Large length-diameter ratio plane metal microneedle array, preparation method and clamping and penetration auxiliary devices of large length-diameter ratio plane metal microneedle array

A technology with a large aspect ratio and microneedle arrays, applied in the field of medical devices, can solve the problems of difficult mass production, complicated manufacturing process, and high cost, and achieve the effects of cost reduction, low cost, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

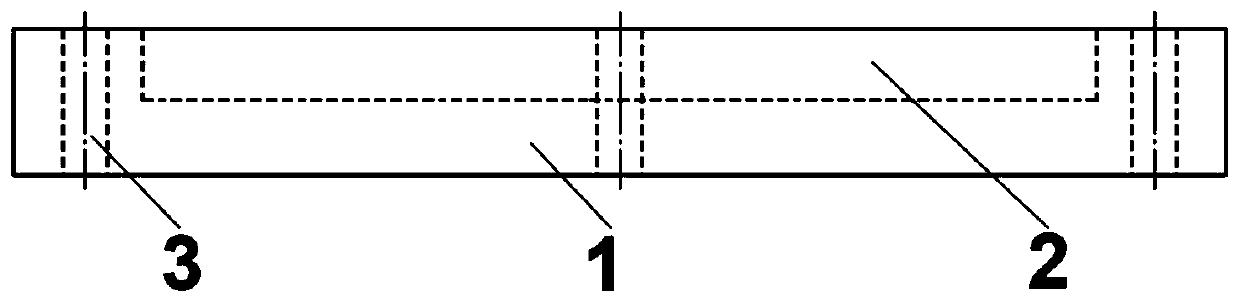

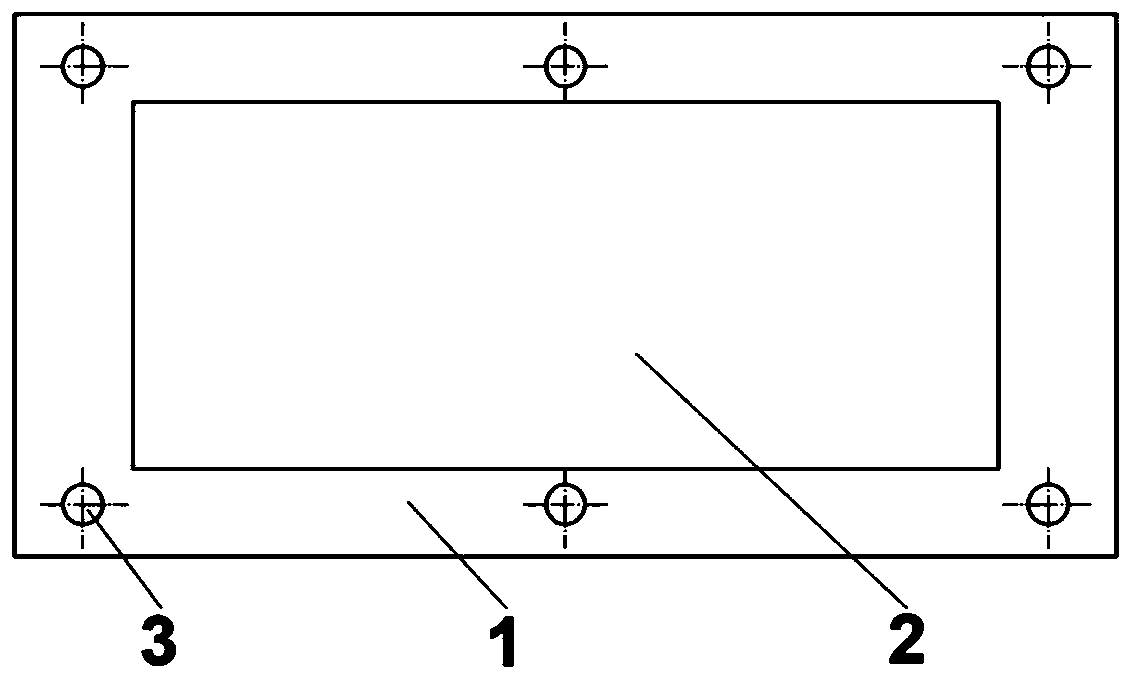

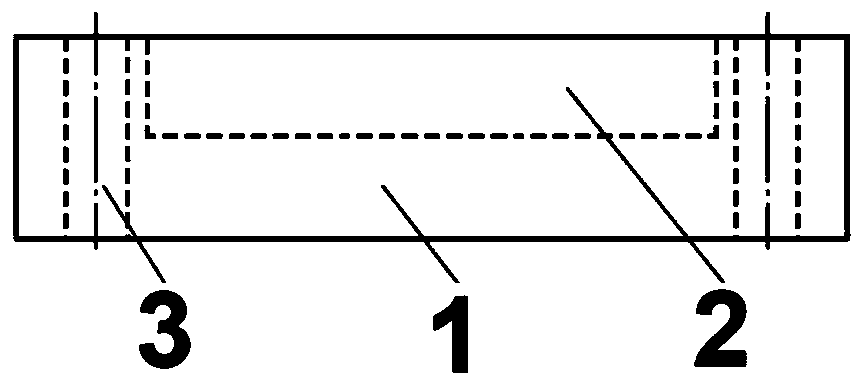

[0052] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings. The present invention processes metal microneedle arrays in batches at one time, and the ideal total cutting thickness of wire cutting is 2 cm. For example, the overall wall thickness of the tooling is 5 mm, the depth of the groove is 2 mm, and the thickness of each metal sheet is 100 microns. The number of microneedles that can be cut at one time is 140 pieces, and compared with other microneedle processing methods, the efficiency is greatly improved. In addition, the cost of wire cutting processing technology is relatively low, so the microneedle array processing method provided by the present invention has low cost. After the clamping tool is used, except that the material at the path of the cutting wire is cut off, other parts remain intact, which can improve efficiency and reduce costs. The clamping tool compacts multiple sheets of metal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com