Novel foldable light emergency cable and implementation method thereof

An emergency optical cable and a technology for its realization, applied in the direction of fiber mechanical structure, etc., can solve problems such as fiber breakage, optical path obstruction, and loose loss of tight-packed optical fibers, etc., and achieve the effect of enhanced adhesion, less wrinkling, and internal compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

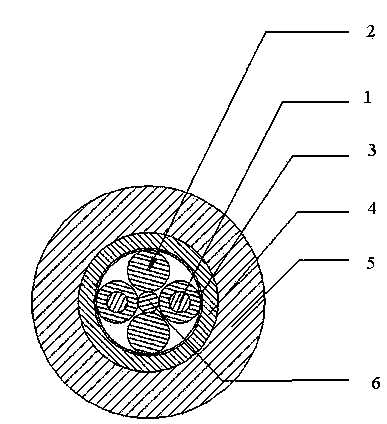

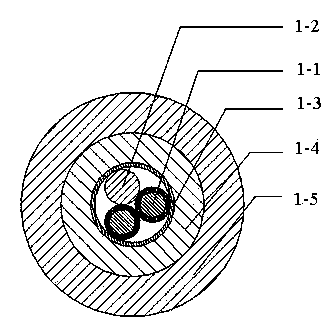

[0040] Example 1 is shown in Figure 2(a). In Figure 2(a), 1-1 is the bending-resistant tight-clad optical fiber, 1-2 is the core filler, 1-3 is the nylon layer, 1-4 is the aramid fiber reinforcement, and 1-5 is the polyurethane outer sheath. In this embodiment 1, the core 1-2 is formed by extruding a layer of plastic from aramid fiber; in some occasions where the requirements are not high, the core can also be replaced by optical fiber. Reinforcement members 1-4 can also be made of reinforcement materials such as glass fiber, polyparabenzoxazole or carbon fiber.

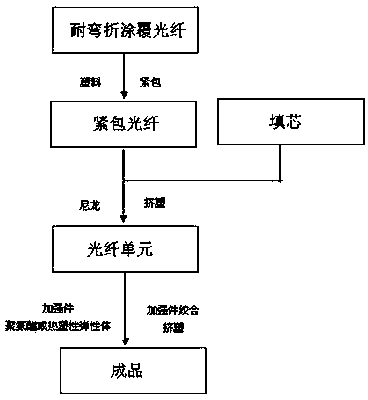

[0041] Referring to Figure 2(b), the specific implementation process of Example 1 is as follows:

[0042] 1. Optical fiber tightly packed

[0043] A layer of nylon is tightly wrapped around the bending-resistant coated optical fiber, which has the characteristics of low density, low friction coefficient, wide temperature resistance range, and wide processing and molding temperature range.

[0044] Nylon materials ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com