A method for manufacturing a separator plate for a fuel cell, a separator plate, and an intermediate product for a separator plate

A technology of fuel cells and manufacturing methods, applied in the direction of fuel cells, layered products, final product manufacturing, etc., can solve the problems of fragile manufacturing, expensive bipolar plates, etc., and achieve long durability and long use The effect of high life and energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

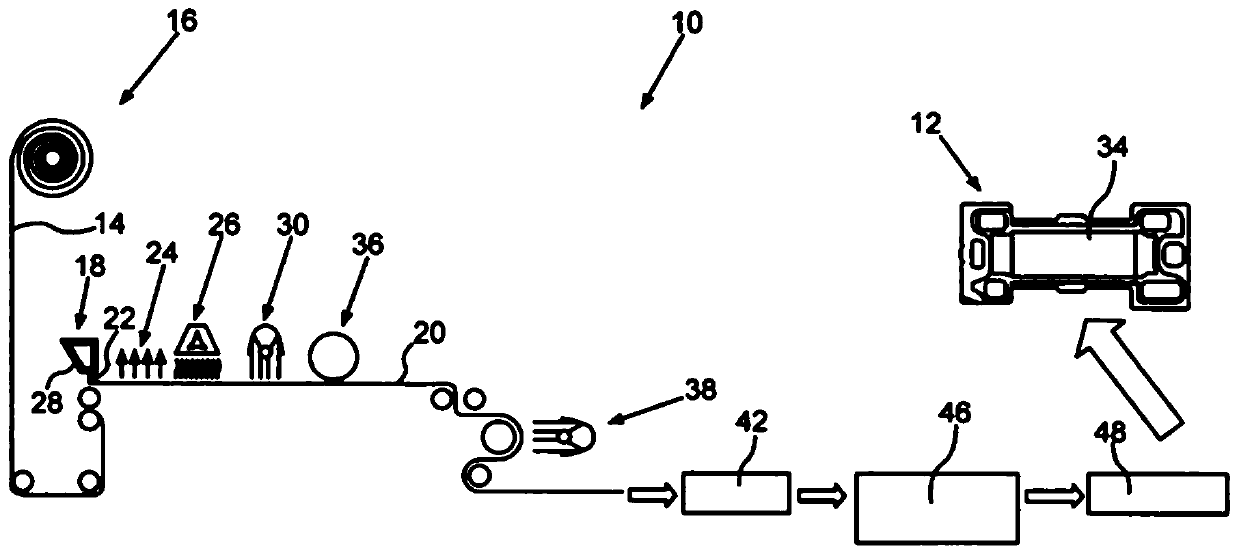

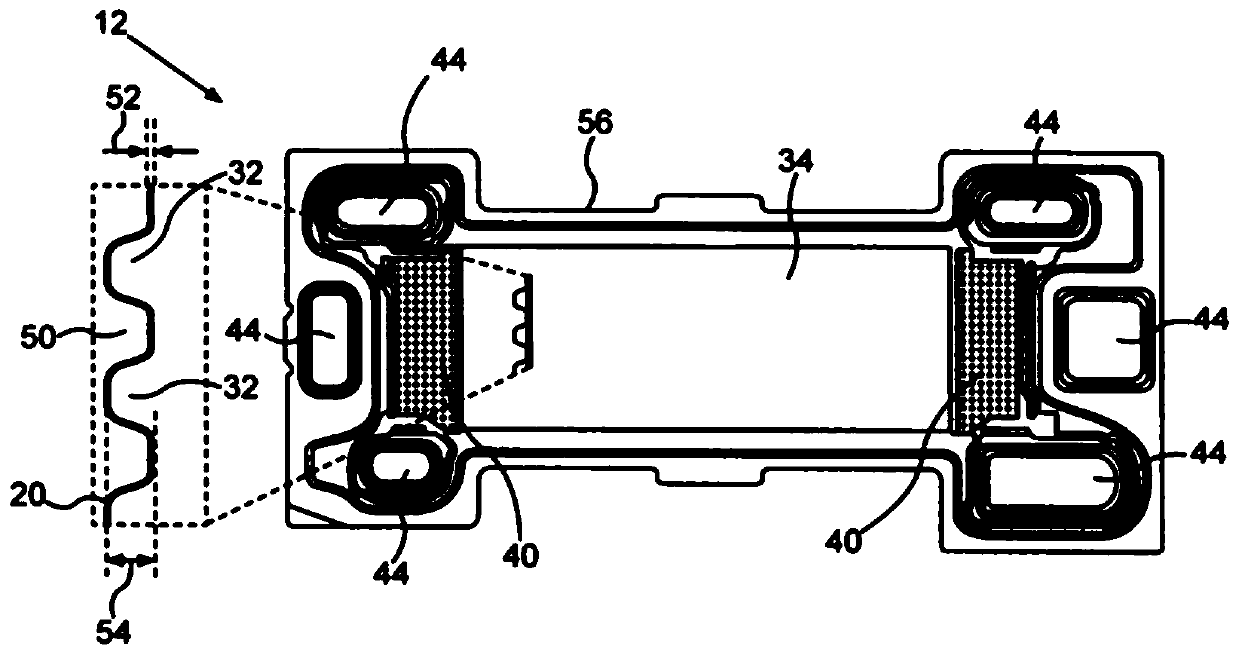

[0060] exist figure 1 The manufacturing equipment 10 schematically shown in is used to manufacture insulation panels, wherein, in figure 2 The separating plates of the bipolars in plan view are shown in the form of bipolar plates, which can be produced in the production plant 10 . The bipolar plates 12 are used for the fuel cells of a fuel cell stack, which may be used, for example, in motor vehicles.

[0061] When producing the bipolar plate 12 , first a carrier material is provided here in the form of a carrier film 14 . This can be a carrier film 14 wound on a roll 16 . In particular biaxially stretched or biaxially oriented polyester films can be used as carrier film 14 .

[0062] The carrier film 14 is unwound from the roll 16 and then fed to the further processing stations of the production plant 10 . A mixture 28 is applied to the carrier film 14 at the first processing station 18 , the mixture comprising the electrically conductive material 20 , wherein the materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| double bond equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com