Technology for cutting semiconductor silicon wafer by diamond wire

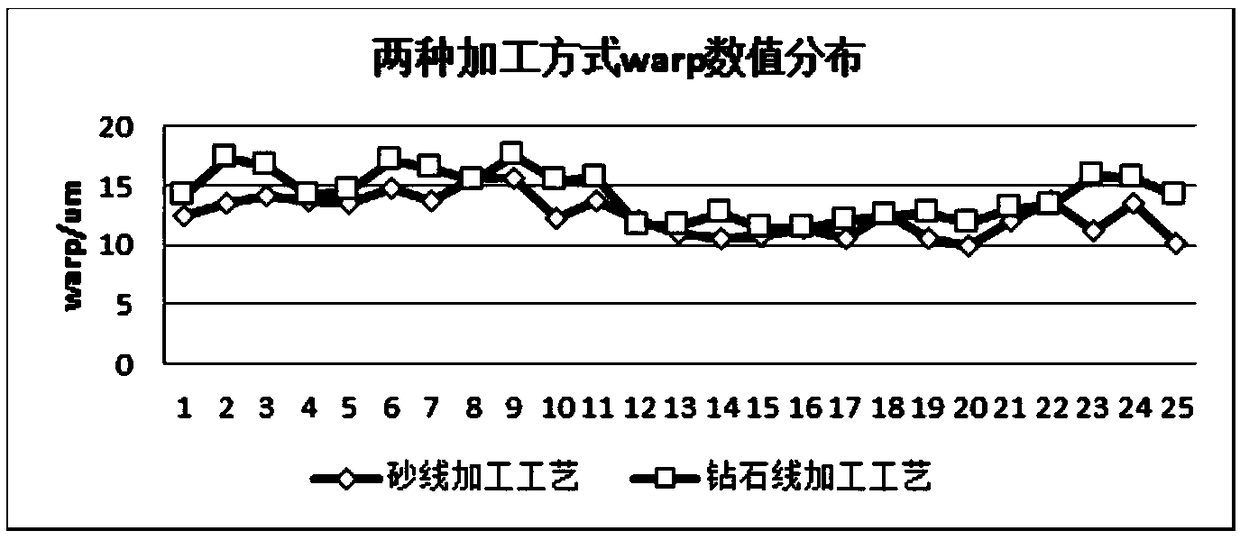

A diamond wire and semiconductor technology, applied in the field of semiconductor manufacturing, can solve the problems of high cost and low production capacity, and achieve the effect of expanding production capacity, fast cutting speed, and increasing the number of chips produced.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Unless otherwise defined, the technical terms used in the following embodiments have the same meaning as commonly understood by those skilled in the art to which the present invention belongs. The test reagents used in the following examples, unless otherwise specified, are conventional biochemical reagents; the experimental methods, unless otherwise specified, are conventional methods.

[0036] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

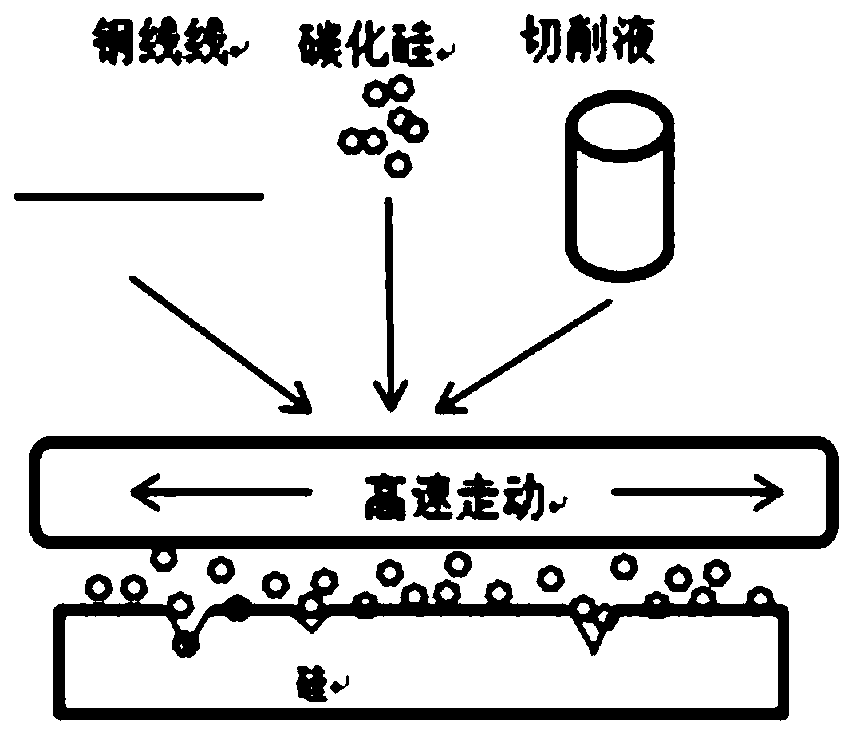

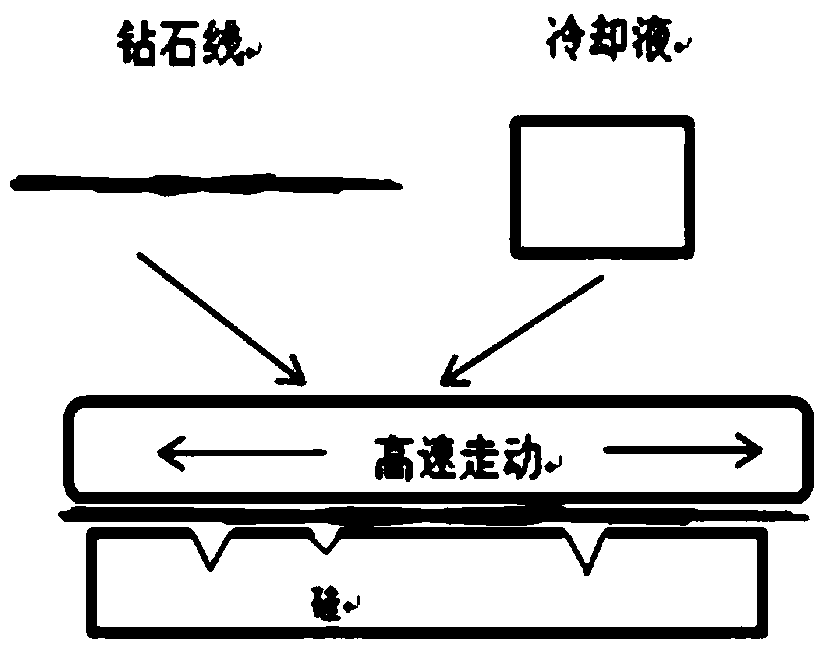

[0037] A process for diamond wire cutting semiconductor silicon wafers, the specific process flow is as follows:

[0038] (1) Take a 6-inch semiconductor silicon single crystal (the single crystal is cylindrical, about 650mm in length, and 150.7mm in diameter) and wipe the surface with absolute ethanol, and take Japanese sticky glue (curing agent A and adhesive The ratio of glue B is 2:1) stick the single crystal to the resin board, and then stick the resin b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| warpage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com