Loose control method for fine and long thin-wall crowned isometric crystal cast turbine blade

A technology of turbine blades and control methods, applied in casting molding equipment, casting molds, casting mold components, etc., can solve problems such as size difference, large internal stress, blade body cracks, etc., to expand the number of pieces, improve production efficiency, and reduce production. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

[0032] 1. Wax mold preparation

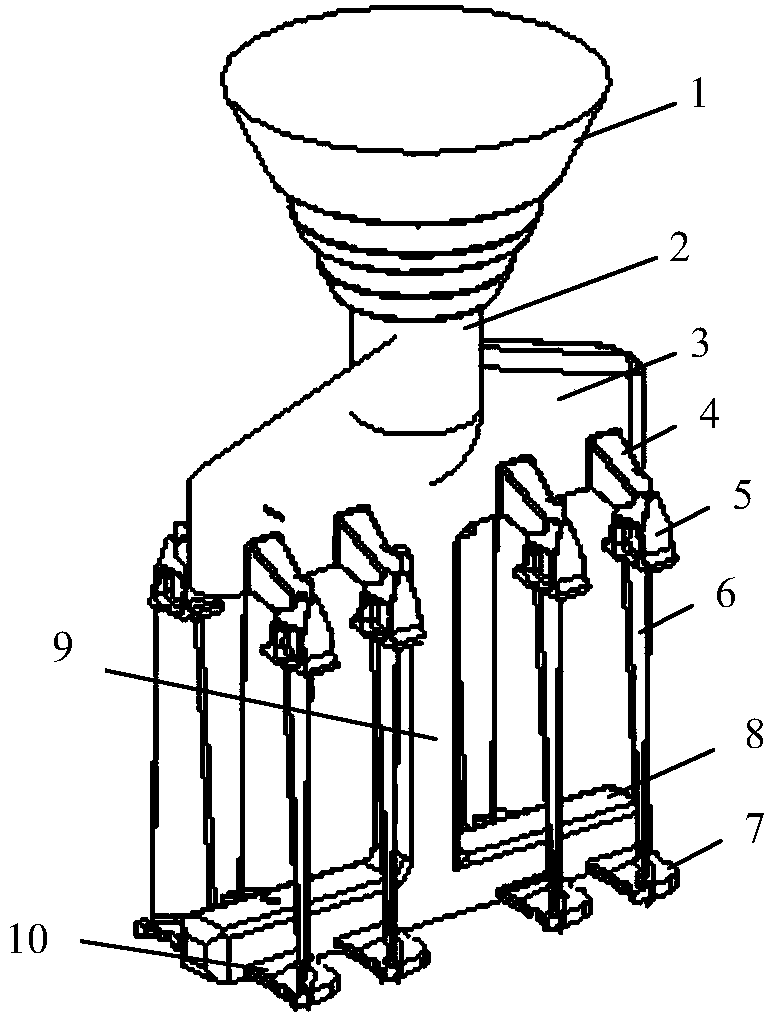

[0033] Such as figure 1 As shown, in the looseness control method of a slender and thin-walled crowned equiaxed crystal casting turbine blade of the present invention, the wax mold combination adopts a straight plate-shaped module, and the runner is "I"-shaped, including the sprue cup 1 and The transition drainage cylinder 2 connected with the sprue cup 1, the tenon end runner 3, the blade crown end runner 8 and the center column tube 9 are composed. The tenon end runner 3 is connected to the blade tenon inner gate 4, the blade tenon inner gate 4 is connected to the blade tenon 5, the leaf crown end runner 8 is connected to the blade crown inner gate 10, and the blade crown inner gate 10 is connected to the The leaf crown 7 is connected. The welding positions on both sides of the "I"-shaped runner correspond to each other and are distributed symmetrically with respect to the central axis of the central column tube.

[0034] In this embodimen...

Embodiment II

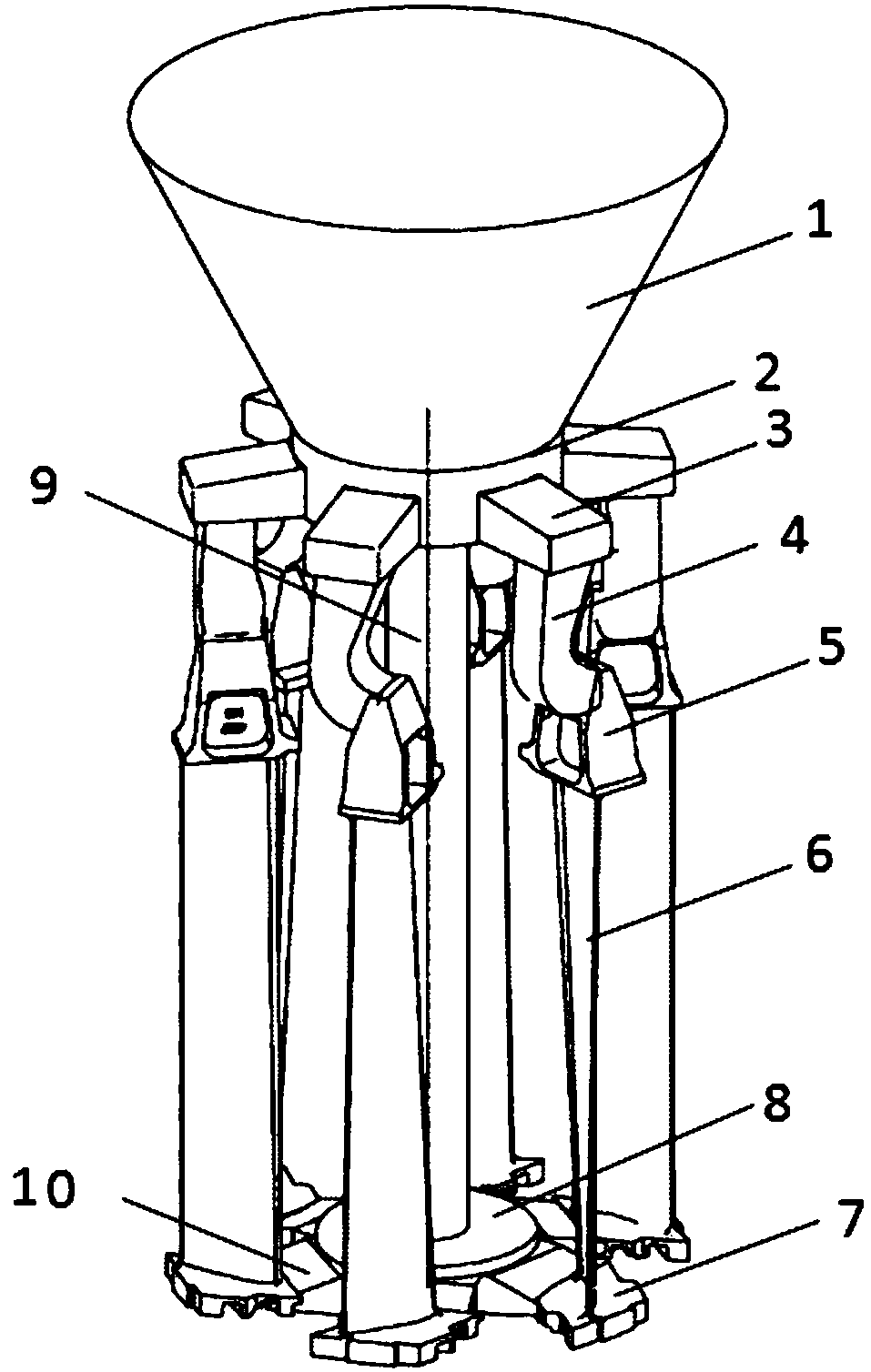

[0041] Such as figure 2 As shown, in the looseness control method of a slender and thin-walled crowned equiaxed crystal casting turbine blade of the present invention, the wax mold combination adopts a circular mold group, including the sprue cup 1 and the transition set in communication with the sprue cup 1 Drainage cylinder 2, mortise end runner 3, blade crown end runner 8 and center column tube 19 are composed. The runner 3 at the tenon end is in the shape of a petal, and its position is equally divided along the circumference. The petal-shaped runner 3 at the tenon end is connected to the inner gate 4 of the blade tenon, and the inner gate 4 of the blade tenon is connected to the tenon 5 of the blade, and the runner 8 at the leaf crown end is round cake-shaped, and is connected to the inner gate 20 of the blade crown. The shroud ingate 10 is connected with the blade shroud 7 .

[0042] In this embodiment, the length of the blade is about 150mm, the maximum wall thicknes...

Embodiment III

[0049] The thickness of the insulation cotton used is 13mm. The implementation of the remaining steps is performed with reference to the wax mold preparation, mold shell preparation and smelting and pouring process requirements in Example I, Example II or Example III.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com