Planar metal micro-needle array and preparation method thereof

A microneedle array and planar technology, applied in the field of medical devices, can solve problems such as difficulty in mass production, low processing precision, and low processing efficiency, and achieve the effects of flexible use, improved efficiency, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solution of the present invention will be described in detail below with reference to the accompanying drawings. The embodiments of the present invention are only used to illustrate and explain the technical solutions of the present invention, not to limit them. Although the present invention has been described in detail with reference to the preferred embodiments, those of ordinary skill in the art should understand that the technical solutions of the invention can be modified or modified. Equivalent replacements without departing from the spirit and scope of the technical solution of the present invention should be covered in the scope of the claims of the present invention.

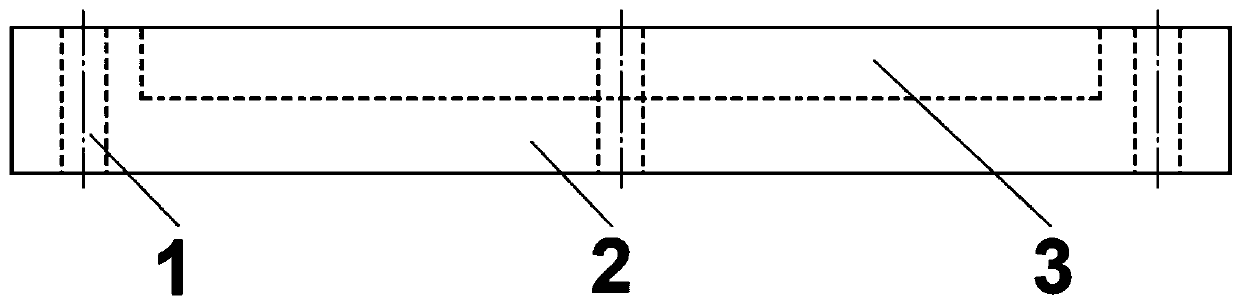

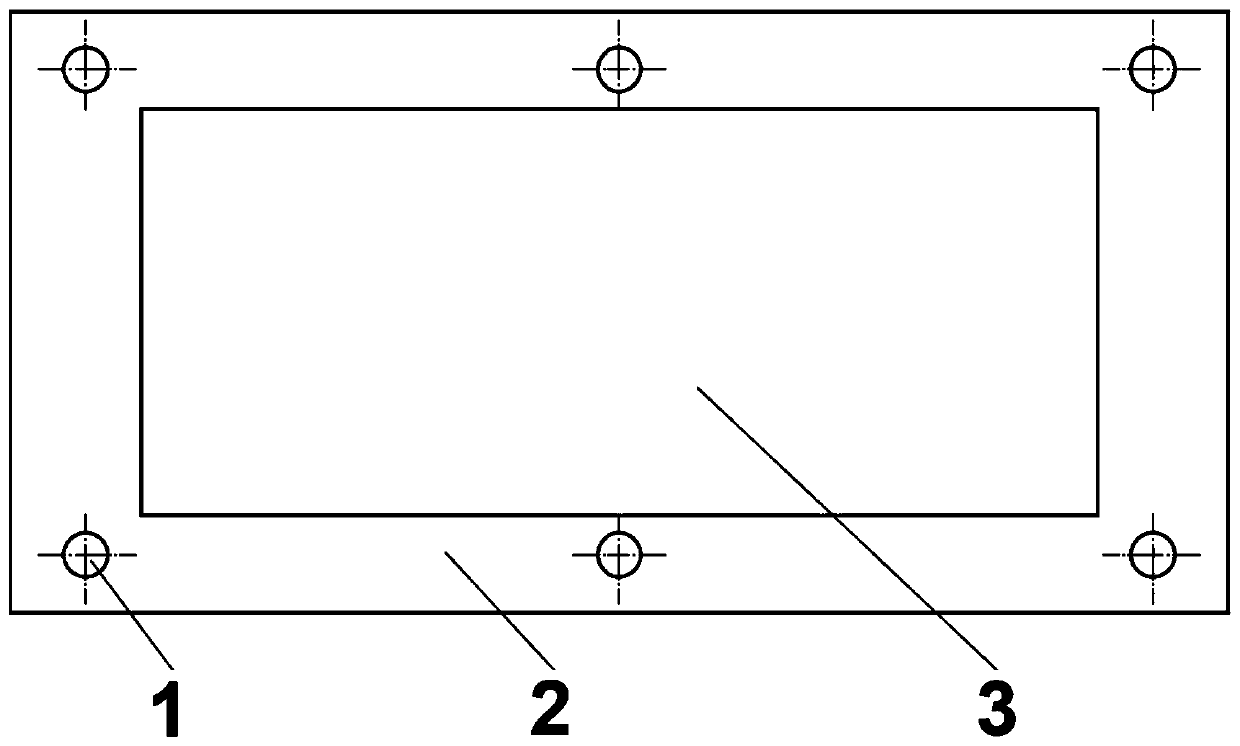

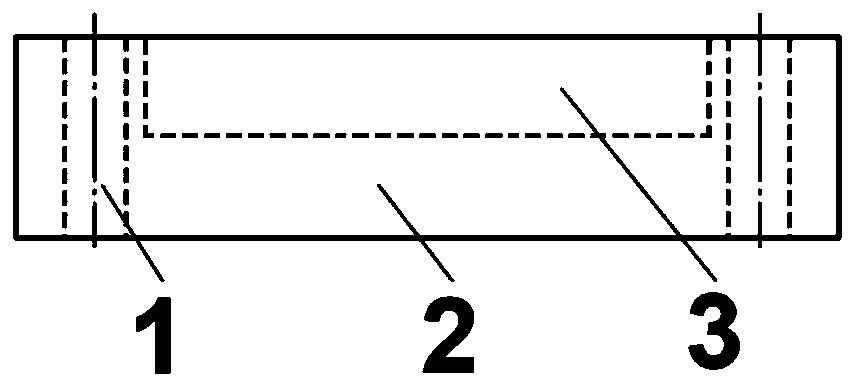

[0033] S1: The microneedle material is a medical 304 stainless steel sheet material with good biocompatibility, strength and toughness. The size of the sheet shown is 1000 mm in length, 100 mm in width, and 80 microns in thickness. The large-size stainless steel sheet is cut into smal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com