Webbing winding device

A technology for a winding device and a seat belt, which is applied to the seat belt in the car, combined with an energy-absorbing device, a belt tensioner, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

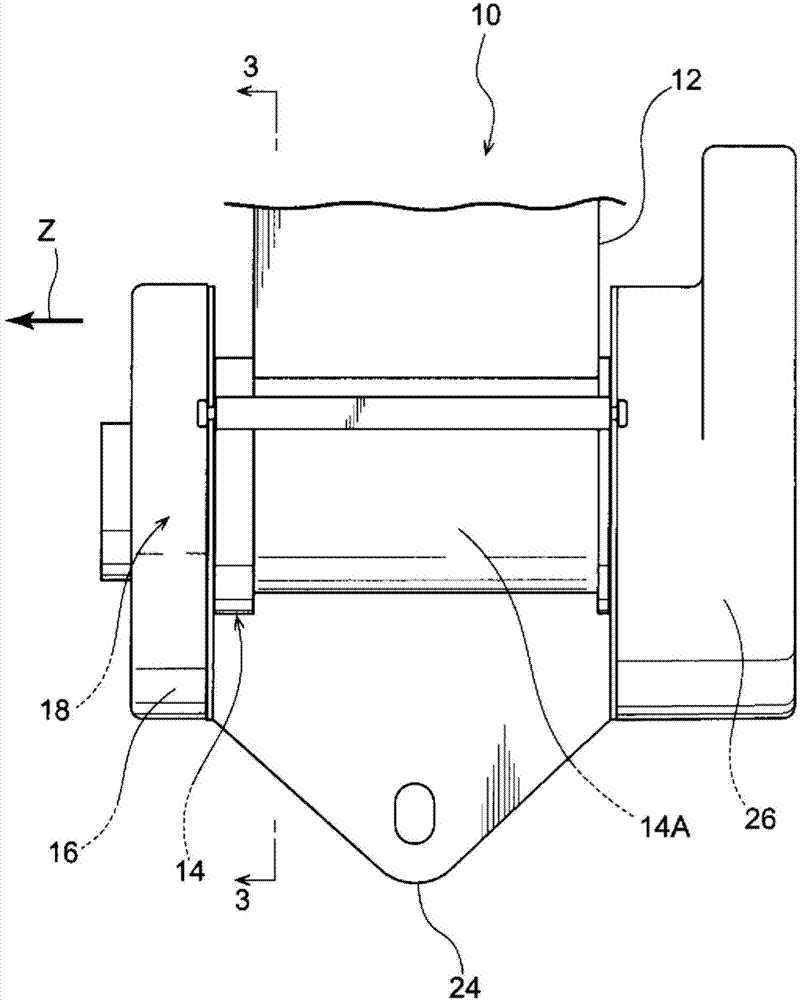

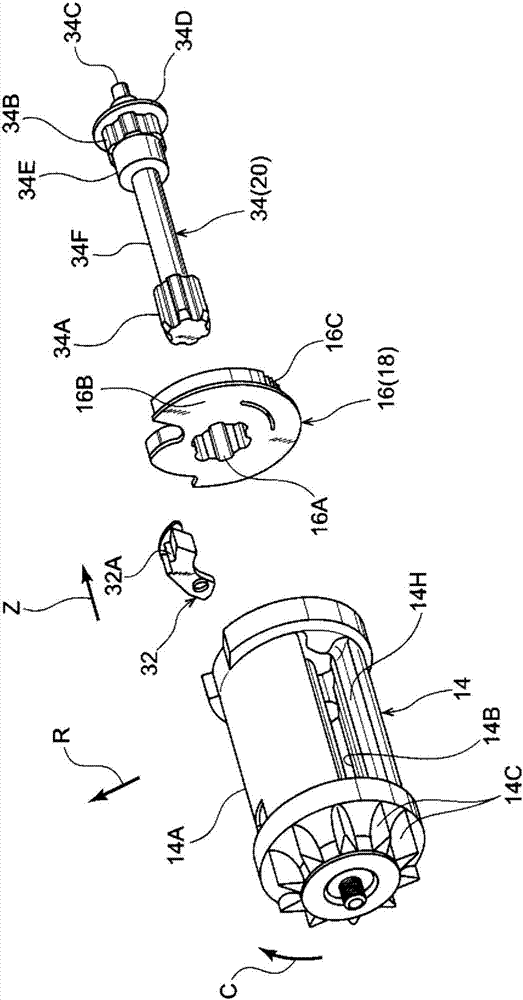

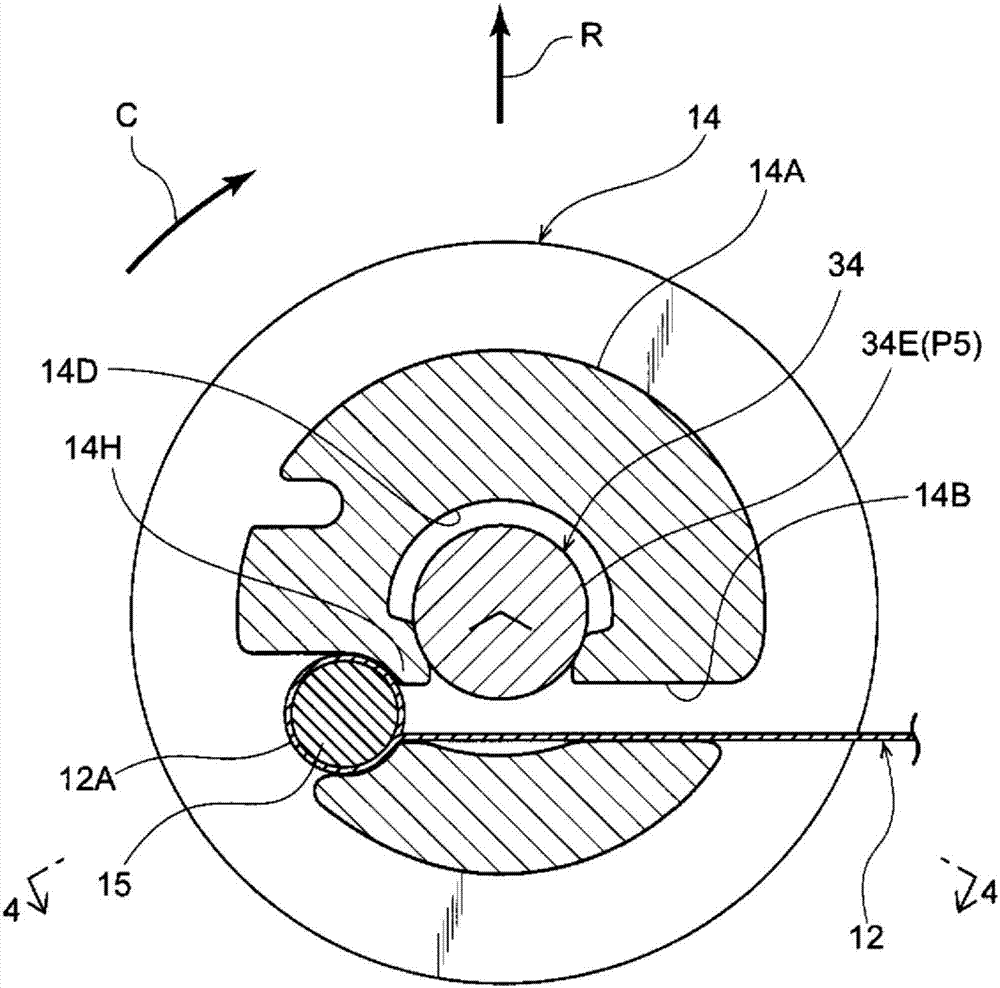

[0016] use Figure 1 ~ Figure 4 The seat belt take-up device according to the embodiment of the present invention will be described. In addition, the arrow Z direction, the arrow R direction, and the arrow C direction appropriately shown in the figure indicate the axial direction, radial direction, and circumferential direction of the tape shaft, respectively. In addition, in the following, when only the axial direction, radial direction, and circumferential direction are shown, unless otherwise specified, the axial direction, radial direction, and circumferential direction of the tape shaft are indicated.

[0017] like figure 1 as well as figure 2 As shown, the seat belt winding device 10 of the present embodiment includes: a belt shaft 14 around which the seat belt 12 to be worn by a passenger is wound, and rotates in the pulling direction when the seat belt 12 is pulled out; and a locking mechanism 18 , which has a locking portion 16 that is configured to be rotatable i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com