Dual-breakpoint moving contact system of moulded-case circuit breaker

A molded case circuit breaker and moving contact technology, which is applied in the direction of circuit breaker contacts and circuit breaker components, can solve the problems of limited contact bridge thickness, limited power supply capacity, and inability to apply molded case circuit breakers, so as to improve work efficiency. The effect of increasing the current value and current-carrying area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with accompanying drawing.

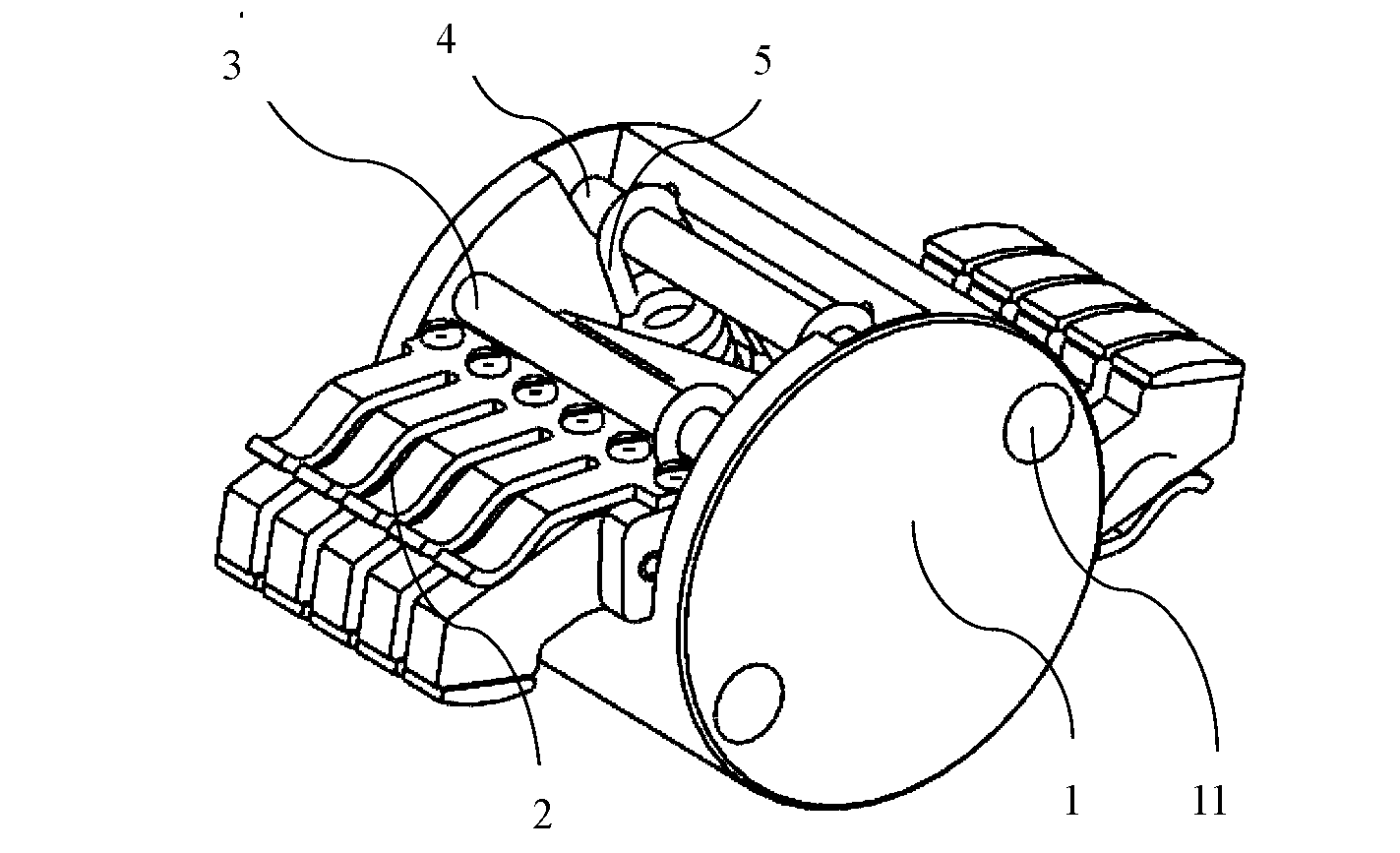

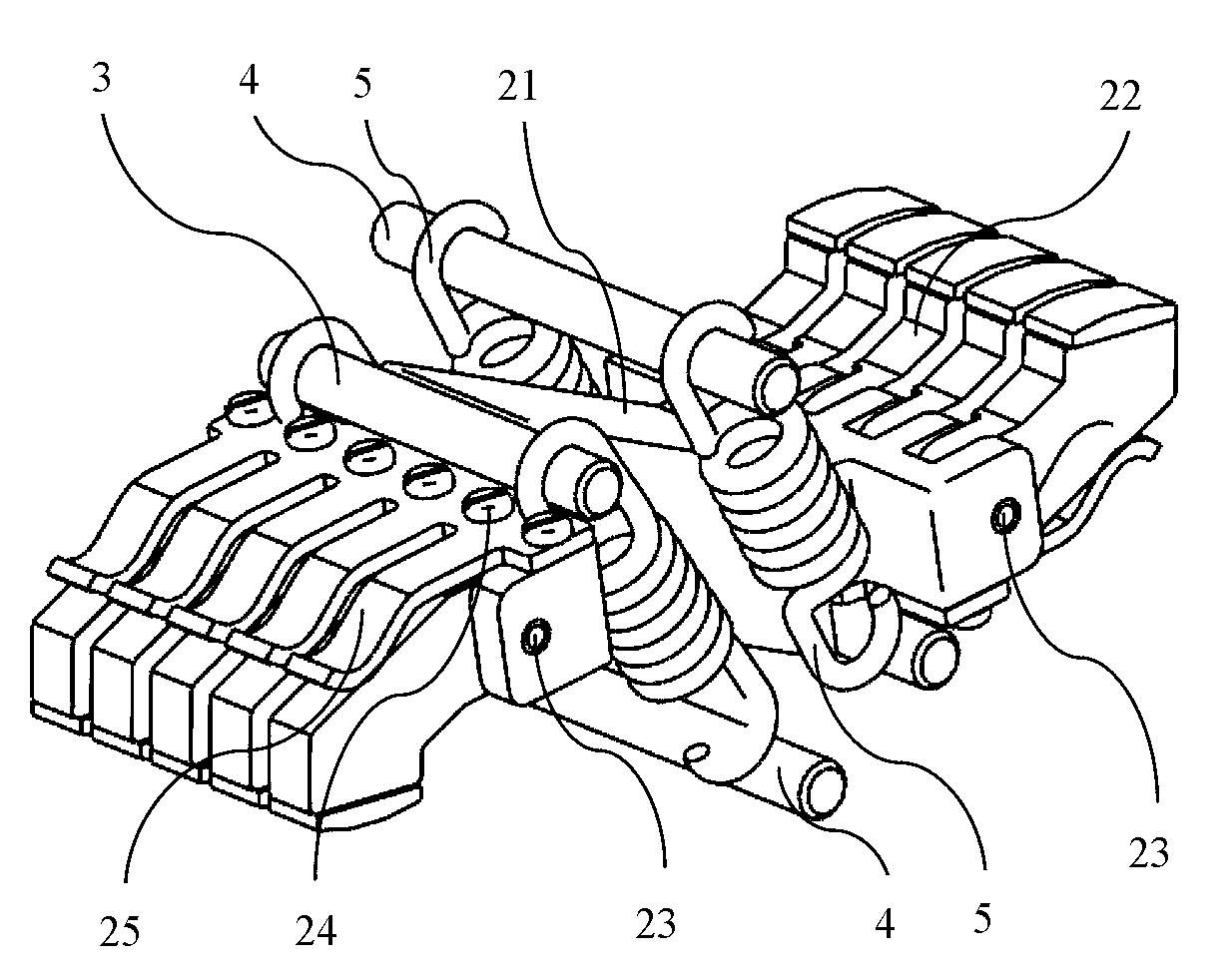

[0023] figure 1 The multi-piece double break point rotary moving contact system shown includes a rotating shaft 1, a moving contact assembly 2, a spring shaft 3, 4, a shaft 23, a spring 5, a leaf spring 25, and a compression spring 26.

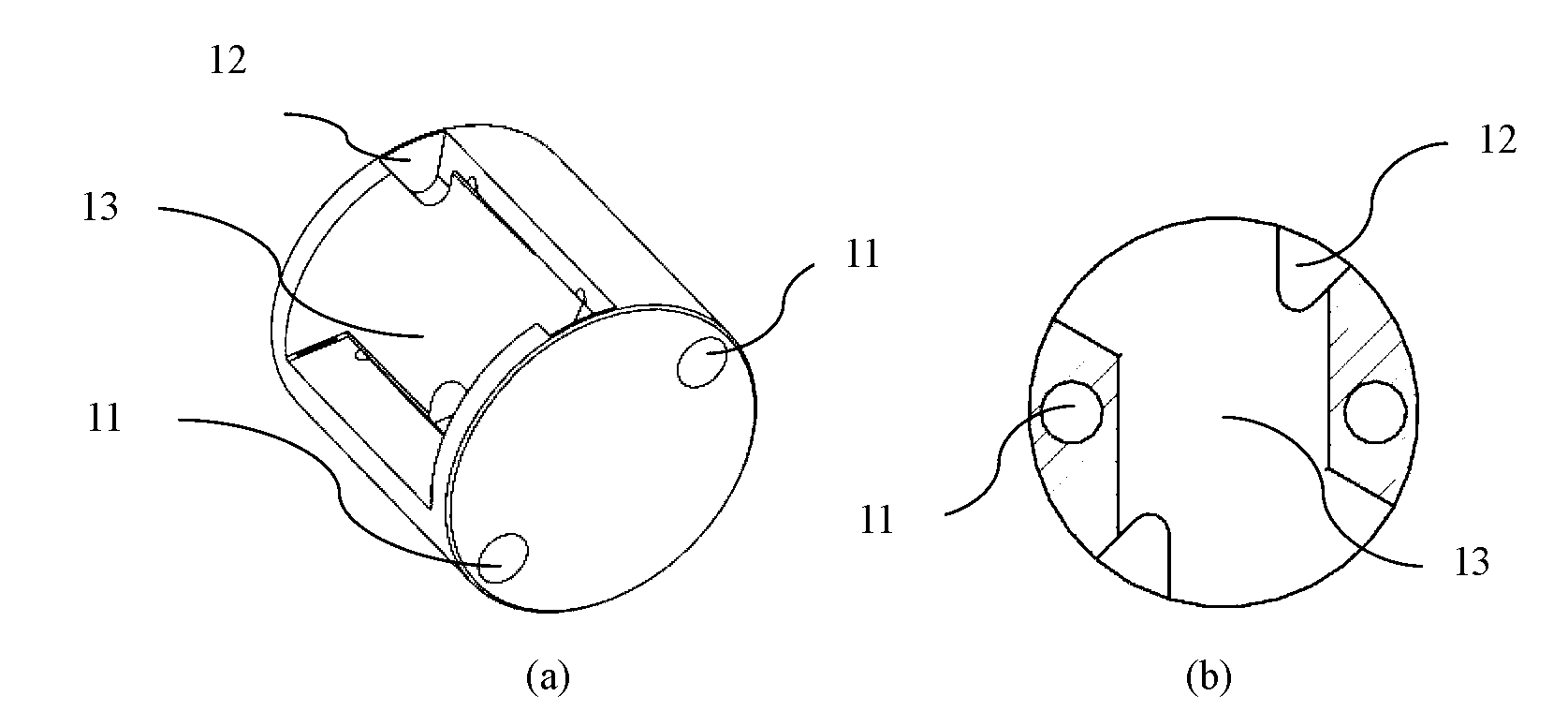

[0024] The rotating shaft 1 is cylindrical, and there are two through holes 11 symmetrically about the center for the shaft to pass through. The rotating shaft 1 is provided with a through groove 13 for placing the moving contact assembly 2, and the inner side wall is slotted 12 for hanging the spring shaft 4.

[0025] The moving contact assembly 2 includes a rotating member 21 , a moving contact piece 22 , a shaft 23 , a leaf spring 25 , a compression spring 26 and a fastening screw 24 .

[0026] The moving contact system has a tension spring 5, a leaf spring 25 and a compression spring 26, wherein the tension spring 5 provides the initia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com