Oil-free chain

一种油链、套筒的技术,应用在传动链、输送机、运输和包装等方向,能够解决增加表面精加工加工负担、弯曲阻力变大、组装工时数多等问题,达到避免件数的增加、防止滑动接触磨损、防止链磨损的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0041] Hereinafter, an oil-free chain 100 as a first embodiment of the present invention will be described based on the drawings.

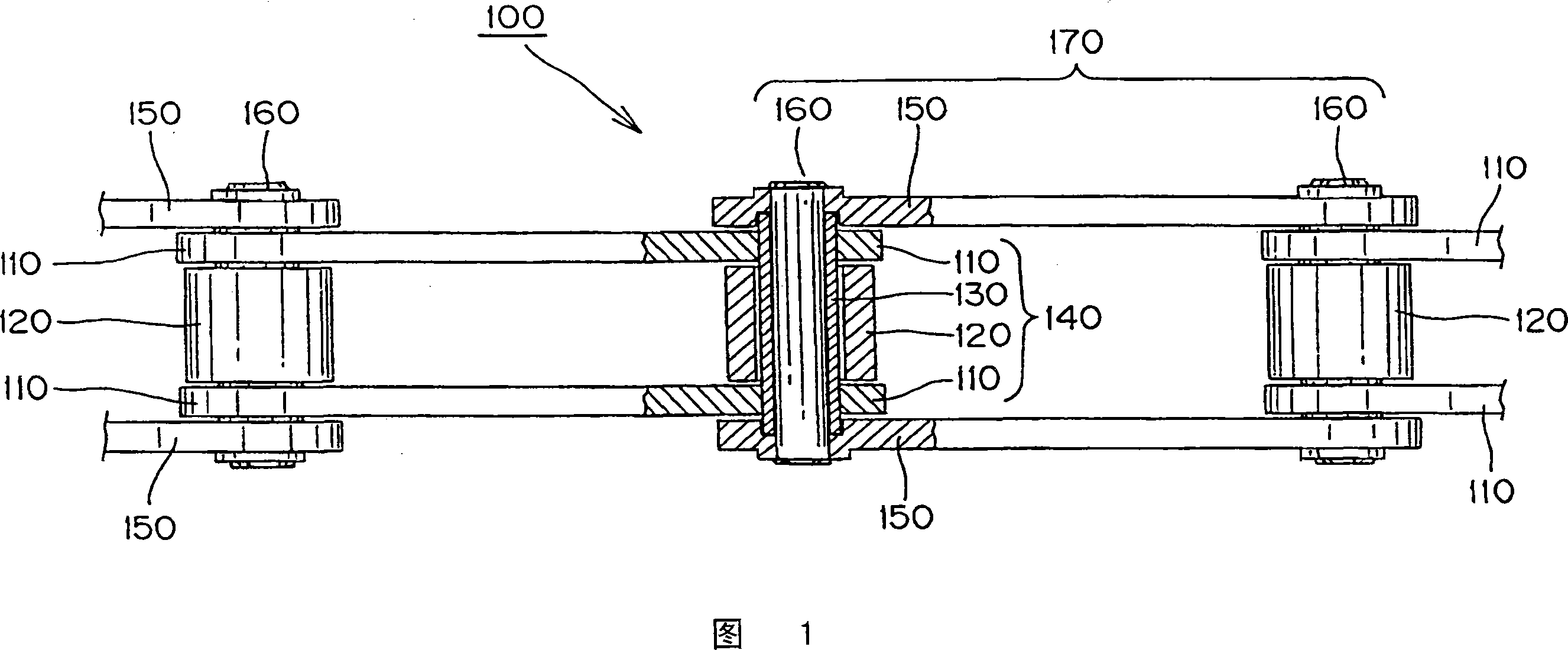

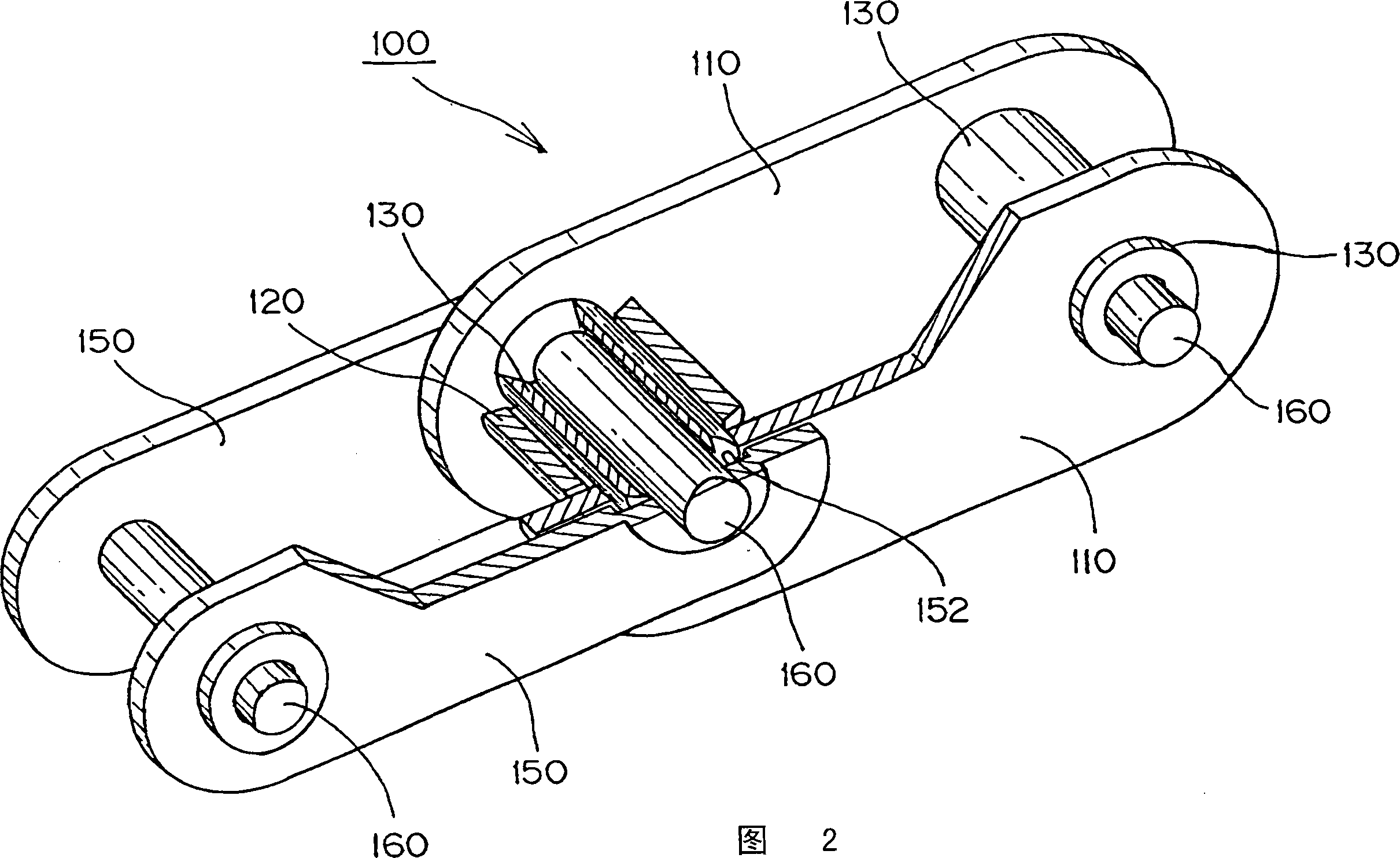

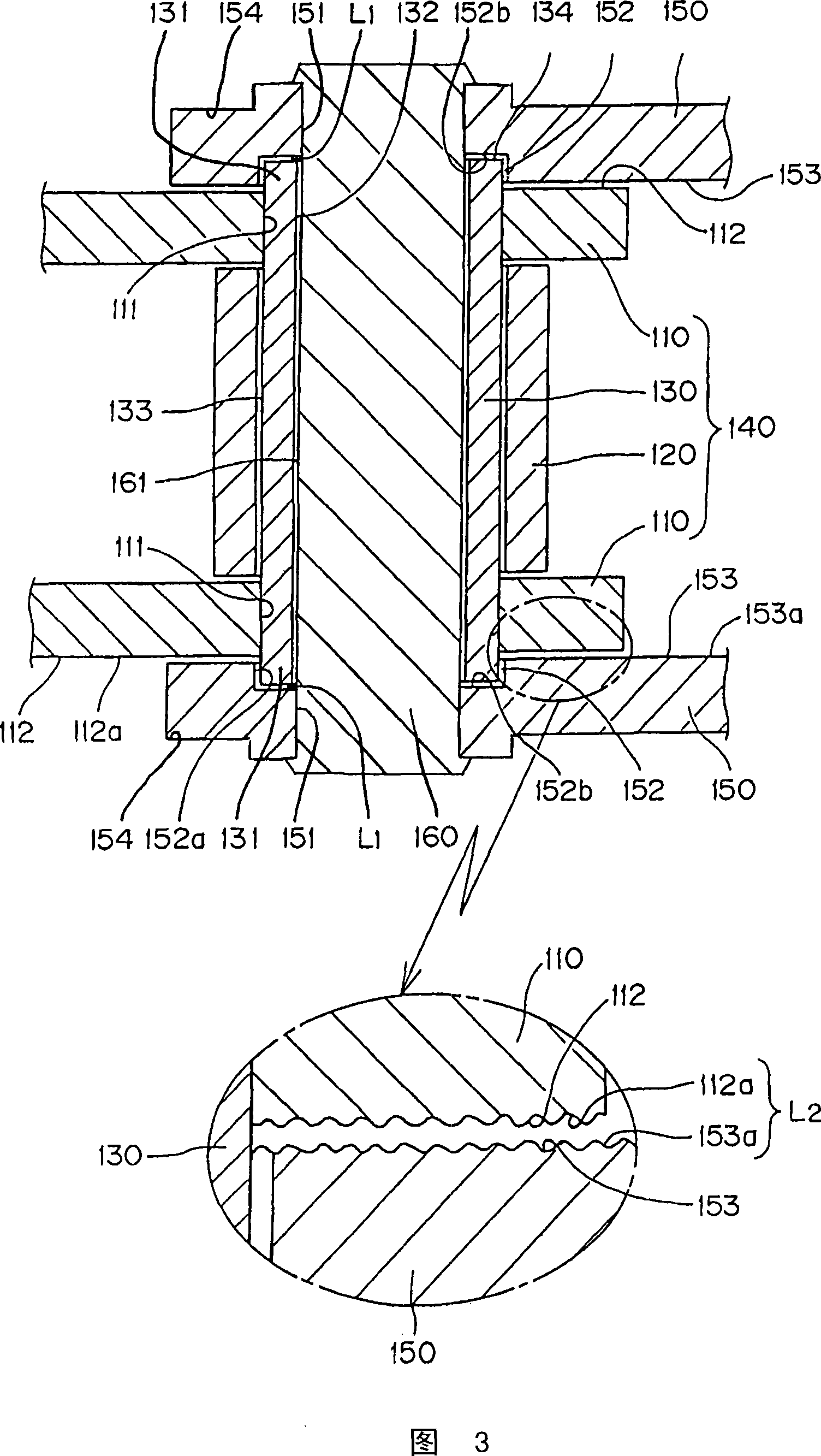

[0042] Here, FIG. 1 is an overall schematic view showing a part of the oil-free chain as a first embodiment of the present invention, FIG. 2 is a perspective view showing a connected state of the oil-free chain shown in FIG. 1 , and FIG. 3 is a The sectional view of the oil-free chain shown in Fig. 1 is enlarged and observed. Fig. 4 is an assembly dimension drawing of the oil-free chain shown in Fig. 1. Fig. 5 shows that the oil-free chain shown in Fig. 1 is moved in the direction of chain travel A dimensional view of a stretched state. FIG. 6 is a dimensional view showing a state in which the oil-free chain of FIG. 1 is deflected in the chain width direction.

[0043] First, as shown in FIGS. 1 and 3 , the oil-free chain 100 according to the first embodiment of the present invention includes a pair of front and rear sleeves 130 , 130 in which bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com