Optical device and camera device

A technology for optical devices and optical components, applied in the directions of optics, optical components, installation, etc., can solve the problems of increasing the number of components, increasing the manufacturing cost of lens barrels, etc., and achieve the effect of preventing movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

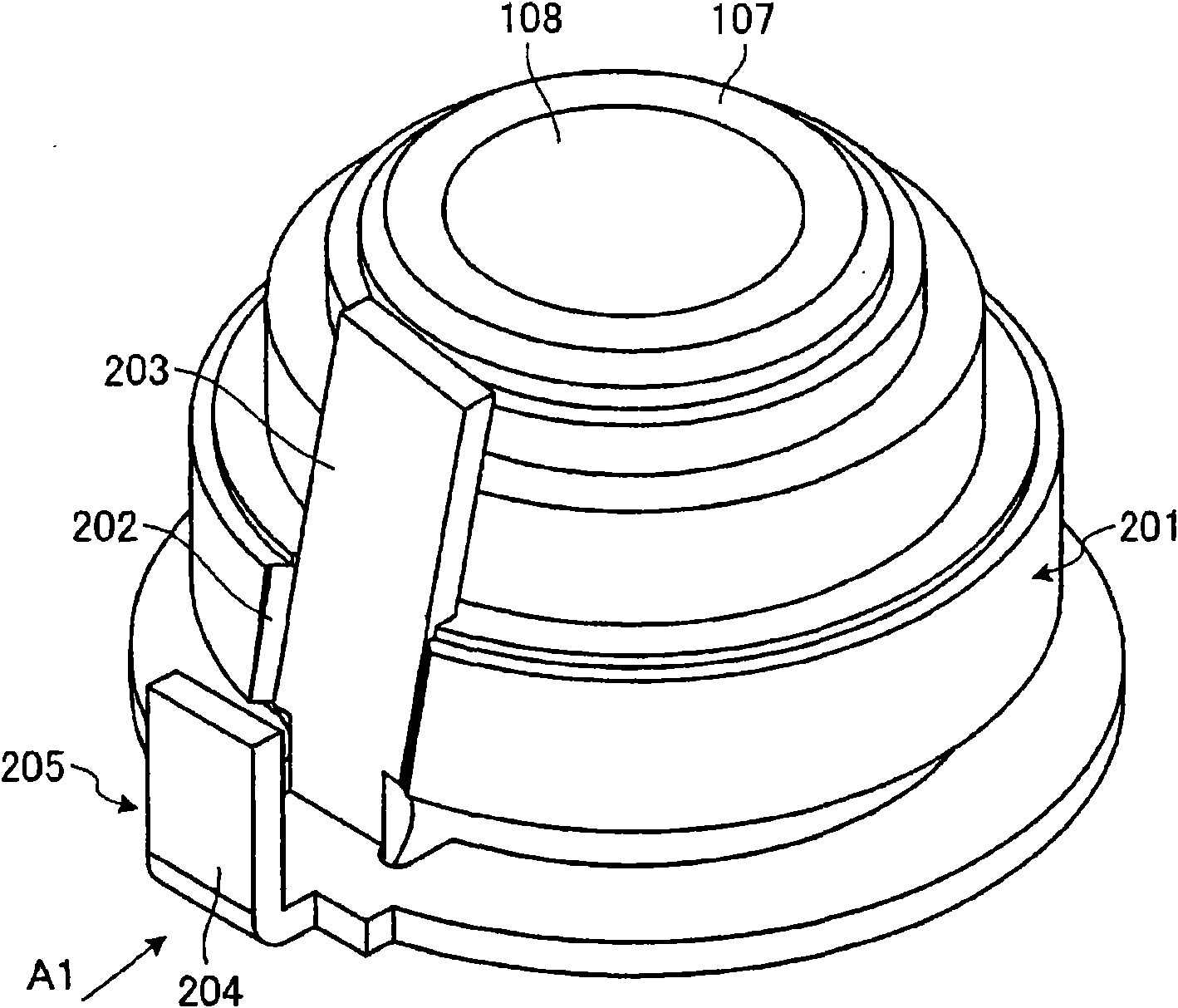

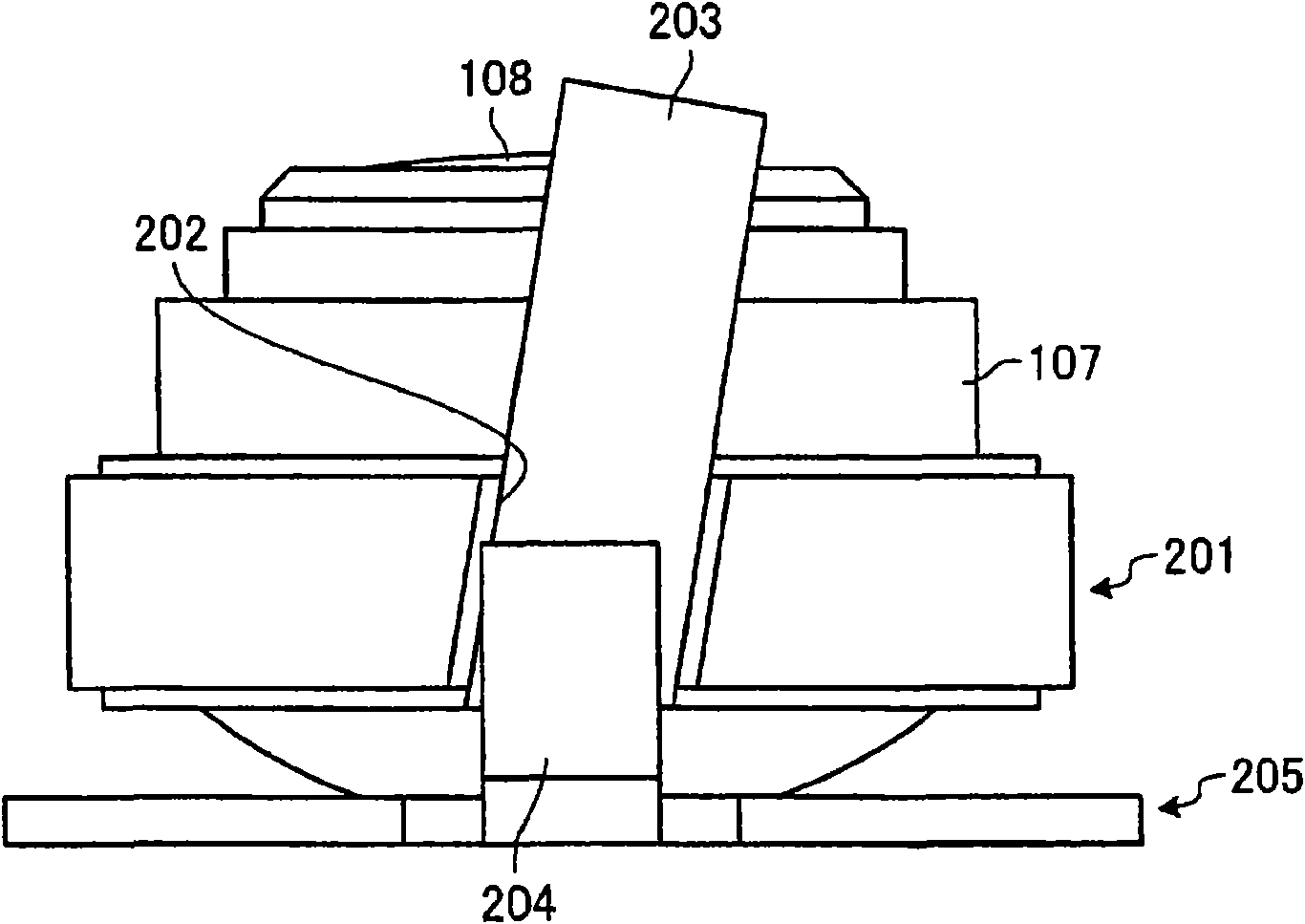

[0033] Preferred embodiments of the optical device and the imaging device of the present invention will be described in detail below with reference to the drawings. In this embodiment, as an example of the optical device according to the embodiment of the present invention, an application example applied to a lens device mounted on an imaging device is shown.

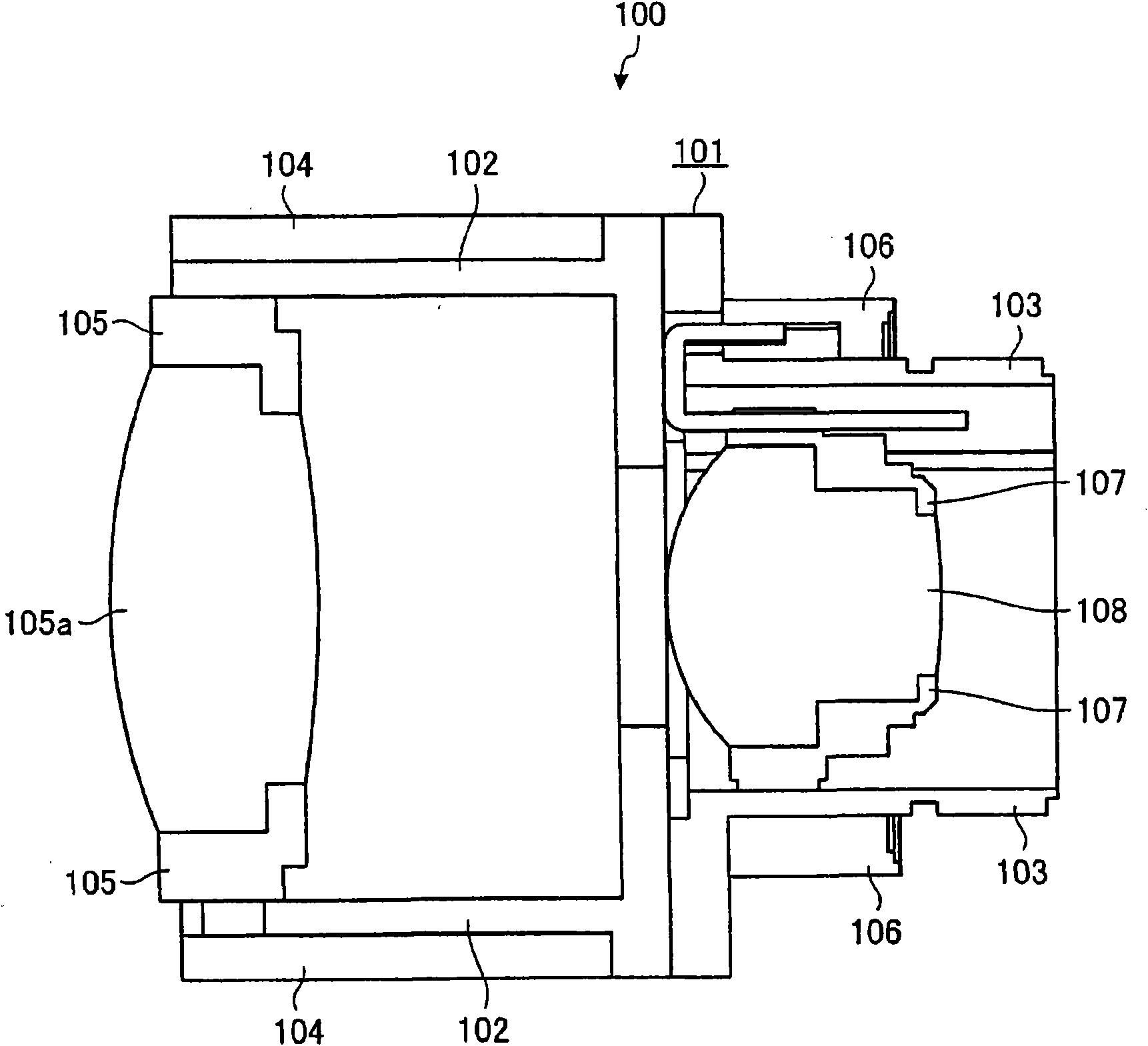

[0034] First, a lens device according to an embodiment of the present invention will be described. figure 1 It is an explanatory diagram showing a lens device according to an embodiment of the present invention. exist figure 1 In , a cross section of the lens device according to the embodiment of the present invention is shown on a plane passing through the optical axis. exist figure 1 Among them, the lens device 100 according to the embodiment of the present invention includes a lens barrel body 101 having a substantially cylindrical shape.

[0035] The lens barrel body 101 is composed of a main lens barrel 102 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com