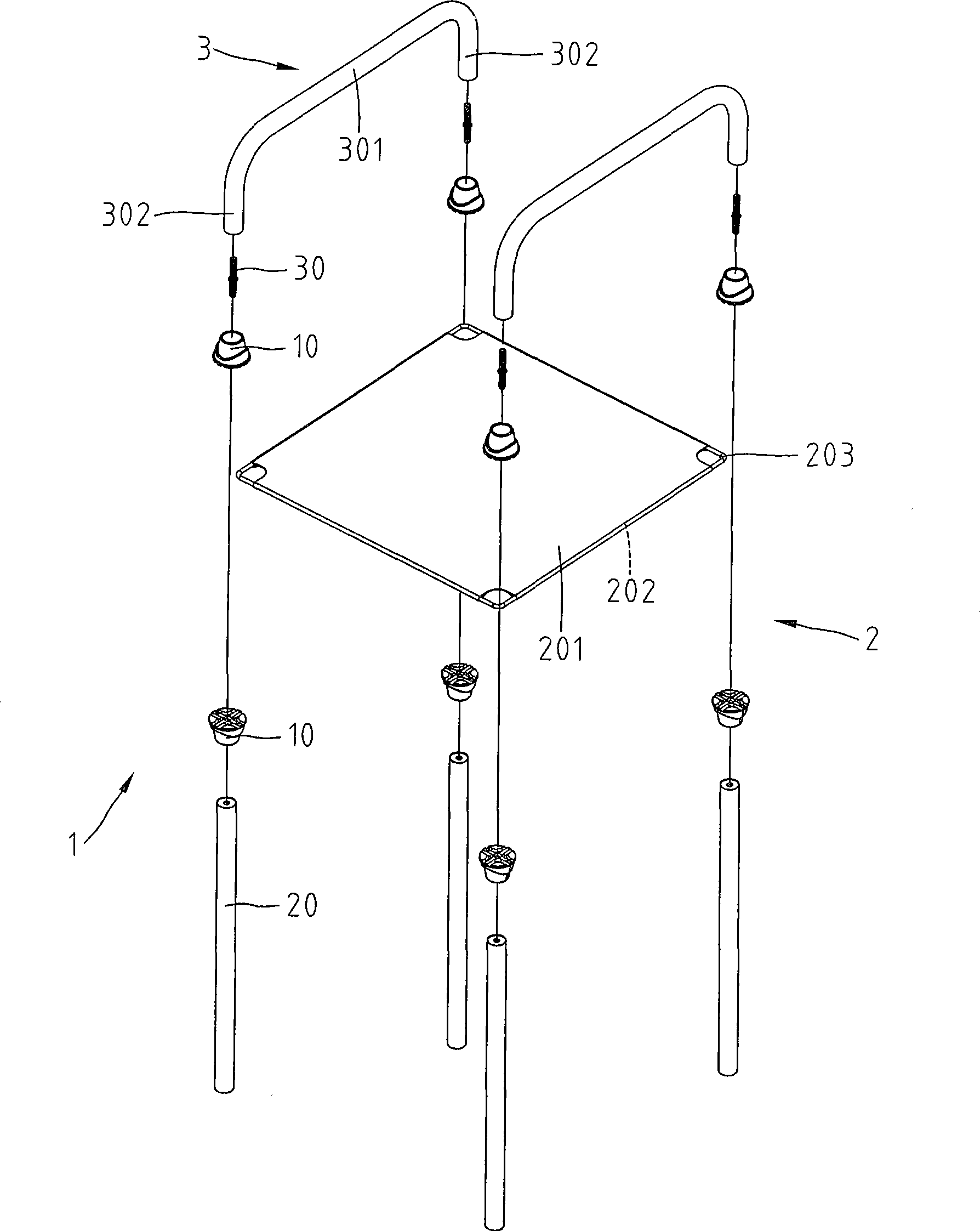

Shelf capable of infinitely stretching

InactiveCN101433405AIncrease the number of piecesIncrease the number of layersVariable dimension cabinetsFurniture joiningDevice formEngineering

Owner:HUEI TYNG ENTERPRISE

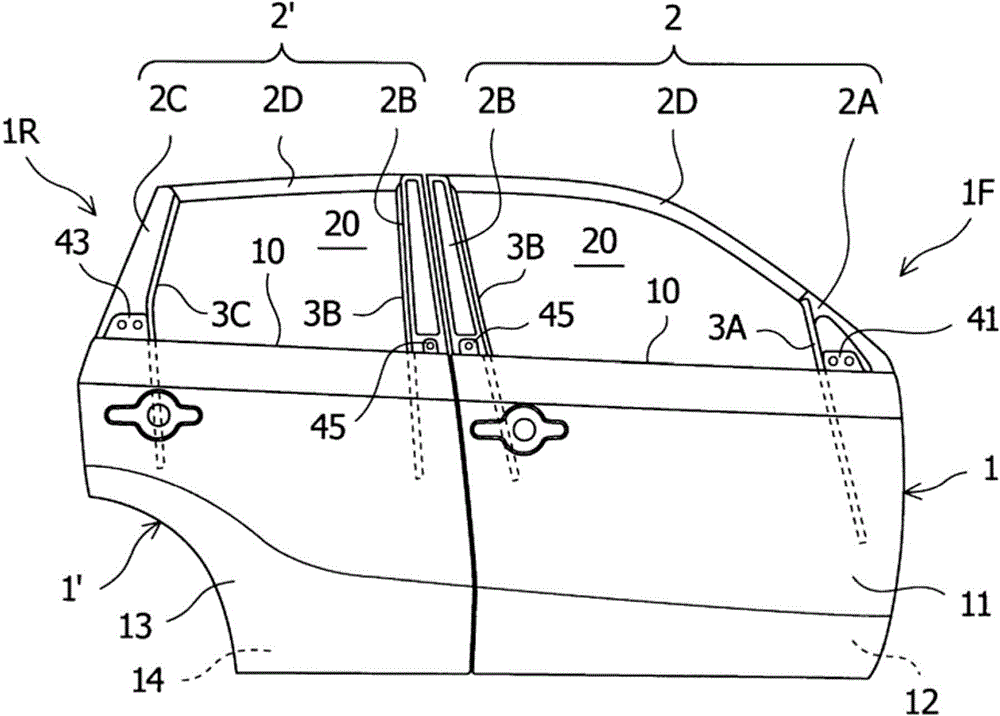

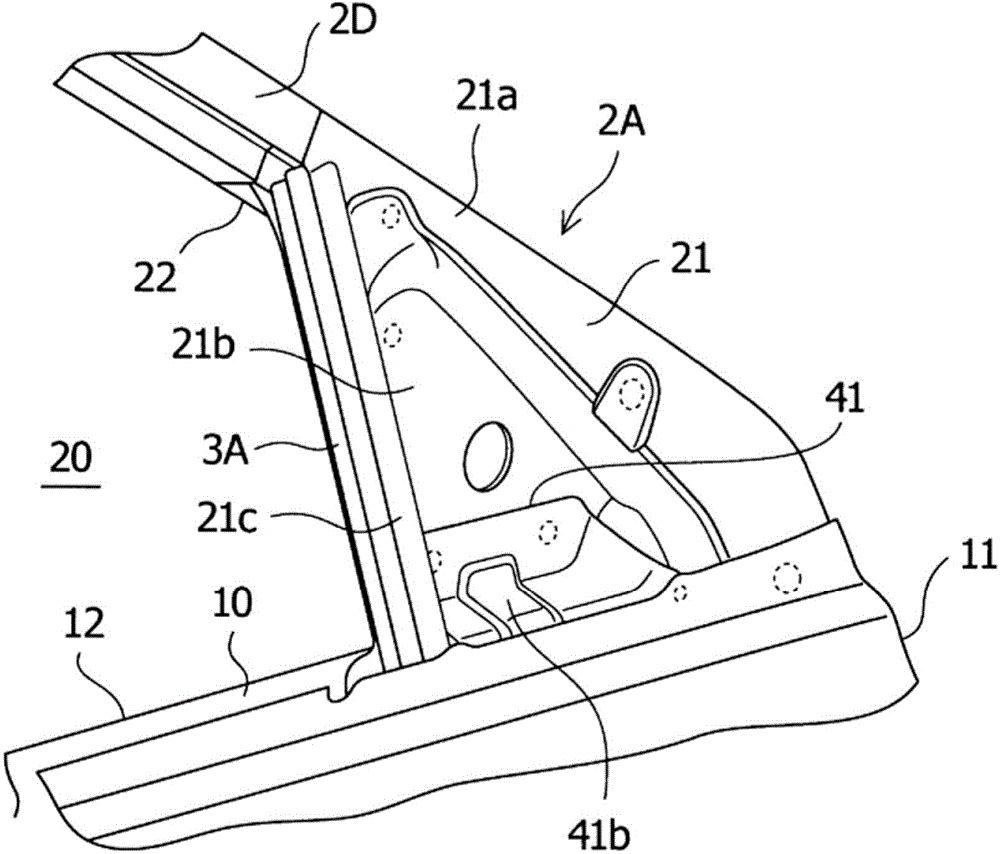

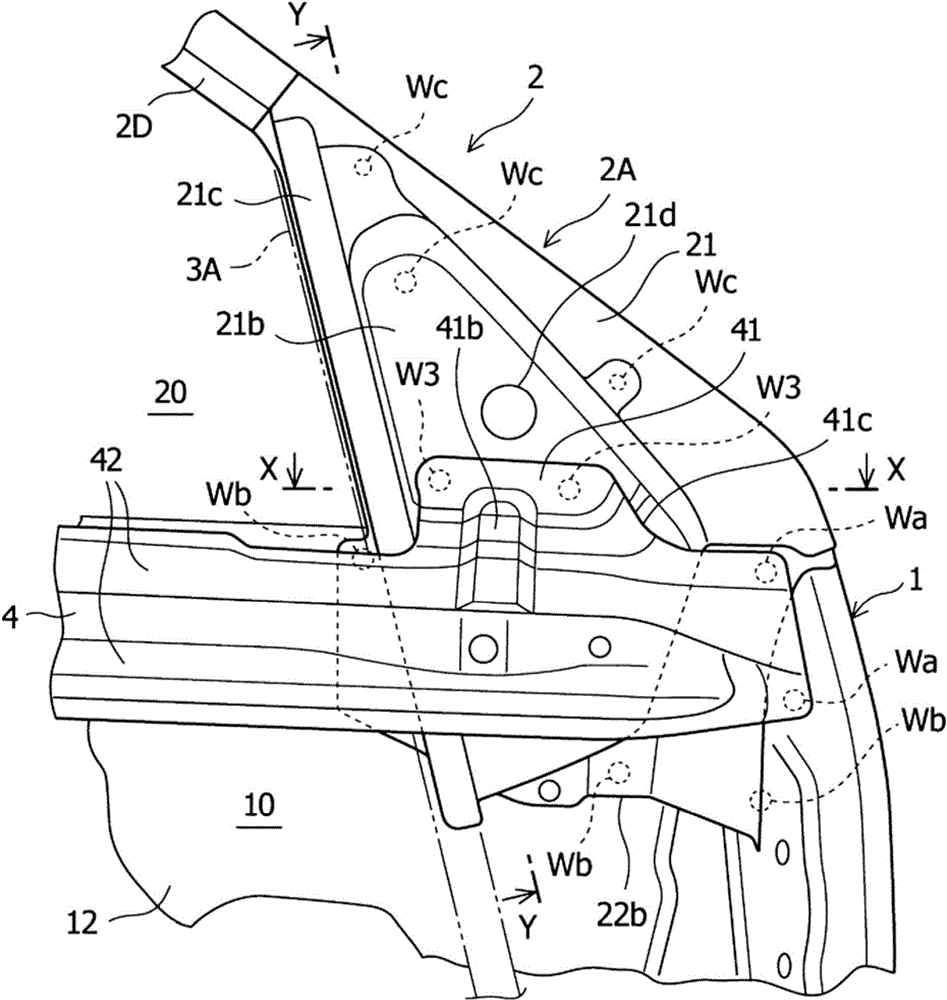

Door construction for vehicle

The invention provides a door construction for a vehicle, and rigidity of a base portion of a window frame portion can be reliably improved through simple construction. An inner side reinforcer (22) is engaged to an inner side of a carriage supporting a window outer side reinforcer (21) of a window frame (3A), a lower portion (22b) of the inner side reinforcer is engaged to an inner plate (12), the inner side reinforcer (22) and the window outer side reinforcer (21) have an expansion surface (21b), and the expansion surface is formed at one side opposite to a door window based on the window frame (3A), wherein, an outer side reinforcer (4) has an extension portion (41) extending to the expansion surface and engaged with the inner side reinforcer (22) via the extension portion.

Owner:SUZUKI MOTOR CORP

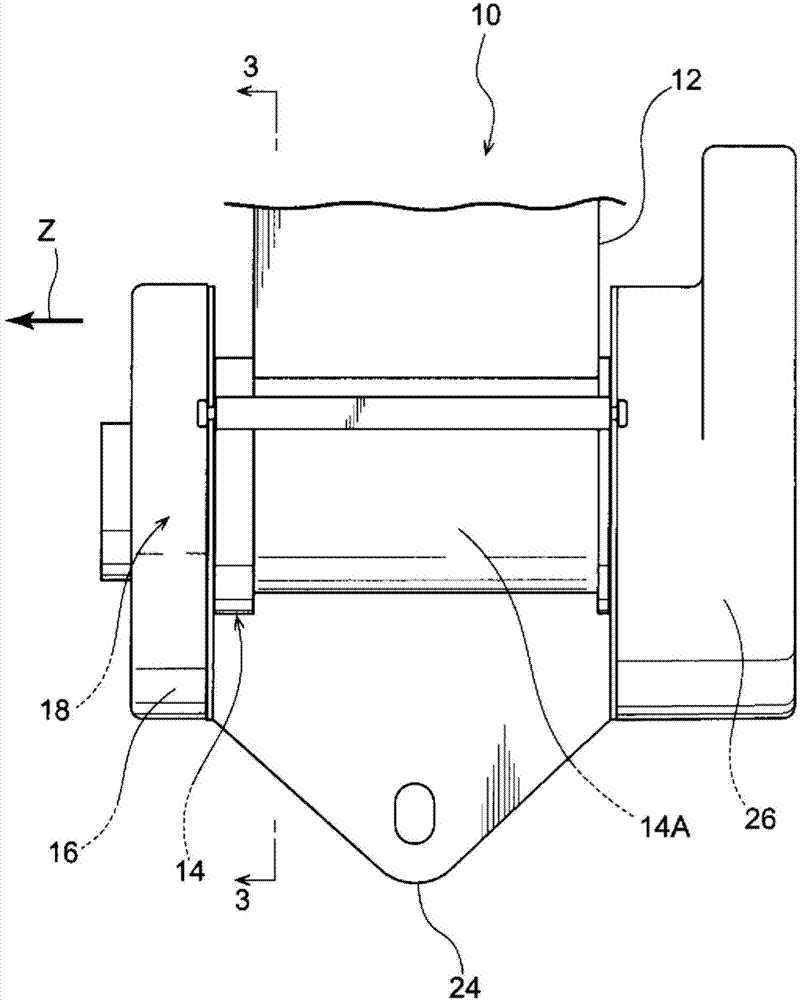

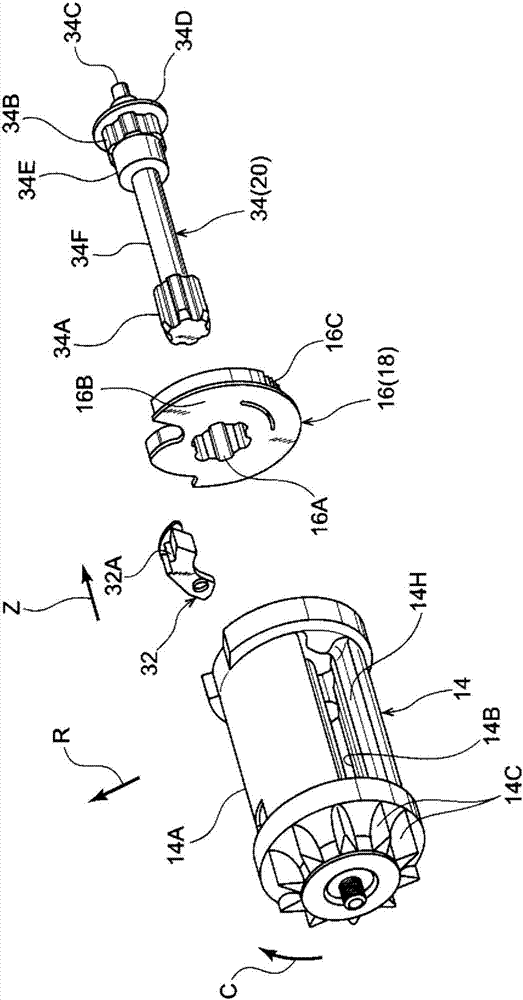

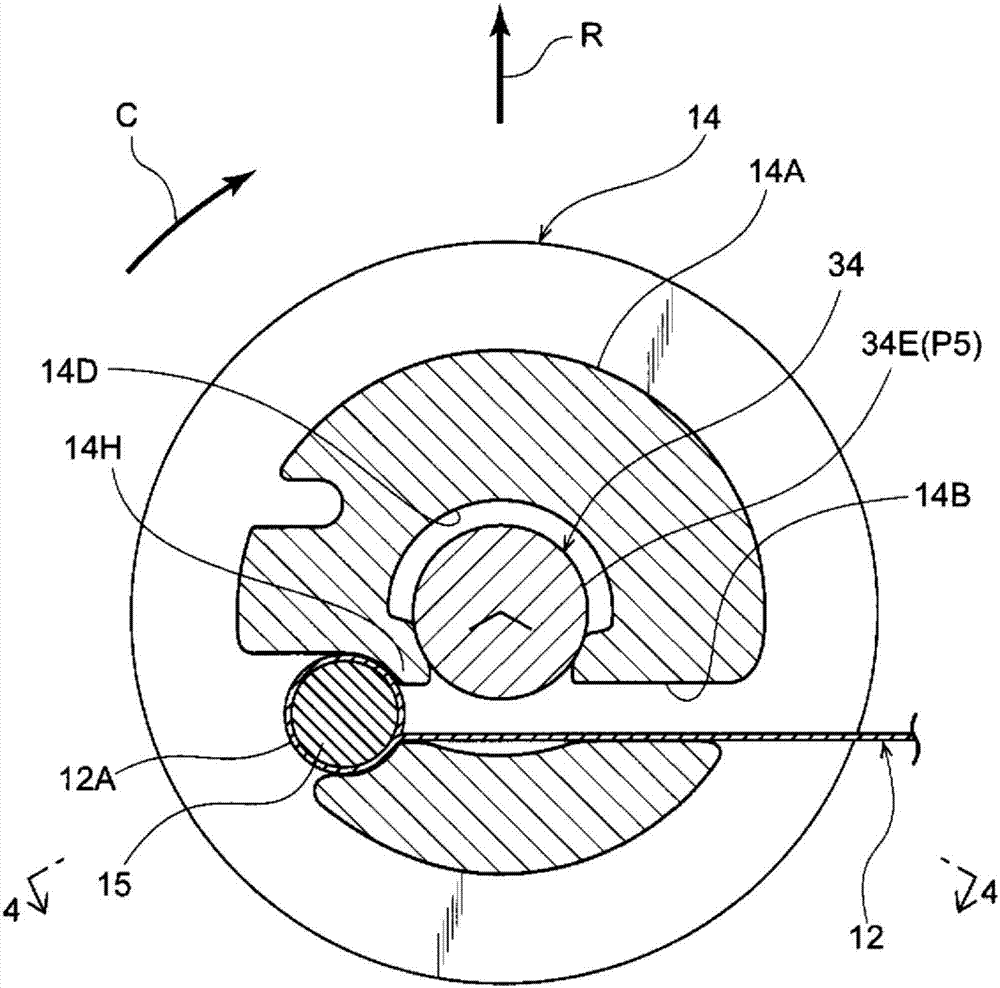

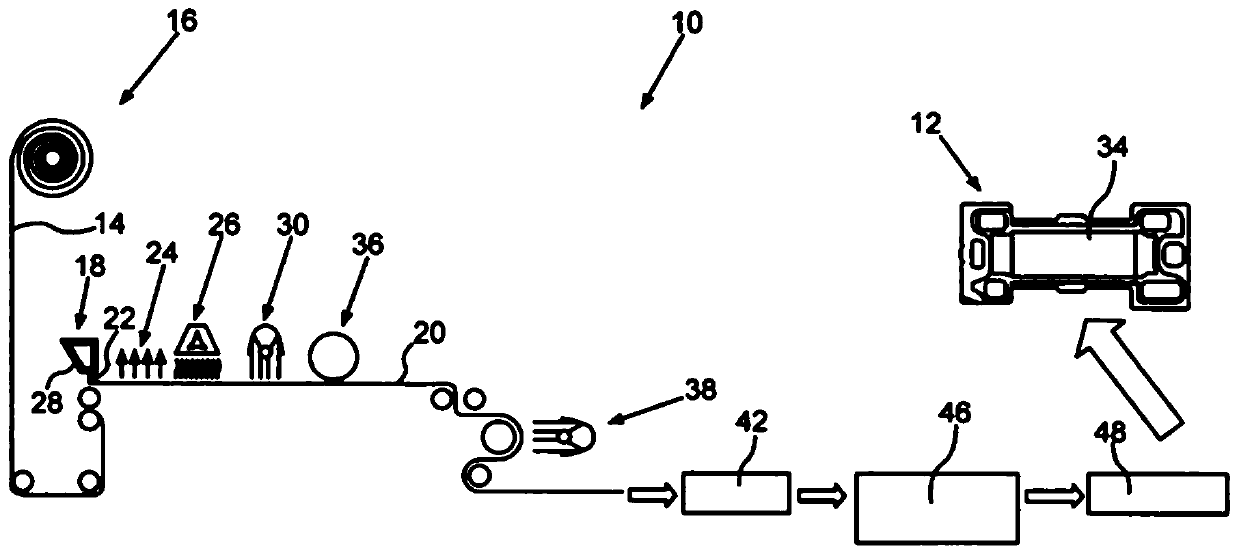

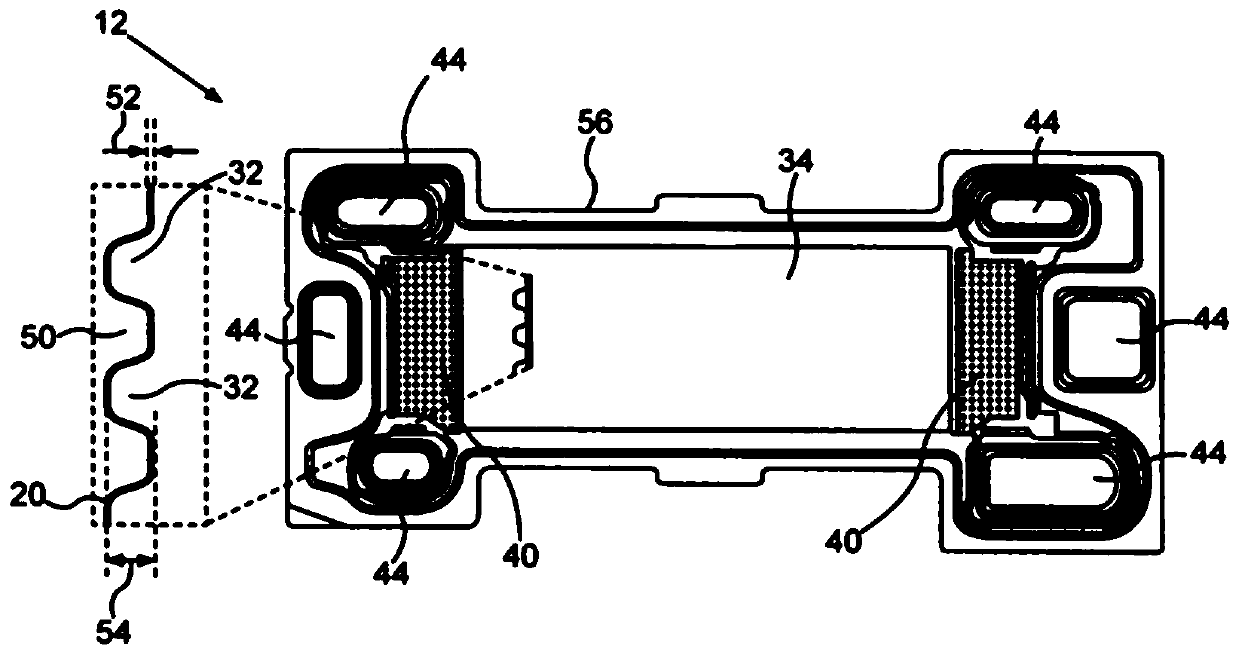

Webbing winding device

InactiveCN107000677AAvoid deformationRealize structural simplificationBelt retractorsEnergy-absorbing device incorporationMechanical engineeringWebbing

A webbing winding device (10) is provided with: a spool (14) on which webbing (12) is wound and which has a webbing insertion hole (14B) through which the webbing (12) is passed; and a stopper member (15) which engages with a peripheral edge of the webbing insertion hole (14B) to affix an end of the webbing (12) to the spool (14). The webbing winding device (10) is further provided with load support sections (a portion (P2) which is located on one axial side of a first serration section (34A) and a portion (P5) which is located on the other axial side of a cylindrical section (34E), the first serration section (34A) and the cylindrical section (34E) being formed on a torsion shaft (34)), the load support sections being disposed radially inside the spool (14) relative to the stopper member (15) so as to be located close to the spool (14), the load support sections supporting a load inputted from the webbing (12) to the spool (14) through the stopper member (15).

Owner:KK TOKAI RIKA DENKI SEISAKUSHO

Surface type repairing method of large-sized sapphire substrate wafer

InactiveCN110465846AEliminate stress residueReduce warpagePolycrystalline material growthAfter-treatment detailsWaxWafering

The invention discloses a surface type repairing method of a large-sized sapphire substrate wafer. The surface type repairing method of the large-sized sapphire substrate wafer comprises the specificsteps that firstly, one side of the wafer is uniformly coated with UV glue and is lightly pressed onto a ceramic plate, and the surface of the wafer is irradiated with ultraviolet rays until the UV glue is solidified; the wafer on the ceramic plate is subjected to single-side grinding; after the grinding effect is detected, the wafer is removed and cleaned; then the wafer is annealed; and then theside subjected to single-side grinding is uniformly coated a liquid wax, baked and pasted on the ceramic plate; hard polishing is carried out on the other side of the wafer; after the hard polishingeffect is detected, the wax is removed, and cleaning is carried out. The method has good surface type repairing effect on the sapphire substrate wafer, and the grinding amount is small, on the one hand, the warpage of the wafer can be effectively reduced, and on the other hand, the production efficiency and cost can be improved.

Owner:江苏吉星新材料有限公司

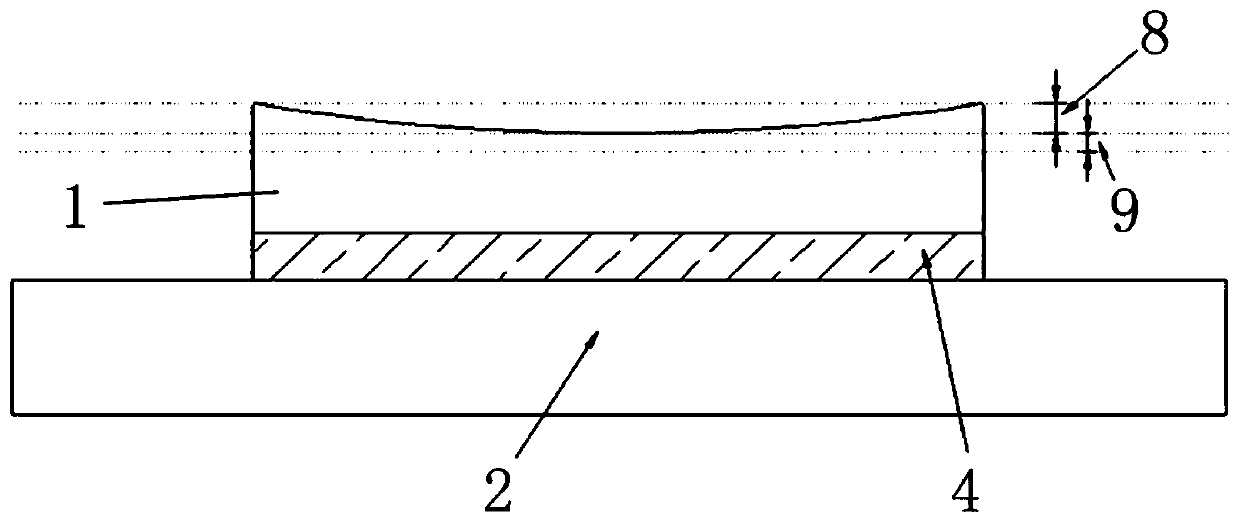

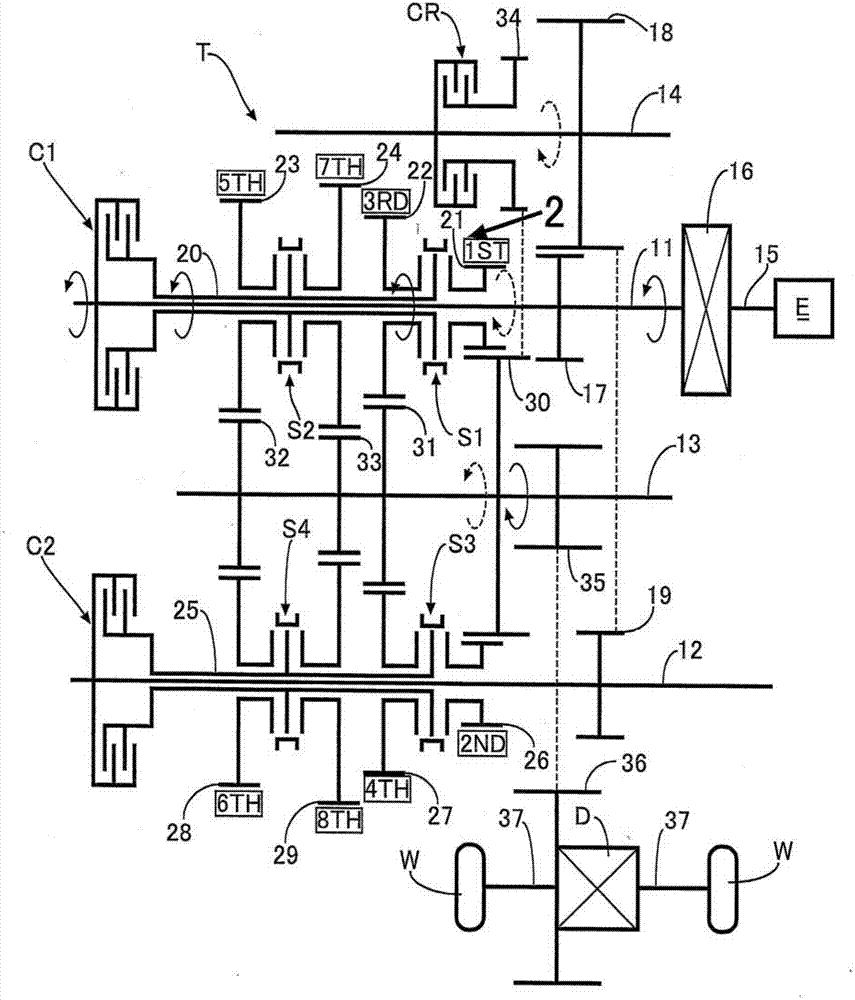

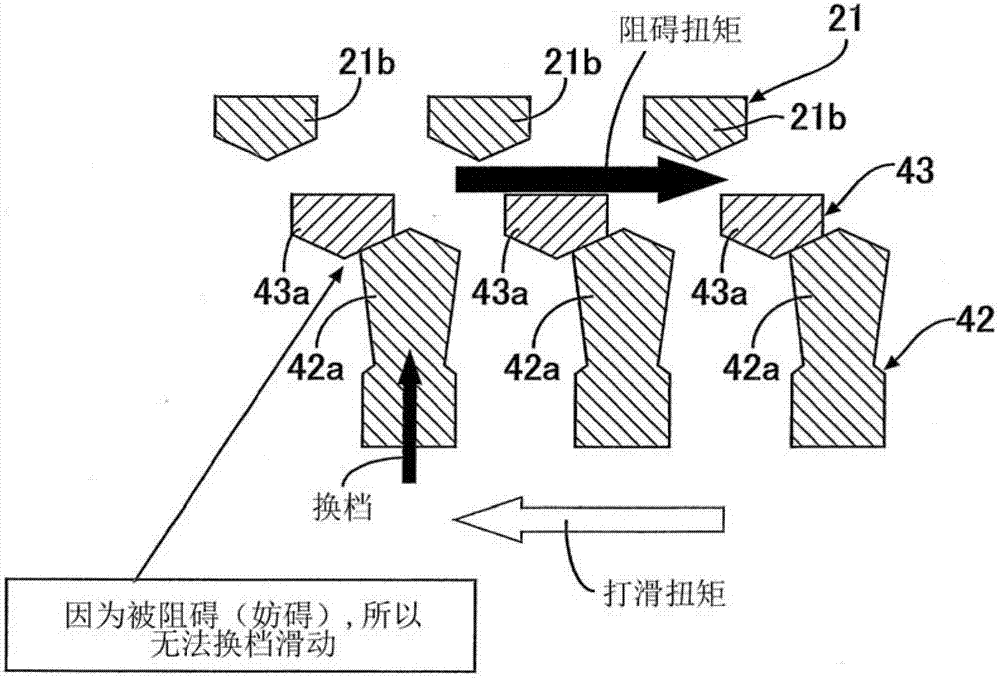

Control system of transmission

ActiveCN102966727AGuaranteed stable workIncrease the number of piecesMechanical actuated clutchesToothed gearingsDrive wheelControl system

According to aspects of the disclosure, provided is a transmission control system to enable smooth engagement of meshing engagement means When establishing a forward gear position by engaging the meshing engagement means and a forward clutch while a vehicle is stationary. For example, when a synchro device is operated so as to establish a predetermined forward gear position, it becomes difficult to smoothly couple a first speed drive gear to the input shaft by the synchro device. However, temporarily engaging a reverse clutch during the process of operation of the synchro device allows a reverse torque to act on the first speed drive gear to apply torsion to a power transmission path between the first speed drive gear and a driven wheel. Furthermore, a repulsive force is applied and generates backlash between the synchro device and the first speed drive gear, thus enabling smooth operation of the synchro device.

Owner:HONDA MOTOR CO LTD

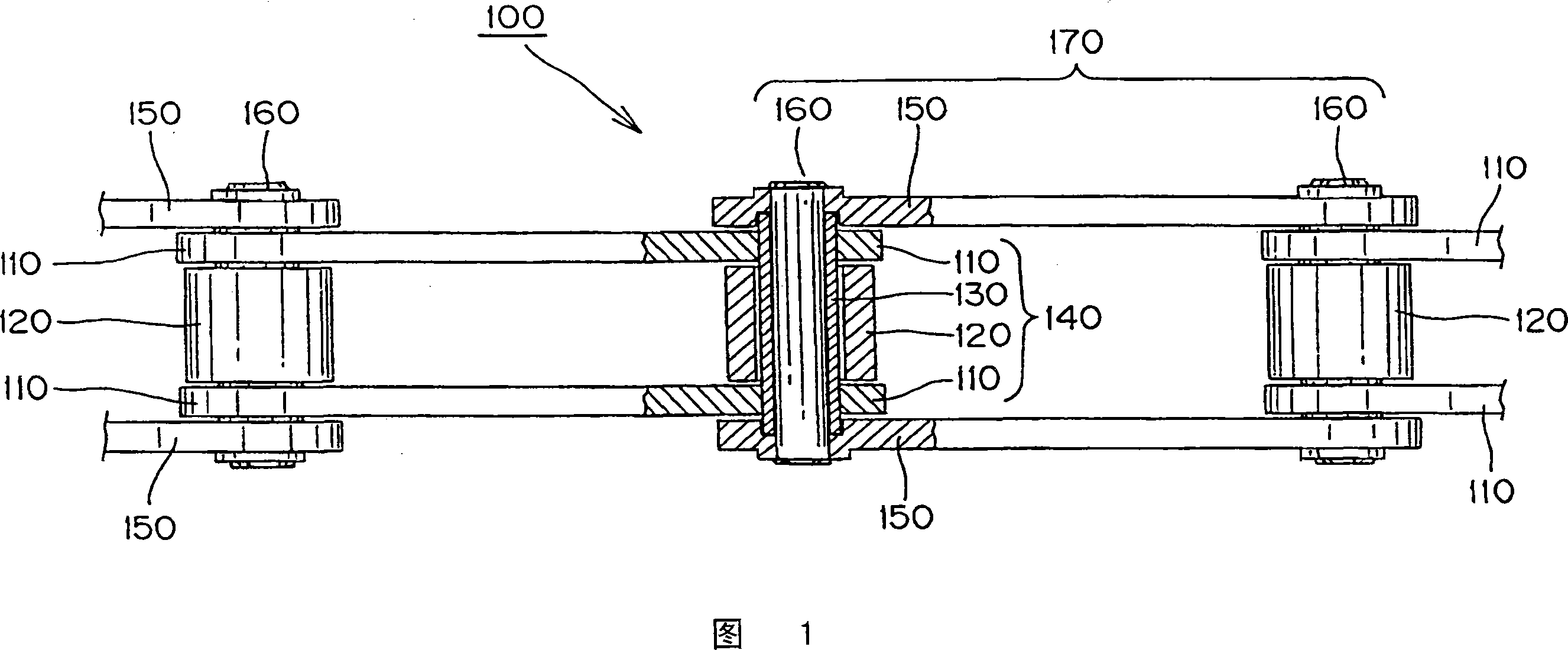

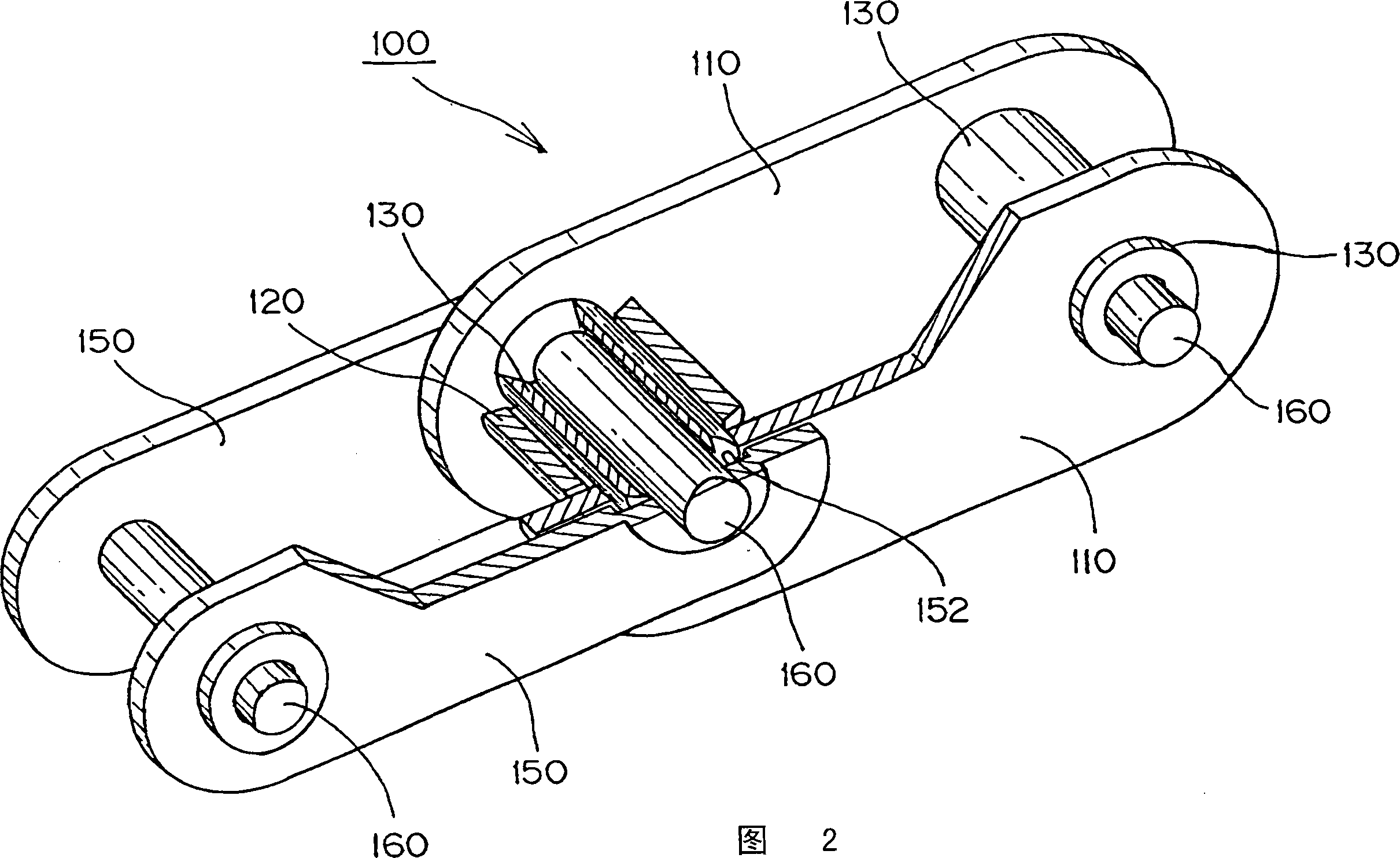

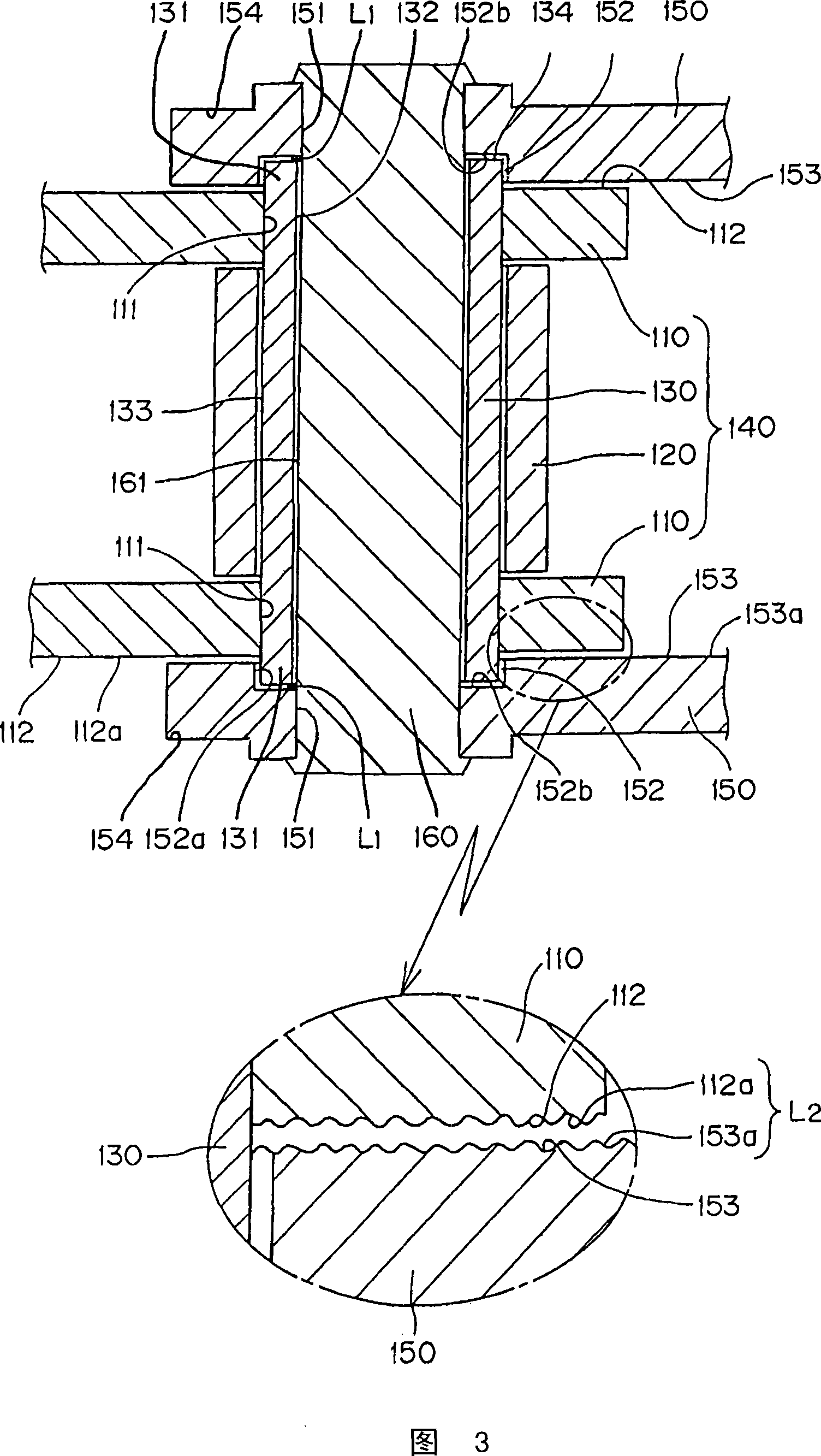

Oil-free chain

Owner:TSUBAKIMOTO CHAIN CO

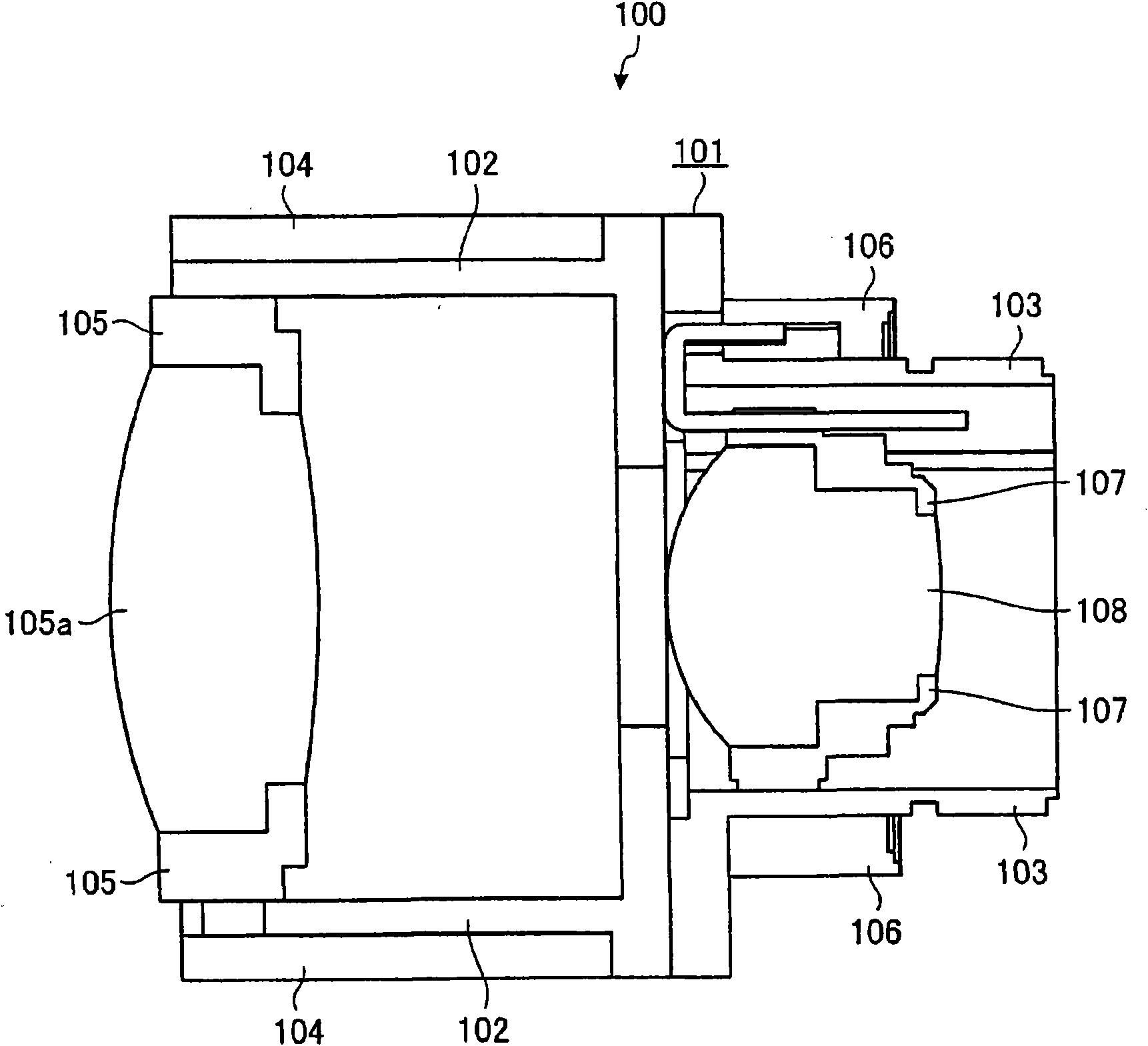

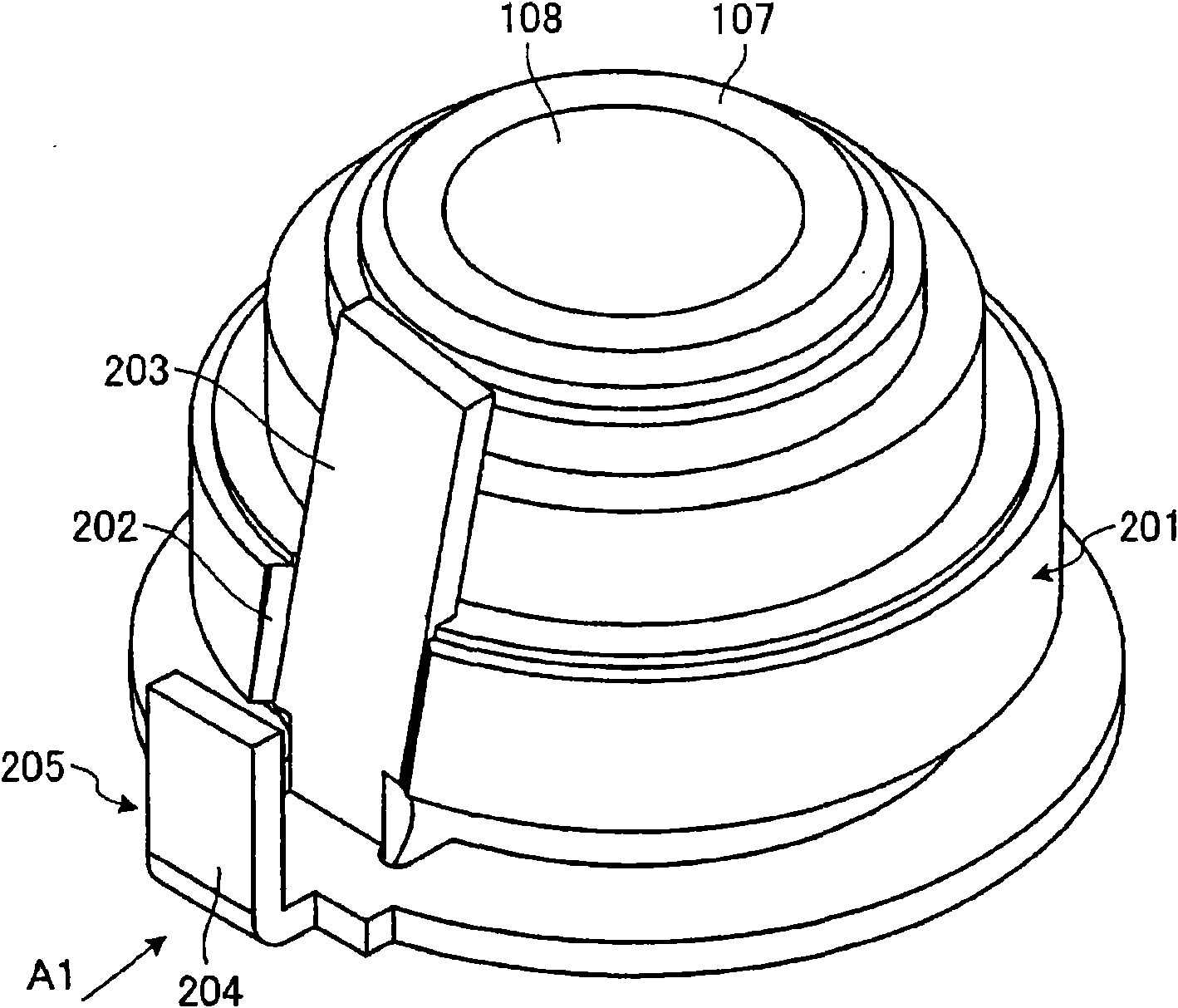

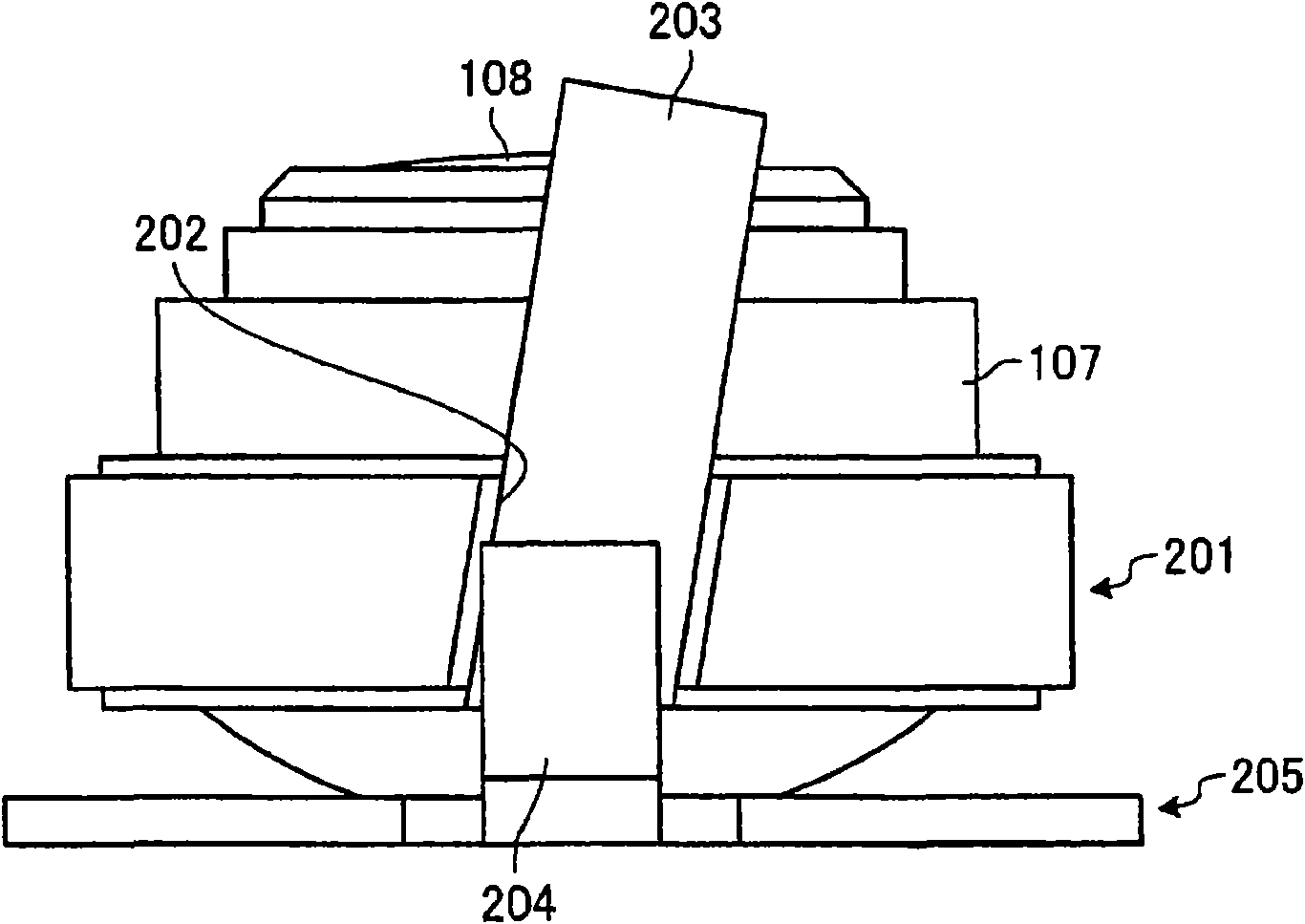

Optical device and camera device

InactiveCN101551503APrevent movementIncrease the number of piecesTelevision system detailsColor television detailsEngineeringOptical axis

The present invention provides an optical device and a camera device, wherein a lens unit is provided with a ganged plate (204), having a ganged key (203) extending in an optical axis direction and rotating gangedly along with a rotation of a zooming loop; a rear element lens frame (107), having a helical part (201) on an external circumference surface containing an arris extending in a direction inclined relative to the optical axis direction, and a key groove (202) jointed with the ganged key (203) rotating along with the rotation of the ganged plate (204); and a back lens cone, arranged on an external side of the rear element lens frame (107) and showing a approximate cylinder shape, and having helical parts for forming a helical mechanism by conjoining with the helical part (201) on an inner circumference surface, so as to support the rear element lens frame (107), the ganged key (203) and the key groove (202) movably in the optical axis direction through the helical mechanism, inclined in a direction different from the helical part (201) relative to the optical axis direction. Thereby, by means of a simple structure, it is capable of preventing the position of the optical component from departure caused by a clearance between the helical part and the helical support part, and the mobile performance of the optical component will not be reduced.

Owner:TAMRON

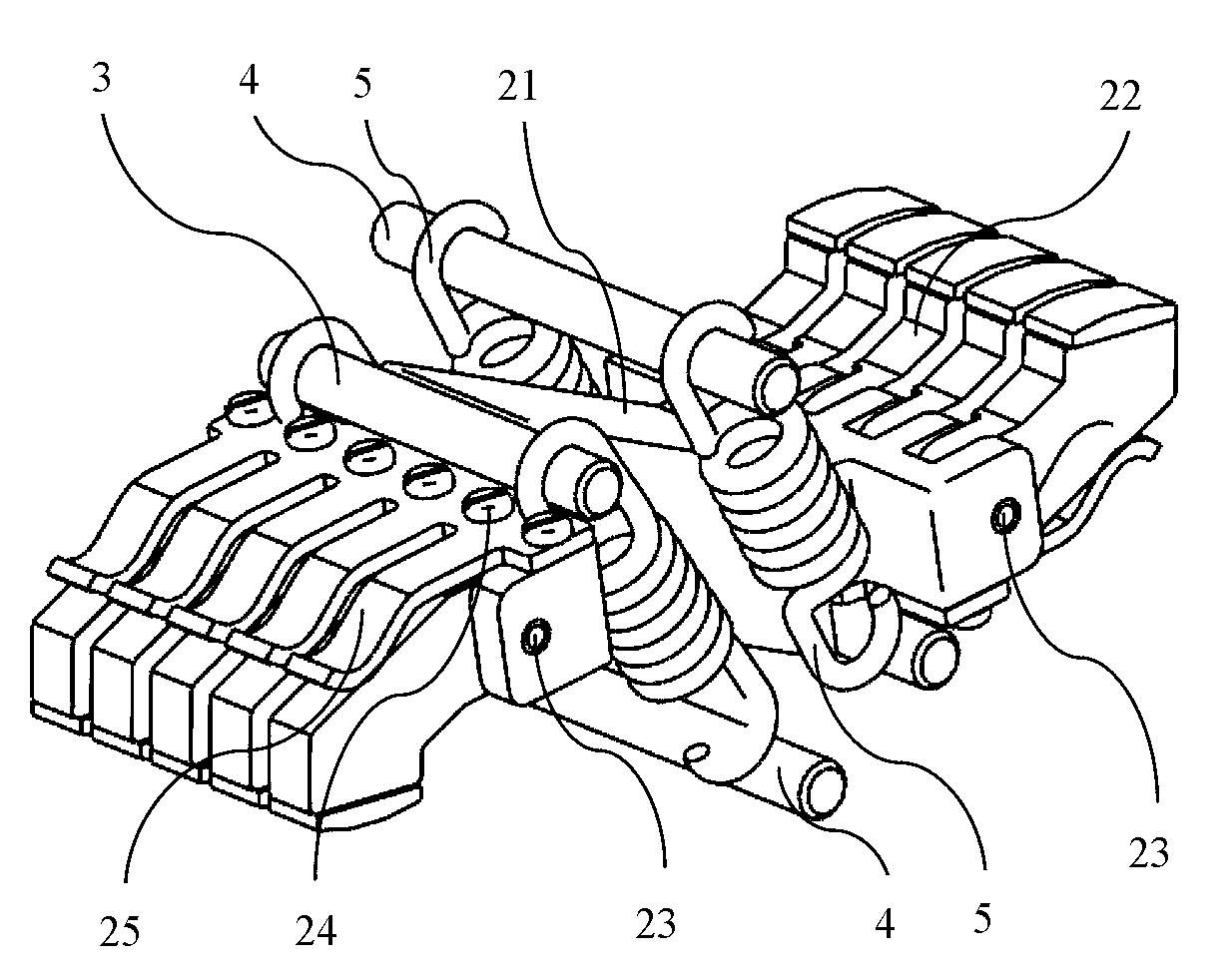

Dual-breakpoint moving contact system of moulded-case circuit breaker

ActiveCN103311064AIncrease the number of piecesIncreased current carrying areaCircuit-breaking switch contactsEngineeringContact system

The invention discloses a dual-breakpoint moving contact system of a moulded-case circuit breaker. The dual-breakpoint moving contact system comprises a spindle, a moving contact module, shafts, and springs. The spindle is cylindrical. Two through holes in central symmetry and for passage of the shafts are formed in the spindle. A through channel is formed in the spindle, and the edge of the inner wall of each end of the through channel is provided with two grooves. The moving contact module comprises a rotor, moving contact plates, the rotating shafts, spring-hanging shafts, plate springs and fastening screws. The rotor is disposed in the through channel. The springs are hung between the spring-hanging shafts. The rotor is in central symmetry. Two ends of the rotor are provided with grooves, and the side of each groove is provided with a through hole used for passage of one rotating shaft and mounting of the corresponding moving contact plates. The plate springs are mounted at one end of the rotor through the fastening screws, are located above the moving contact plates and contact with the moving contact plates. The dual-breakpoint moving contact system is provided with multiple moving contact plates, and through both increase of the moving contact plates and increase of contact bridge current-carrying area, operating current value of the dual-breakpoint moulded-case circuit breaker is increased effectively.

Owner:JIANGSU DAQO KFINE ELECTRIC

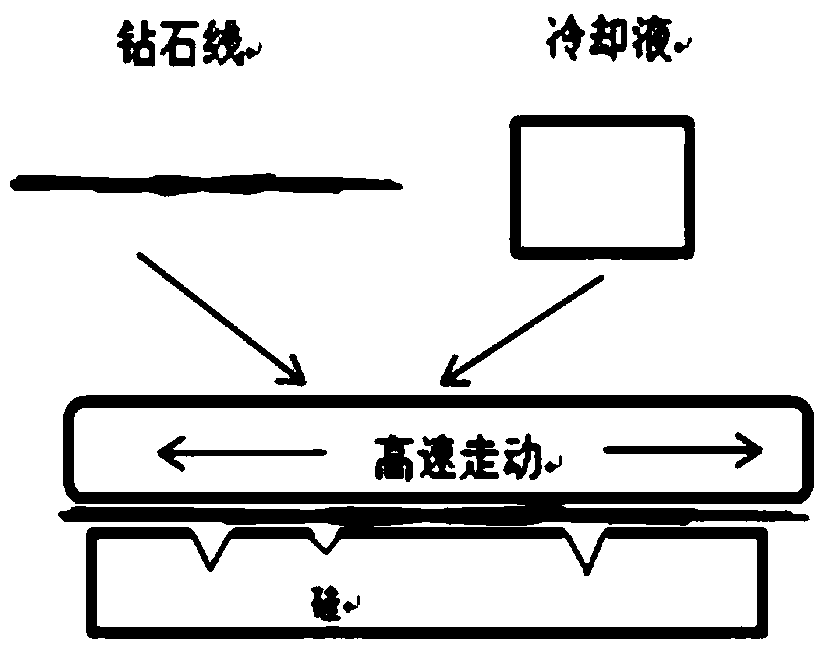

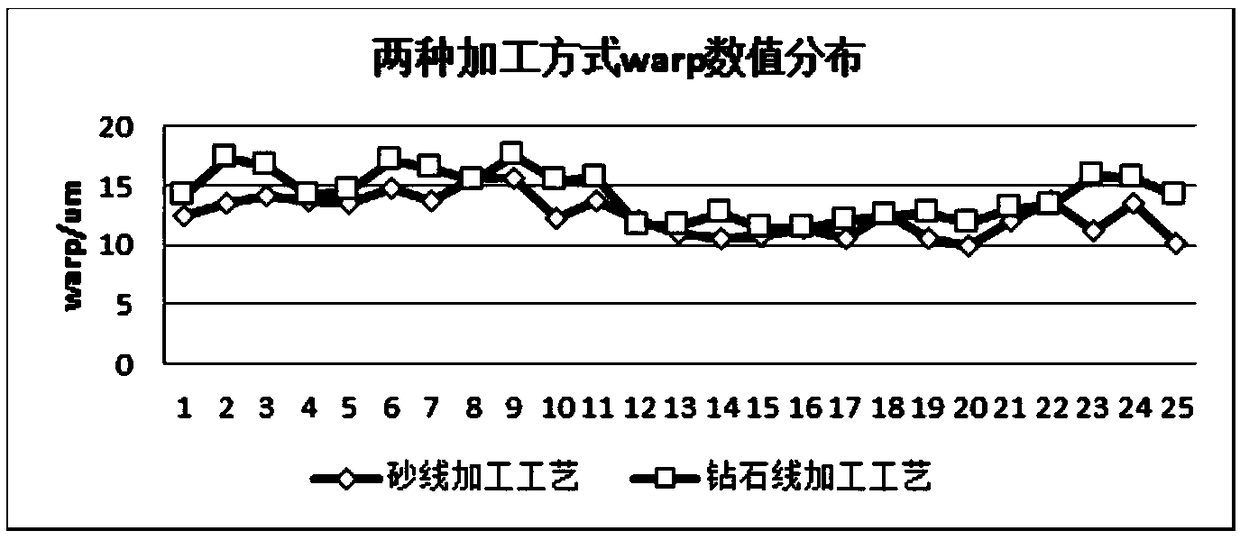

Technology for cutting semiconductor silicon wafer by diamond wire

InactiveCN109435085AFast cutting speedExtended cutting timeGrinding machinesFine working devicesWire speedWire cutting

The invention provides a technology for cutting a semiconductor silicon wafer by a diamond wire. Diamond wire equipment is used for cutting the semiconductor silicon wafer, during the cutting process,the falling speed of a worktable is 1.5-2.5 mm / min, the wire speed of diamond wire cutting is 1100-1400m / min, the flow rate of coolant is adjusted to 80-100L / min, the temperature of the coolant is 23-28 DEG C, and the wire supply quantity of steel wire is 0.4-1.5m / sheet. The technology of the diamond wire cutting the semiconductor silicon wafer has the advantages of increasing the number of chipsper kilogram and enlarging the output capacity, and can effectively reduce the costs of existing semiconductor cutting and grinding film and polishing film, and a strong foundation is laid for a large-size polishing film products costs reducing plan.

Owner:TIANJIN ZHONGHUAN ADVANCED MATERIAL TECH

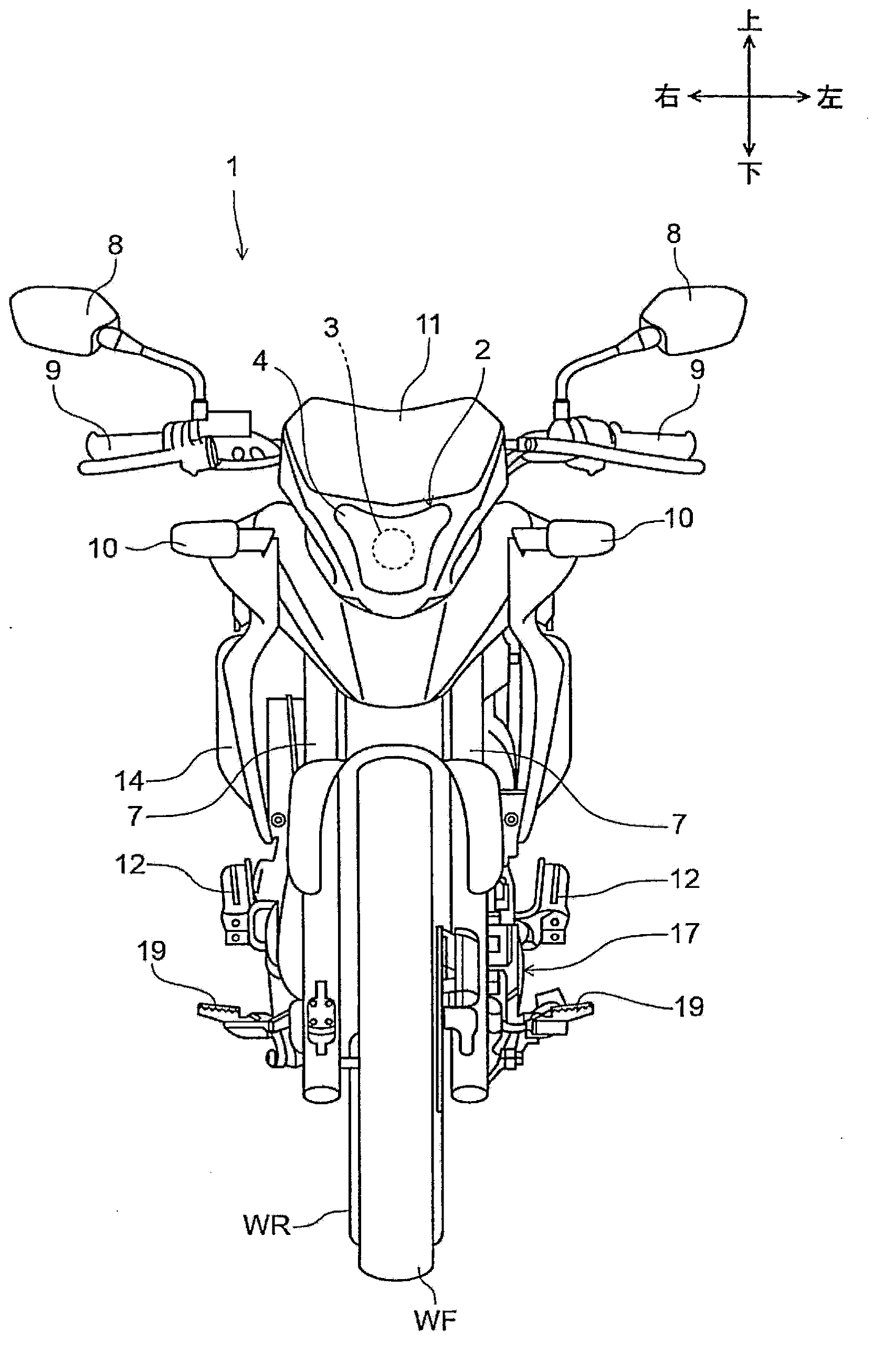

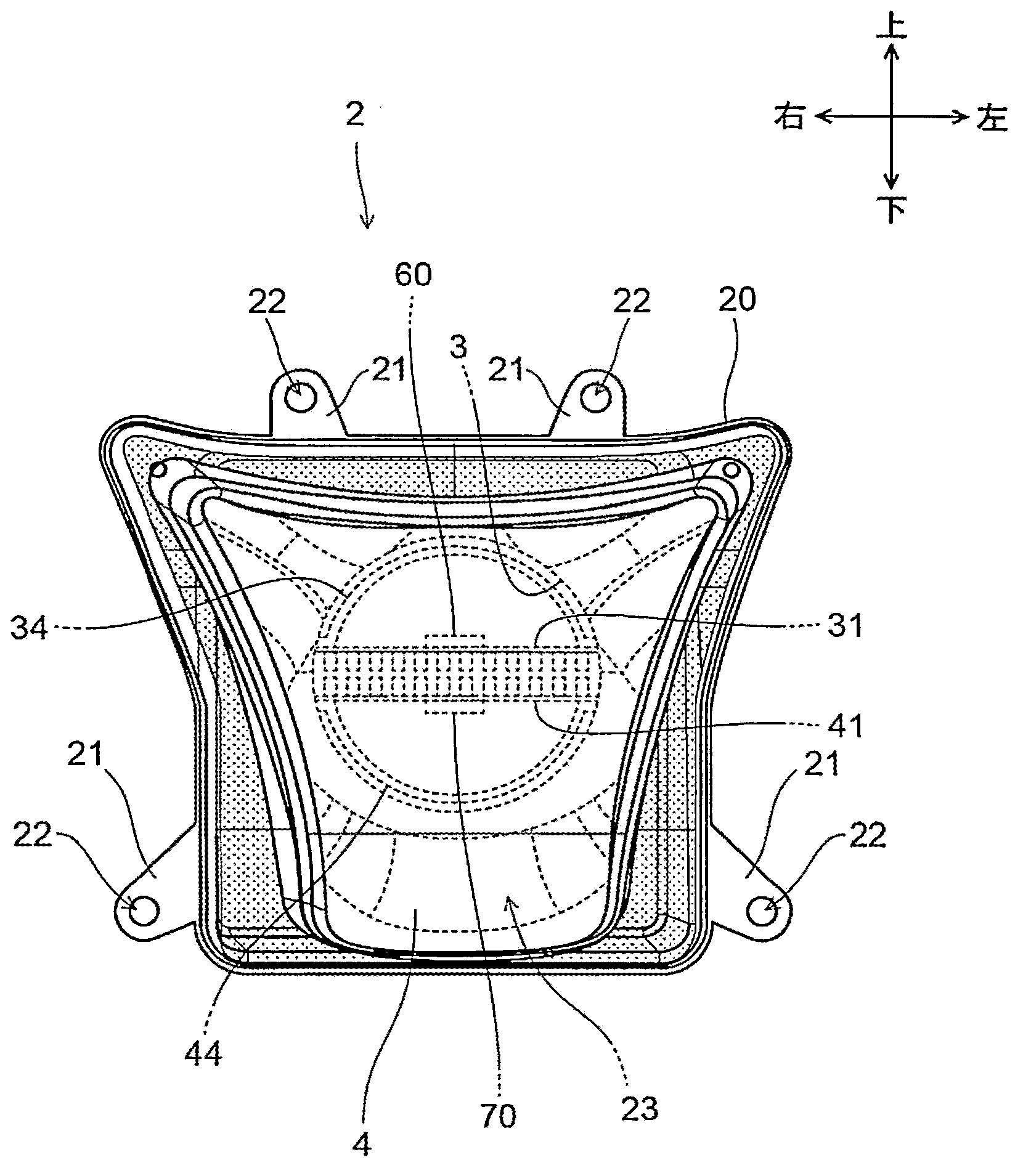

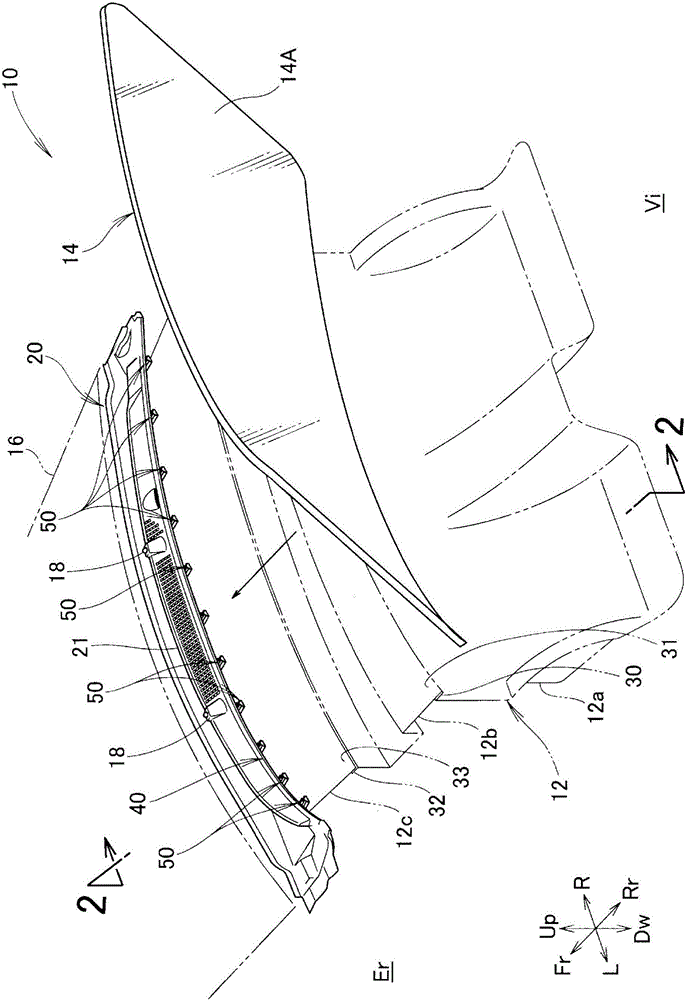

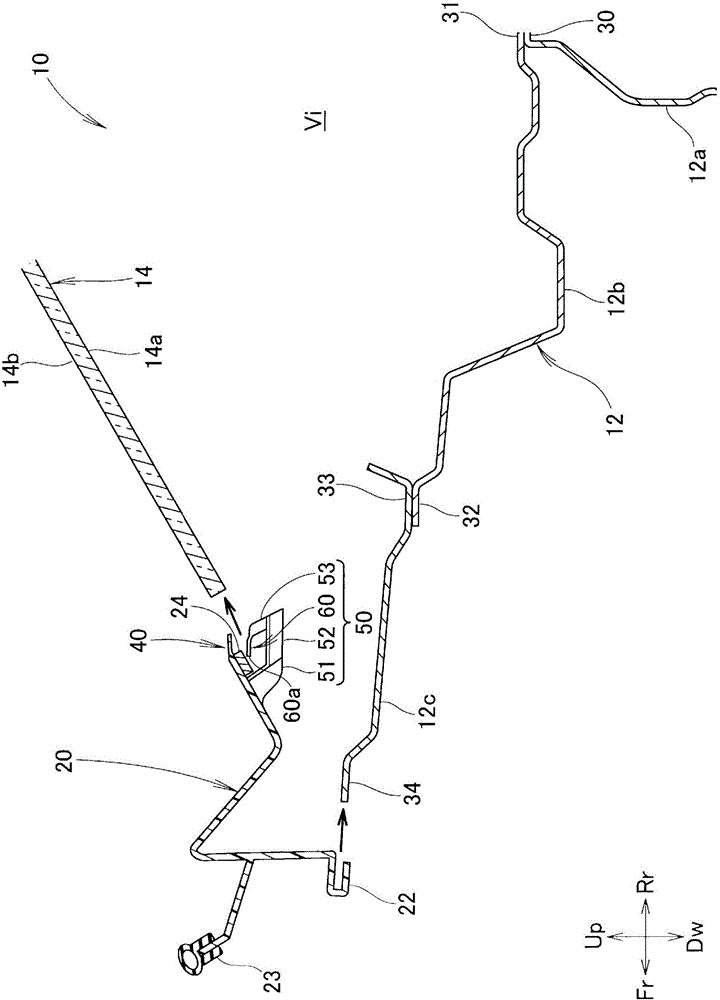

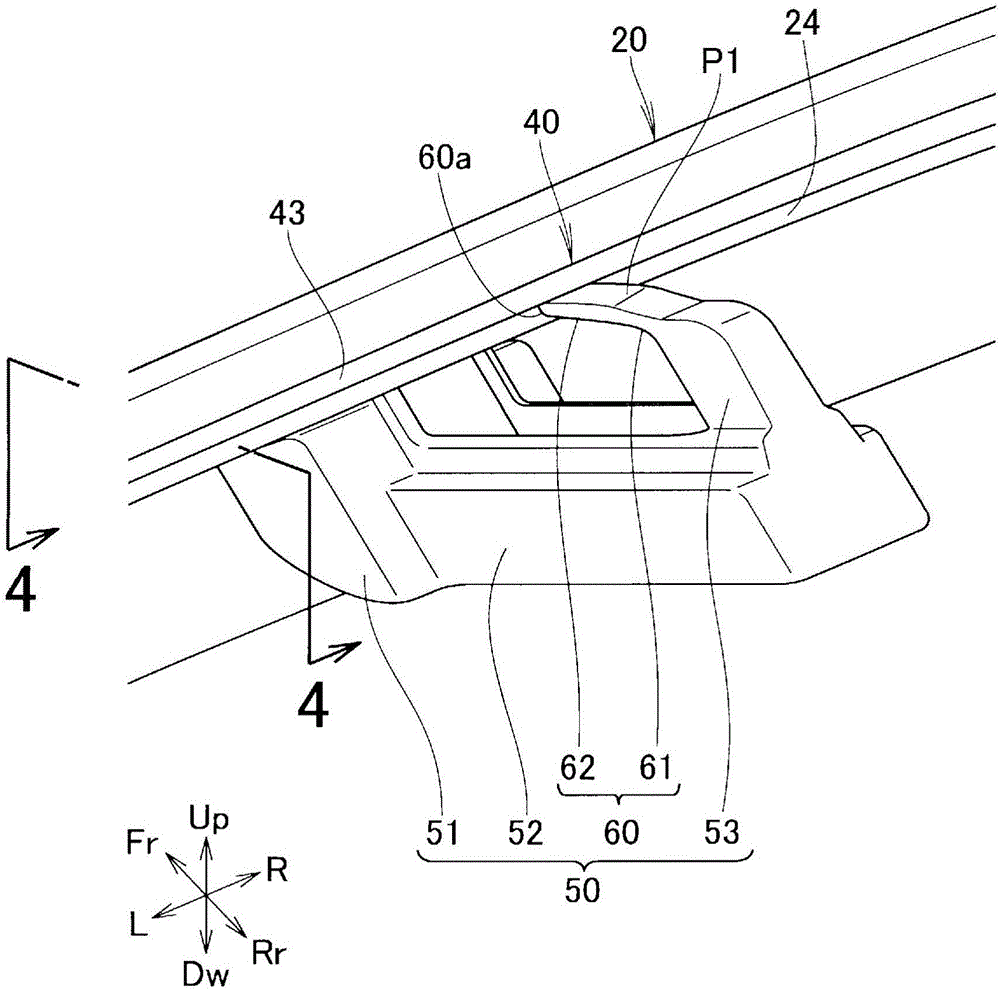

Cowl structure

An outer glass contact section (40), which is parallel to and comes into close contact with the outer surface of a windscreen (14), and inner glass contact parts (50), which have lips that press the inner surface of the windscreen (14), are formed at the vehicle rear-side edge of a cowl body (20). The lips (60) each have a folded shape or a curved shape, have a folding point (P1) for the folded shape or a curving point (P2) for the curved shape as a boundary, and comprise a base-side first lip section (61) and a distal-side second lip section (62).

Owner:HONDA MOTOR CO LTD

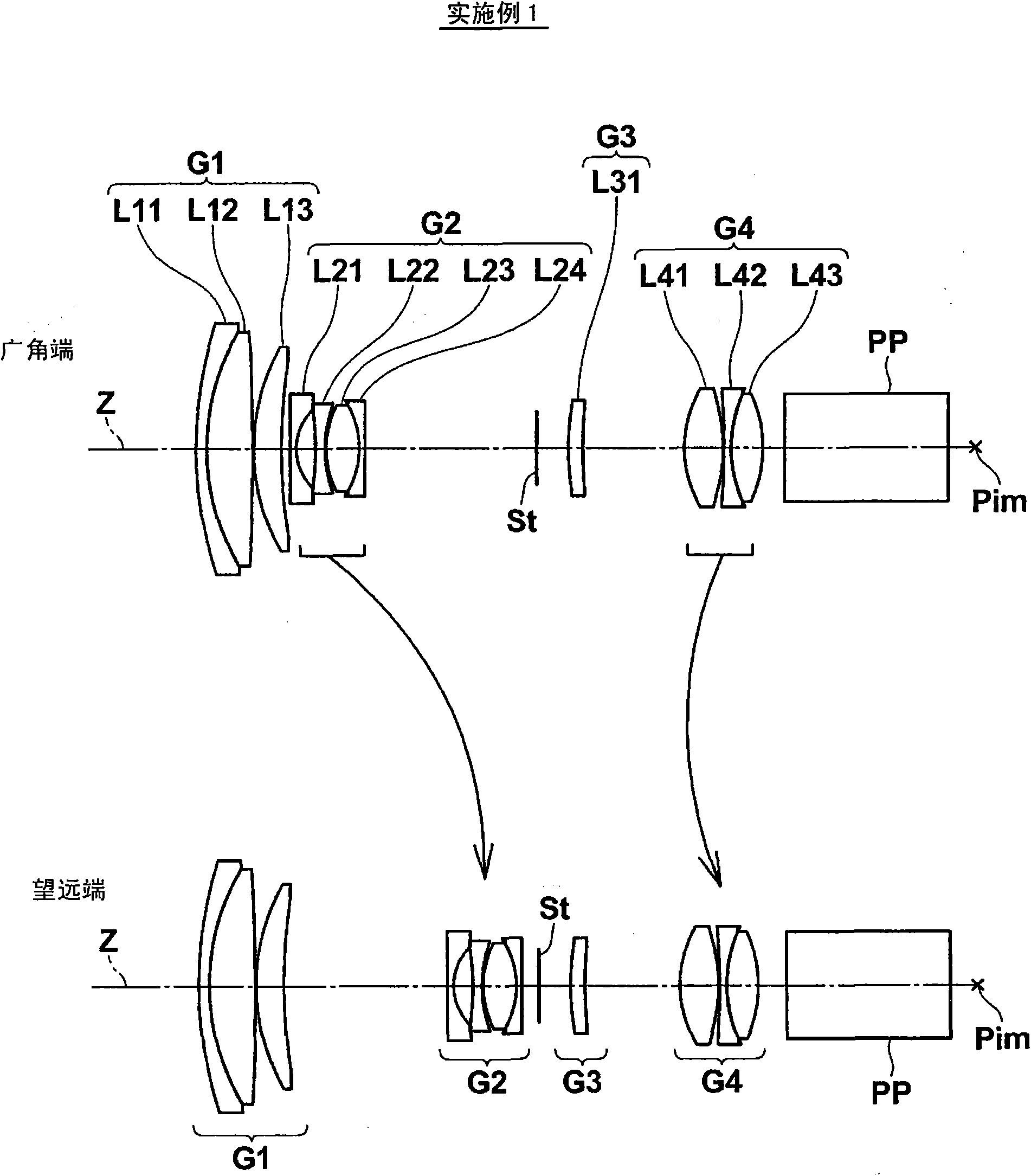

Zoom lens and camera device

InactiveCN101672977AIncrease the number of piecesGood distortion correctionTelevision system detailsColor television detailsOptical axisMiniaturization

The invention provides a zoom lens, wherein the zoom lens realizes miniaturization of diameter of a front lens and shortens total length of the lens system in light axis direction apart from maintaining high optical performance. The zoom lens comprises four lens assemblies from a first lens assembly (G1) to a forth lens assembly (G4). The first lens assembly (G1) and the third lens assembly (G3) are fixed, and the second lens assembly (G2) is moved when zooms in or out, and the forth lens assembly (G4) is moved to correct image plane position of the zoom and focus. The first lens assembly (G1)comprises a negative lens and two positive lens. The second lens assembly (G2) comprises four lens with one negative lens having a aspheric surface. The following conditional expression (1), (2) aresatisfied: 6.0<f1 / fw<8.0 (1), 0.10<H2f / fw<0.20 (2). Further more, f1 means focal distance of the first lens assembly, fw means focal distance of the entire system on a wide-angle end, H2f means distance from object side of a lens that nearest to the object side of the second lens assembly to an light axis of a principal point on an object side of the second lens assembly.

Owner:FUJI PHOTO OPTICAL CO LTD

Method and device for manufacturing an optical fiber end

ActiveUS7056031B2Increase the number of piecesShort timeCoupling light guidesLight waveBiomedical engineering

Owner:BERNHARD SCHAFER WERKZEUG & SONDERMASCHINEN GMBH +1

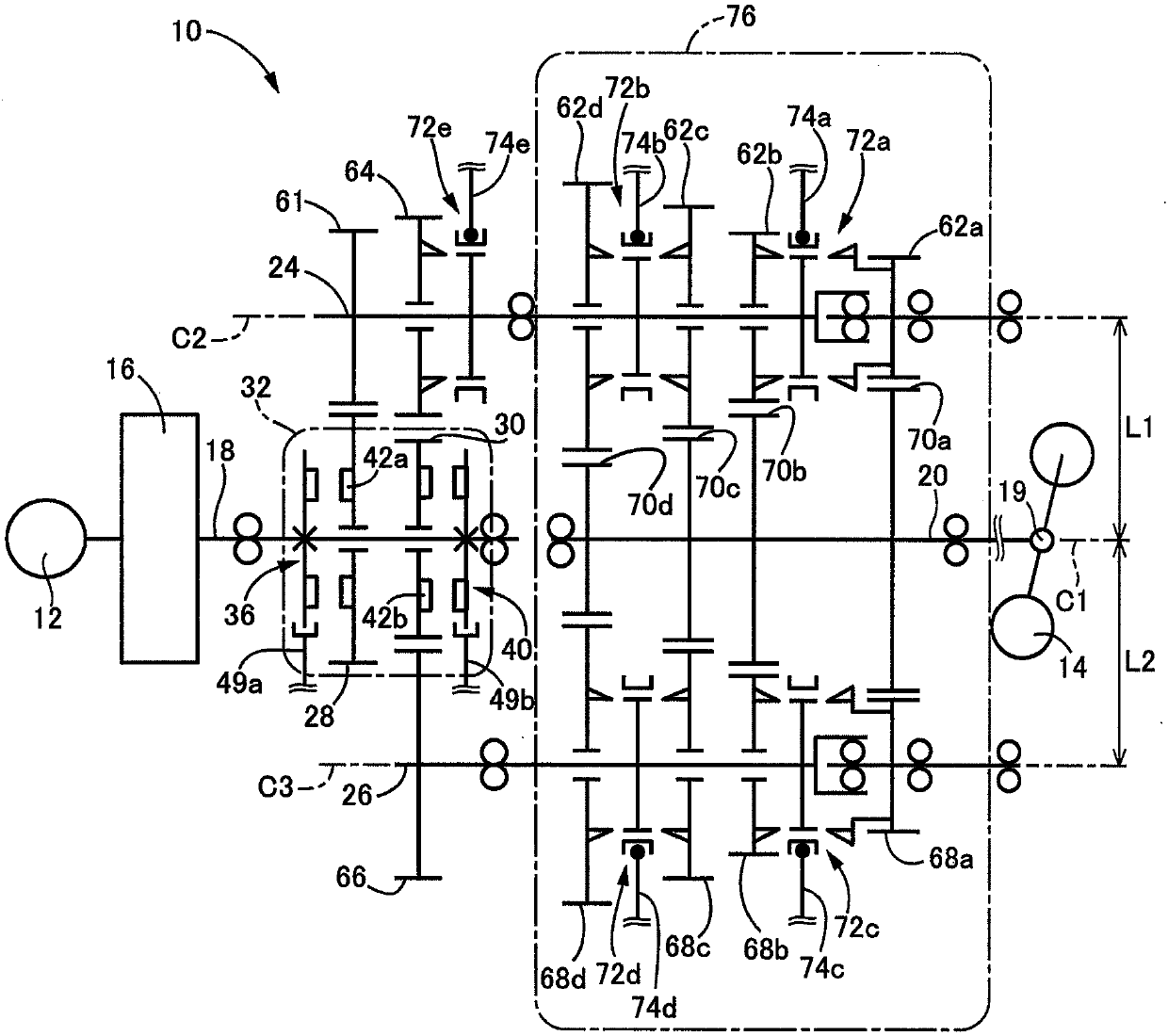

Vehicle transmission

ActiveCN107830128ARealize multi-levelWill not increaseToothed gearingsGearing controlControl theoryComputer science

The invention provides a vehicle transmission. Connection and disconnection of power transmission paths between an input shaft (18) and a first shaft, and between the input shaft and the second shaft(26) are switched by a jaw clutch (32); power transmission paths of odd stages and even states are connected and disconnected by a synchronization clutch (72a,72e); therefore, regardless of a number of a variable speed of a gearbox (18), only one jaw clutch (32) is provided; thus, a number of detectors for detecting rotation positions of the opposite jaw teeth forming the jaw clutch (32) cannot beincreased proportionally based on a variable speed number of the gearbox; and increase of part numbers can be prevented and multi-stage of the gearbox can be realized.

Owner:TOYOTA JIDOSHA KK +1

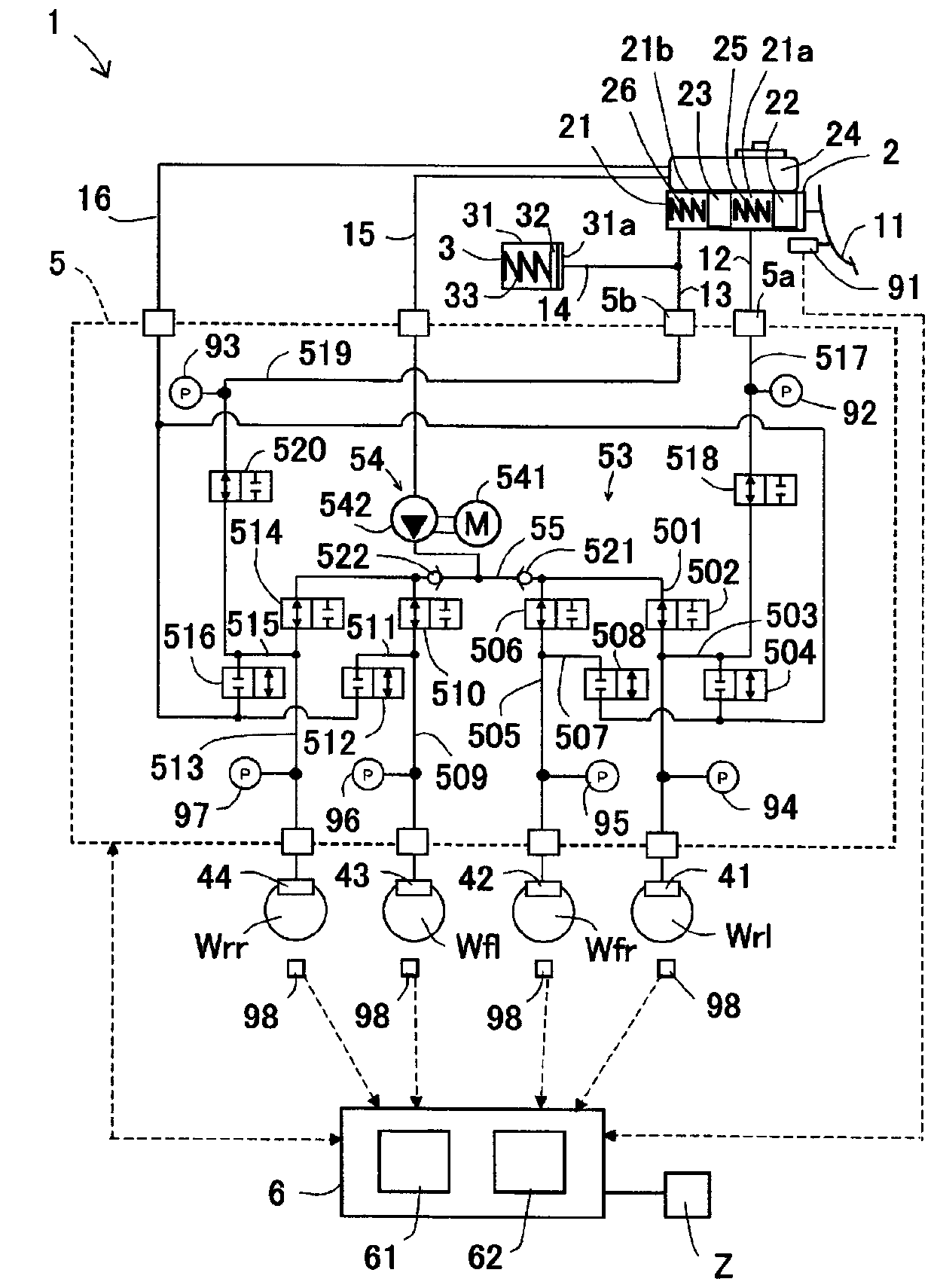

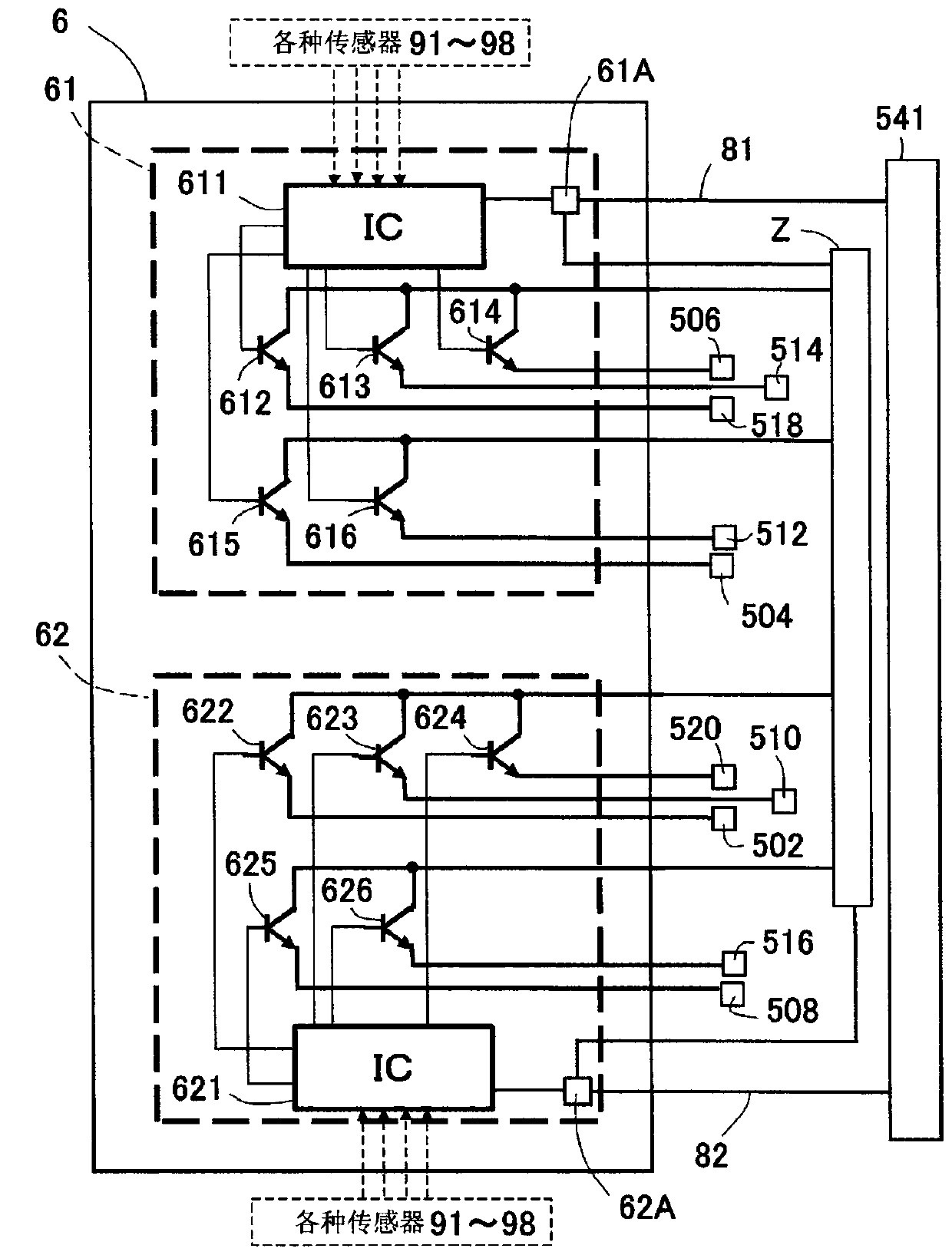

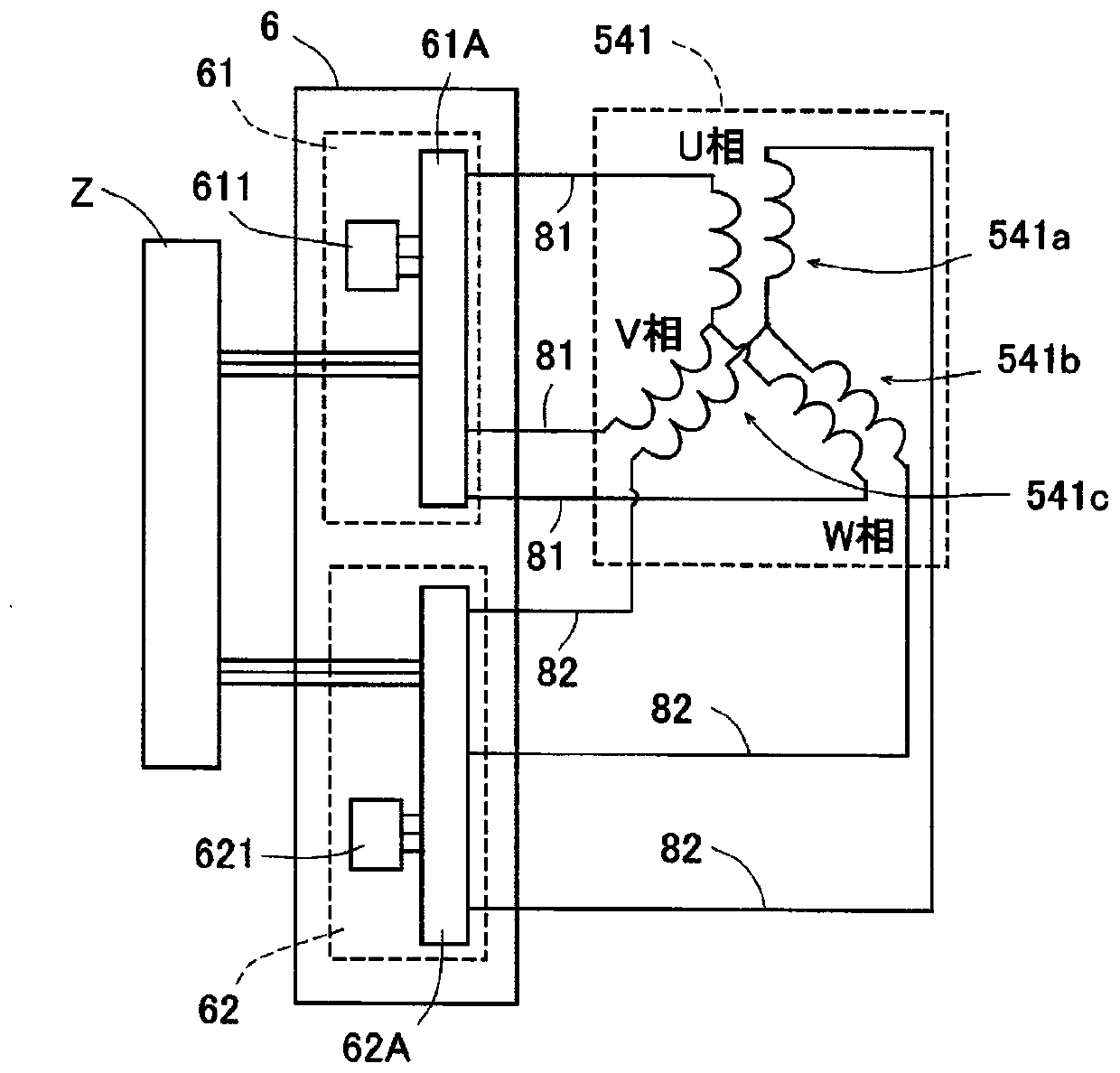

Vehicle braking device

ActiveCN110099825AIncrease the number of piecesIncreased fail-safetyBraking action transmissionBrake control systemsEngineeringVehicle brake

In the present invention, a hydraulic circuit (53) comprises: a first pressure-boosting flow path (501) that connects a first main flow path and a first wheel cylinder (41); a first pressure-boostingvalve (502) that is disposed in the first pressure-boosting flow path (501) and that opens in a non-energized state; a first pressure-reducing flow path (503) that connects the first wheel cylinder (41) and a reservoir (24); a first pressure-reducing valve (504) that is disposed in the first pressure-reducing flow path (503) and that closes in a non-energized state; a second pressure-boosting flowpath (505); a second pressure-boosting valve (506); a second pressure-reducing flow path (507); and a second pressure-reducing valve (508). A control unit (6) comprises: a first drive circuit (61) that controls the first pressure-reducing valve (504); and a second drive circuit (62) that is separate from the first drive circuit (61) and that controls the second pressure-reducing valve (508).

Owner:ADVICS CO LTD

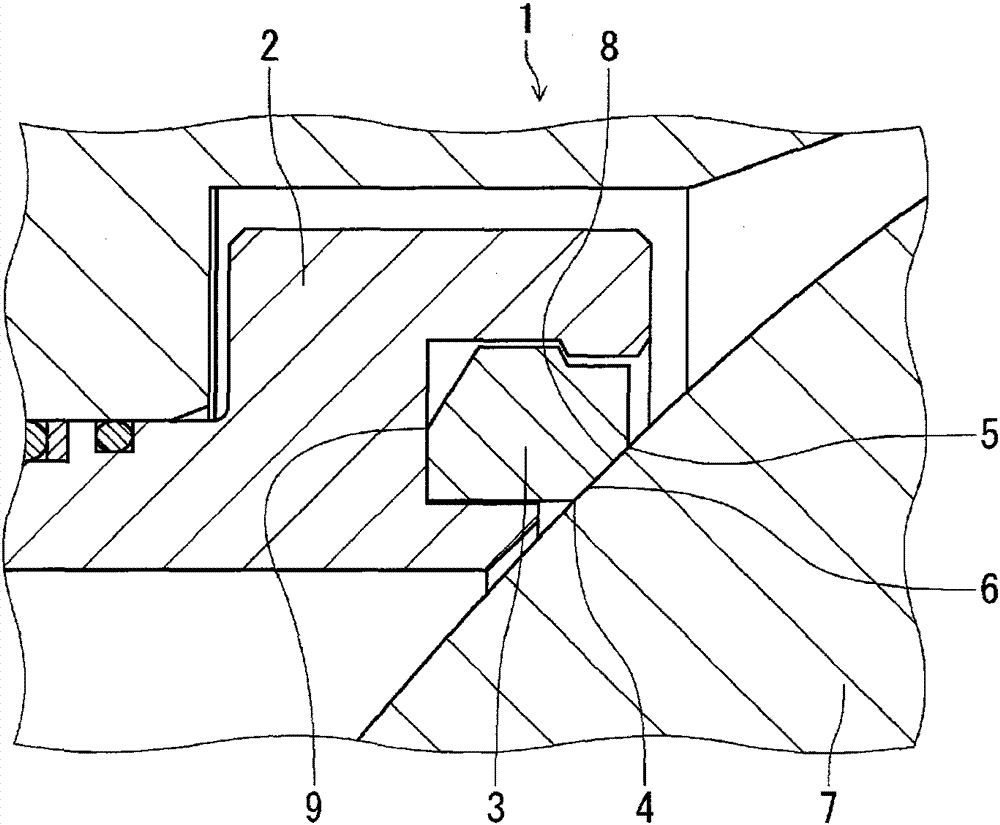

A method for manufacturing a separator plate for a fuel cell, a separator plate, and an intermediate product for a separator plate

ActiveCN110313091ALow costEasy to manufactureFinal product manufactureLayered productsFuel cellsPhysical chemistry

The invention relates to a method for manufacturing a separator plate (12) for a fuel cell, wherein a curable and electrically conductive material (20) is applied to a substrate material (14). A flowfield (34) for a reactant which can be supplied to the fuel cell is formed in the material (20). After the flow field (34) is formed, the material (20) is cured. The invention also relates to a separator plate (12) for a fuel cell and an intermediate product for a separator plate (12).

Owner:CELLCENTRIC GMBH & CO KG +1

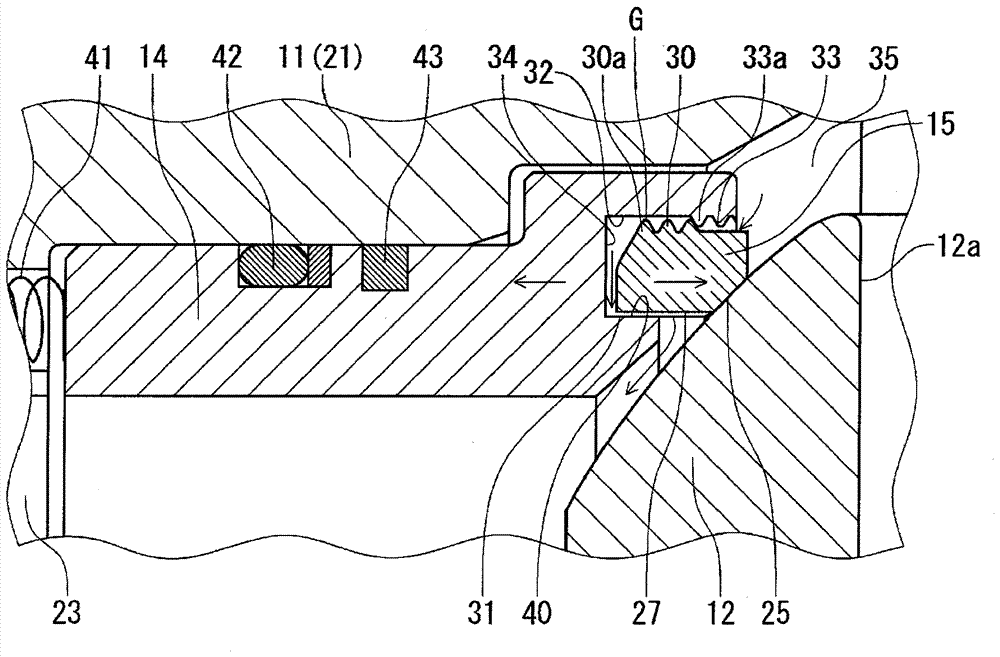

Trunnion-type ball valve

A seat retainer (14) fitted with a ball seat (15) is provided on one or both sides of a ball (12) having a through hole (12a) provided inside a body (11), the ball (12) is provided so as to be rotatable by a stem (13), and the ball seat (15) is prevented from flying out into a fitting groove (32) formed in the seat retainer (14), and is fitted in a free state. Excess pressure due to abnormal pressure increases in a cavity (35) when fully open or fully closed causes the seat retainer (14) to move in an opposite direction from the ball (12) due to a self-sealing force making use of this pressure, and excess pressure that has flowed to the rear surface side of the ball seat (15) inside the fitting groove (32) pushes the ball seat (15) toward the ball (12), and is relieved to a flow channel via a communication part (40) provided between the inner circumferential surface (27) of the ball seat (15) and the fitting groove (32).

Owner:KITZ CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com