Epoxy resin vacuum degassing mixing tank

A vacuum degassing and epoxy resin technology is applied in the field of transformers to eliminate local friction and overheating, improve efficiency and reduce equipment cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

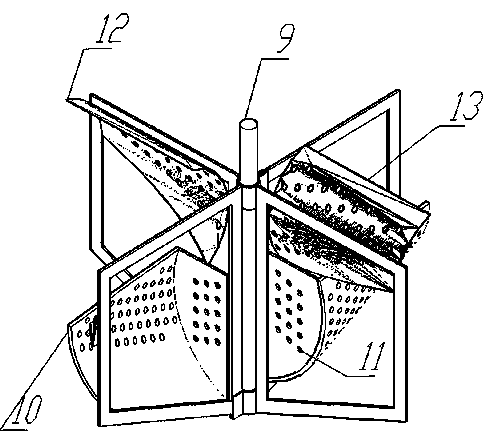

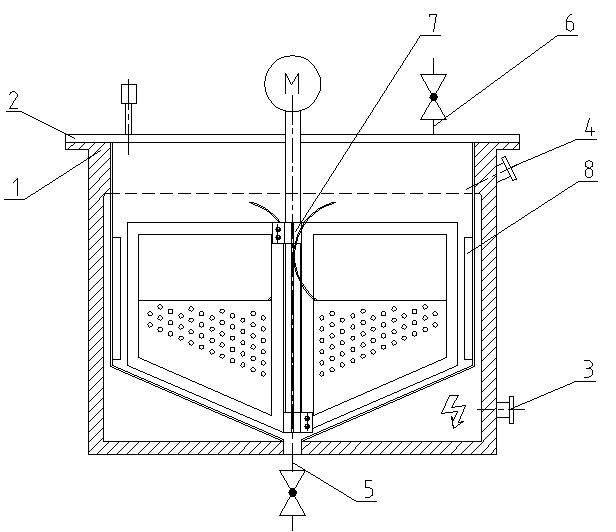

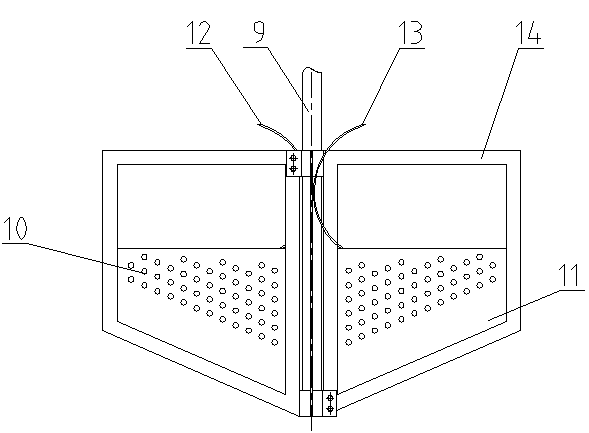

[0027] An epoxy resin vacuum degassing mixing tank, which consists of a tank body 1, a tank cover 2, an electric heating device 3, a material inlet 4, a material outlet 5, a vacuum valve 6, and a stirring assembly 7 driven by a motor, etc. Composition, the bottom of the tank body 1 is in an inverted conical shape, and a spoiler 8 is welded axially on the cylindrical inner wall side of the tank body 1 . The stirring assembly 7 is composed of a rotating shaft 9 , two pairs of stirring paddles in the upper and lower layers and a stirring flat steel frame 14 .

[0028] The paddles are distributed in upper and lower layers, the lower stirring paddles 10, 11 are below, the upper stirring paddles 12, 13 are above, and each paddle is placed at intervals between four right-angled trapezoids that form a 90° angle in space. On a flat steel rack.

[0029] The lower stirring blades 10, 11 are the lower stirring blades, which are welded by two parts: one is a right-angled trapezoidal thin ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com