Sandwich component and method for the production thereof

A sandwich structure and component technology, applied in the direction of upper structure, upper structure sub-assembly, chemical instruments and methods, etc., can solve the problems of high cost, unsuitable for auto parts processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

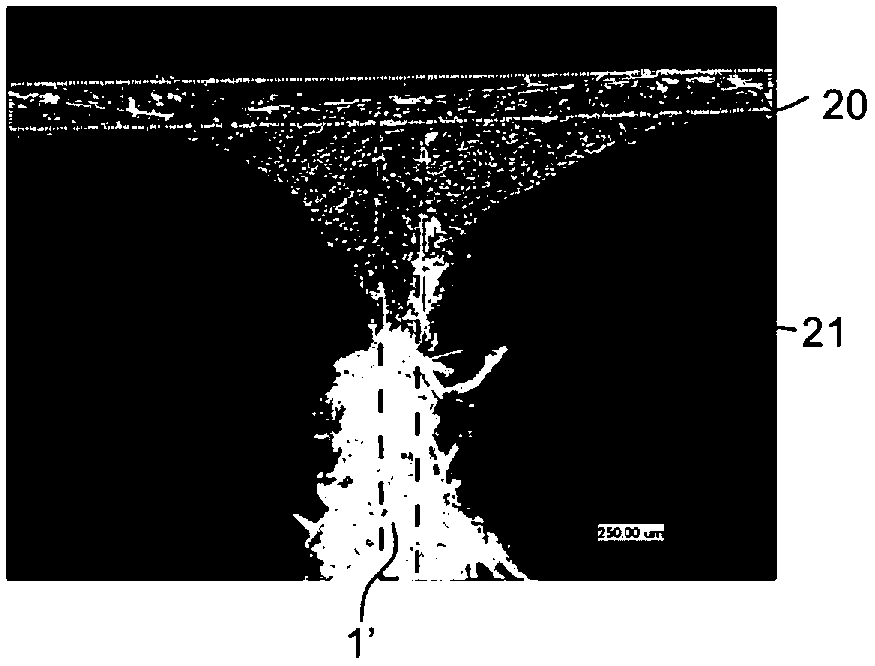

[0046] The sandwich structure according to the invention relates primarily to automotive components, which may be load-bearing components such as floor panels or rear seat backrests, but also to the production of trim parts, in particular for the interior of vehicles.

[0047] Suitable cellulosic materials for the honeycomb core include paper or paperboard.

[0048] The designation "honeycomb" is not intended to limit the structure of the honeycomb core, but includes any structure made of webs (Stegen, connecting plates) with low density and high compressive and shear strength. Suitable honeycomb core structures include hexagonal honeycomb structures, corrugated, circular, rhomboid, or rectangular folded structures, and irregularly formed, seemingly "organic" structures.

[0049] According to the present invention, fiber-reinforced thermoplastic materials are used to form cladding layers of sandwich structures used in the manufacture of automotive components, which offer a num...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com