10kV graphene composite shielding low-noise weather-proof anti-interference overhead insulated cable

An aerial insulated cable and graphene composite technology, which is applied in the direction of insulated cables, power cables with shielding layer/conductive layer, insulated conductors, etc., can solve problems such as waste of labor, difficulty in assembling finished products, disturbing noise, etc., to ensure safety and reliability, ensuring safe and effective operation, and reducing volume resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the drawings.

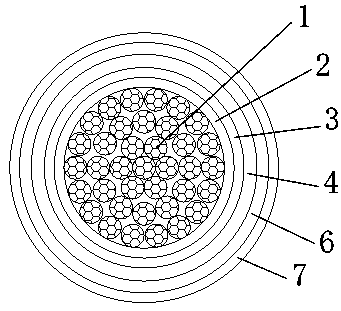

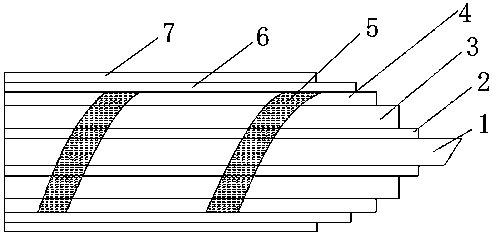

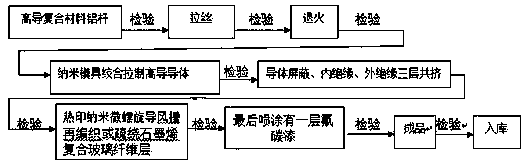

[0021] Such as Figure 1-2 As shown, a 10kV graphene composite shielded low-noise, weather-resistant and anti-interference overhead insulated cable includes a high-conductivity composite aluminum conductor. The high-conductivity composite aluminum conductor is made of 37 high-conductivity composite aluminum wires 1 with a diameter of 2.54 mm. "1+6+12+18" structure is formed by four-layer stranding; the high-conductivity composite aluminum conductor is co-extruded with graphene composite semi-conductive shielding layer 2, cross-linked polyethylene inner insulating layer 3 and Improved weather-resistant insulating outer insulating layer 4; the outer surface of the improved weather-resistant insulating outer insulating layer is thermally printed with nano-microspiral air ducts 5, and then extruded and braided or sparsely wound graphene composite glass fiber layer 6, in graphite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com