Surface type repairing method of large-sized sapphire substrate wafer

The technology of a sapphire substrate and a repairing method is applied in the field of surface repair of large-size sapphire substrate wafers, and can solve the problems of small surface repair effect of wafers, reduced wafer warpage, long repair time, etc. Pit-in thickness, reduced warpage, reduced effect of repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for repairing the surface shape of a large-scale sapphire substrate wafer, the specific steps are as follows:

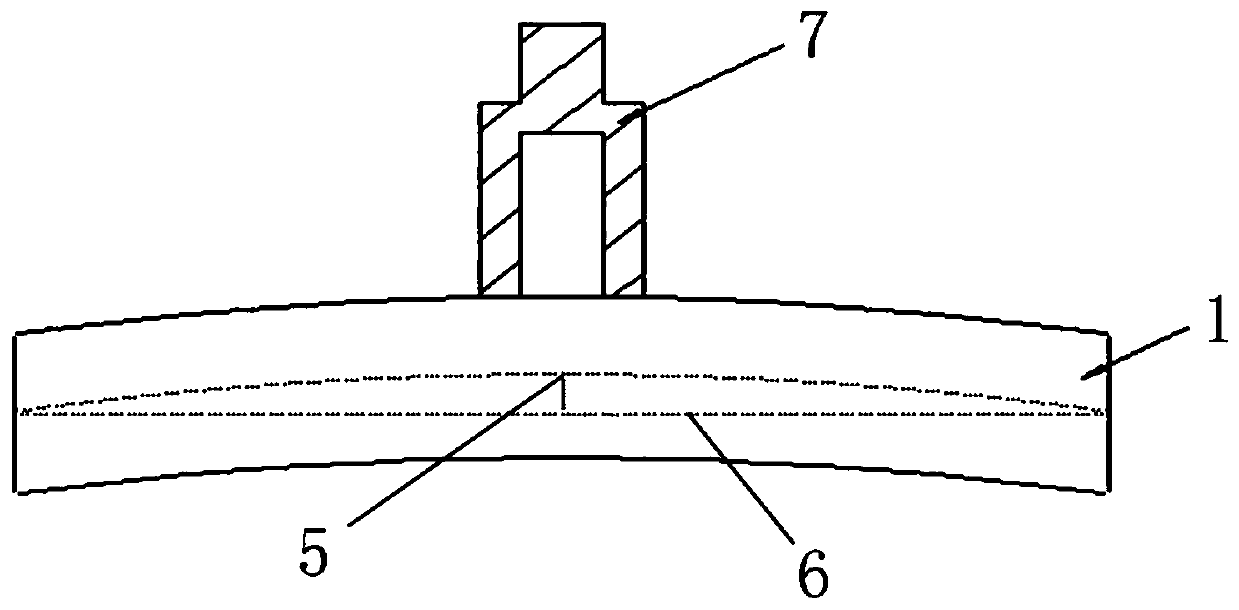

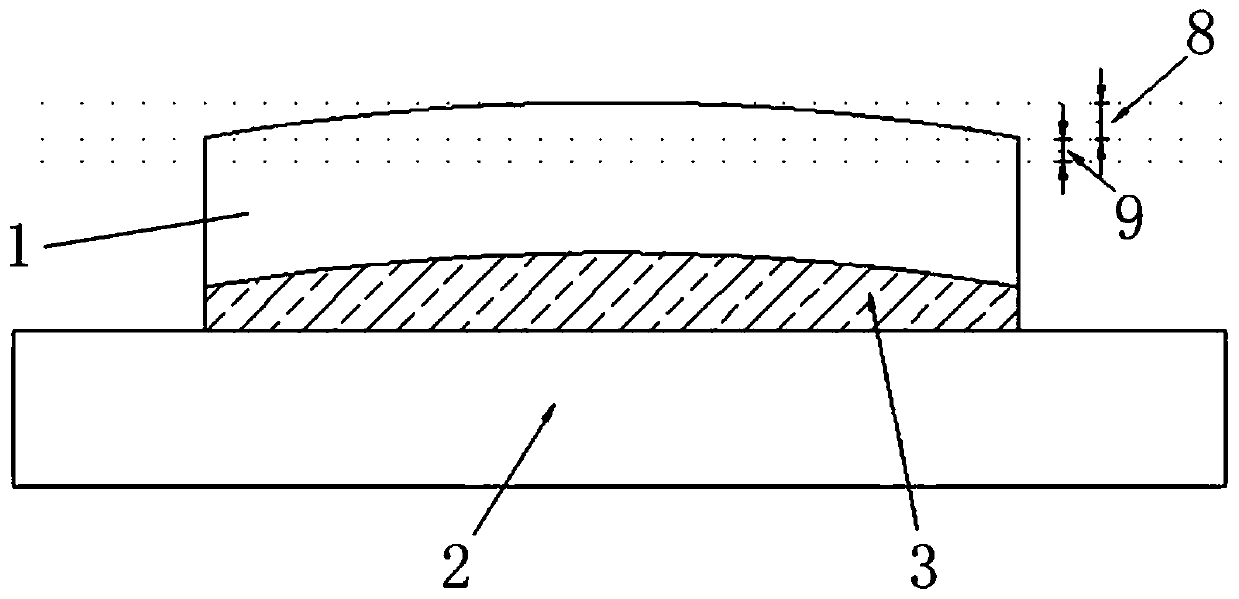

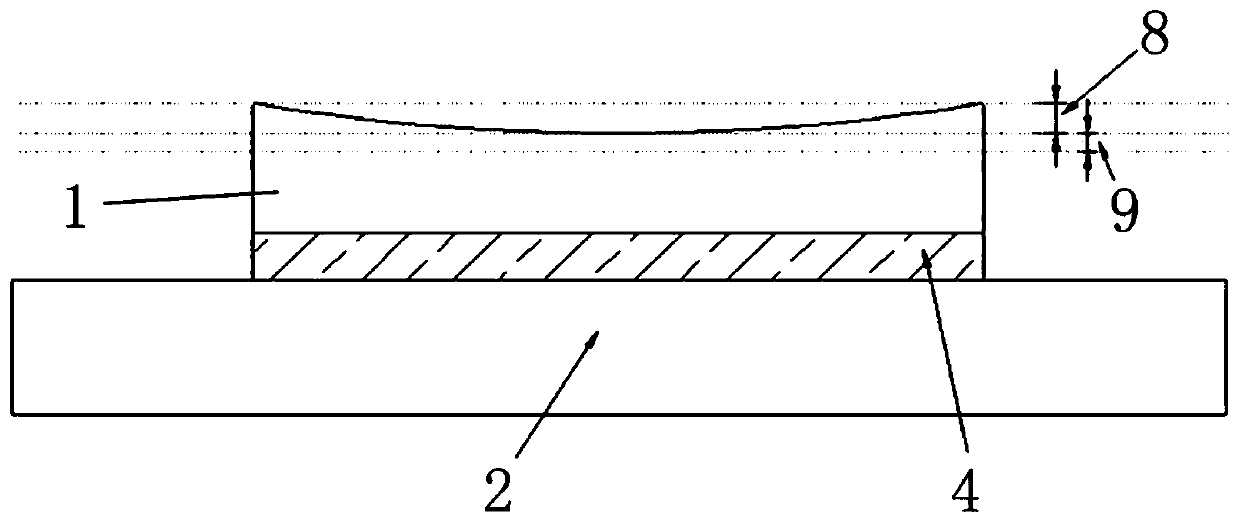

[0030] (1) Patch: such as figure 1 , 2 As shown, the vacuum adsorption device 7 is used to vacuum-adsorb the wafer 1 in an annular manner, and the adsorption area should not be too large, so as to avoid changing the surface shape of the wafer 1 . Apply UV glue 3 evenly on the unadsorbed side of the wafer 1 and lightly press it on the clean and flat ceramic disc 2. The pressure on the wafer must be less than 5kg, so as to avoid pressing the wafer under heavy pressure, which will affect the surface shape of the wafer. Restoration function: irradiate the surface of the wafer 1 with ultraviolet light for 10 seconds until the UV glue 3 is solidified, and then turn off the ultraviolet light.

[0031] (2) Single-sided grinding: place the chipped ceramic disc on a single-sided grinding machine, and use the configured boron carbide grinding liquid with a par...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com