Door construction for vehicle

A technology of car door and structure, which is applied in the field of installation and structure of the window frame, can solve the problems of reduced sealing performance and concentration of the car door, and achieve the effects of improving surface rigidity, preventing dislocation, and improving rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

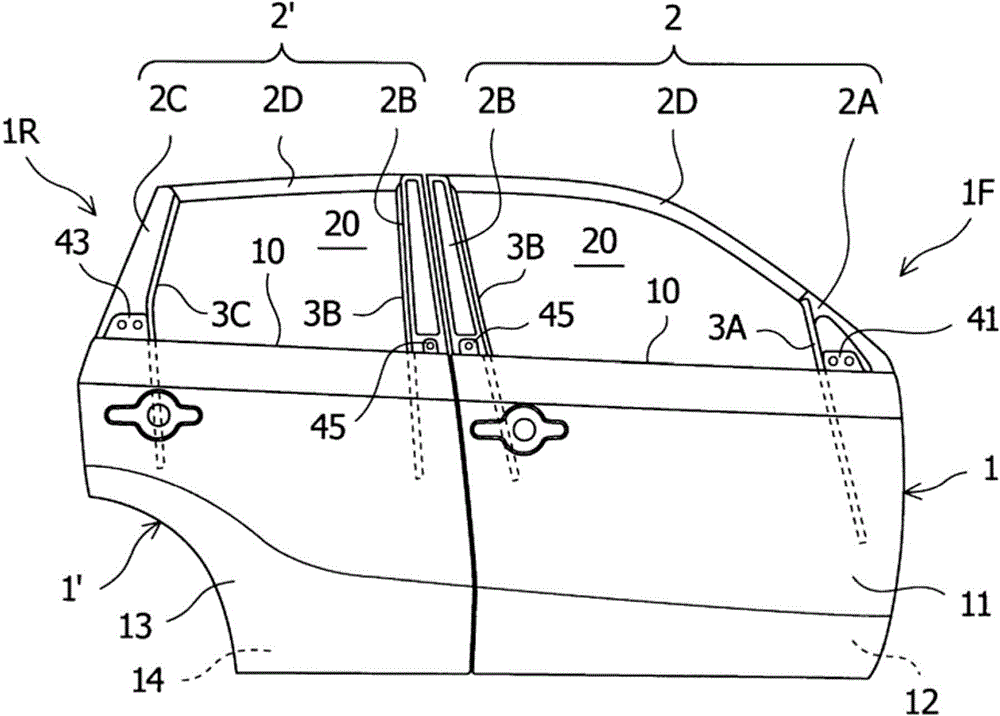

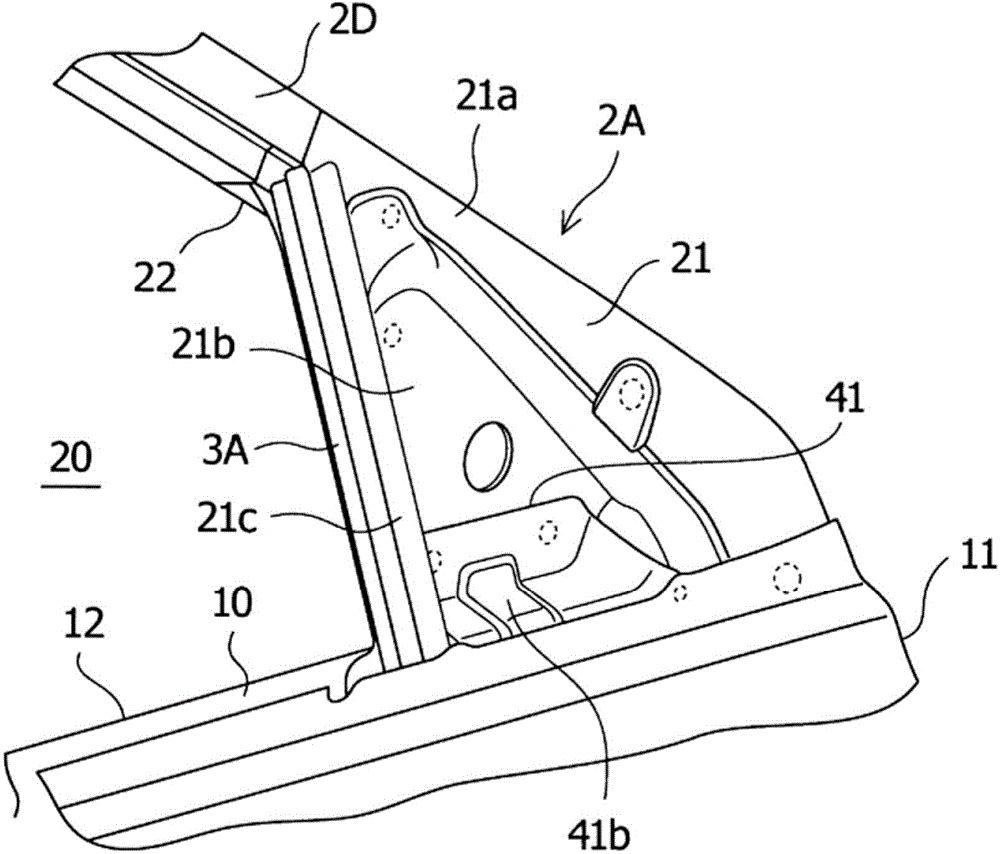

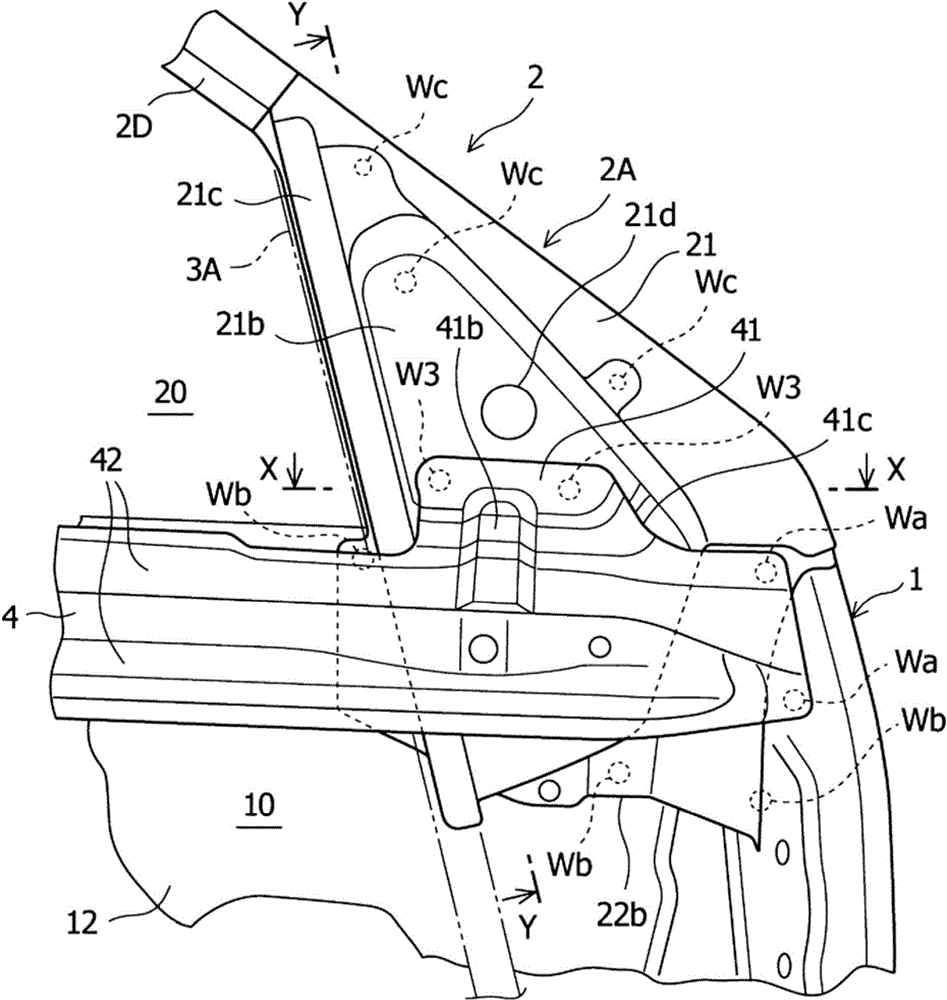

[0036] Figure 2 to Figure 5 A pillar window frame portion 2A of the front door 1F to which the door structure according to the first embodiment of the present invention is applied is shown. In the figure, the pillar sash portion 2A is composed of a sash outer reinforcement 21 and an inner reinforcement 22 joined to the interior of the vehicle compartment of the sash outer reinforcement 21, and the sash outer reinforcement 21 substantially forms the body of the window frame 3A. The mounting portion has an expanding surface (21b) formed on the front side (opposite side to the door glass) of the window frame 3A in the vehicle front-rear direction.

[0037] The sash outer reinforcement 21 (and the inner reinforcement 22) includes: a pillar portion 21a positioned from a joint between the sash outer reinforcement 21 (and the inner reinforcement 22) and the roof side sash portion 2D. On the extension line of the extended roof side sash portion 2D, extending between the above-mentio...

no. 2 Embodiment approach

[0048] Figure 6 A pillar window frame portion 2C of the rear door 1R to which the door structure according to the second embodiment of the present invention is applied is shown. exist Figure 6 Among them, the pillar window frame portion 2C is constituted by joining a window frame outer reinforcement member 23 which serves as an attachment portion on the upper end side of the window frame 3C to an inner reinforcement member 24 disposed on the vehicle interior side of the window frame 3C. An expanded surface is formed on the rear side (side opposite to the door glass) of the window frame 3C in the vehicle front-rear direction, and the expanded surface is welded by spot welding Wc. In addition, the window frame 3C is welded to the window frame outer reinforcement 23 at the lower end corner between the spot weld Wc and the outer reinforcement 4 ′ in addition to the upper end.

[0049] In the rear door 1R of this embodiment, the width of the pillar window frame portion 2C in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com