Concave dual-electrode integrated chip high-voltage ceramic capacitor and manufacturing process thereof

A high-voltage ceramic and double-electrode technology, which is applied in the direction of fixed capacitor dielectric and fixed capacitor parts, can solve the problems of large volume and unfavorable assembly of power devices, so as to reduce the volume, improve the nominal capacitance and compressive strength, The effect of high electric strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

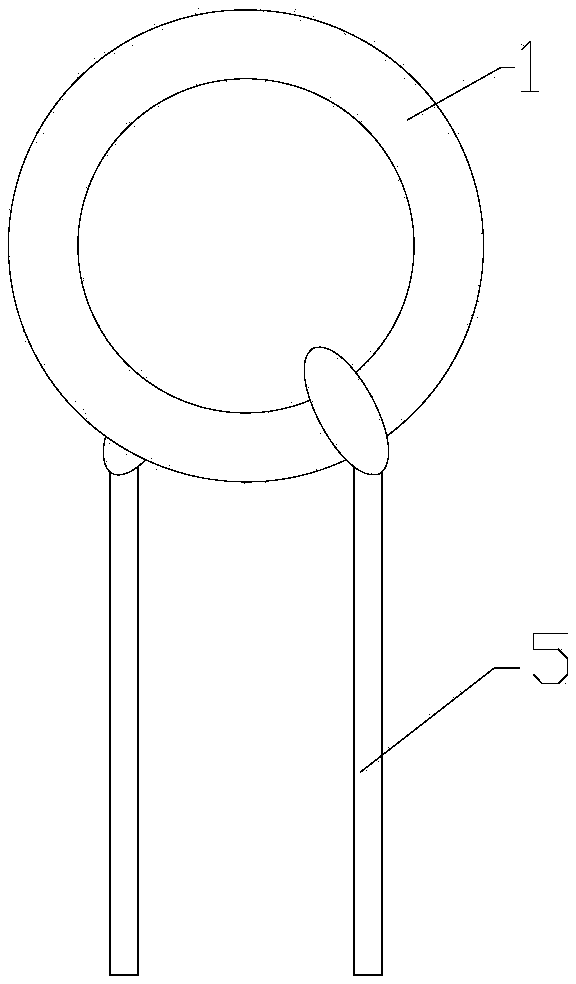

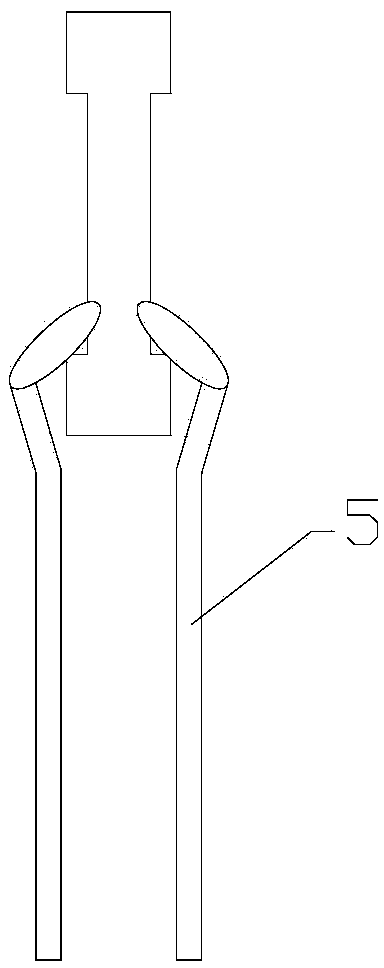

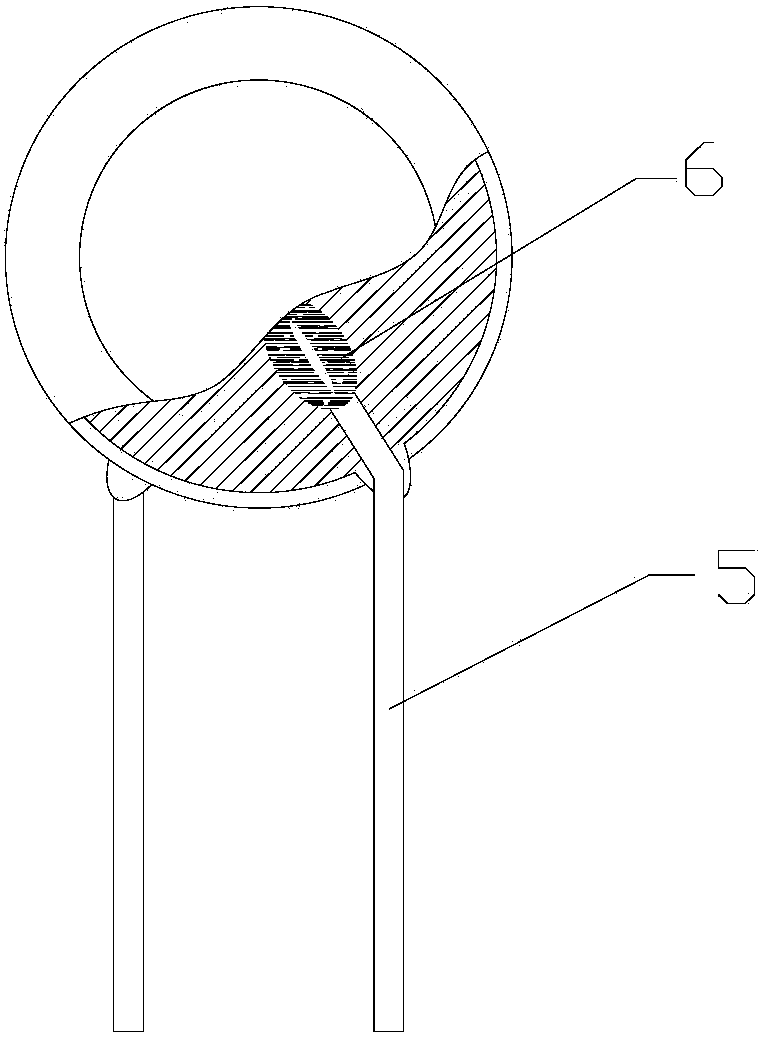

[0026] As shown in Figures 1 to 2, a concave double-electrode integrated chip high-voltage ceramic capacitor includes a resin encapsulation layer 1, an electrode layer, a ceramic dielectric chip 4 and a lead wire 5, and the overall shape is a centrally symmetrical concave dish shape. That is, the center is disc-shaped, and the outside is circular. The disc-shaped and circular-shaped chips form a whole chip. The thickness of the outer circular-shaped chip is greater than that of the central circular-shaped chip. The surface of the circular-shaped chip is provided with external electrodes 2 , the surface of the disk-shaped chip is provided with an internal electrode 3, and the external electrode 2 and the internal electrode 3 are integral copper electrodes. 4 wrapped inside.

[0027] The preparation process of the above-mentioned capacitor includes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com