Automatic platform for plane polishing

A platform and plane technology, applied in the field of automation platform, can solve the problems of restricting automatic production of enterprises, inability to form high-efficiency processing, product positioning and loading and unloading links cannot be guaranteed, so as to improve processing efficiency and save labor costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

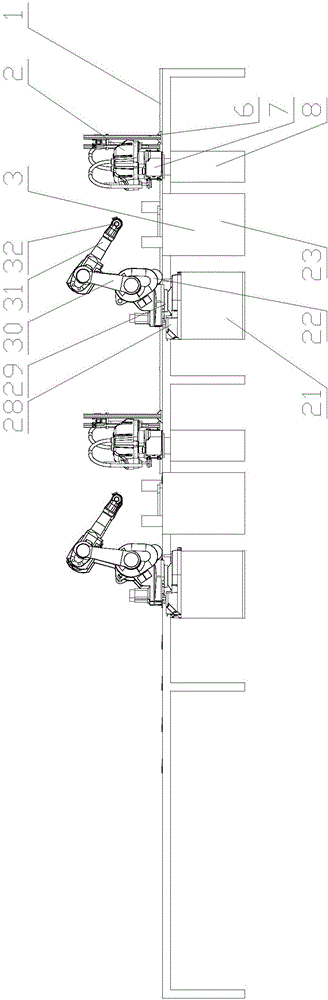

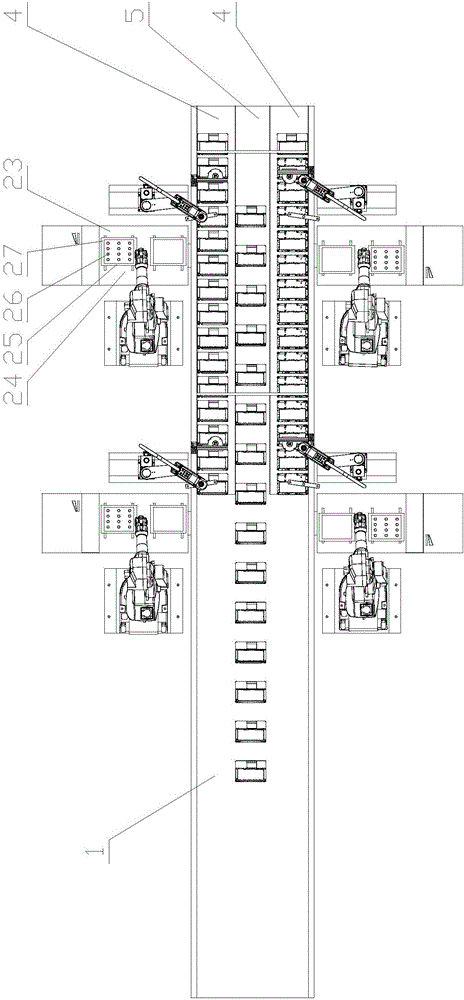

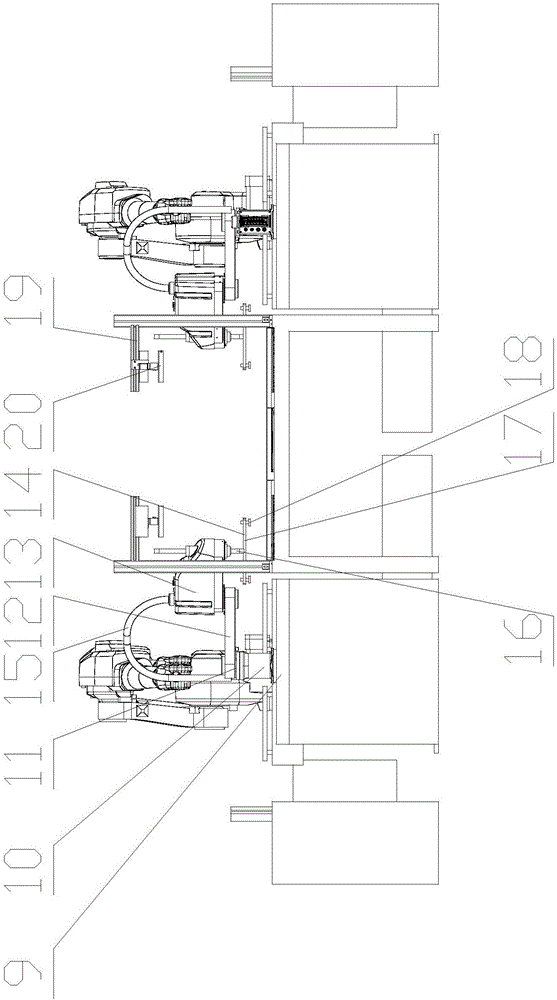

[0019] As shown in the figure, an automatic platform for plane grinding includes a grabbing unit 2, a grinding unit 3 and a conveyor belt 1; The fetching unit 2 corresponds to one of the polishing units 3, which are all arranged on one side of the conveyor belt 1 and fixed in the factory building for grabbing and polishing the products; the conveyor belt 1 is provided with a delivery channel, It is the upper material flow channel 4 and the lower material flow channel 5 in sequence; the upper material flow channel 4 is not less than one, located on one side of the lower material flow channel 5, and adjacent to the grasping unit 2 , used to convey the products to be processed; the said unloading channel 5 is not less than one, adjacent to the said upper material channel 4, used for conveying the processed products.

[0020] Further, the upper material flow channel 4 and the lower material flow channel 5 move simultaneously, the product to be processed is located on the described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com