Small-sized chip type surface mounting (SMD) high-voltage and safety standard recognized ceramic capacitor

A ceramic capacitor, surface mount technology, applied in the direction of fixed capacitor dielectric, fixed capacitor shell/package, fixed capacitor components, etc., can solve the problem of not being suitable, and achieve cost saving, small size, high electric strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific embodiment of the present invention is further described below in conjunction with accompanying drawing:

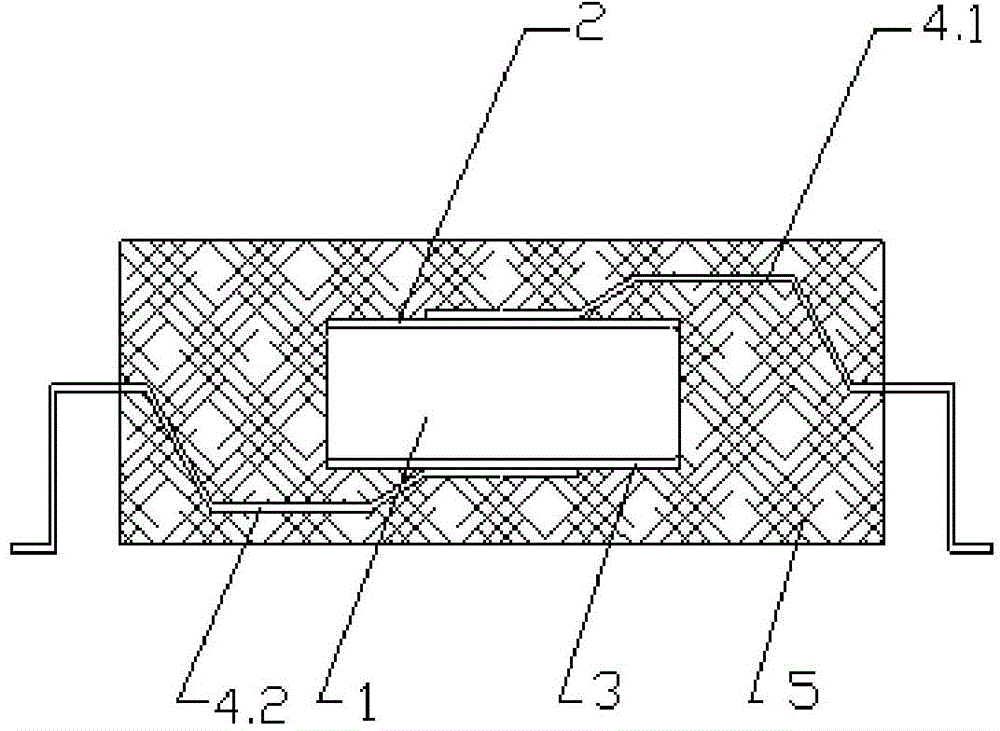

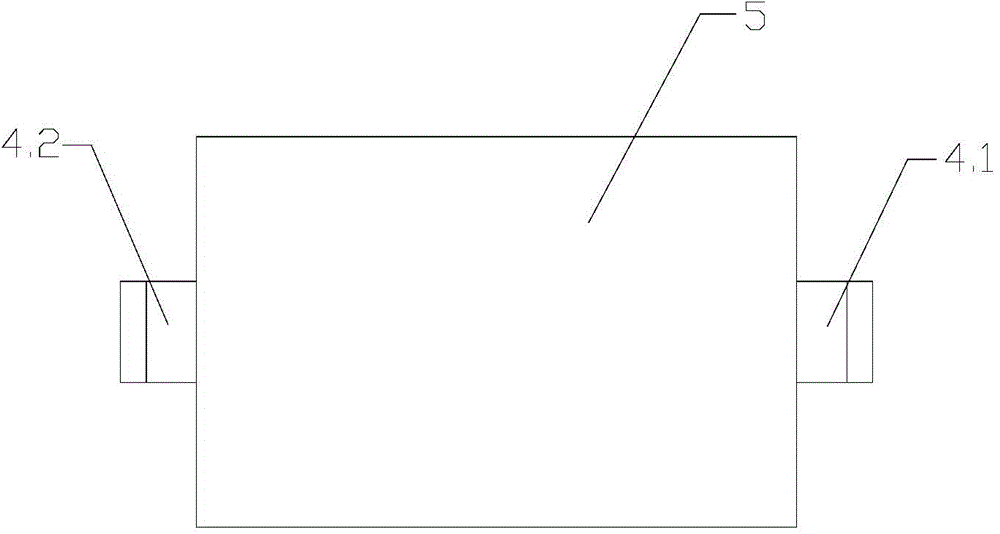

[0029] Such as figure 1 , figure 2 As shown, a surface mount type ceramic safety capacitor includes a copper electrode ceramic chip, a steel strip pin 4 and an epoxy resin encapsulation material 5, the copper electrode ceramic chip is a cylinder, and the ceramic dielectric 1 is located on the upper and lower electrodes 2, In the middle of 3, the upper and lower electrodes 2 and 3 are integral copper electrodes, the upper electrode 2 and the upper steel strip pin 4.1 are welded and fixed, the lower electrode 3 and the lower steel strip pin 4.2 are welded and fixed, and the epoxy resin encapsulation material 5 wraps the copper electrode The ceramic chip and a part of the steel strip pin 4 are encapsulated together, and the end of the steel strip pin 4 is exposed outside the epoxy resin encapsulation material 5 .

[0030] The manufacturing method of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com