Continuous forming device and working method for biaxially oriented polyvinyl chloride pipe

A polyvinyl chloride, biaxial orientation technology, applied in the field of plastic pipe extrusion molding tools, can solve the problem of affecting the performance of PVC-O pipes, poor control of the internal stress of the pipe blank cooling temperature, and difficulties in pipe blank control and wall thickness adjustment and other problems, to achieve the effect of simple structure, high practicability and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

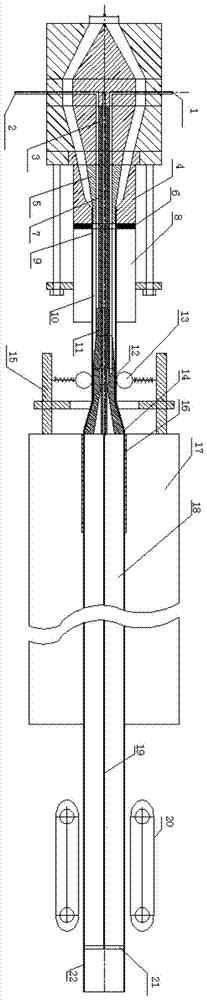

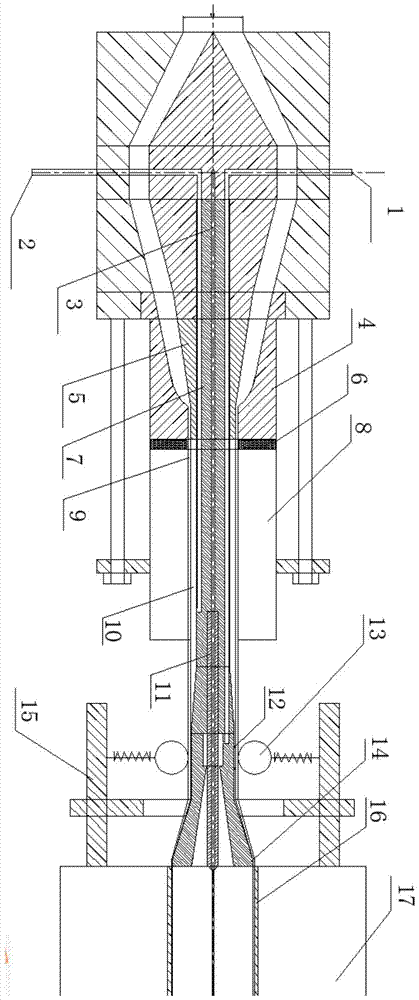

[0038] Such as Figure 1-2 shown.

[0039] A continuous molding device for biaxially oriented polyvinyl chloride pipes, comprising an outer mold 4, a mandrel 5, a tube blank 9 cooling system, and a bidirectional stretch forming system; the tube blank 9 cooling system includes a low-pressure air intake pipe 2, Guide column 7, isolation plate 6, adjustable temperature water immersion water tank 8 and sealing ring 12; the side wall of guide column 7 is provided with high-pressure air hole, low-pressure air hole and air bag air hole; low-pressure air inlet pipe 2 passes through mandrel 5 and communicates with low-pressure air hole ; The temperature-adjustable water-immersion water tank 8 is airtightly connected with the radial section of the outer mold 4 . The tube blank 9 is extruded from the outer mold 4 and the core mold 5 and enters the temperature-adjustable water-immersion water tank 8, and the water in the temperature-adjustable water-immersion water tank 8 contacts the tu...

Embodiment 2

[0044] The continuous forming device for biaxially oriented polyvinyl chloride pipes as described in Example 1 is different in that the left and right ends of the shaped cooling water tank 17 are respectively provided with a sizing sleeve 16 and a circular sealing gasket. The sizing sleeve 16 and the annular gasket are tightly sealed with the outer wall of the pipe to play a sealing role.

[0045] The sealed air bag 21 is stretched by the air bag pull rod 19 and transmits the air pressure. The length of the air bag pull rod 19 should enable the sealed air bag 21 to be placed behind the tractor 20, so that the lumen maintains the air pressure when the pipe passes through the tractor 20, so as to improve the supporting force of the pipe and improve the air pressure. Stability and reliability in the continuous production of pipes.

Embodiment 3

[0047] The continuous molding device for biaxially oriented polyvinyl chloride pipes as described in Embodiment 1, the difference is that the device also includes a pressure roller support frame 15; The rotation plane is the vertical direction; two pressure rollers 13 are arranged on the pressure roller support frame 15 connected by threaded screw rods. The pressure roller support frame 15 can be rotated and adjusted by 360°. According to the wall thickness deviation of the formed pipe, the tightness of the pressure roller 13 at the corresponding position and the position of the pressure roller can be adjusted through the threaded screw; the pressure roller 13 is made of hard plastic with a smooth and flat surface .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com