CNC multi-plate production technology for capacitive touch screen glass cover plates

A capacitive touch screen and glass cover technology, applied in manufacturing tools, metal processing equipment, machine tools suitable for grinding workpiece edges, etc., can solve problems such as complex design and low production efficiency, and achieve improved production efficiency and improved Screen printing speed, the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

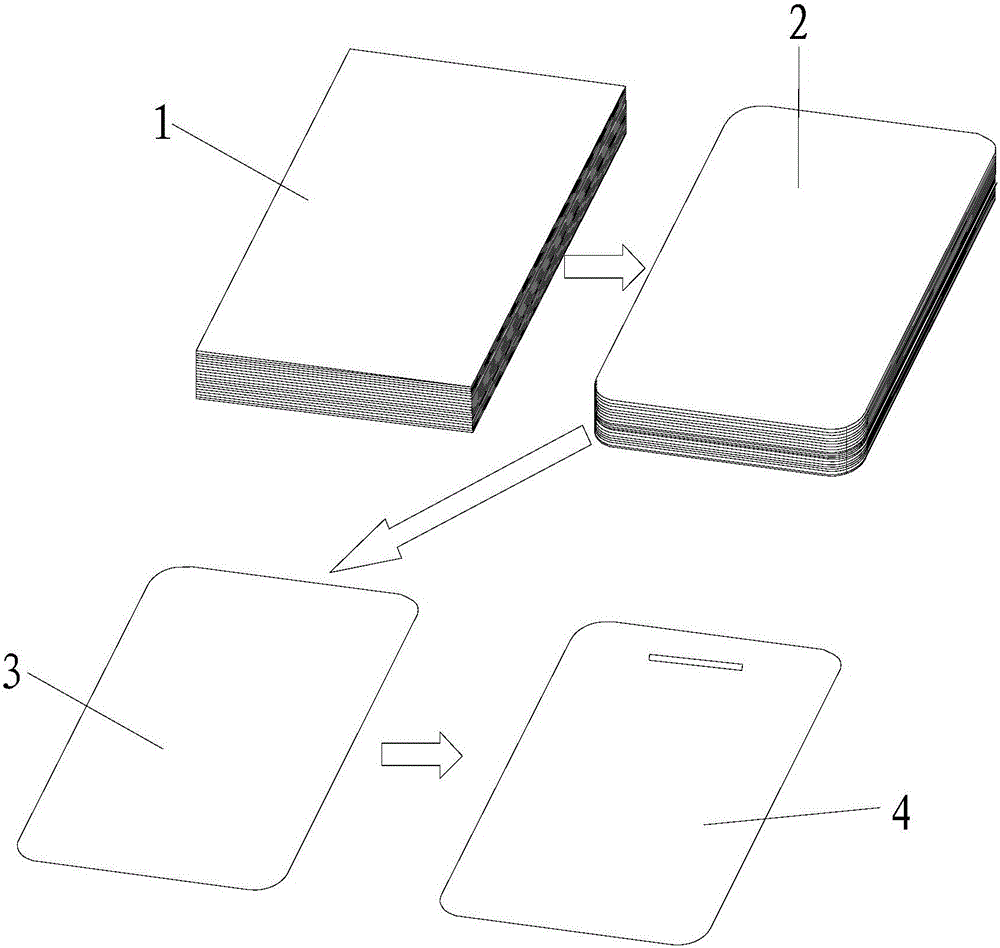

[0015] See figure 2 Shown: the present invention includes the stacking of multiple glass sheets, solidification by rosin, and preprocessing, and the processing steps are as follows:

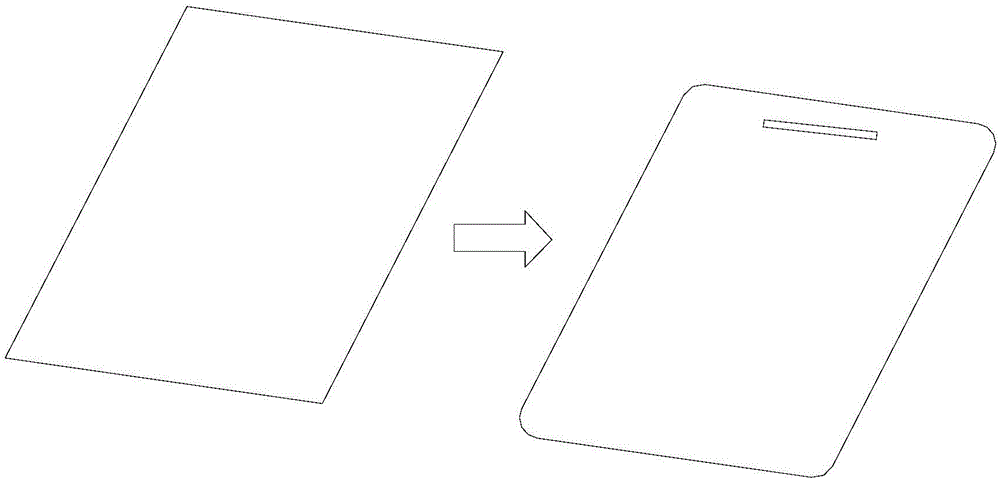

[0016] (1) The glass raw material is cut and blanked by the cutting machine, and the size of the cutting is larger than that of the finished product. A large enough margin is reserved to ensure that the lamination deviation can be eliminated, and 0.8-1.0mm is reserved;

[0017] (2) The raw materials after blanking are neatly stacked into a stack for every 20-30 pieces of products ( figure 2 As shown in 1), when stacked, all sides should be neat, no single piece protruding and other irregularities, and each stack is used as a single stack;

[0018] (3) Every 10-15 or so stacked blocks are installed in the same stainless steel box, and a small piece is used as a spacer between each stacked block to ensure that each stacked block can be distinguished and separated later, and the two ends of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com